1

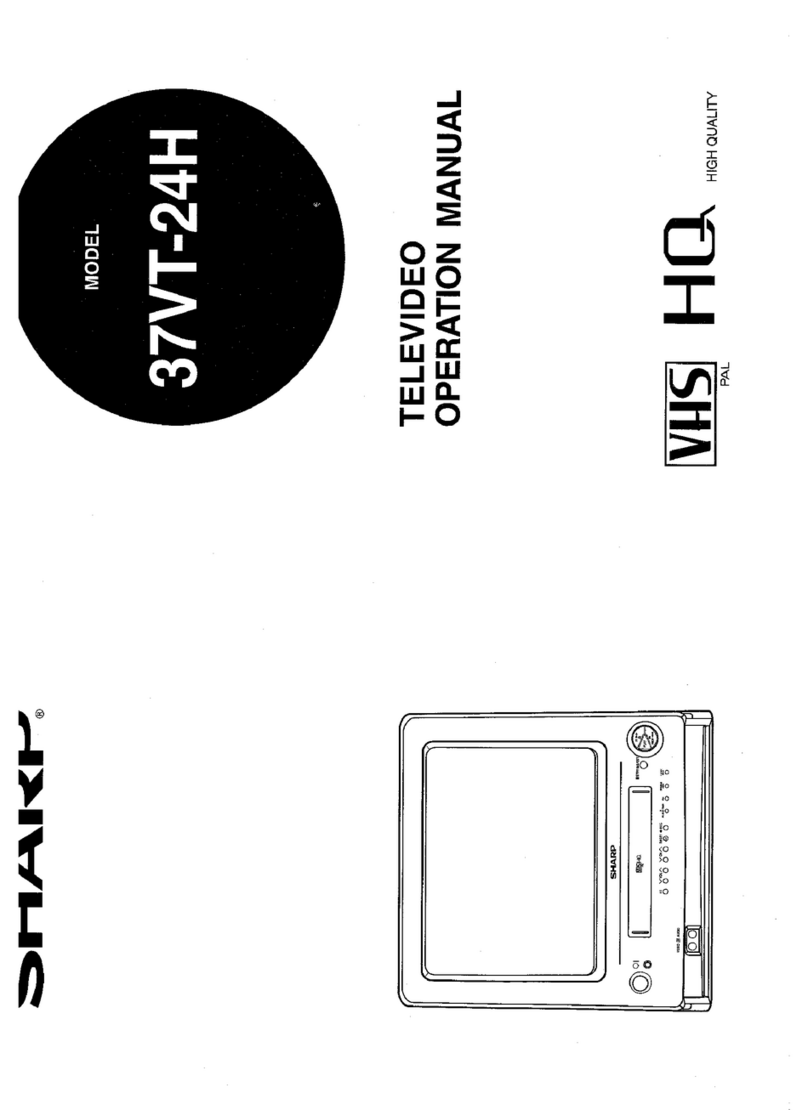

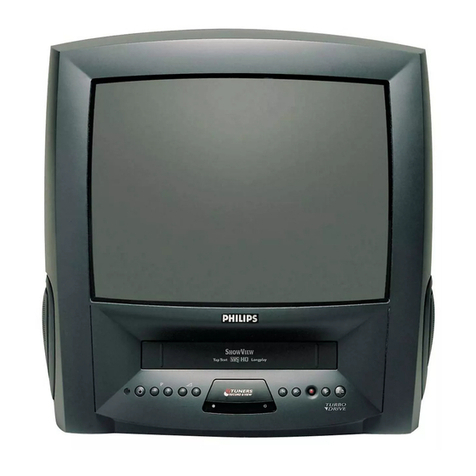

37VT-26H(GY)

WARNING

Thechassisinthisreceiverispartiallyhot.Useanisolationtransformerbetweenthelinecordplugandpower

receptacle,whenservicingthischassis.Topreventelectricshock,donotremovecover.Nouser– serviceable

parts inside. Refer servicing to qualified service personnel.

