5

771M -

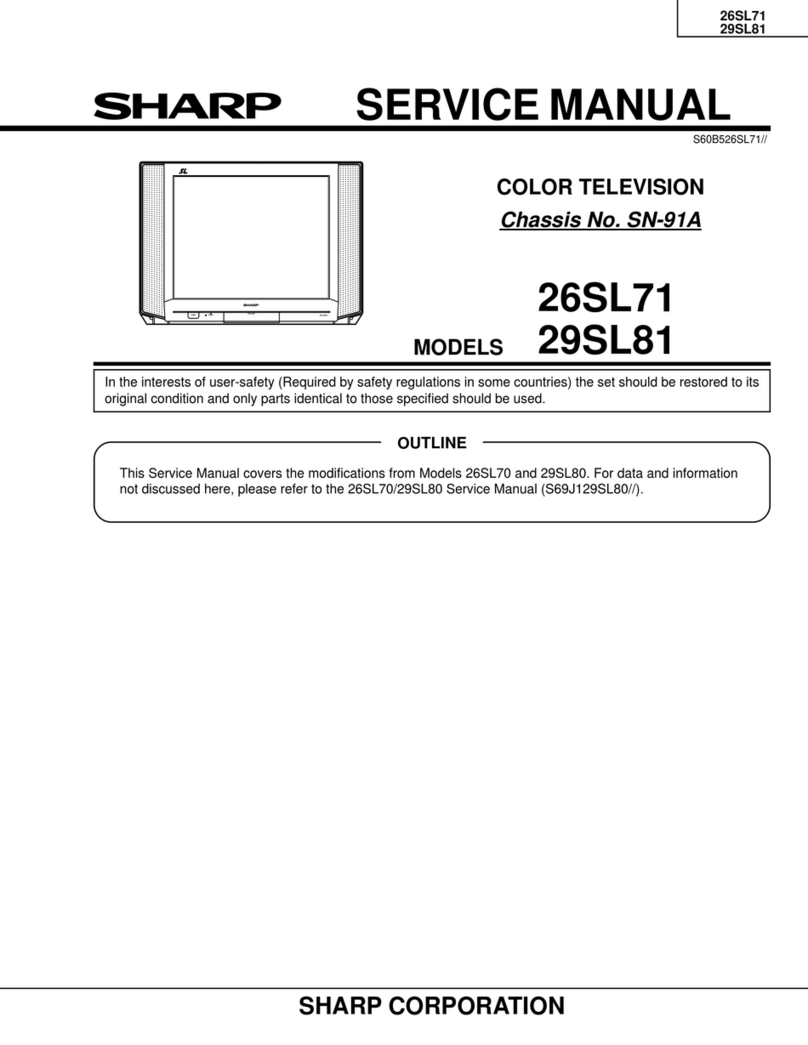

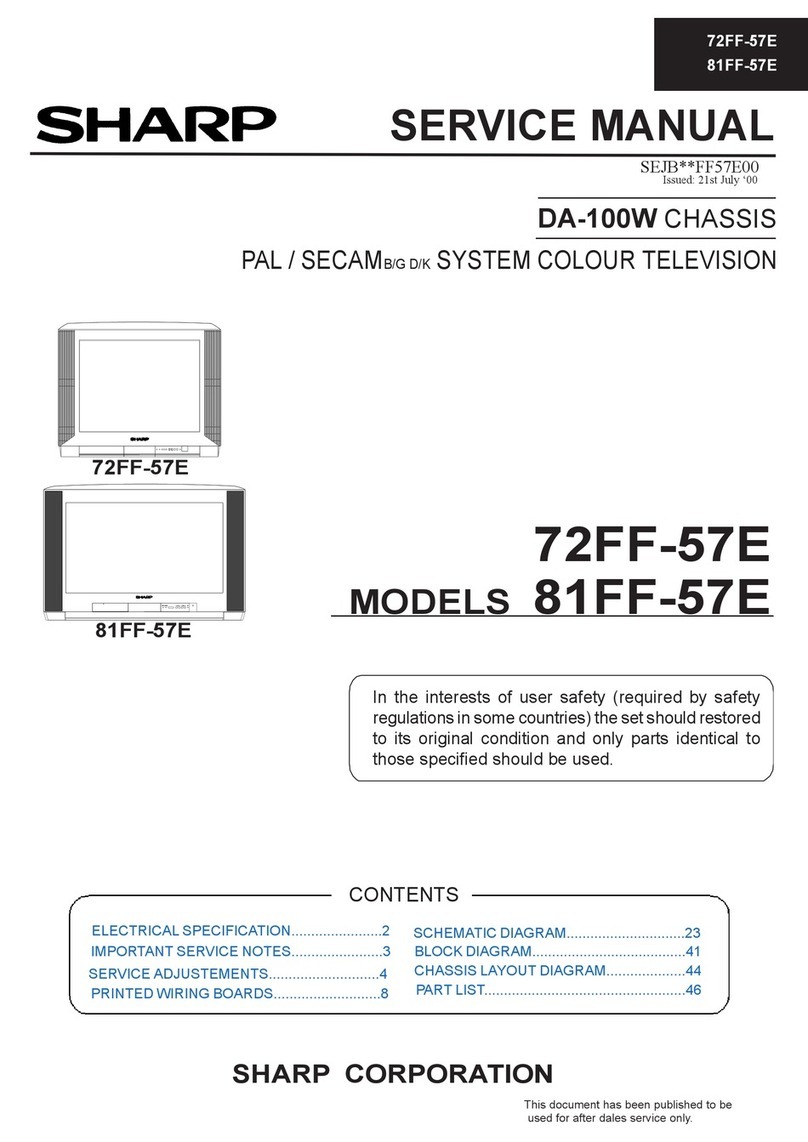

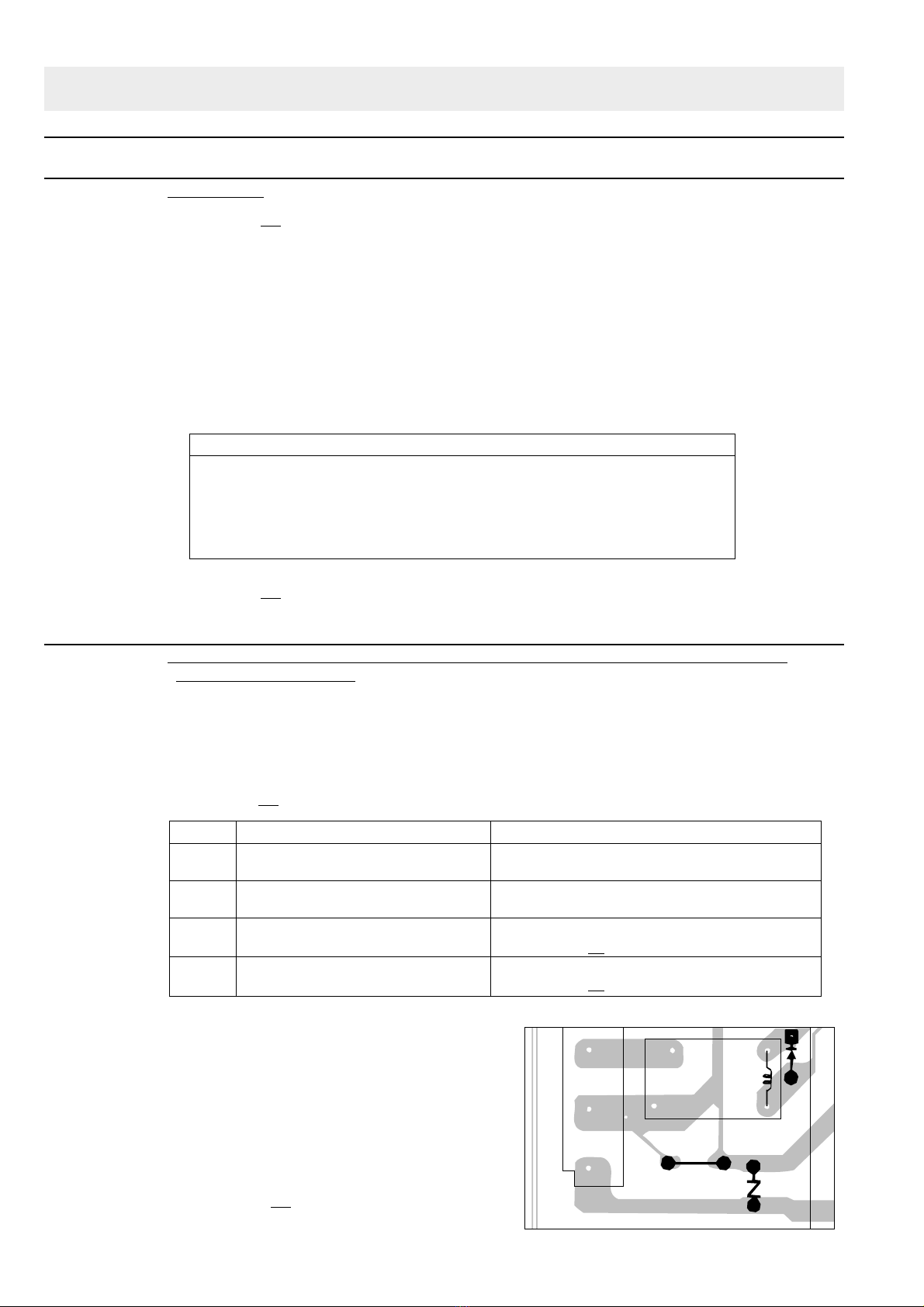

DOOR OPEN MECHANISM

DOOR LATCH HOOK

MONITOR SWITCH

MONITORED

LATCH SWITCH

STOP SWITCH

OPEN LEVER

LATCH

HEADS

Figure D-1. Door Open Mechanism

FIRE SENSING FEATURE

This model incorporates a sensing feature which will stop

the oven's operation if there is a fire in the oven cavity

during microwave cooking.

This accomplished by the LSI repeatedly measures the

voltageacrossthe temperature measurement circuit (ther-

mistor) during it's 32-seconds time base comparing the

obtained voltage measurements. If the most recent volt-

age measured is 300mV grater than the previous voltage

measured, the LSI judges it as a fire in the oven cavity and

switches off the relays to the high voltage transformer and

fan motor. The LSI also stops counting down. Please refer

to the following section for a more detailed description.

Operation

Please refer to the timing diagrams below.

