4

32L-S500,32L-X2000

CL32S50,36L-X2000

PRECAUTIONS A PRENDRE LORS DE LA REPARATION

ËNe peut effectuer la réparation qu' un technicien spécialisé qui s'est parfaitement

accoutumé à toute vérification de sécurité et aux conseils suivants.

AVERTISSEMENT

1. N'entreprendre aucune modification de tout circuit.

C'est dangereux.

2. Débrancher le récepteur avant toute réparation.

3. Les déversoirs thermiques à semi-conducteurs

peuvent présenter un danger de choc électrique

lorsque le réceqteur est en marche.

4. Le châssis de ce récepteur possède deux systèmes

de masse qui sont séparées par du matériel

d'isolation. Le système de masse non-isolée (sous

tension) est pour le circuit du régulateur de tension

B+ et le circuit de sortie horizontale. Le système de

masse isolée est pour les tensions DC B+ basses et

lecircuitsecondaire du transformateur haute tension.

Pour éviter tout risque d'électrocution lors de

l'entretien de ce châssis, utiliser un transformateur

d'isolation entre le cordon de ligne et la prise de

courant.

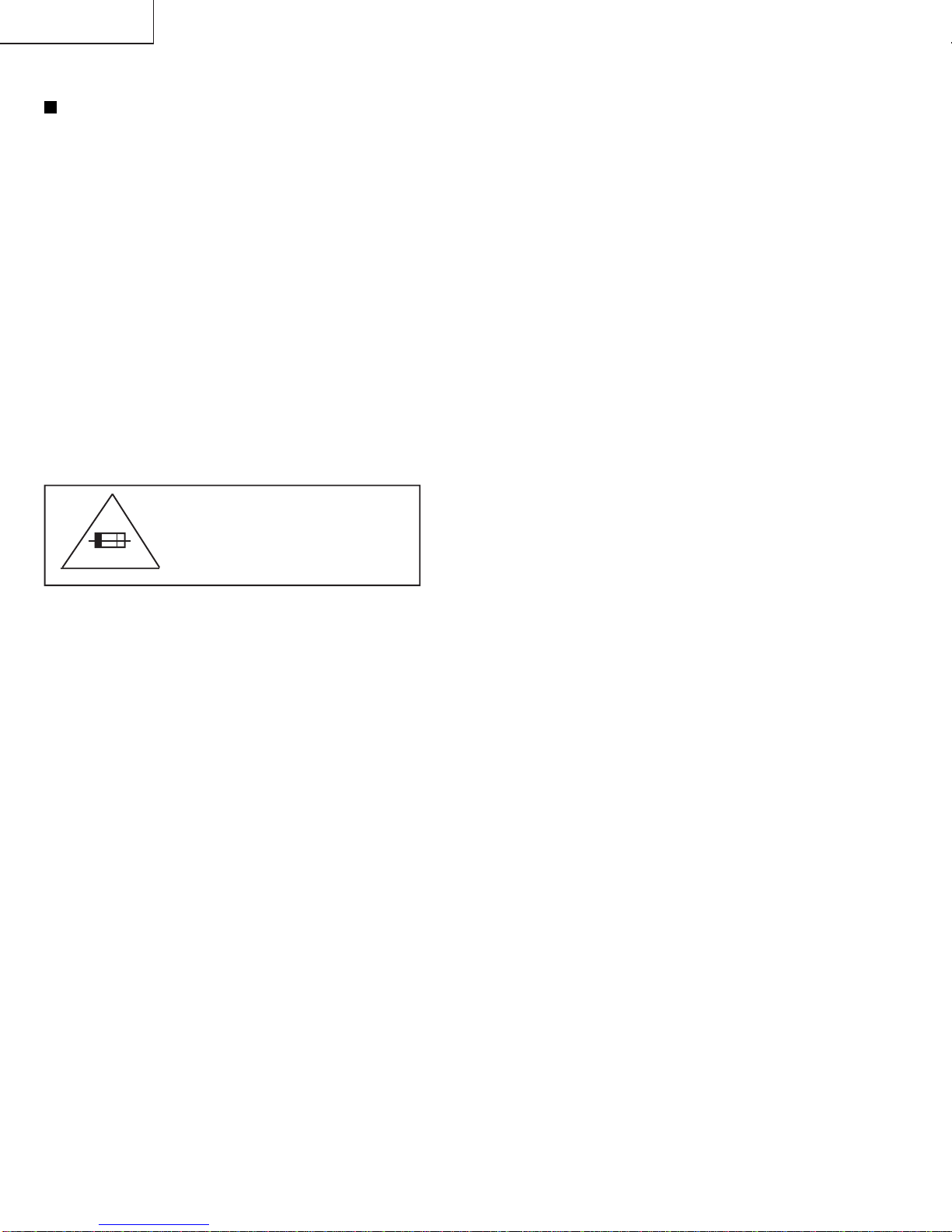

5A 125V

PRECAUTION: POUR LA

PROTECTION CONTINUE

CONTRE LES RISQUES

D'INCENDIE, REMPLACER LE

FUSIBLE PAR UN FUSIBLE DE

MEME TYPE 5A-125V.

REPARATION DU SYSTEMEA HAUTE TEN-

SION ET DU TUBE-IMAGE

Lors de la réparation de ce systéme,

supprimer la charge statique en branchant

une résistance de 10 kΩen série avec un fil

isolé (comme une sonde d'essai) entre la

mise à la terre du tube-image et le fil

d'anodel. (Le corden d'alimentation doit être

retiré de la prise murale.)

1. Le tube image dans ce récepteur emploie une

protection intégrée contre l'implosion.

2. Par mesure de sécurité, changer le tube-image pour

un tube du même numéro de type.

3. Ne pas lever le tube-image par son col.

4. Nemanipulerle tube-image qu'en porant des lunettes

