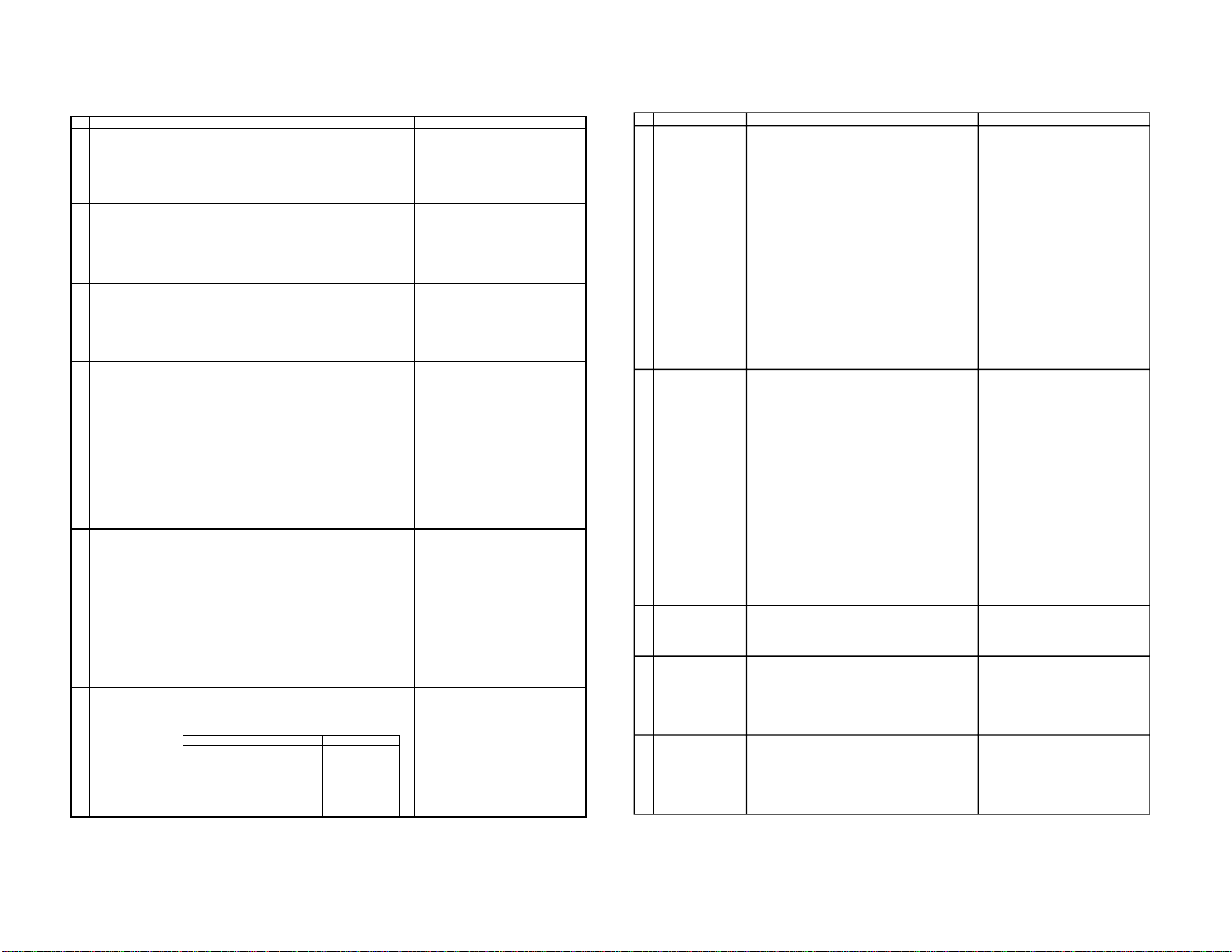

FUNCTION OPERATION CHECKING (1) (VIDEO & AUDIO)

NO

1

2

3

4

5

6

7

8

ADJUSTMENT POINT

CONTRAST

COLOUR

BRIGHTNESS

SHARPNESS

TINT

POWER SAVE

WHITE TEMP

NORMAL

ADJUSTMENT CONDITION / PROCEDURE

(1) Receive "Monoscope Pattern" signal.

(2) Press to Menu mode, then select Picture Mode and set

to select CONTRAST.

(3) Press Volume Up/Down key to check whether the

CONTRAST effect is OK or not.

(1) Receive "Colour Bar" signal.

(2) Press to Menu mode, then select Picture Mode and set

to select COLOUR.

(3) Press Volume Up/Down key to check whether the

COLOUR effect is OK or not.

(1) Receive "Monoscope Pattern" signal.

(2) Press to Menu mode, then select Picture Mode and set

to select BRIGHTNESS.

(3) Press Volume Up/Down key to check whether the

BRIGHTNESS effect is OK or not.

(1) Receive "Monoscope Pattern" signal.

(2) Press to Menu mode, then select Picture Mode and set

to select BRIGHTNESS.

(3) Press Volume Up/Down key to check whether the

BRIGHTNESS effect is OK or not.

