8

8-1 8-2

20CT-250

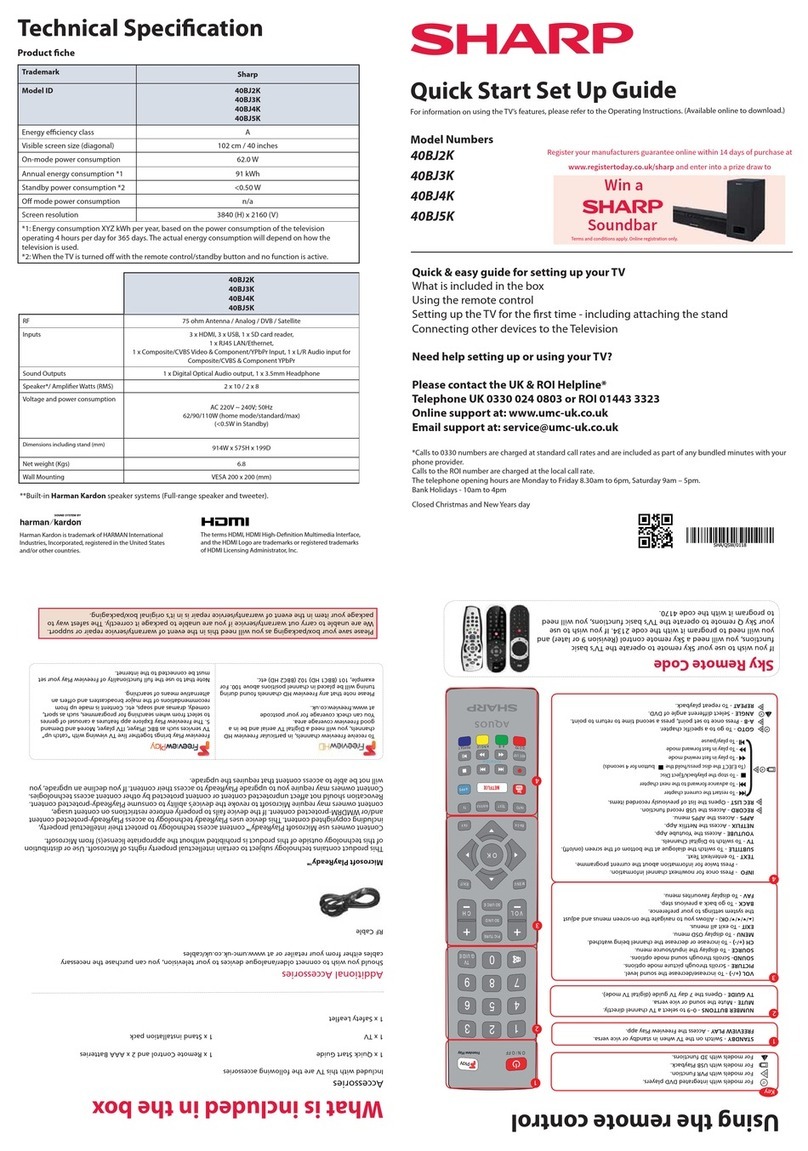

No. Adjusting point Adjusting procedure/conditions Waveform and others

Maximum

beam current

(check item)

1. Receive the Monoscope Pattern signal.

2. Set to the P-NORM mode.

3. Connect the DC ammeter between TP602 and

TP603.

»Ammeter’s full-scale : 3 mA range

»Ammeter’s positive (+) lead : TP603

»Ammeter’s negative (-) lead : TP602

4. Make sure the beam current is 1,100 ±100 µA.

Note:Before starting this adjustment, warm

up the unit for 30 minutes or longer at

a beam current of over 700 µA.