incassables et qu'après avoir déchargé totalement

la haute tension.

LIMITES DES RADIATIONS X ET DE LA

HAUTE TENSION

1. Tout le personnel réparateur doit être instruit des

instructions et procédés relatifs aux radiations X.

Le tube-image, seule source de rayons X dons les

téleviseurs transistorisés, n'émet pourtant pas de

rayonsmesurables si lahautetension est maintenue

à un niveau préconisé dans la section "Vérification

de la haute tension".

C'estseulementquandlahautetensionestexcessive

que les rayons X peuvent entrer dans l'enveloppe du

tube-image y compris le conducteur de verre. Il est

important de maintenir la haute tension en-dessous

du niveau spécifié.

2. Il est essentiel que le réparateur ait sous la main un

voltmètreàhautetensionquidoitêtrepériodiquement

étalonné.

3. La haute tension doit toujours être maintenue à la

valeur de régime -et pas plus haute. L'opération à

des tensions plus élevées peut entraîner une panne

du tube-image ou du circuit à haute tension et, dans

certaines conditions, peut entraîner une radiation

dépassant les niveaux préscrits.

4. Quand le régulateur à haute tension fonctionne

correctement, il n'y a aucun problème de radiation

X. Chaque fois qu'un châssis couleurs est réparé, la

luminosité doit être examinée bout en contrôlant la

haute tension à l'aide d'un voltmètre pour s'assurer

que la haute tension ne dépasse pas la valeur

spécifiée et qu'elle soit correctement réglée.

5. Nepas utiliser untube-imageautreque celui spécifié

et ne pas effectuer de modifications déconseillées

du circuit à haute tension.

6. Lors de la recherche des pannes et des mesures

d'essai sur un récepteur qui présente une haute

tension excessive, éviter de s'approcher inutilement

du récepteur.

Ne pas faire fonctionner le récepteur plus longtemps

que nécessaire pour localiser la cause de la tension

excessive.