INSTALLATION

The easiest way to mount it is in a tilted position on the rear part of the quad bike.

ATTENTION: CAREFULLY SECURE ALL FASTENERS TO ENSURE SAFETY

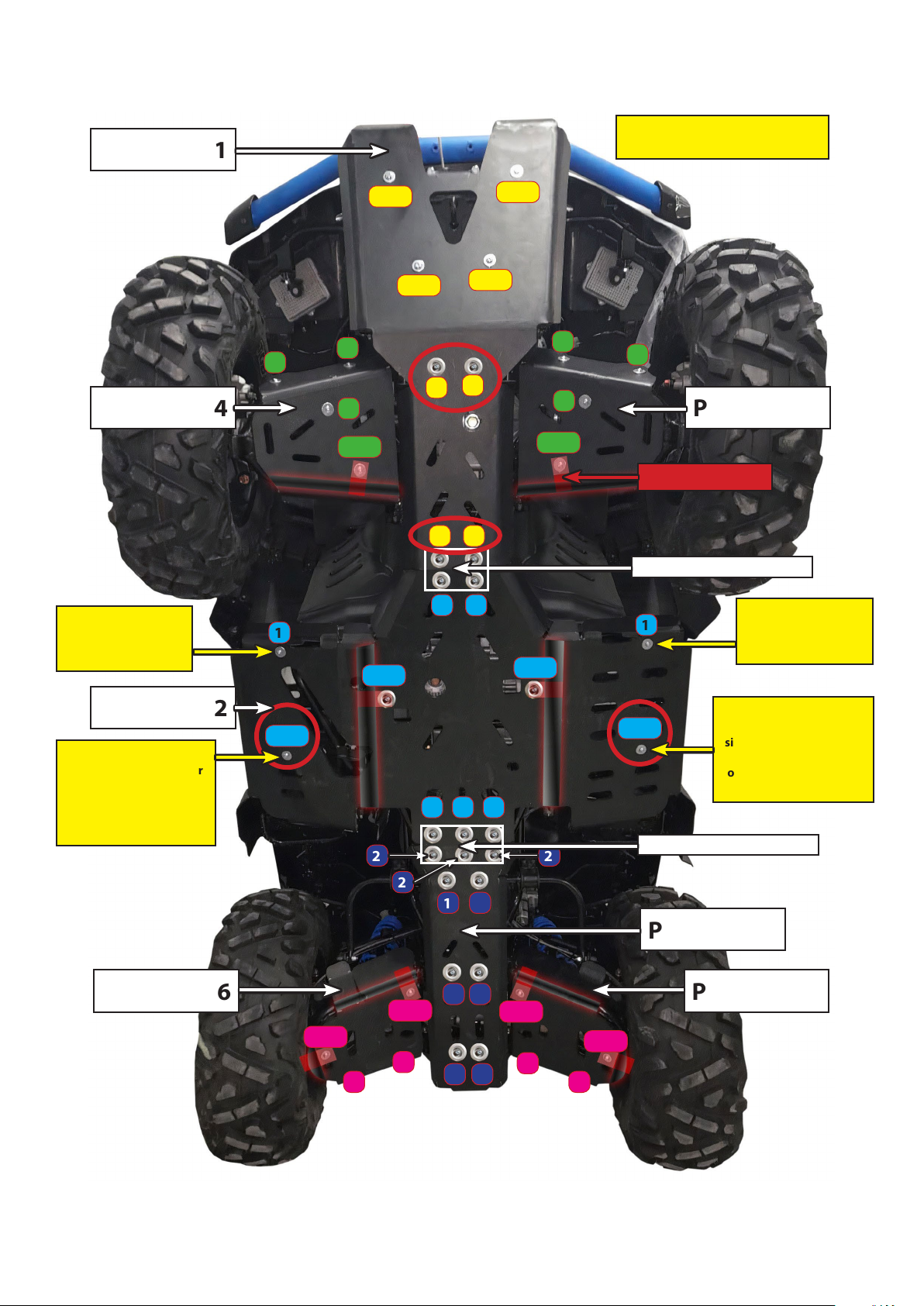

