Table of Contents

Introduction.......................................................................................................................................1

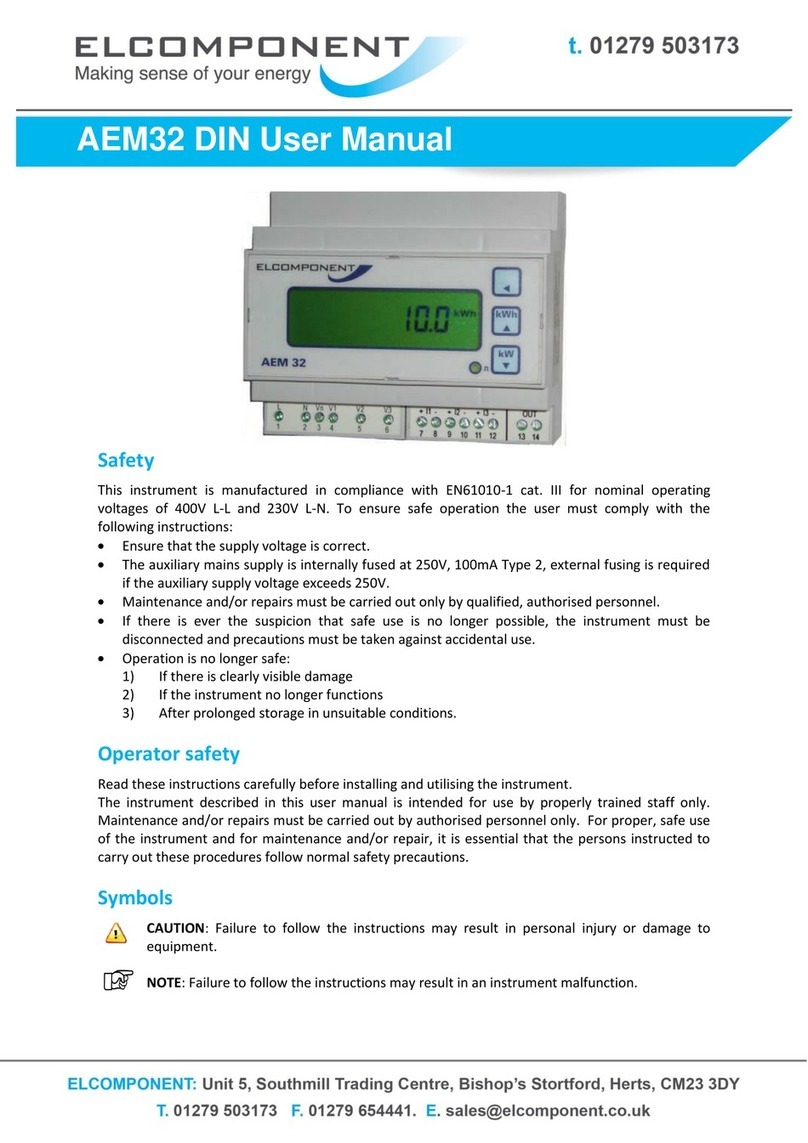

Safety...............................................................................................................................................2

Quick Start........................................................................................................................................3

