I

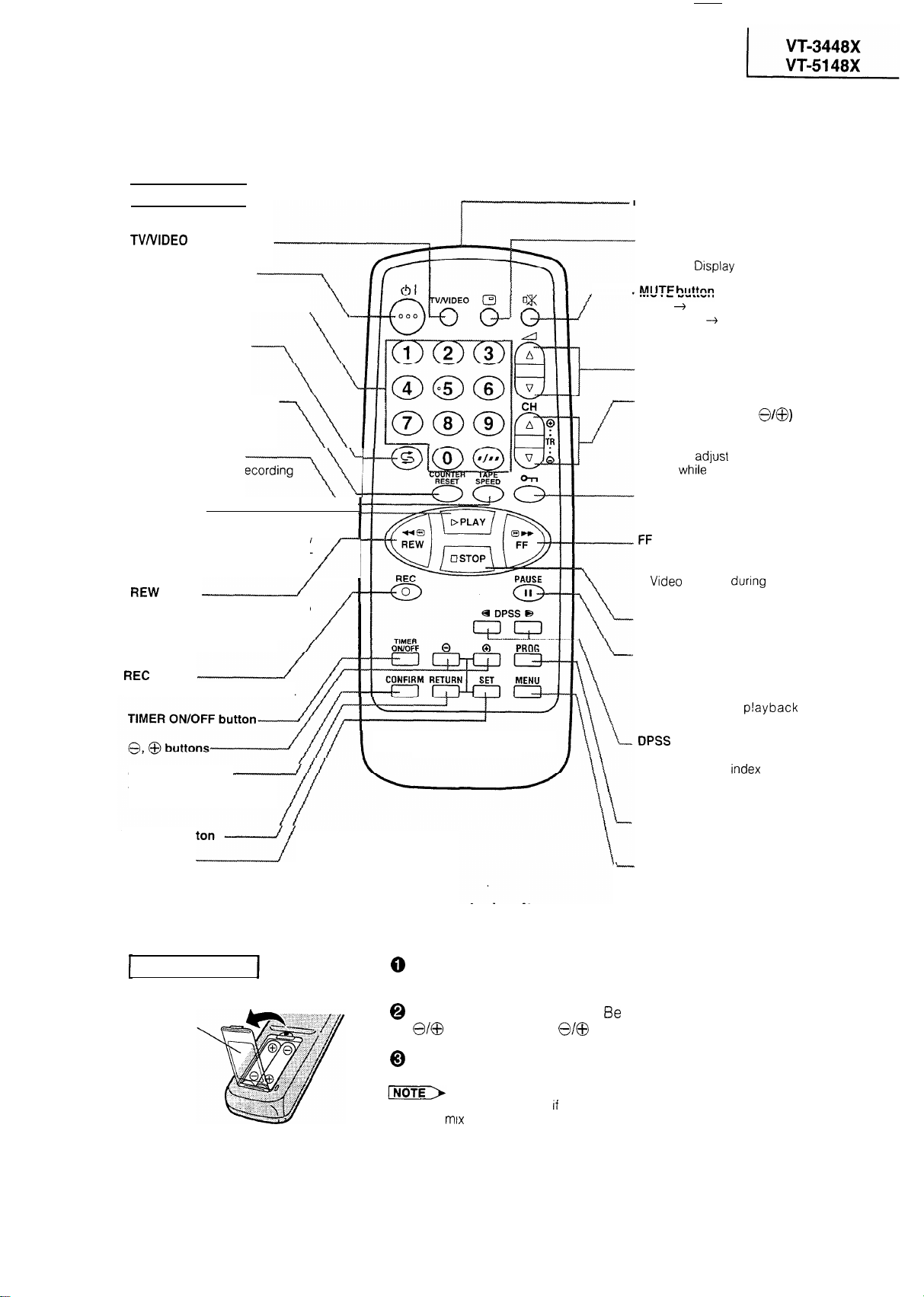

VT-3448X

VT-51

48X

’

SHARP

SERVICE MANUAL

S77Cl

VT-3448X

TV/VCR COMBINATION

TELEVIDEO

9

VT-3448X

VT-51

48X

,

MODELS

VT-51

48X

i

I

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its

original condition and only parts identical to those specified should be used.

FEATURE

n

Full Auto Search Tuning System

n On Screen Digital Channel/Sound Level/Tuning

Display, Control (Contrast,

Colour,

Brightness, Tint, P-

Tone) Symbol and Level

n

Blue Back Off Timer

n

39

Key, Wireless Remote Control Unit

n

Channel Skip

n High Speed and Double Speed Video Search System

l

PAL : 3 times/7 times

(SP/LP)

@

NTSC

: 3

times/5

times

(SP/LP)

5 times/l5 times

(EP)

n

DPSS

(Digital Program Search System)

n Quick Start Playback with Full Loading System

n

Digital Automatic Tracking Control

n

Automatic Playback Function

n

AHC

(Automatic Head Cleaning System)

n

Sharp Super Picture

CONTENTS

Page

l

SPECIFICATIONS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

l

IMPORTANT SERVICE NOTES . . . . . . . . . . . ..a............ 3

l

LOCATION OF USER’S CONTROL . . . . . . . . . . . . . . . . . . . . 4

l

DISASSEMBLY AND REASSEMBLY

. . . . . . . . . . . . . . . . . . 6

l

ADJUSTMENT OF THE TV ELECTRICAL

CIRCUITRY

..................

..~....................................

9

l

PRECAUTIONS IN REASSEMBLING . . . . . . . . . . . . . . .

23

l

FUNCTION OF MAJOR MECHANICAL

PARTS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

24

l

ADJUSTMENT, REPLACEMENTAND

Page

l

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

46

l

CHASSIS LAYOUT

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

65

l

BLOCK DIAGRAM OF TV SECTION . . . . . . . . . . . . . . . . .

67

l

DESCRIPTION OF TV SECTION

SCHEMATIC DIAGRAM

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

71

l

BLOCK DIAGRAM OF VCR SECTION

. . . . . . . . . . . . .

85

l

DESCRIPTION OF VCR SECTION

SCHEMATIC DIAGRAM

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

95

l

PRINTED WIRING BOARD ASSEMBLIES......

101

l

ASSEMBLY OF MECHANICAL UNITS . . . . . . . . . . . . . .

26

REPLACEMENT PARTS LIST . . . . . . . . . . . . . . . . . . . . . . . . .

107

l

PACKING

l

ADJUSTMENT OF THE VCR

OF THE SET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

133

ELECTRICAL CIRCUITRY

. . . . . . . . . . . . . . . . . . . . . . . ..a......

44

WARNING

The chassis in this receiver is partially hot. Use an isolation transformer between the line cord plug and

power

receptacle,

when servicing this chassis.

To

prevent electric shock, do not remove

cover.

No user

-

serviceable parts inside.

Refer servicing to qualified service personnel.

SHARP CORPORATION