SGM LEKTRA RSL200 User manual

RSL200

vibration level switch, with rigid and semi-flexible extension for bulk

solids and powders.

technical documentation EN Rev. M

Page 2 of 16 www.sgm-lektra.com

RSL200 - contents

CONTENTS

1-WARRANTY

2-PRODUCT

3-TECHNICAL SPECIFICATIONS

4-DIMENSIONS

5-INSTALLATION

6-ELECTRICAL CONNECTIONS

7-LOCAL OPERATOR INTERFACE (LOI)-VL601

8-PARAMETER PROGRAMMING

9-TESTING AND QUALITY CERTIFICATE

page 3

page 4

page 5

page 6

page 7

page 10

page 11

page 12

page 16

Page 3 of 16

www.sgm-lektra.eu

RSL200 - warranty

Products supplied by SGM LEKTRA are guaranteed for a period of 12 (twelve) months from delivery date according to

the conditions specified in our sale conditions document.

SGM LEKTRA can choose to repair or replace the Product.

If the Product is repaired it will maintain the original warranty terms, whereas if the Product is replaced it will have 12

(twelve) months of warranty.

The warranty will be null if the Client modifies, repair or uses the Products for other purposes than the normal conditions

foreseen by instructions or Contract.

In no circumstances shall SGM LEKTRA be liable for direct, indirect or consequential or other loss or damage whether

caused by negligence on the part of the company or its employees or otherwise howsoever arising out of defective goods