3

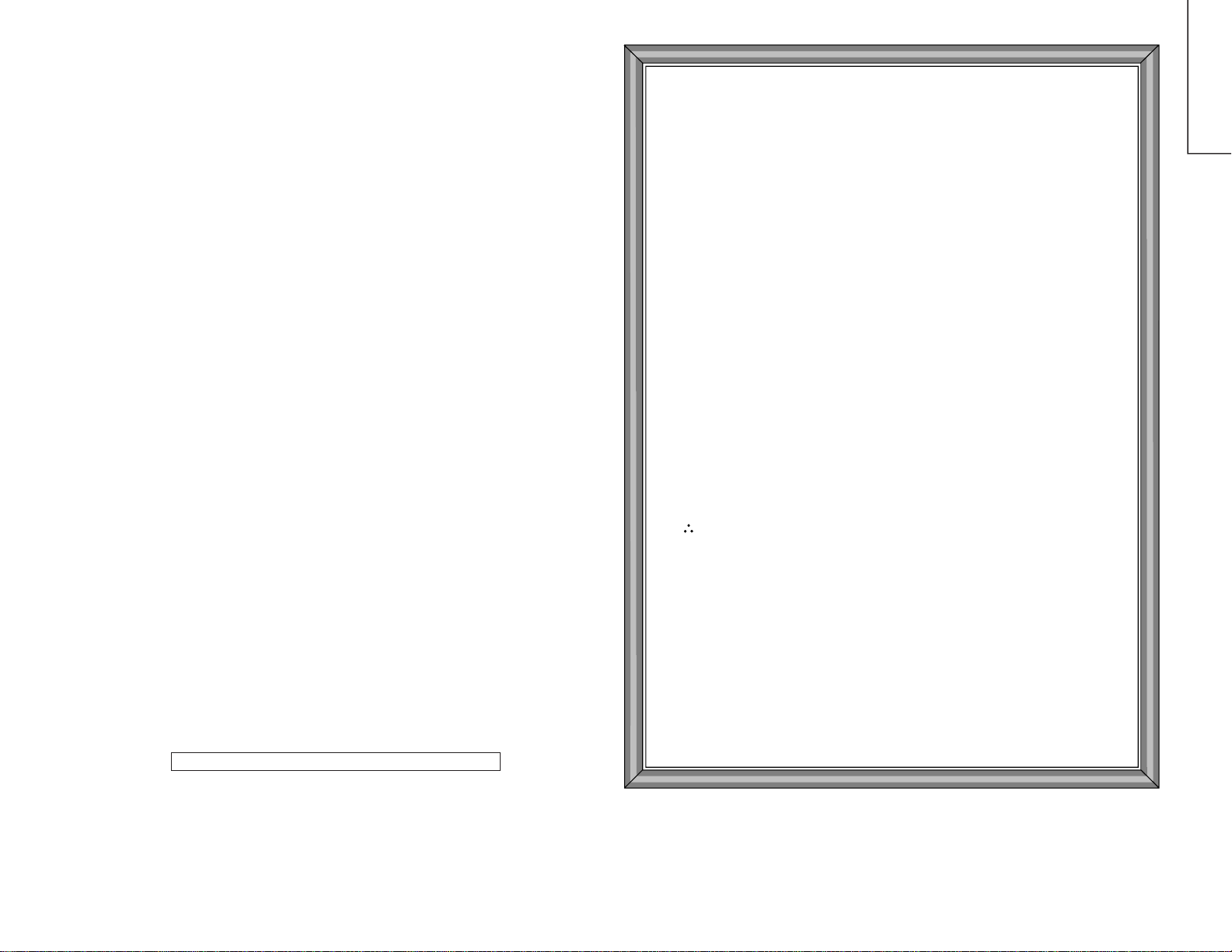

HORIZONTAL AND VERTICAL CIRCUIT ADJUSTMENT

No. Adjusting point Adjusting procedure/conditions Waveform and others

V-AMP 50

V-LINEARITY -

50 Hz

V-S CORREC-

TION - 50 Hz

V-SHIFT 50 (V-

CENTER)

H-SHIFT (50)

(H-CENTER)

1. Adjust the overscan to 9% typical.

1. Adjust to get the best linearity.

1. Adjust the proper condition.

1. Align the screen center with the CRT's geometri-

cal center (E-5).

1. Align the screen center with the CRT's geometri-

cal center (E-5).

Note: For the V-AMP 60, V-LINEARITY 60, V-S

CORRECTION 60, V-SHIFT 60 and H-

SHIFT 60 adjustments, their corrected

data are automatically entered when the

corresponding 50 Hz mode adjustments

are made.

1The selected channels in paren-

theses have the following signals.

(E-2): crosshatch pattern (50 Hz)

signal

(E-5): monoscopepattern (50 Hz)

signal

Focus adjust-

ment 1. Receive the Monoscope Pattern signal.

2. Set to the P-NORM mode.

3. Adjust the focus control so that the screen be in

best focusing.