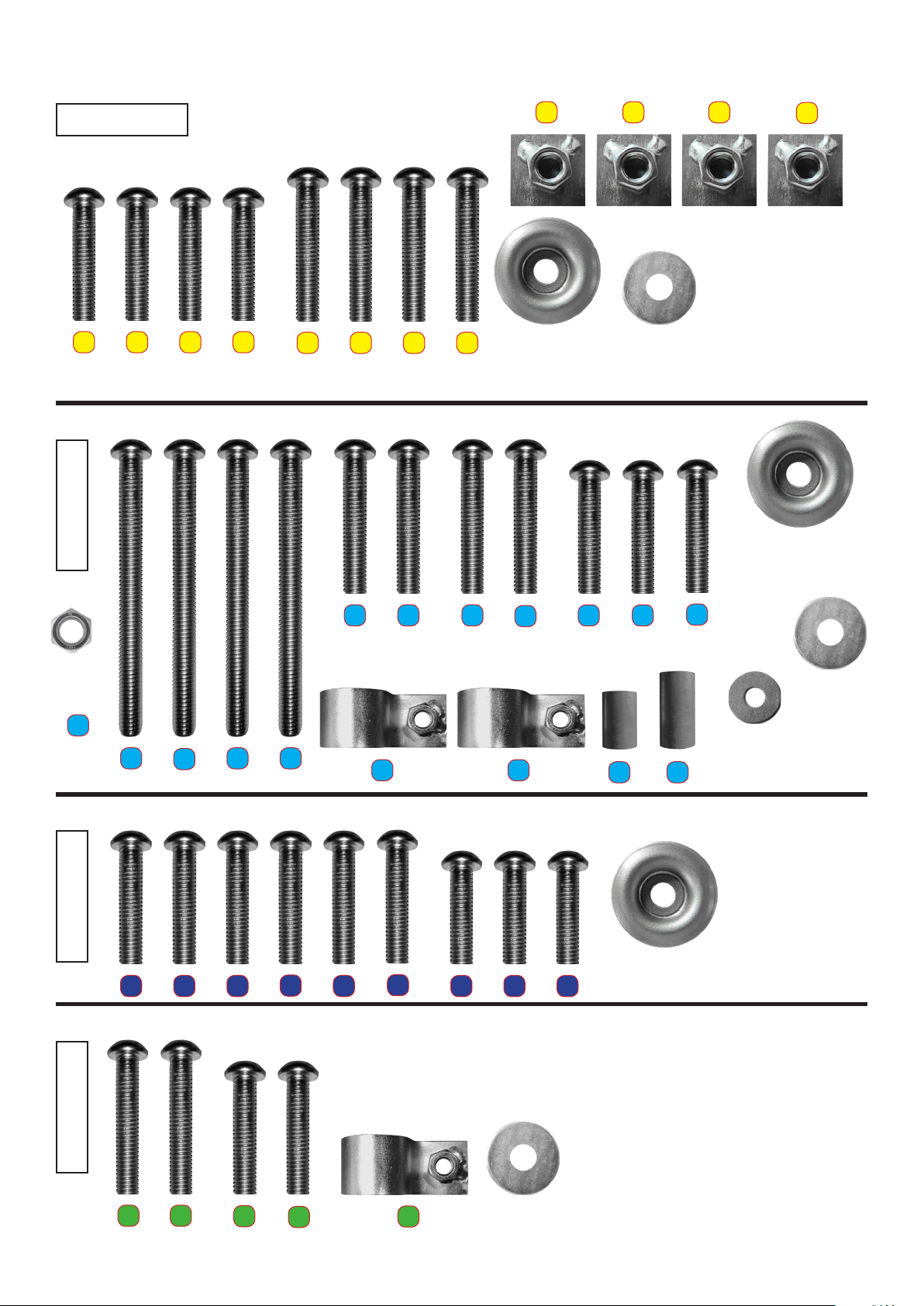

The manual provides a view of the placement of elements helping to localize fasteners and the use of individual connecting

elements.