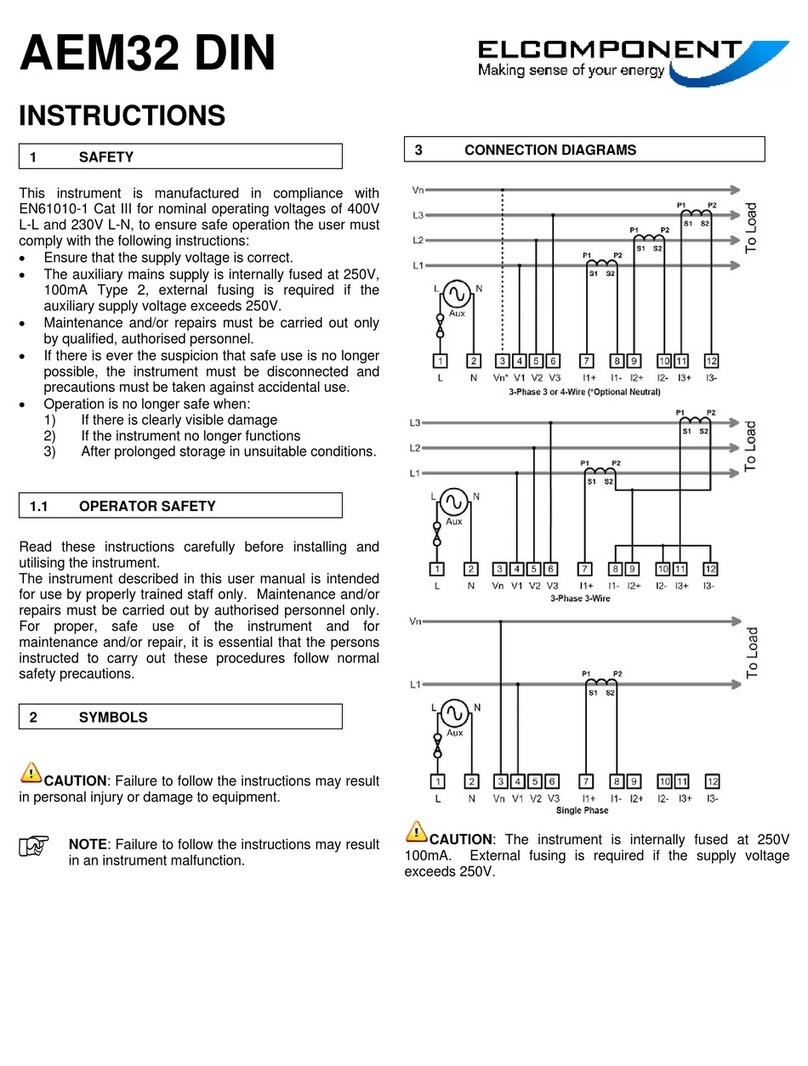

Hookup Configurations.....................................................................................................................4

Hookup Diagnostic Warnings...........................................................................................................5

PQPro™ Firmware Features............................................................................................................7

RMS and Waveform Data Storage.........................................................................................7

Harmonics ..............................................................................................................................7

Interharmonics........................................................................................................................8

Power Calculations.................................................................................................................8

Frequency...............................................................................................................................8

Event Capture ........................................................................................................................8

Under/Over Voltage Events....................................................................................................9

High Speed Voltage Transients .............................................................................................9

Current Inrush ........................................................................................................................9

Voltage and Current Unbalance.............................................................................................9

