3

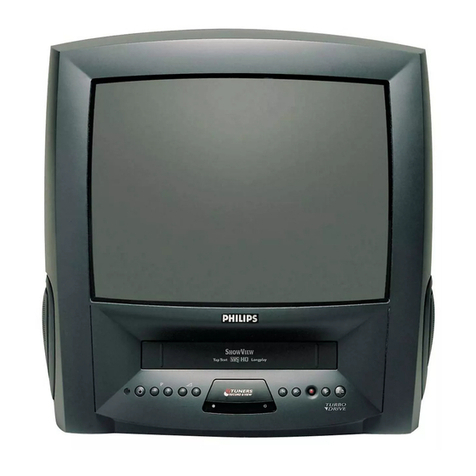

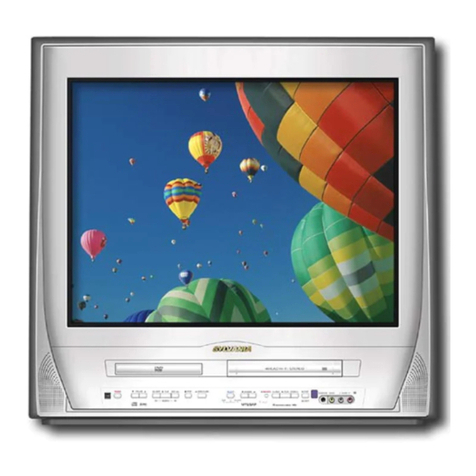

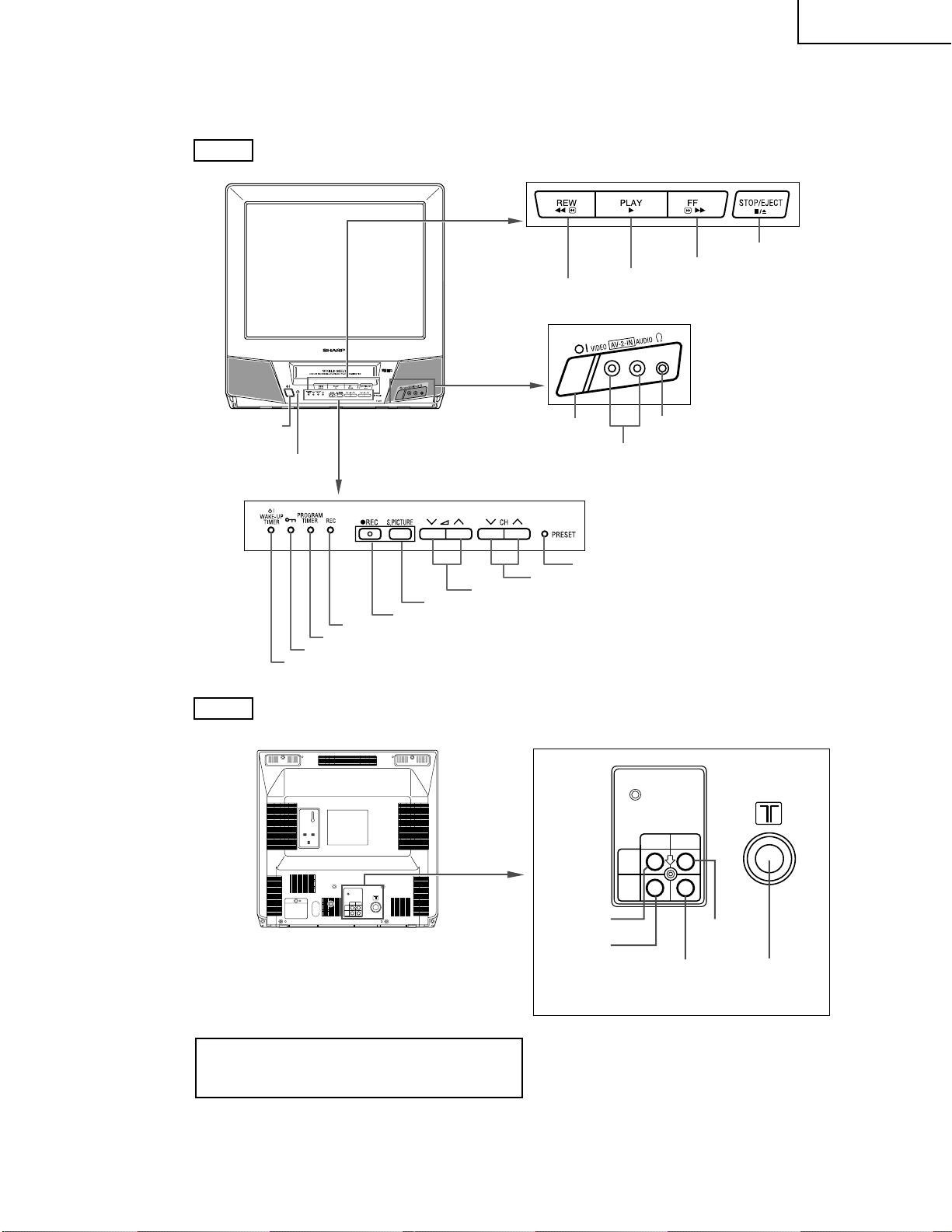

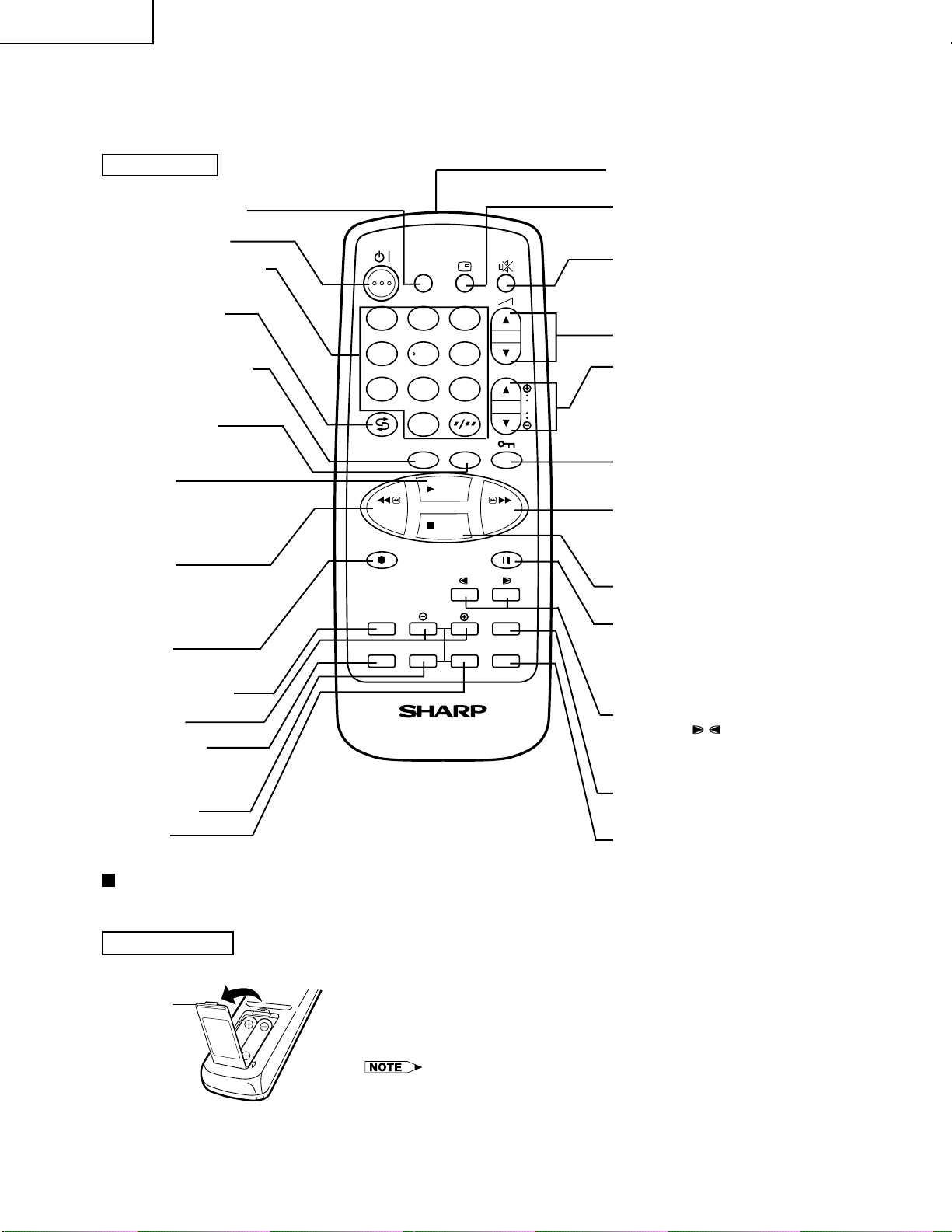

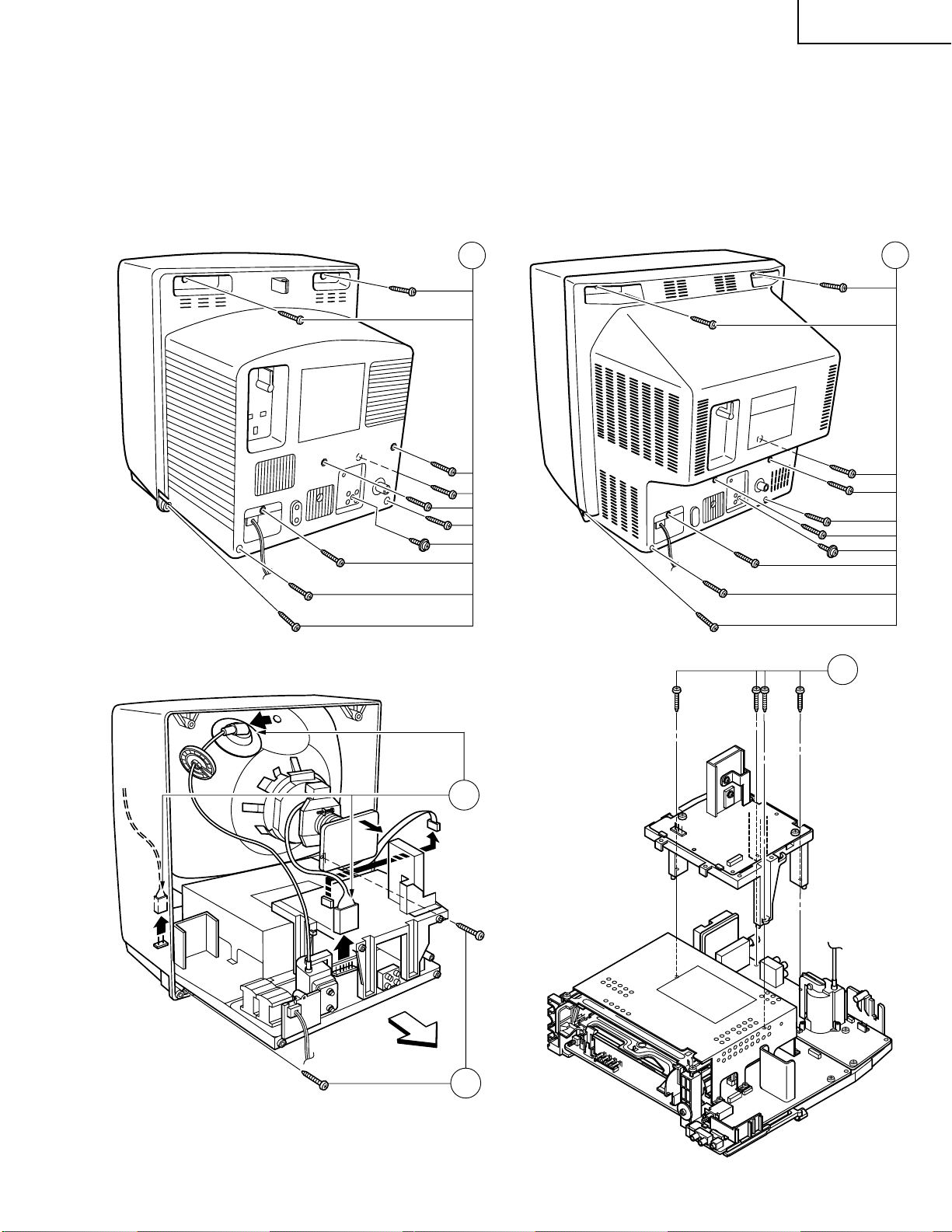

VT-G14

VT-G21

SPECIFICATIONS

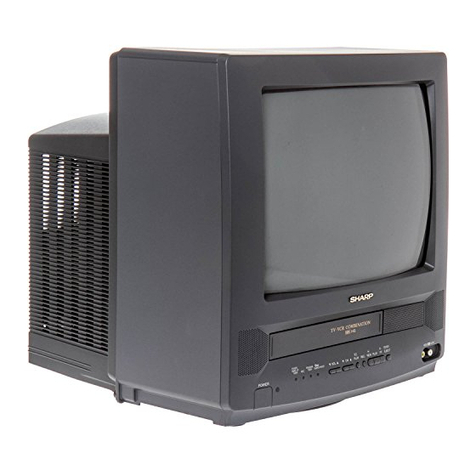

ËOUTLINE OF THE PRODUCT

Power Source: 110~240 V AC, 50/60 Hz

Power Consumption: VT-G14 : 94 W

VT-G21 : 112W

Receiving Broadcast Standard: B/G, I, D/K, M

Receiving Channel: VHF; 1A~S36

UHF; S37~C57

Receiving System: Sound; 5.5/6.0/6.5/4.5 MHz

Colour; PAL/SECAM/NTSC

Antenna Input Impedance: VHF/UHF;75 ohm Unbalanced (DIN)

