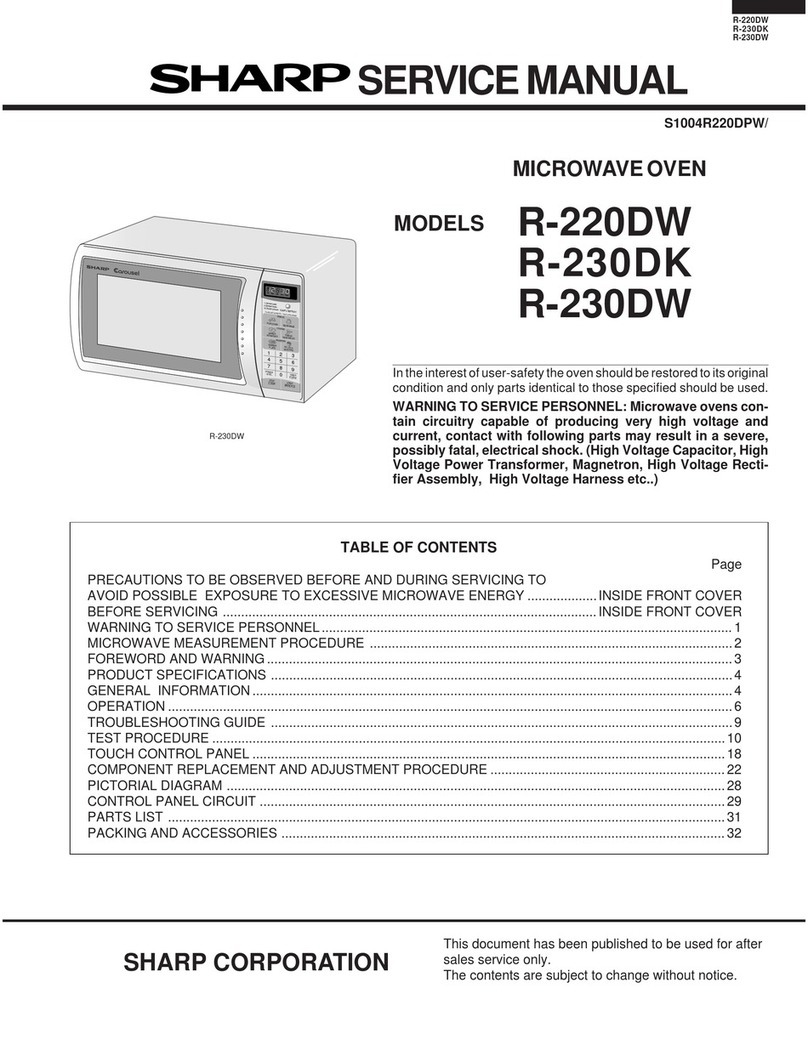

CONTENTS

CHAPTER 1. BEFORE SERVICING

[1] GENERAL IMPORTANT INFORMATION................1-1

[2] CAUTION MICROWAVE RADIATION .....................1-1

[3] WARNING .....................................................................1-1

CHAPTER 2. WARNING TO SERVICE PERSONNEL

CHAPTER 3. PRODUCT SPECIFICATIONS

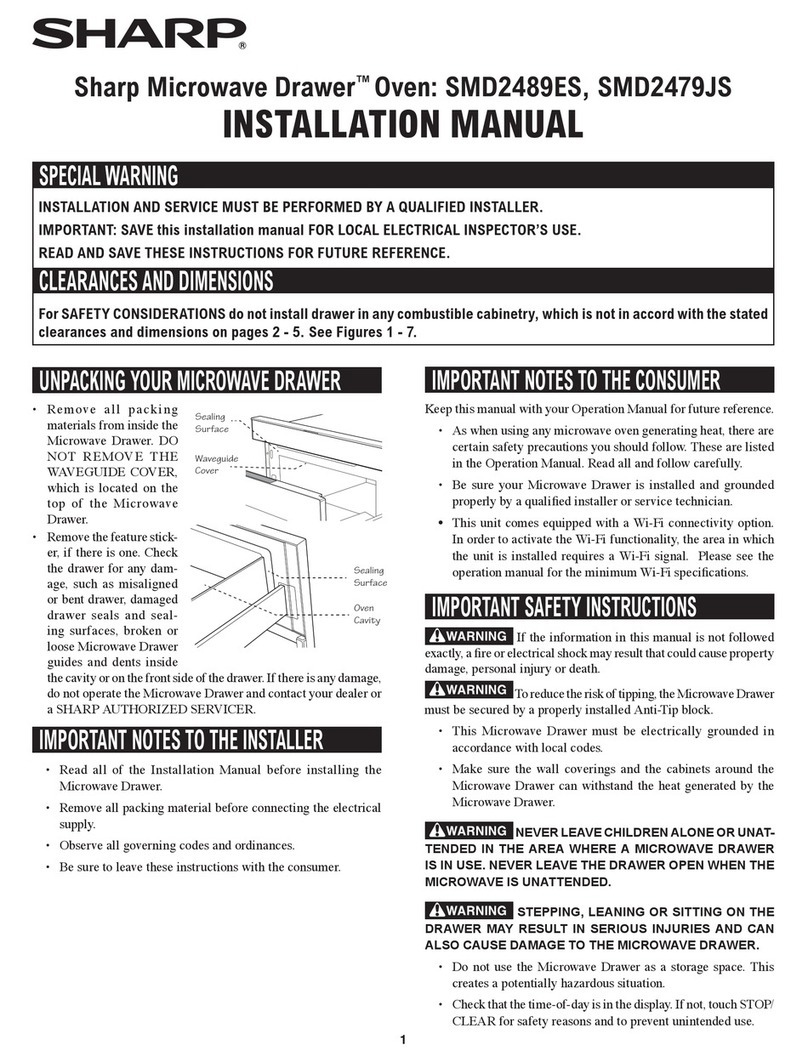

CHAPTER 4. APPEARANCE VIEW

[1] OVEN ..............................................................................4-1

[2] TOUCH CONTROL PANEL.........................................4-1

CHAPTER 5. OPERATION SEQUENCE

[1] OFF CONDITION .........................................................5-1

[2] MICROWAVE COOKING CONDITION ...................5-1

[3] POWER OUTPUT REDUCTION..............................5-1

CHAPTER 6. FUNCTION OF IMPORTANT COMPO-

NENTS

[1] DOOR OPEN MECHANISM.....................................6-1

[2] MONITORED LATCH SWITCH AND

LATCH SWITCH............................................................6-1

[3] MONITOR SWITCH .....................................................6-1

[4] FUSE T6.3A.................................................................6-1

[5] HIGH VOLTAGE FUSE .................................................6-1

[6] TEMPERATURE FUSE 150C (OVEN).......................6-1

[7] TURNTABLE MOTOR................................................6-1

[8] FAN MOTOR .................................................................6-1

[9] TIMER MOTOR..............................................................6-1

CHAPTER 7. TROUBLESHOOTING GUIDE

[1] FOREWORD..................................................................7-1

[2] CHART............................................................................7-1

CHAPTER 8. TEST PROCEDURES

[1] Procedure A: MAGNETRON (MG) TEST...............8-1

[2] Procedure B: HIGH VOLTAGE TRANS-

FORMER TEST..............................................................8-2

[3] Procedure C: HIGH VOLTAGE RECTIFI-

ER TEST..........................................................................8-2

[4] Procedure D: HIGH VOLTAGE CAPACI-

