10

PRECISIONMACHINETOOLS Ver 2 Maintenance Manual

1-3 Cautions for Machine Maintenance

It is important to perform maintenance on each listed items in order to maintain machine precision

and extend machine lifespan.

Erroneous operation may damage the machine or lead to injury of the operator. Be cautious about

the following matters:

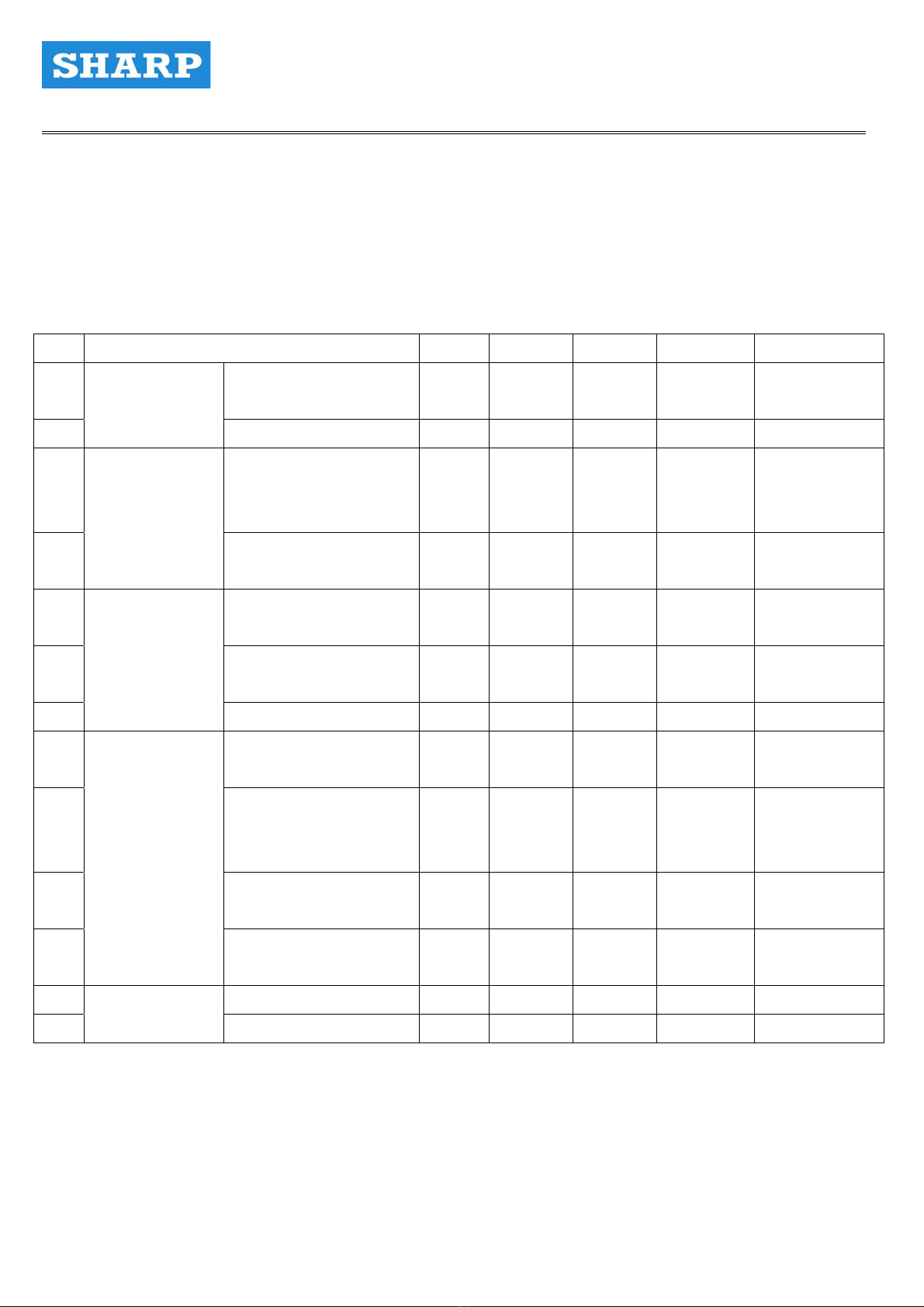

Cautions Prevention

Spindle operation warm-up

To extend the lifespan, follow the instructions given in Section

2-3 for machine warm-up before turning on the machine.

If the machine has been stopped for a long period, follow the

instructions given in Section 2-3 for machine warm-up before

turning on the machine in order to extend the life span.

Dynamic balance of the cutter

To extend the lifespan as well as to increase the precision,

please follow instructions given in Section 2-1 for usage as

well as achieving a dynamic balance for the cutter.