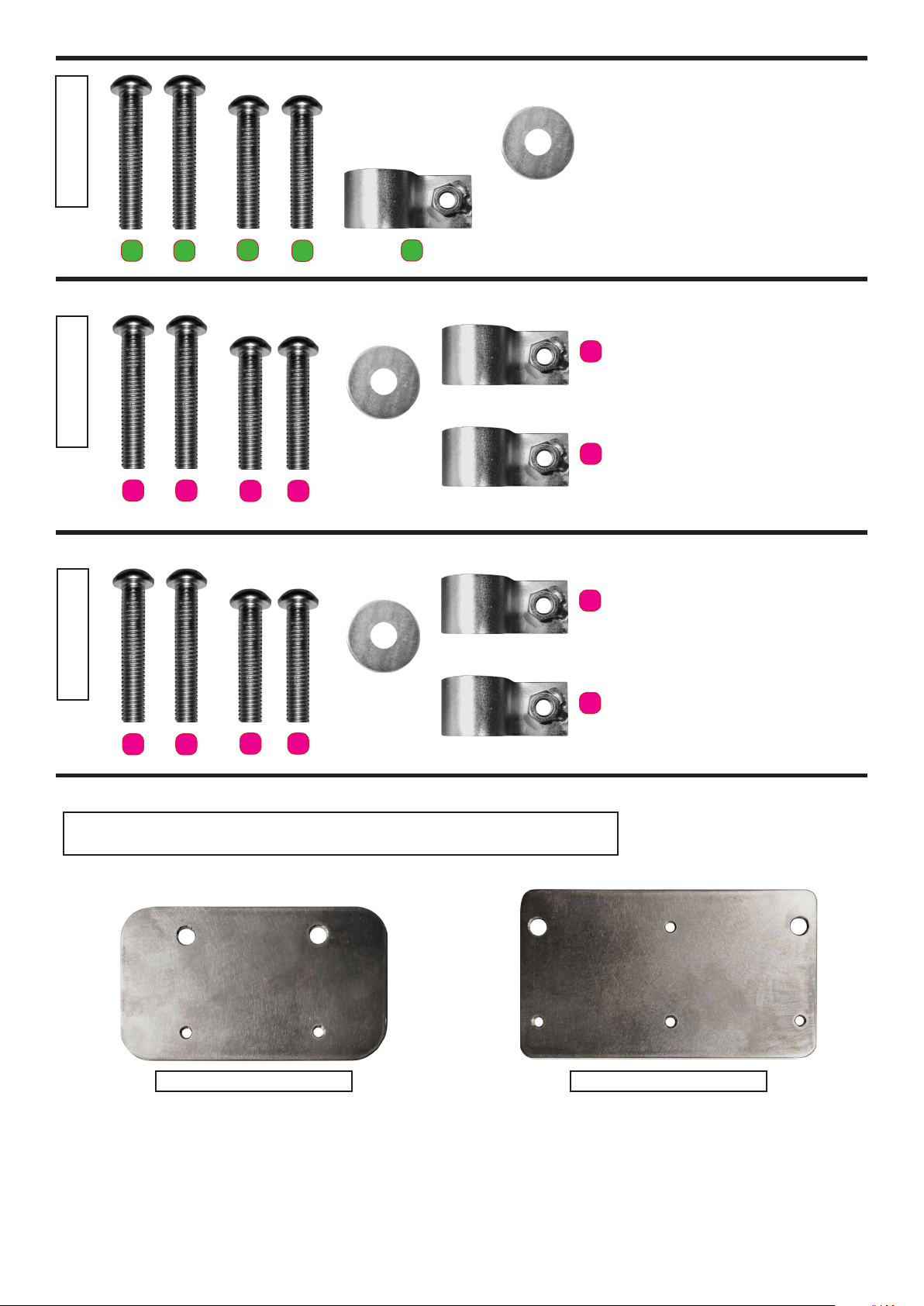

Start the assembly sequence with the front plate [1] and the fastening plate A1.

INSTALLATION OF PROTECTIVE PLATES 1, 2, 3, 4, 5, 6, 7

[Plate no. 1] When assembling the protective plate, do not unscrew the front metal plate that comes with your ATV. Start from

tightening the M6 screws (points marked with red circles on the diagram) then perform the fastening with M8 screws, which

screw is marked in yellow on the diagram as screw no. 1 with square elements A (Fig. 3). Scheme 1+A. The last step is screwing

the connecting plate A1. The mounting plate is installed between the screwed-on plastic cover and the quad’s chassis.

[Plate no. 2] Place the washers on the screws. Screw in from above through the outer feet of the leg space. Install two hooks

and screw 2-3 threads into the center protection plate, the hooks will hold the plate on the quad frame. Install the plate on the

screws located in the leg space. Put washers on the bolts, then the nuts Btwisting with your ngers. Attach the tabs through

the square holes to the frame tubes, tighten, so that the tabs do not fall out. Then adjust the position of the plate, place

the mounting plate A2 and tighten it. NOTE Place the distance sleeves Con the bolt behind the protective plate (points marked

with red circles in the diagram).

[Plate no. 3] Place the back protection plate over the appropriate holes and install the screws with washers. Before tightening

the bolts, set the rear protection plate to the correct position and then fully tighten all 9 bolts.

[Plate no. 4 and 5] First, put the cover and install the hooks (orientation on the diagram) to the front rocker arms covers,

do not fully tighten the screws, center the cover on the appropriate holes and tighten the screws, not forgetting the washers :-).