1-WARRANTY

Page 4 of 16 www.sgm-lektra.com

RSL200- product

2- 2- PRODUCT

1. Cover

2. VL601 (opt.)

3. Skintop M20

4. Process connection

5. Forks

6. Anti-condensate filter

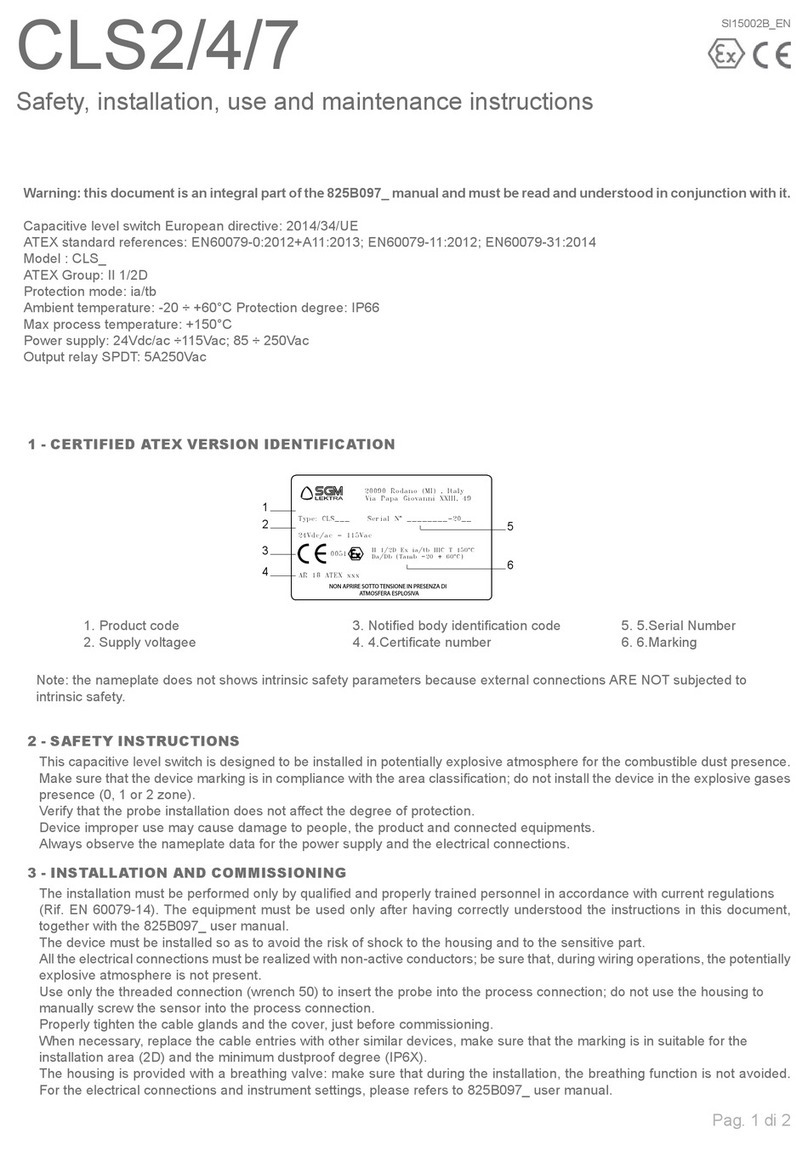

2.1 IDENTIFICATION

Every instrument has an adhesive identification plate on which the main information about the meter is outlined.

The following image describes the information and data on the plate.

RSL200A0F1D

CV0081901422

2

3

1Mod.

P.S.

S.N.

85÷250Vac

1. Product code 3. Serial number2. Power supply

1

2

3

5

4

6

Page 5 of 16

www.sgm-lektra.eu

3-3- TECHNICAL SPECIFICATIONS

RSL200 - technical specifications

Casing material

PC/AL

Vibrating prong material

AISI316 (AISI304 for semi-flexible extension tube)

Protection rating

IP67/IP68 in process

Pressure

-1 ÷ +6bar

Ambient temperature

-20 to +60°C

Max. process temperature

150°C

Power supply

24Vdc ÷ 115Vac; 85÷230Vac

Max. input power

1.5W

Cable glands

M20x1.5

Electrical connection

Plug-in terminal blocks

Relay output

3A 230Vac

Trigger mode

min. or max. level

Trigger delay

0÷30s (programmable)

Programming

Via extractable VL601 module

Trigger sensitivity and delay

configurable via VL601

Thermal stability

1 typical minute

Display

LCD display on extractable VL601-SGM module Green LED: power on

Red LED: relay status (on with relay energized)

Certification

ATEX II 1/2D Ex ta/tb IIIC T150°C Da/Db (opt.)

Page 6 of 16 www.sgm-lektra.com

4-4- DIMENSIONS

RSL200 - dimensions

5.1 MECHANICAL DIMENSIONS

Ø95 130

132,5

1"½ G

155

20

353

Ø95

132,5

1"½ G

130

20

513

Ø95

132,5

1"½ G

20

Ø12

86 62155

45,5

20

155 205,5

20

130

20

L=....

L=....

Page 7 of 16

www.sgm-lektra.eu

RSL200 - installation

5-5- INSTALLATION

5.1 PRECAUTIONS FOR INSTALLATION

5.1.1 CORRECT INSTALLATION

Correct installation of RSL200 sensors to control a Max. level (“a” and “c”) and Min. level (b).

To avoid triggering problems, follow the instructions below:

- Install away from loading zones and keep a minimum distance of 300mm from the walls of the tank.

- When placing the order, select the option for the extension length, allowing the sensitive element to be

positioned at least 200 mm from the bottom of the tank.

Min. dist.

300mm

Min. dist.

200mm

“a” “b”

“c”

Maximum

level

Minimum

level

Page 8 of 16 www.sgm-lektra.com

RSL200 - installation

5.1.2 Incorrect installation

Incorrect installation of RSL200 sensors.

• do not install near loading zones (c); false alarm signals may be generated and the RSL200 sensors may be

damaged by the pouring in of the material.

• do not install at the centre of the tank loading point (d); the RSL200 sensors and/or ceiling of the tank may be

damaged and eventually break the RSL200 sensor, due to the elevated mechanical stress created in this point.

• do not install in points where accumulations of product may form (e); the RSL200 sensors might remain blocked

in the ‘product present’ position: false max. level alarm or, vice versa, failed min. level alarm signal.

