Sharp 26SL71 User manual

Other Sharp TV manuals

Sharp

Sharp 21E-FG1S User manual

Sharp

Sharp Aquos LC-60LE830E User manual

Sharp

Sharp Aquos LC-40LE540E User manual

Sharp

Sharp 14LK22 User manual

Sharp

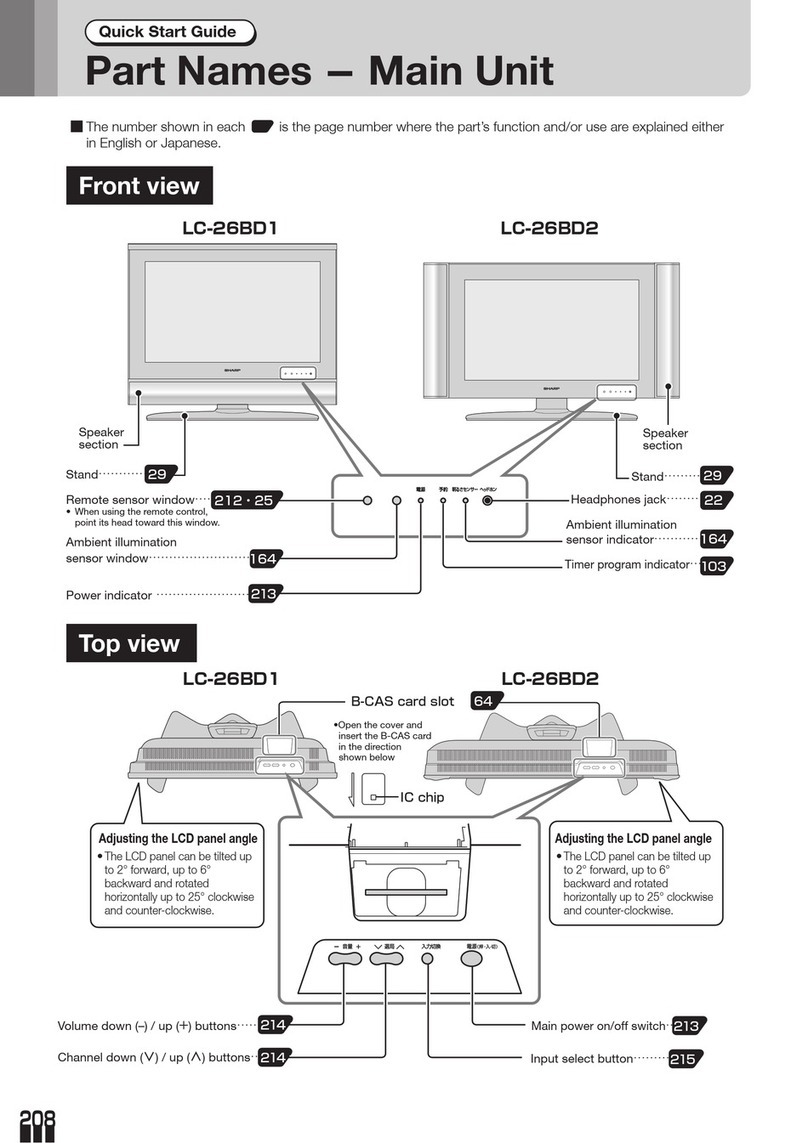