1. Thethermistor operates within a32-seconds time base

and it is energized for three (3) seconds and off for 29

seconds. Two (2) seconds after the thermistor is

energized, the voltage across the temperature meas-

urement circuit is sampled by the LSI.

2. The above procedure is repeated. If the difference

between the first voltage measured (in step 1) and the

voltage measured when the procedure is repeated

(step 2) is greater than 300mV the LSI makes the

judgment that there is a fire in the oven cavity and will

switch off the relays to the high voltage transformer and

fan motor. The LSI also stops counting down.

CAUTION: BEFORE REPLACING A BLOWN FUSE

F8A TEST THE MONITORED LATCH

SWITCH, MONITOR SWITCH AND

MONITOR RESISTOR FOR PROPER

OPERATION.

When troubleshooting the microwave oven, it is helpful to

followtheSequenceofOperationinperformingthechecks.

Many of the possible causes of trouble will require that a

specific test be performed. These tests are given a proce-

dure letter which will be found in the “Test Procedure”

section.

TROUBLESHOOTING GUIDE

IMPORTANT: If the oven becomes inoperative because

of a blown fuse F8A in the primary latch

switch - monitor switch circuit, check the

primary latch switch, monitor switch and

monitor resistor before replacing the fuse

F8A.

3. Once the fire sensor feature has shut the unit down, the

programmed cooking cycle may be resumed by press-

ing the "START" pad or the unit may be reset by

pressing the "CLEAR" pad.

THERMISTOR

SENSING

VOLTAGE

ON

OFF

ON

OFF

0 29 64 (sec.)

3 sec.

Sensing the voltage across temperature mesure circuit.

OPEN JUDGE BY THERMISTOR

1. If the temperature of the thermistor does not rise to

more than 40˚C after 4 minutes and 15 seconds from

when the oven is started in convection, grill or dual

cooking (Microwave and Convection) mode, the oven

is turned off.

2. When the thermistor or the wire harness to the thermis-

tor is opened, the oven is turned off after 4 minutes and

15 seconds because this condition is same as above.

MONITORED

FUNCTION OF IMPORTANT COMPONENTS