“c” “d” “e”

Page 9 of 16

www.sgm-lektra.eu

RSL200 - installation

5.1.3 Semiflex Extension

Bent extension (h) (g)

The extension must be straightened (i) to prevent the sensitive element from touching the wall of the tank and

sending a false ‘product present’ signal: false max. level alarm or, vice versa, failed min. level alarm signal.

“g” “h” “i”

Page 10 of 16 www.sgm-lektra.com

RSL200 - electrical connections

NO

C

NC

+Vdc / L (Vac)

-Vdc / N (Vac)

24Vdc÷115Vac and

85÷230Vac RL

Plug-in terminal blocks for connection of

power supply

Power ON green LED: On and fixed

Plug-in terminal blocks for connection of

relay contacts

RL red LED indicates the status of the relay:

on, RL relay energized

Earth connection of connector

6-ELECTRICAL CONNECTION

6.1 CONNECTIONS

1) Before energizing this product, make sure all connections have been correctly made and that the mains voltage

corresponds to that on the rating plate.

2) Tighten the cable glands and cover to ensure a protection rating of IP67.

3) To prevent the infiltration of water or humidity, which may damage the level sensor, do not remove the caps

of unused cable glands.

6.2 INFILTRATIONS OF HUMIDITY

To avoid infiltrations of humidity inside the cover, we recommend:

- Using a cable with an external diameter of 6÷12mm for the electrical connections and fully tightening the M20

cable gland

- Fully tighten the cover

- Position the cable in such a way as to form a downward curve in the output of the M20 cable gland;

in this way condensation and/or rainwater will tend to drip from the bottom of the curve.

Page 11 of 16

www.sgm-lektra.eu

RSL200 - local operator interface (LOI) - VL601

7-LOCAL OPERATOR INTERFACE (LOI) - VL601

The RSL200 vibration level checks are programmed and calibrated using the VL601 display module

7.1 VL601 FEATURES

The VL601 programming module can be activated and deactivated on-board the RSL200 without affecting the

unit’s operation.

The VL601 module is equipped with an LCD dot-matrix display and allows simple and fast start-up using the 4

programming keys.

The symbol

ON

on the display indicates that the relay is energized, normal condition.

The symbol

OFF

on the display indicates that the relay is de-energized, alarm condition.

1. From “RUN” mode: press to select the parameter to be programmed.

2. Press to confirm the selection.

3. To select the parameter option press .

4. Press to confirm and save the selection, press to exit without saving.

LEFT-HAND ARROW key:

• Exit without saving

• When pressed with the ENTER key

performs a void calibration

UP ARROW key:

• Parameter option selection

SCROLL key:

• Scroll parameters

ENTER key:

• Confirm parameter selection

• Save parameter setting

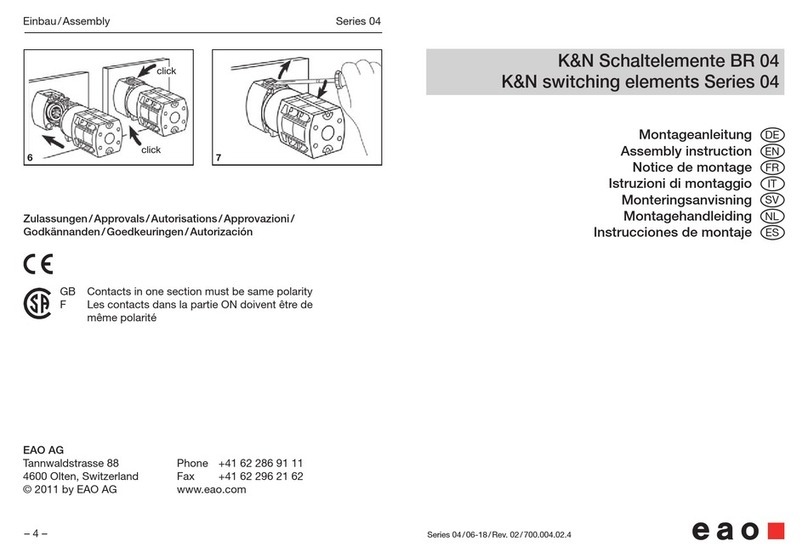

By unscrewing the cover, it is possible to lock the VL601 module (by turning it clockwise until it clicks) or unlock it

(by turning it anti-clockwise) as shown in the figure.