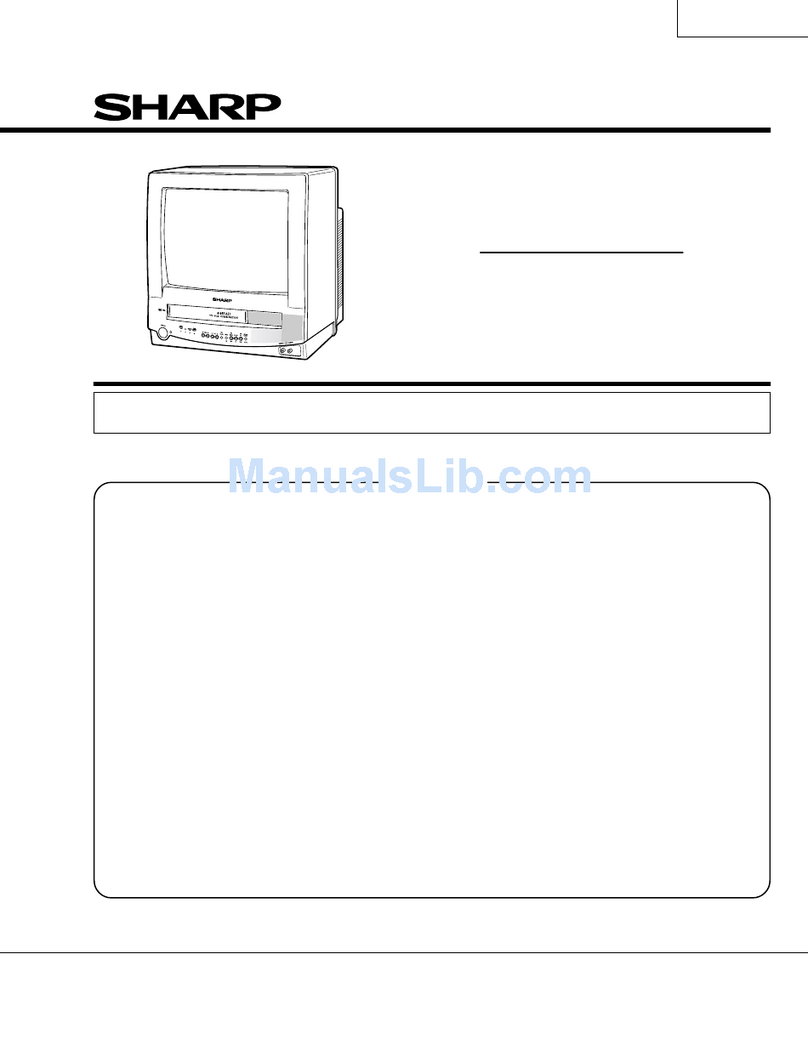

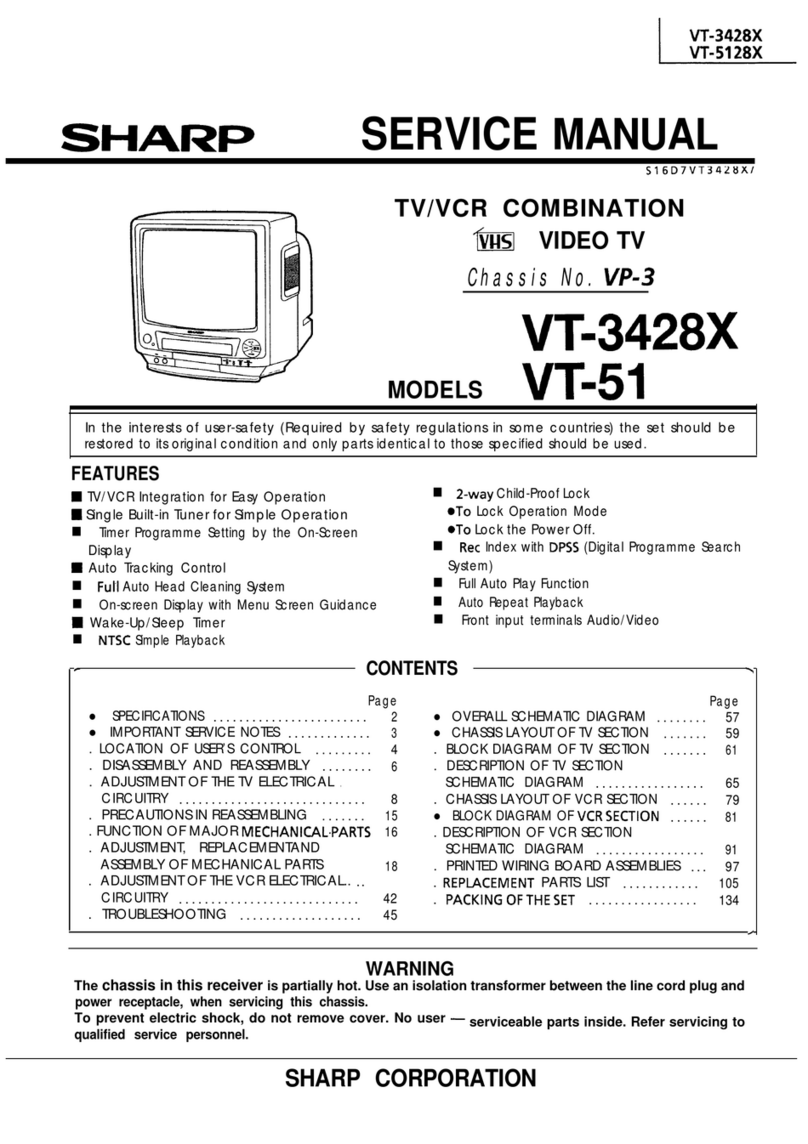

SERVICE MANUAL

S99P337VT26H/

In the interests of user-safety (Required by safety regula-

tions in some countries) the set should be restored to its

originalcondition and onlyparts identical tothose specified

be used.

MODEL

SERVICE MANUAL TV/VCR COMBINATION TELEVIDEO MODEL 37VT-26H(GY)

SHARP CORPORATION

37VT-26H(GY)

TV/VCR COMBINATION

TELEVIDEO

Chassis No.VP-8

37VT-26H(GY)

FEATURE

ËAIS (Automatic Instruction System)

ËASS (Automatic Sorting System)

ËVPS/PDC (Video Program System / Program Delivery

Control)

ËFASTEXT

ËVIDEO Plus+

ËPost Cord Security

ËOn Screen Digital Channel/Sound Level/Tuning Display,

Control (Contrast, Colour, Brightness, Tint, Sharpness,

White temp) Symbol and Level

ËBlue Back OffTimer

Ë52 Key, Wireless Remote Control Unit

ËChannel Skip

ËHigh Speed and Double Speed Video Search System

»PAL : 3 times/7 times (SP/LP)

»NTSC : 3 times/5 times (SP/LP)

5 times/15 times (EP)

ËDPSS (Digital Program Search System)

ËQuick Start Playback with Full Loading System

ËDigital Automatic Tracking Control

ËAutomatic Playback Function

ËAHC (Automatic Head Cleaning System)

ËSharp Super Picture

Ë345 Times Hi-Speed FF/REW

CONTENTS Page

»SPECIFICATIONS ................................................................................................................................................................................. 2

»IMPORTANT SERVICE NOTES ............................................................................................................................................................ 3

»LOCATION OF USER'S CONTROL...................................................................................................................................................... 4

»DISASSEMBLY AND REASSEMBLY .................................................................................................................................................... 6

»ADJUSTMENT OF THE TV ELECTRICAL CIRCUITRY ........................................................................................................................9

»PRECAUTIONS IN REASSEMBLING ................................................................................................................................................ 19

»FUNCTION OF MAJOR MECHANICAL PARTS ................................................................................................................................. 20

»ADJUSTMENT, REPLACEMENT AND ASSEMBLY OF MECHANICAL UNITS ................................................................................. 22

»ADJUSTMENT OF THE VCR ELECTRICAL CIRCUITRY ...................................................................................................................41

»MECHANISM OPERATION FLOWCHART AND TROUBLESHOOTING GUIDE ............................................................................... 44

»CHASSIS LAYOUT .............................................................................................................................................................................. 63

»BLOCK DIAGRAM OFTV SECTION .................................................................................................................................................. 64

»BLOCK DIAGRAM OFVCR SECTION ............................................................................................................................................... 66

»DESCRIPTION OF SCHEMATIC DIAGRAM ...................................................................................................................................... 75

»SOLID STATE DEVICE BASE DIAGRAM ........................................................................................................................................... 76

»WAVEFORMS .....................................................................................................................................................................................77

»SCHEMATIC DIAGRAM ...................................................................................................................................................................... 78

»PRINTED WIRING BOARD ASSEMBLIES......................................................................................................................................... 92

»REPLACEMENT PARTS LIST ............................................................................................................................................................ 99

»PACKING OF THE SET ..................................................................................................................................................................... 115