Video Signal: Input; 0.5~2.0 Vp-p/75 ohm (RCA)

Output; 1.0 Vp-p/75 ohm (RCA)

Audio Signal: Input; 0.5 Vrms/10k ohm (RCA)

Output; 0.5 Vrms/1k ohm (RCA) (54% MOD)

Temperature: Operation; 5°C to 40°C

Storage; -10°C to 60°C

Dimensions (Approx.): VT-G14 : 378 mm (W) ×387 mm (H) ×384 mm (D)

VT-G21 : 505 mm (W) ×503 mm (H) ×478 mm (D)

Weight (Approx.): VT-G14 : 12.7 kg

VT-G21 : 23.5 kg

Cabinet Material: Plastic

Accessories: Operation Manual

Infrared Remote Control Unit

Dry Batteries, Type AA (×2 pcs.)

ËTV SECTION

Viewing Area: VT-G14 : 33.54 cm Diagonal Measurement

VT-G21 : 50.8 cm Diagonal Measurement

Picture Power: VT-G14 : 22.0 kV at 800 µA Beam Current

VT-G21 : 25.0 kV at 1100 µA Beam Current

Speaker Output: VT-G14 : 3.0 W at Max. (5×9 cm oval type ×1pc.)

VT-G21 : 3.0 W at Max. (5×9 cm oval type ×2pcs.)

Picture Tube: Type; VT-G14 : VB370BVBK1S-S (Tint Tube)

VT-G21 : VB540ADAC1S*S (Tint Tube)

Heater; VT-G14 : 6.3 V, 300 mA

VT-G21 : 6.3 V, 600 mA

Focus; High Bi-Potential Electrostatic

ËVCR SECTION

Outline: VHS Video System Colour Video Cassette Recorder

Format: VHS PAL/NTSC Standard

Video Recording System: Rotary Slant Azimuth 2-Head Helical Scan System

Luminance: FM Recording

Chrominance: Low Frequency Converted Direct Recording

Video Signal System: PAL/SECAM(MESECAM Rec)/NTSC 3.58MHz Colour

Cassette Tape: VHS Type Video Cassette Tape

Tape Width: 12.7 mm

Tape Speed: PAL ; 23.39 mm/s (SP), 11.70 mm/s (LP)

NTSC ; 33.35 mm/s (SP), 16.68 mm/s (LP·PB only), 11.12 mm/s (EP)

Recording/Playback Time: SP ; Max. 240 min (with E-240)

LP ; Max. 480 min (with E-240, PAL only)

EP ; Max. 480 min (with T-160, NTSC only)

Note: The antenna must correspond to the new standard DIN 45325 (IEC 169-2) for combined UHF antenna with

75 ohm connector.

Specifications are subject to change without prior notice.