TOR TEST.......................................................................8-2

[5] Procedure E: SWITCH TEST .....................................8-2

[6] Procedure F: TEMPERATURE FUSE

TEST ...............................................................................8-3

[7] Procedure G: MOTOR WINDING TEST.................8-3

[8] Procedure H: FUSE T6.3A ........................................8-3

[9] Procedure I: HIGH VOLTAGE FUSE TEST ..............8-3

[10] Procedure J: TIMER MOTOR TEST.........................8-3

CHAPTER 10. COMPONENT REPLACEMENT AND

ADJUSTMENT PROCEDURE

[1] BEFORE OPERATING ................................................... 10-1

[2] OUTER CASE REMOVAL ............................................. 10-1

[3] HIGH VOLTAGE TRANSFORMER RE-

MOVAL ........................................................................... 10-2

[4] HIGH VOLTAGE RECTIFIER ASSEMBLY,

HIGH VOLTAGE FUSE AND HIGH VOLT-

AGE CAPACITOR REMOVAL.................................... 10-2

[5] MAGNETRON REMOVAL .......................................... 10-2

[6] POSITIVE LOCK CONNECTOR (NO-

CASE TYPE) REMOVAL ............................................. 10-2

[7] TURNTABLE MOTOR REMOVAL............................. 10-3

[8] COOLING FAN MOTOR REMOVAL........................ 10-3

[9] POWER SUPPLY CORD REPLACE-

MENT.............................................................................. 10-4

[10] CONTROL PANEL ASSEMBLY REMOV-

AL ................................................................................... 10-4

[11] MONITORED LATCH SWITCH, LATCH

SWITCH AND MONITOR SWITCH RE-

MOVAL .......................................................................... 10-4

[12] MONITORED LATCH SWITCH, LATCH

SWITCH AND MONITOR SWITCH AD-

JUSTMENT................................................................... 10-4

[13] DOOR REPLACEMENT.............................................. 10-5

CHAPTER 11. MICROWAVE MEASUREMENT

CHAPTER 12. CIRCUIT DIAGRAMS

[1] Oven Schematic........................................................ 12-1

[2] Pictorial Diagram(Figure S-1) .............................. 12-2

Parts List

R-20A1(S)VN