LOCK UNLOCK

Page 12 of 16 www.sgm-lektra.com

RSL200 - parameter programming

8-PARAMETER PROGRAMMING

8.1 TH

Press ENTER to modify the programming.

Using the UP ARROW adjust the limit from 0 to 1000:

during programming a “transparent” cursor will be displayed, which indicates

the new positioning of the level alarm limit. Press ENTER to confirm.

NOTE: the TH value must always be less than the value shown in void conditions.

TH: 0350

DELAY: 00 S

MODE: MAX

ŹON

850

In the case of “light” products that tend not to completely block the vibrating forks,

it may be necessary to set the TH value close to the free vibration value.

TH: 0700

DELAY: 00 S

MODE: MAX

ŹON

850

8.2 DELAY

Press ENTER to modify the programming.

Using the UP ARROW, adjust the delay time from 0 to 30 seconds for the

switching of the sensor from the normal state to the alarm state

(for MAX alarm, relay de-energized in the presence of product;

for MIN alarm, relay de-energized in the absence of product).

When the process ceases to be in alarm conditions, the sensor

instantly switches without a delay, from the alarm state to the normal state

(for MAX alarm, relay energized in absence of product; for MIN alarm, relay

energized in presence of product).

TH: 0350

DELAY: 00 S

MODE: MAX

ŹON

8.3 MODE

Press ENTER to modify the programming. Set the sensor alarm mode.

Use the UP ARROW to change the alarm mode, MAX or MIN,

highlighted in negative.

Press ENTER to confirm.

TH: 0350

DELAY: 00 S

MODE: MAX

ŹON

Page 13 of 16

www.sgm-lektra.eu

RSL200 - parameter programming

By setting the MODE parameter with the “MAX” option, the RSL200 sensors will work in maximum level alarm mode:

- normal condition; relay energized in absence of product

- alarm condition; relay de-energized in presence of product

NO

C

NC

Led RL

ON RL

NORMAL

CONDITION

TH: 0300

DELAY: 00 S

MODE: MAX

ŹON

NO

C

NC

Led RL

OFF

RL

ALARM

CONDITION

TH: 0300

DELAY: 00 S

MODE: MAX

ŹOFF

By setting the MODE parameter with the “MIN” option, the RSL200 sensor will work in minimum level alarm mode:

- normal condition; relay energized in presence of product

- alarm condition; relay de-energized in absence of product

NO

C

NC

Led RL

ON RL

TH: 0300

DELAY: 00 S

MODE: MIN

ŹON

NORMAL

CONDITION

NO

C

NC

Led RL

OFF

RL

TH: 0300

DELAY: 00 S

MODE: MIN

ŹOFF

ALARM

CONDITION

Page 14 of 16 www.sgm-lektra.com

RSL200 - notes

NOTES

________________________________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

____________________________________________________________________ ______________________

____________________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

___________________________________________ _____________________________________________________

________________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________ _____________________________________________________________________________________

__________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

________________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________ _________

______________________________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_____________________________________________________________ ______________________________

___________________________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

_______________________________________________________________________________________

Page 15 of 16

www.sgm-lektra.eu

SGM-LEKTRA S.r.l.

Via Papa Giovanni XXIII, 49

20090 Rodano (MI) - ITALY

tel: ++39 02 95328257

fax: ++39 02 95328321

e-mail: [email protected]

web: sgm-lektra.com

10-FACTORY TEST AND QUALITY CERTIFICATE

Documentation subject to technical change with no prior warning

In conformity to the company and check procedures I certify that the equipment:

is conform to the technical requirements on Technical Data and it is made in conformity to the procedure

Quality Control Manager: .......................................................... Production and check date: .................................................

(Vibration probe) (Electronic Unit)

Table of contents

Other SGM LEKTRA Switch manuals