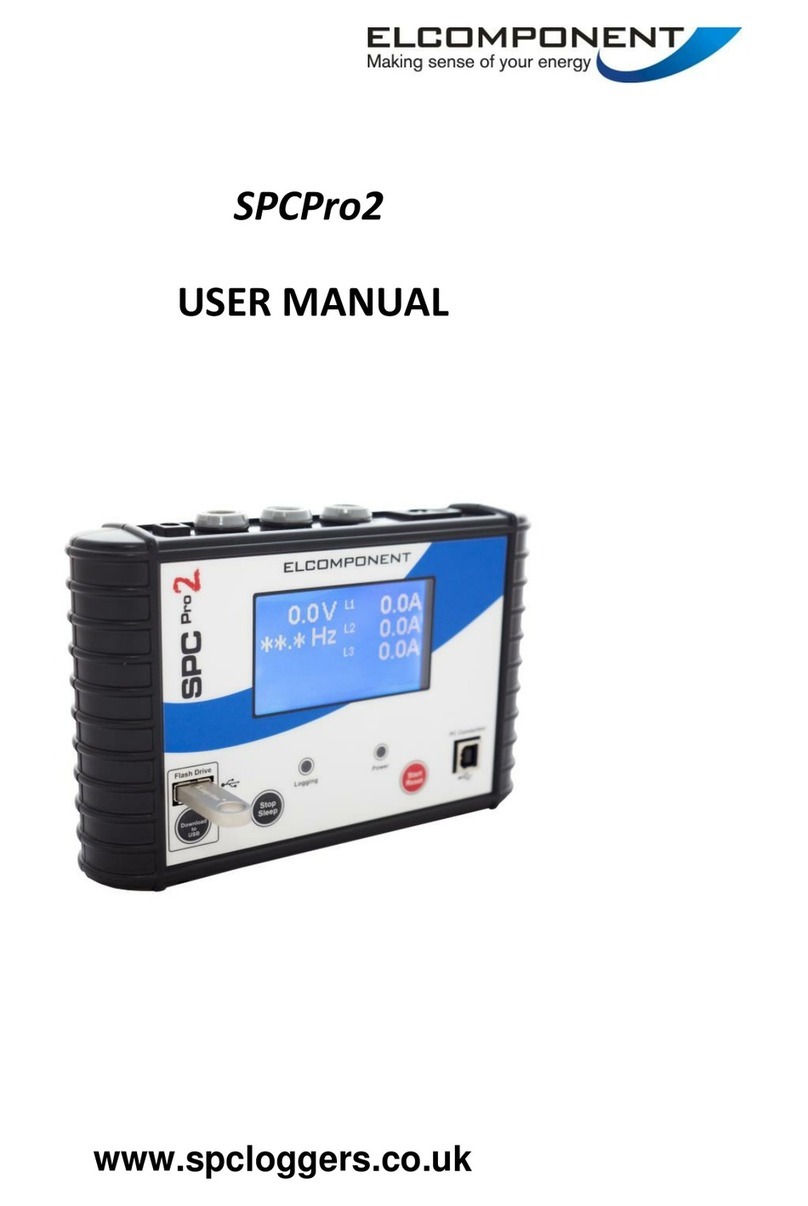

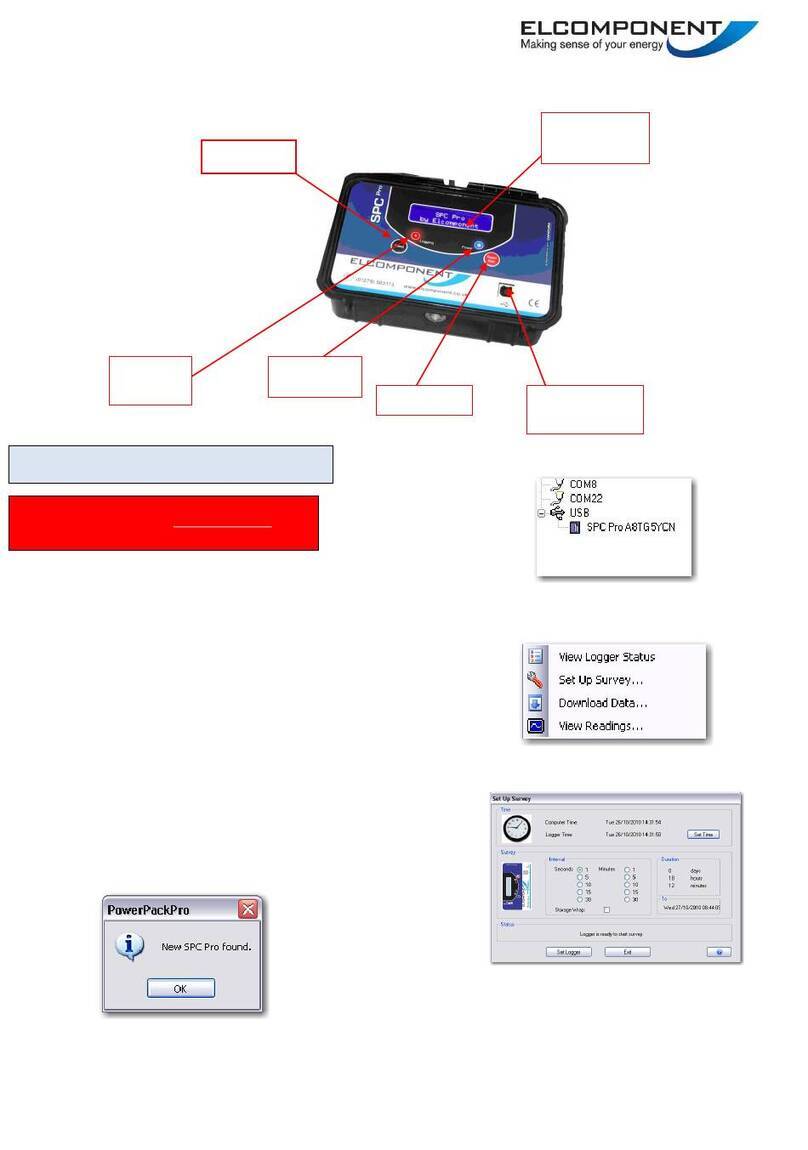

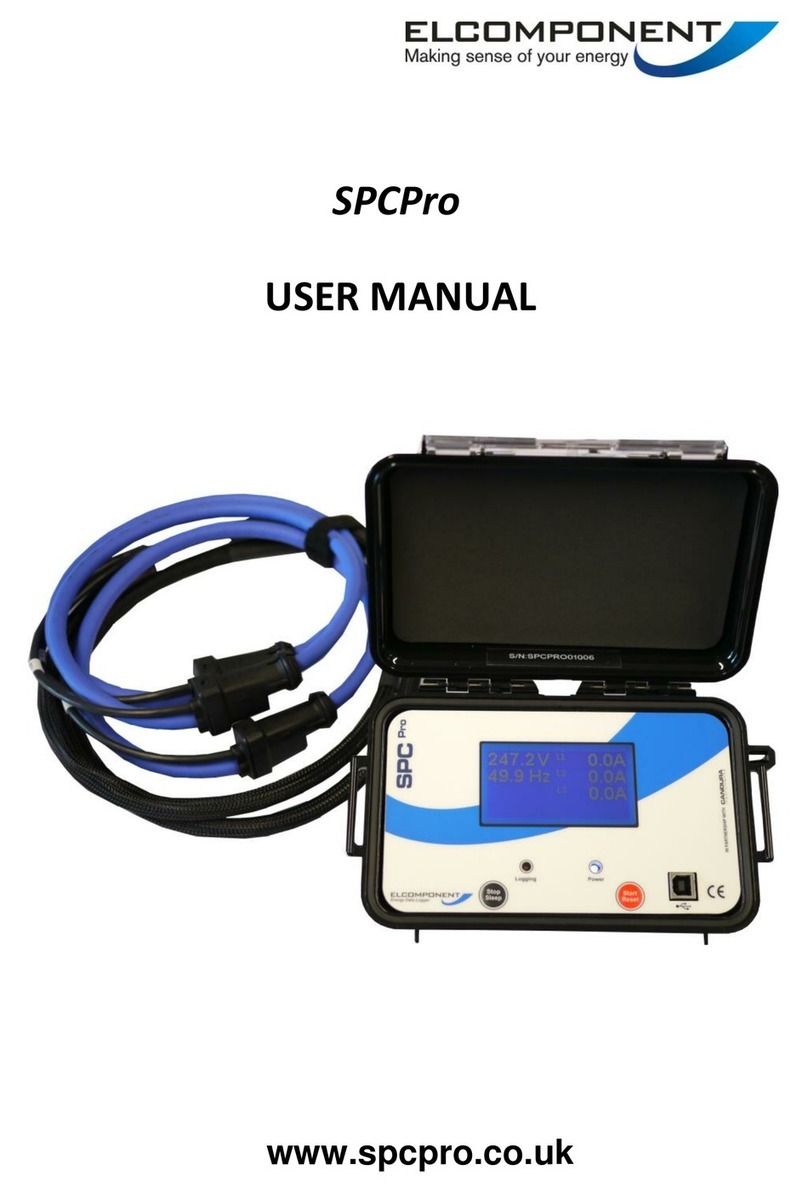

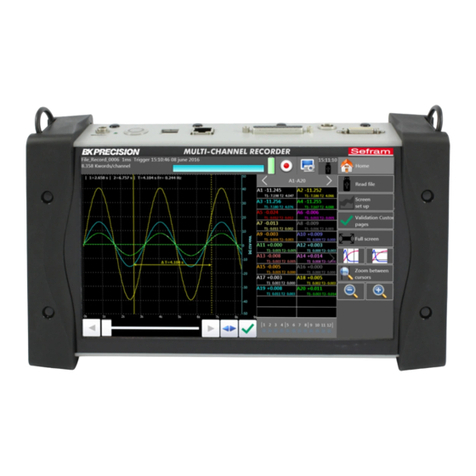

PQPro™ Back Panel......................................................................................................................10