Sharp LC-26BD1 User manual

Sharp

Sharp 28JF-76E User manual

Sharp

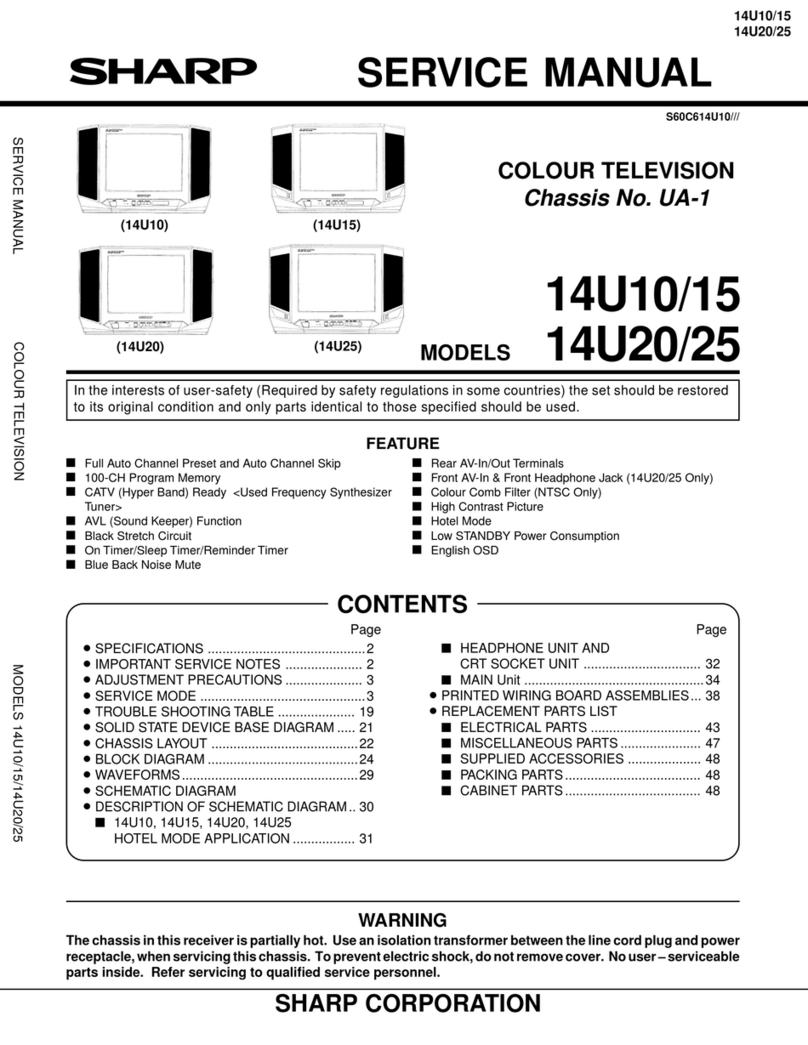

Sharp 14U10 User manual

Sharp

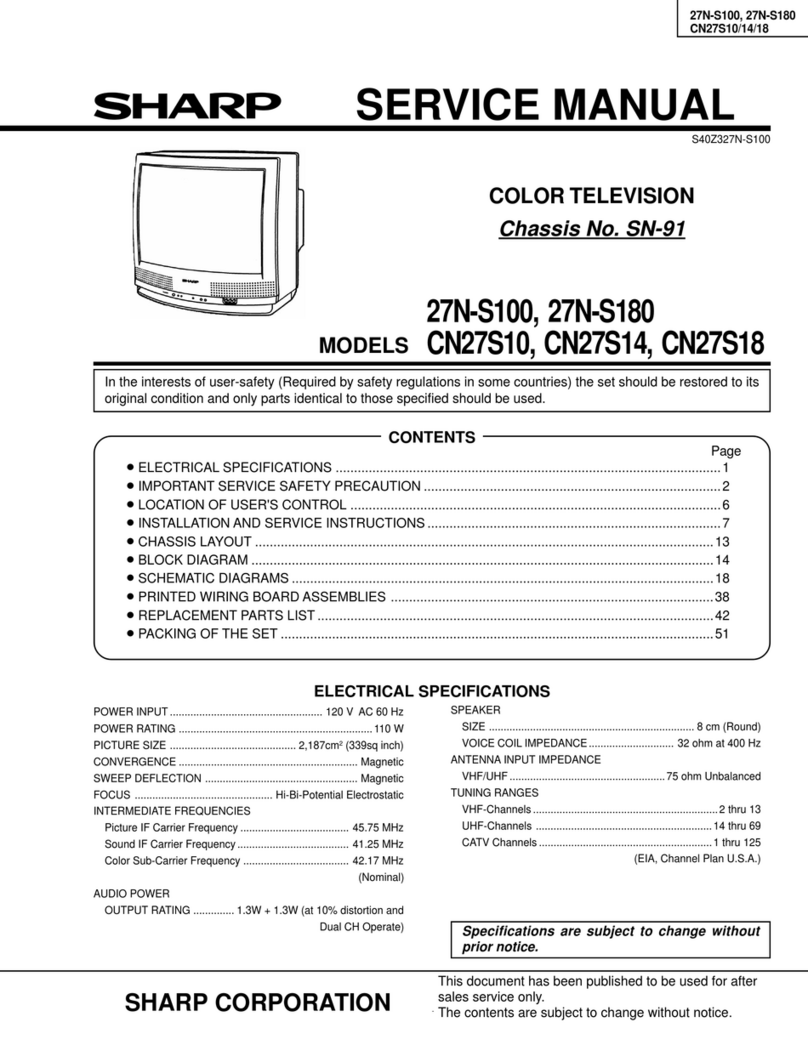

Sharp CN27S10 User manual

Sharp

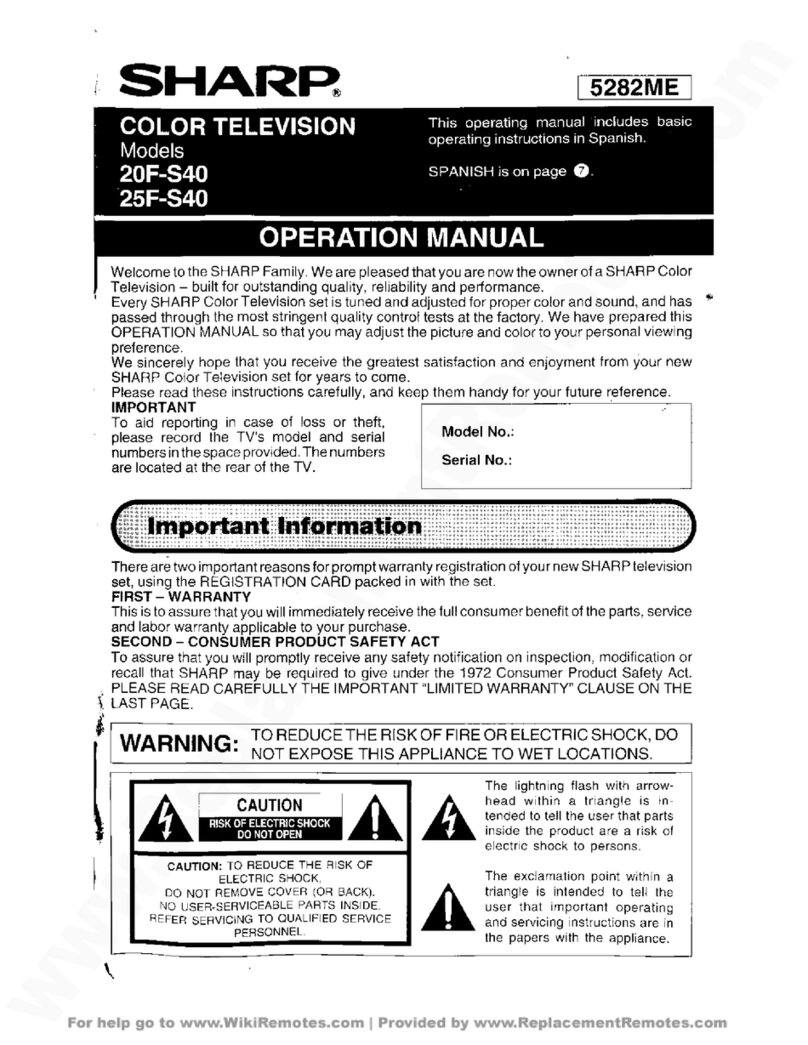