Standard broach bolts

Broach bolt is an important component jointing the spindle and

the tool shank. Using a wrong broach bolt is hazardous for the

operation. Make sure that only the standard one is used.

Spindle pre-operation check

Check the machine before spindle operation according to

instructions given in Section 2-4 in order to extend the lifespan

of the spindle.

Manually loosening the

spindle’s cutter

When loosening the cutter of the spindle, make sure that each

step is executed correctly or may lead to personnel injury.

Manual installing the cutter onto

the spindle

When changing the cutter, be cautious not to drop the cutter,

which may damage the workbench or tools. Manually change

the cutter only if necessary, and the procedures are written on

the operation panel at the front. Press and let go of the spindle

cutter loosening button to loosen up or to grasp the cutter.

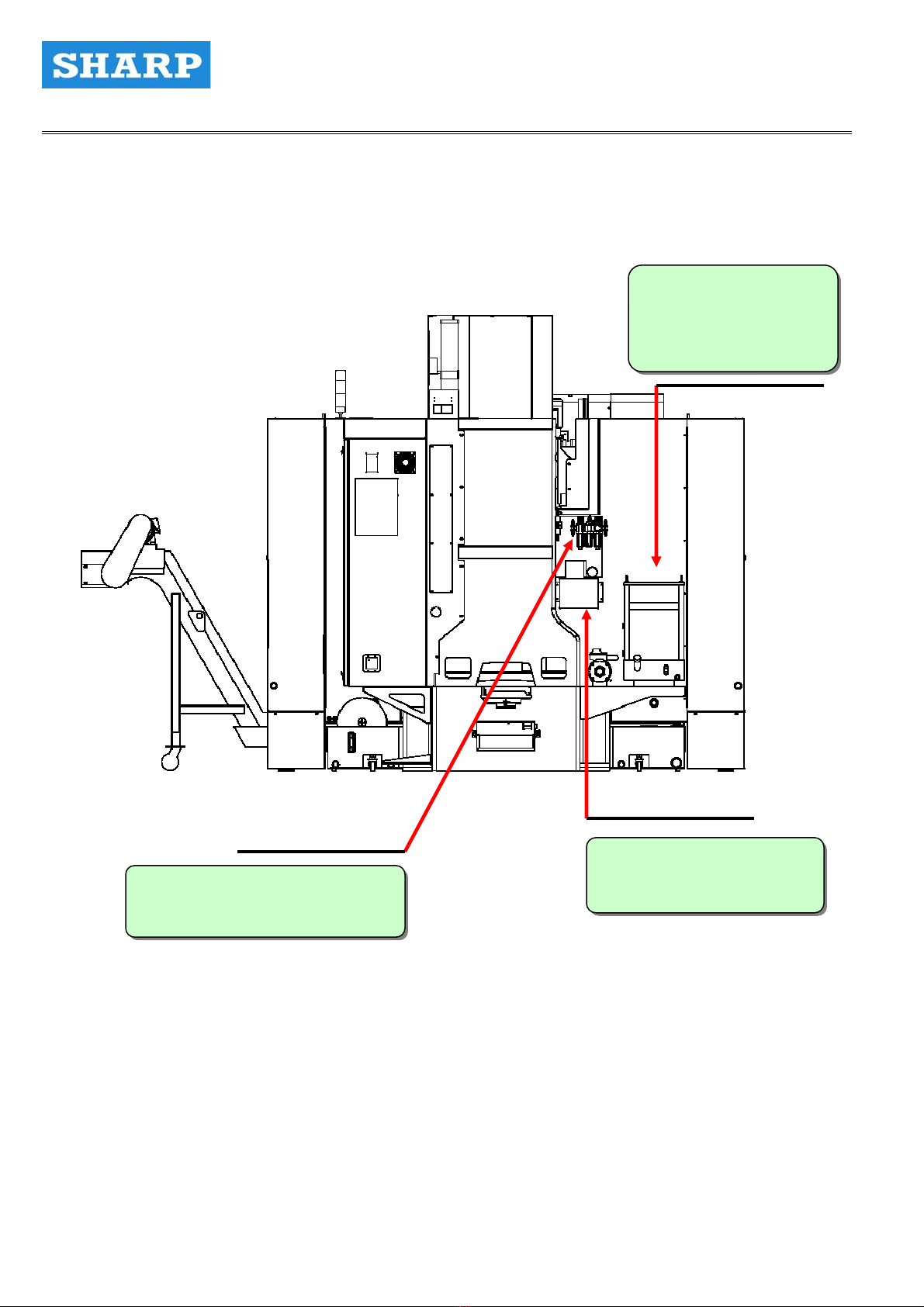

Do not touch the spinning tool

magazine

The tool magazine is controlled by CNC and motor. After

turning on the machine, do not touch the tool magazine or may

be injured. Turn off the power for changing the cutter.