Position the cover and tighten the screws. Make a double check, if there is no contact between the wheel and the guard

by turning your steering wheel completely right and left, in the event of a contact, make the proper adjustment of the guard by

moving it to the correct position. Also check, if there is sucient space between the front protection plate and the rocker arm

covers to avoid contact in the event of complete compression of the suspension.

[Plate no. 6 and 7] First, put the cover and install the hooks (orientation on the diagram) to the rear rocker arms covers,

do not fully tighten the screws, center the cover on the appropriate holes and tighten the screws, not forgetting the washers :-).

Position the cover and tighten the screws. Make a check that there is no contact between the wheel and the guard by turning

your steering wheel completely right and left, in the event of a contact, make the proper adjustment of the guard by moving it

to the correct position. Also check that there is adequate space between the rear protective plate and the rocker arm covers to

avoid contact in the event of complete compression of the suspension.

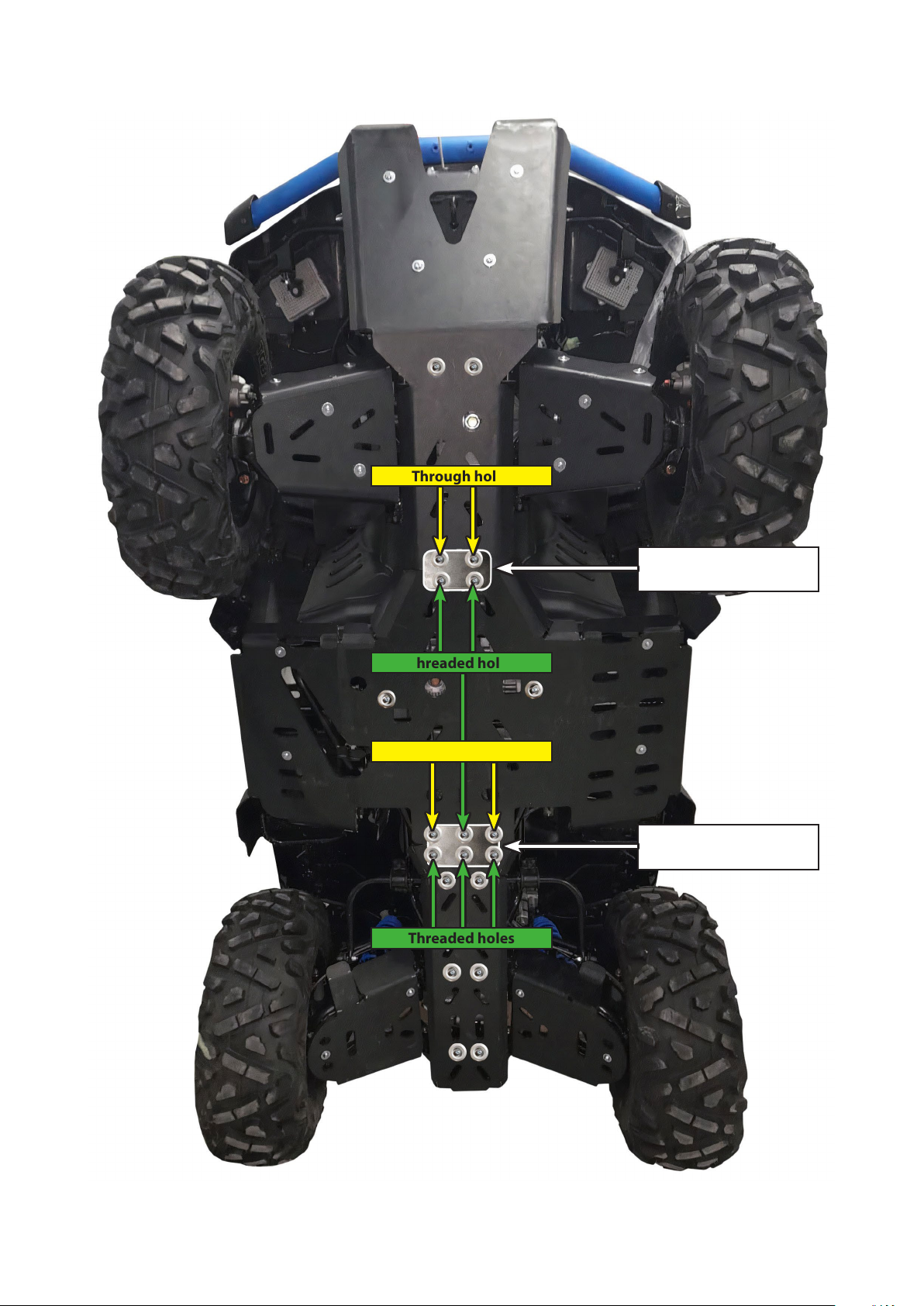

INFORMATION

Sucient space for the hands allows mounting clamps of the control arm covers at the marked points after attaching the

cover to them. To do this, tighten the cover with the screws on the front and rear transverse arms (points marked with circles

in the diagram). Clamp the clamp (without the screw on the other side) on the swing arm tube (observe the orientation

of the clamps in the diagram), move the thread to the hole in the protective cover and x the clamp with the screw (Fig. 1 and 2).