2

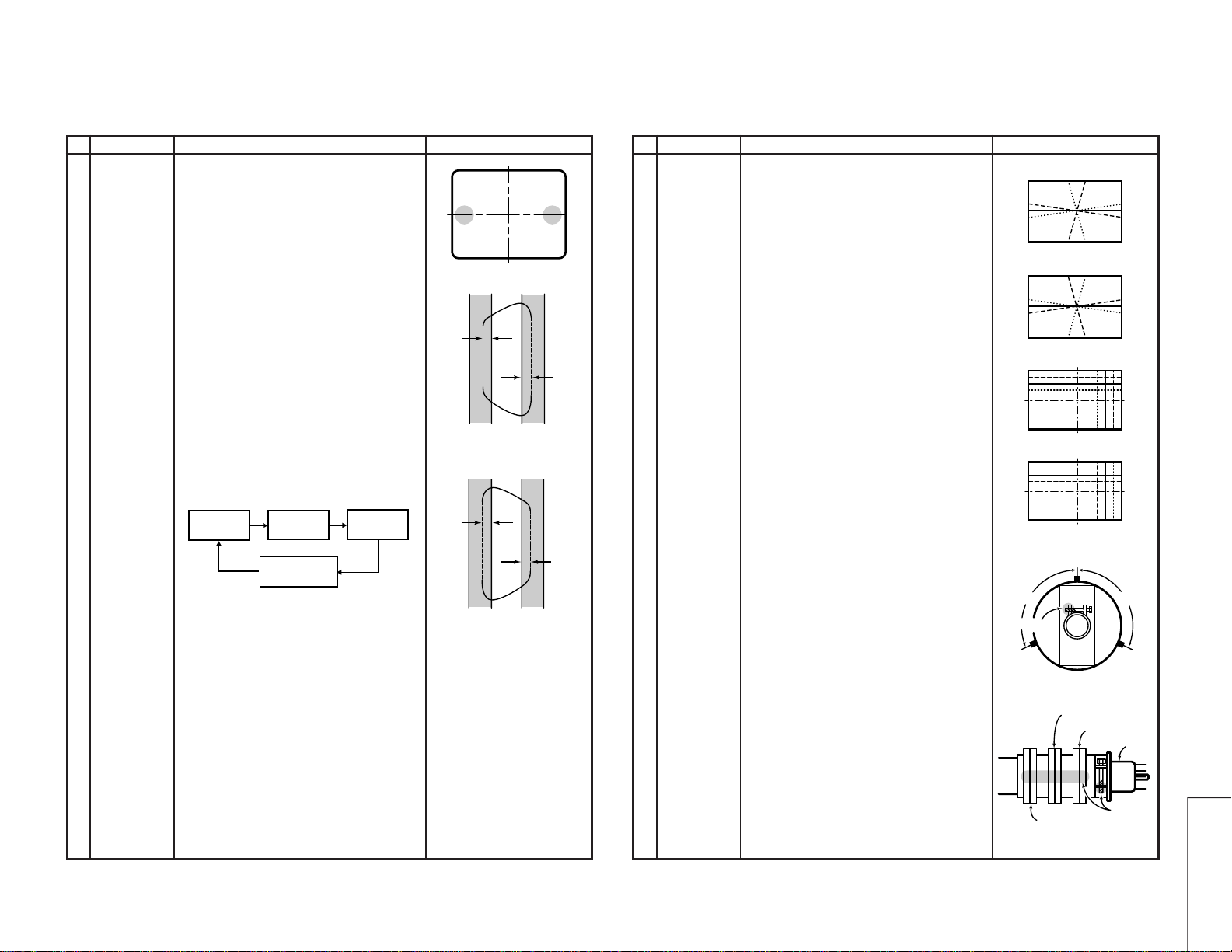

CRT CUT-OFF, SUB-CONTRAST, WHITE BALANCE AND SUB

BRIGHTNES ADJUSTMENT

No. Adjusting point Adjusting procedure/conditions Waveform and others

CRT cut-off

adjustment:

I2C bus control

adjustment

1. Receive the Monoscope Pattern signal.

2. Set to the P-NORM mode.

3. Turn on the service switch and select the "Cut-

off/background" mode.

4. Set the screen control to 0/10 position.

5. Pressthe “9” keyon the remote controllerto reach

the horizontal centering mode.

6. Turn the screen control clockwise until the hori-

zontal raster of the first glimmering colour be-

comes slightly visible.

7. Adjust the cut-off data of the other two colours

until the horizontal raster becomes whitish.

8. Turnoffthescreen control (counterclockwise) until

the horizontal raster disappears.

Note:Before starting this adjustment, warm

up the unit for 30 minutes or longer at

a beam current of over 700 µA.

9. Press the “9” key on the remote controller to call

the NORMAL mode.

1* First of all, make sure that the

R/G/B cut-off data are all initial

values.

Note:

R CUT OFF UP “1” KEY

DOWN “4” KEY

G CUT OFF UP “2” KEY

DOWN “5” KEY

B CUT OFF UP “3” KEY

DOWN “6” KEY

The data can be turned up and

down with the above keys.