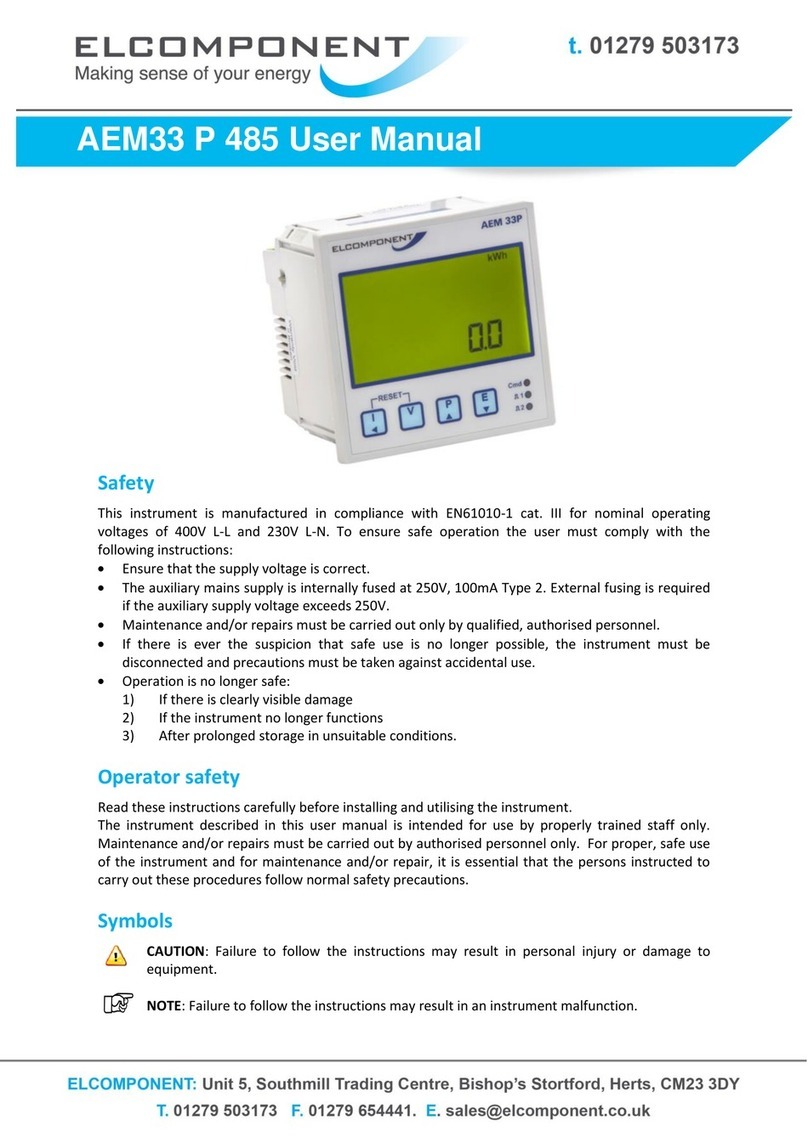

PQPro™ Front Panel .....................................................................................................................11

PQPro™ Operation ........................................................................................................................12

Turning On and Off...............................................................................................................12

Memory Card........................................................................................................................12

PQPro™ Setup ..............................................................................................................................13

Phase CT Range..................................................................................................................13

CH 4 CT Range....................................................................................................................13

Connection ...........................................................................................................................13

1P2W - 1 Phase 2 Wire .............................................................................................................13

1P3W - 1 Phase 3 Wire (Edison circuit).......................................................................................13

3P3W - 3 Phase 3 Wire (Delta circuit) ........................................................................................13

3P4W - 3 Phase 4 Wire (Wye circuit)..........................................................................................13

2.5E - 2½ Element ....................................................................................................................13

PQPro™ Data Storage...................................................................................................................14

Storage Rate ........................................................................................................................14

Recording Mode...................................................................................................................14

Interharmonics......................................................................................................................15

Voltage Spike Waveforms....................................................................................................15

Under/Over Voltage Waveforms ..........................................................................................15

Current Inrush Waveforms...................................................................................................15

RMS Capture........................................................................................................................15

PQPro™ Trigger Levels .................................................................................................................16

Event Enable........................................................................................................................16

Phase Current Inrush ...........................................................................................................16

Channel 4 Current Inrush.....................................................................................................16

Phase Voltage Nominal........................................................................................................16

Channel 4 Voltage Nominal..................................................................................................16

Voltage Spike .......................................................................................................................16

Phase Voltage Over .............................................................................................................16

Phase Voltage Under...........................................................................................................17

Channel 4 Voltage Over.......................................................................................................17

Channel 4 Voltage Under.....................................................................................................17