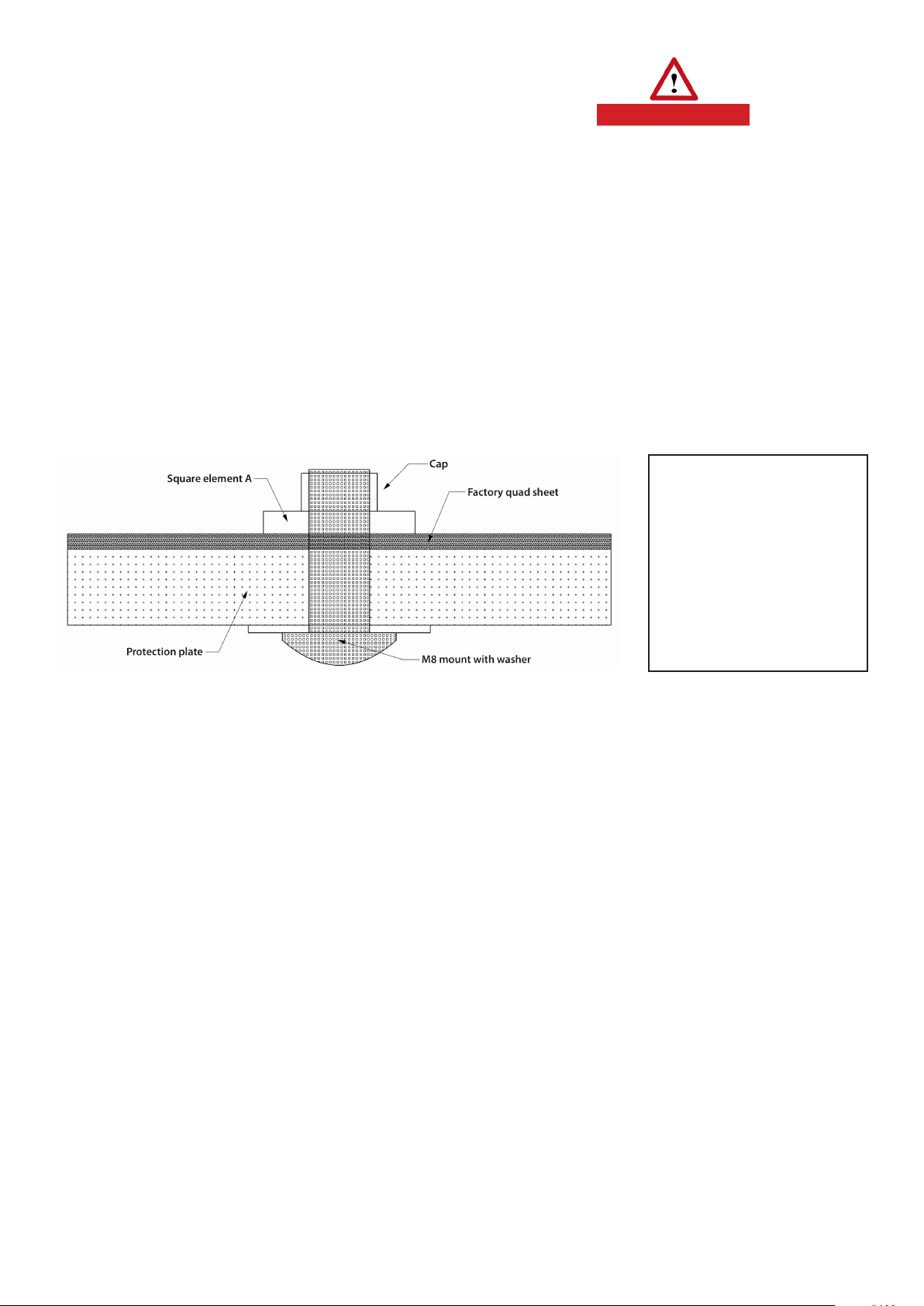

Fig. 3 plate [no. 1] INFORMATION

Fastened with M8 screws

with square elements A we carry

out through the notches located

in the factory plate of the quad

cover

CAUTION