– 9 –

SD-NX10W

Troubleshooting Chart

Many potential "problems" can be resolved by the owner without calling a service

technician.

General

CD player

MiniDisc

Tuner

Remote control

Symptom Possible cause

"TIME ADJUST" appears when the

clock time is checked. Did a power failure occur? Reset the clock.

When a button is pressed, the unit

does not respond. Set this unit to the power stand-by mode and

then turn it back on.

No sound is heard. Is the volume level set to "0"?

Are the headphones connected?

Are the speaker wires disconnected?

The picture on the TV screen is dis-

torted. When a radio or TV which uses an indoor

aerial is placed near the unit, the picture on

the TV screen may be distorted or the radio

may not function properly.

It is recommended that you use an external

aerial.

Cannot adjust the volume. Is the sound connection lead connected to

the LINE OUT sockets on the MD/CD/tuner

unit? Set the unit to the stand-by mode and

connect the lead to the SYSTEM OUT sock-

ets.

Symptom Possible cause

Eventhoughadischasbeenloaded,

"CD NO DISC" or "Can't READ" is

displayed.

The disc is very dirty.

Is the unit located near excessive vibrations?

Has condensation formed inside the unit?

Playback does not start. The disc is loaded upside down.

Playbackstopsinthemiddleoris not

performed properly. The disc does not satisfy the standards.

The disc is distorted or scratched.

Playback sounds are skipped, or

stopped in the middle of a track. Is the unit located near excessive vibrations?

The disc is very dirty.

Has condensation formed inside the unit?

Symptom Possible cause

A recording cannot be made. Is the MiniDisc protected against accidental

erasure?

Did you try to make recording on a playback-

only MiniDisc?

Can you see the "DISC FULL" or "TOC

FULL" message in the display?

Eventhoughadischasbeenloaded,

"MD NO DISC" or "Can't READ" is

displayed.

The disc is very dirty.

Is the unit located near excessive vibrations?

Playback sounds are skipped. Has condensation formed inside the unit?

Symptom Possible cause

Radio makes unusual noise consec-

utively. The stereo system is placed near the TV or

computer.

FM/AM loop aerial is not placed properly.

Move the AC power lead away from the aeri-

al if located near.

The preset channel cannot be re-

called. Did a power failure occur?

Preset the channel again.

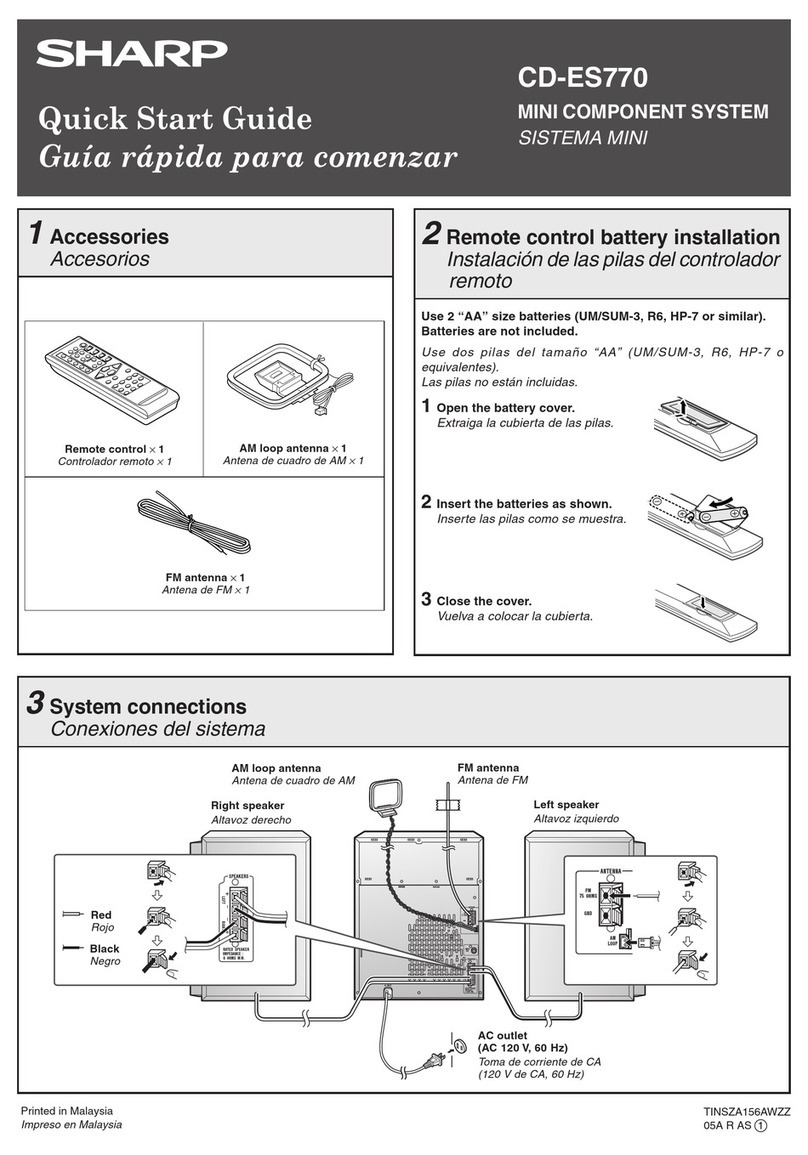

Symptom Possible cause

The remote control does not oper-

ate. Is the AC power lead of the stereo system

plugged in?

The battery polarity is not correct.

The batteries are dead.

Incorrect distance or angle.

Does the remote control sensor receive

strong light?

If trouble occurs (reset)

When this product is subjected to strong external interference (mechanical shock,

excessive static electricity, abnormal supply voltage due to lightning, etc.) or if it is

operated incorrectly, it may malfunction.

If such a problem occurs, do the following:

Unplug the power lead from the AC socket. Then, plug it in again and retry the

operation.

Caution:

This operation will erase all data stored in memory including clock, timer settings,

tuner preset, and CD or MiniDisc programme.

Condensation

Before transporting the unit

Remove the CD and MiniDisc from the unit. Your unit checks whether there are any

discs inside. "CD NO DISC" and "MD NO DISC" appear if no disc is inside. Then, set

the unit to the power stand-by mode. Carrying the unit with discs left inside can dam-

age it.

Sudden temperature changes, storage or

operation in an extremely humid environ-

ment may cause condensation inside the

cabinet (CD pickup, MD pickup, etc.) or on

the transmitter on the remote control.

Condensation can cause the unit to mal-

function. Ifthis happens, leave the power on

with no disc inthe unit until normal playback

is possible (about 1 hour). Wipe off any con-

densationonthe transmitterwitha softcloth

before operating the unit.