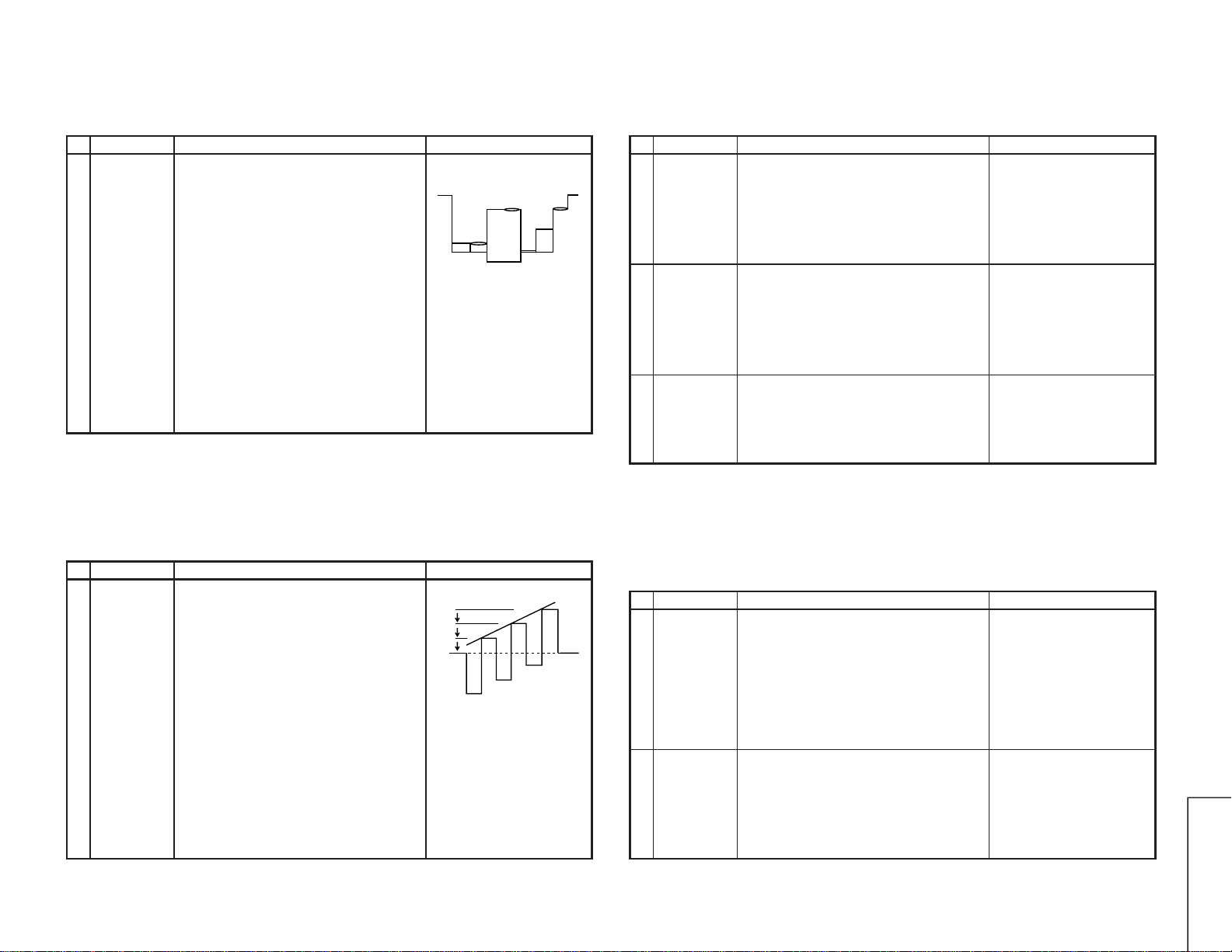

1. Receive the Monoscope Pattern signal.

2. Set to the P-NORM mode.

3. Connect the DC miliammeter between TP602 (-)

and TP603 (+).

» Full Scale: 3.0mA range

4. Make sure the beam current be 1,100µA.

5. Adjust the "G-DRIVE" and "B-DRIVE" data to have

a colour temperature of 12,300°K (white).

6. Adjust the contrast and brightness control to have

a beam current of 200µA.

Ifthecolour temperature is notat12,300°K, go back

to step1 above.

7. Receive the Crosshatch Pattern signal.

8. Adjust the "SUB BRI" bus data, so that the block

1st to 3rd inside the window area will

disappear.(black)

2Sub contrast,

white balance,

& sub bright-

ness Service

mode adjust-

ment:

I2C Bus Con-

trol Adjust-

ment

* 12,300°K X: 0.273

Y: 0.276

(with colour temperature meter

CA-100(MINOLTA).)

Note:

G-DRIVE UP “7” KEY

DOWN “-/--” KEY

B-DRIVE UP “8” KEY

DOWN “0” KEY

The data can be turned up and

down with the above keys.

1 2 3 4 5

Make sure all the 1st, 2nd

and3rd blackportions are at

the same black level.