Sharp 20F-S40 User manual

Sharp

Sharp LC13-B2E User manual

Sharp

Sharp LC-40LE820E User manual

Sharp

Sharp 27F543 XFlat User manual

Sharp

Sharp 32N-S500 User manual

Sharp

Sharp 32C240 User manual

Sharp

Sharp LC-49UI8652E User manual

Sharp

Sharp 51AT15H Service manual

Sharp

Sharp LC-45GD6U - AQUOS - 45" LCD TV User manual

Sharp

Sharp 21H1-FRU User manual

Sharp

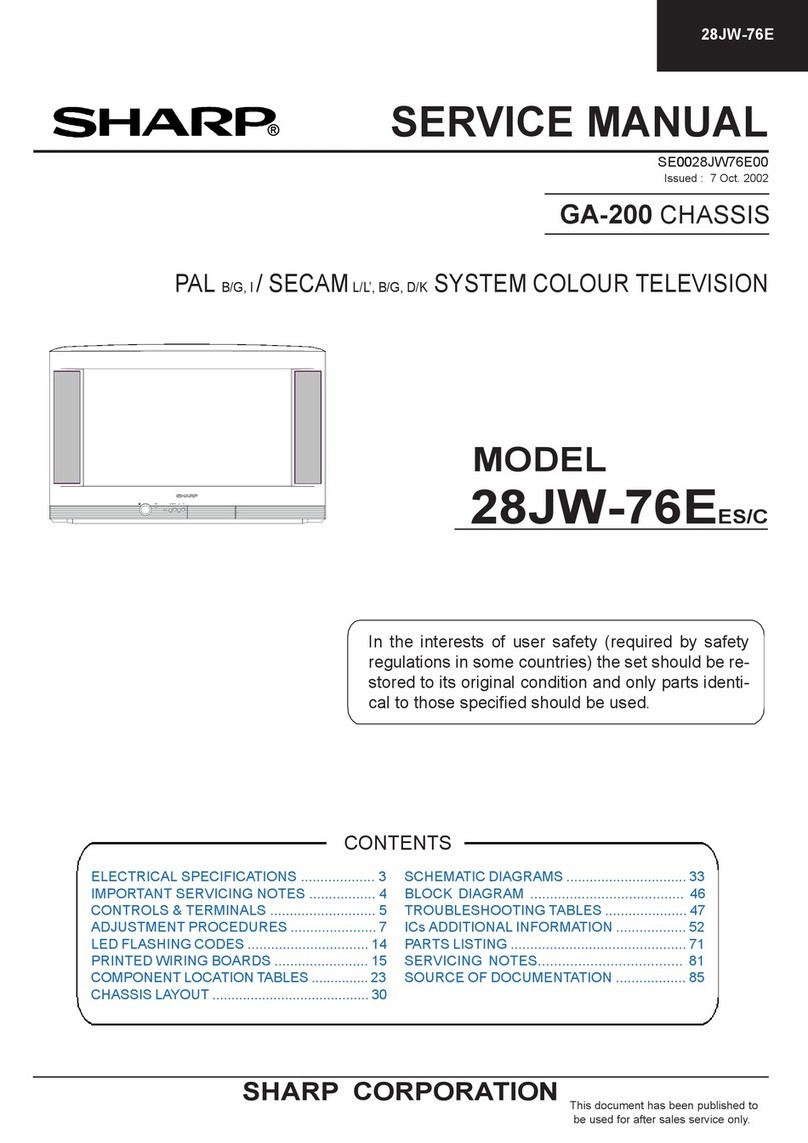

Sharp 28JW-76E User manual

Sharp

Sharp LC-32LB261U User manual