(1) Receive "NTSC Colour Bar" signal thru AV in.

(2) Press to Menu mode, then select Picture Mode and set

to select TINT.

(3) Press Volume Up/Down key to check TINT, UP for

GREEN direction and DOWN for RED direction whether

is OK or not.

(1) Receive "Monoscope Pattern" signal.

(2) Set FEATURE to select SAVE.

(3) Press Volume Up/Down key to check the POWER SAVE

effect is OK or not. and whether LED(POWER SAVE)

light up or not.

(1) Receive "Monoscope Pattern" signal.

(2) Press to Menu mode, then select Picture Mode and set

to select WHITE TEMP.

(3) Press Volume Up/Down key to check WHITE TEMP

Option.

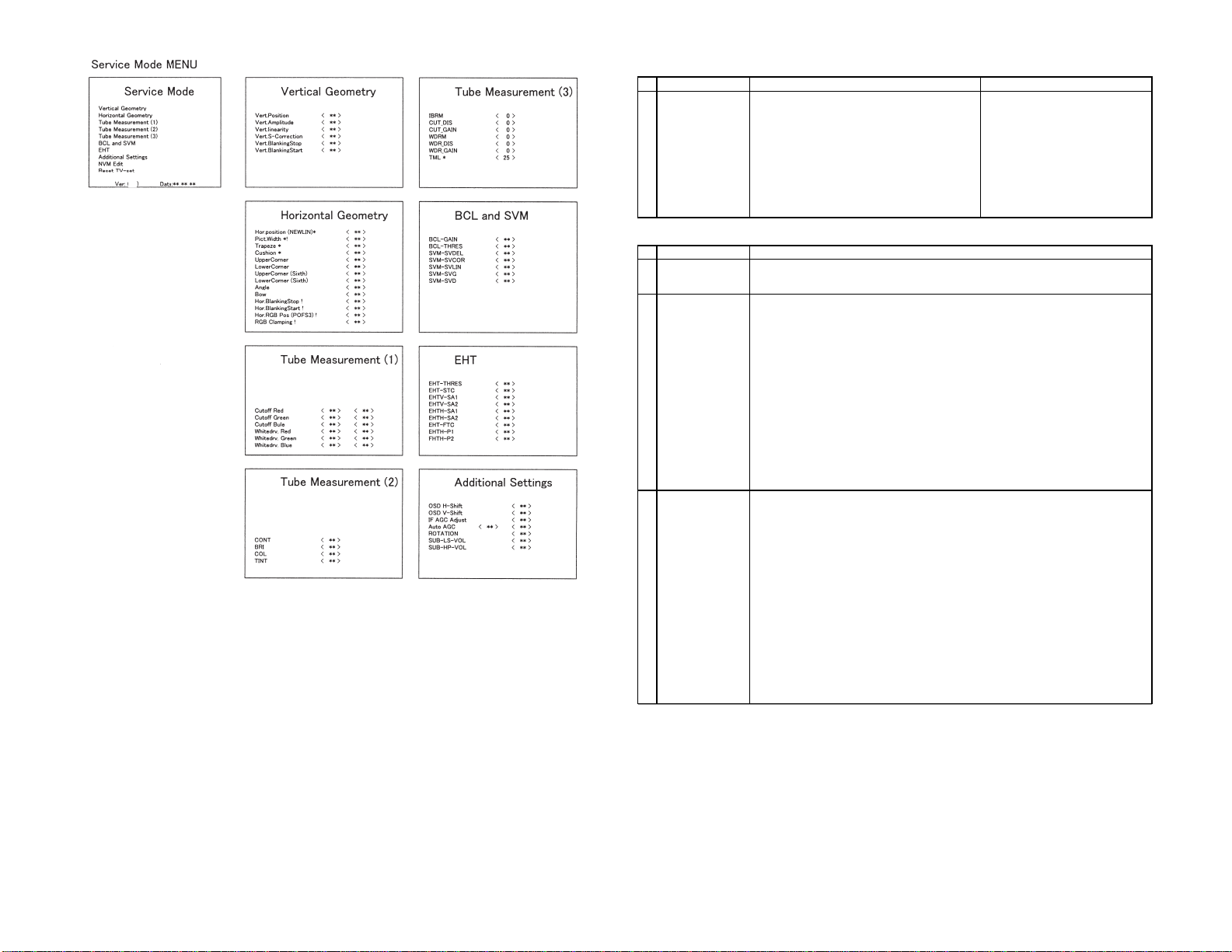

(1) Once in PICTURE Mode, and the NORMAL key is

pressed, all the settings will be present to normal setting.

(Normal setting value for every mode, refer on the

following figure).

WAVEFORM OR OTHERS

standerd movie music news

CONTRAST 50 60 45 45

COLOUR 0 0 5 5

BRIGHT 0 5 5 0

TINT 0 0 0 0

SHARPNESS 0 0 0 0

PICTURE NR LOW LOW LOW LOW

WHITE TEMP. 0 10 0 0

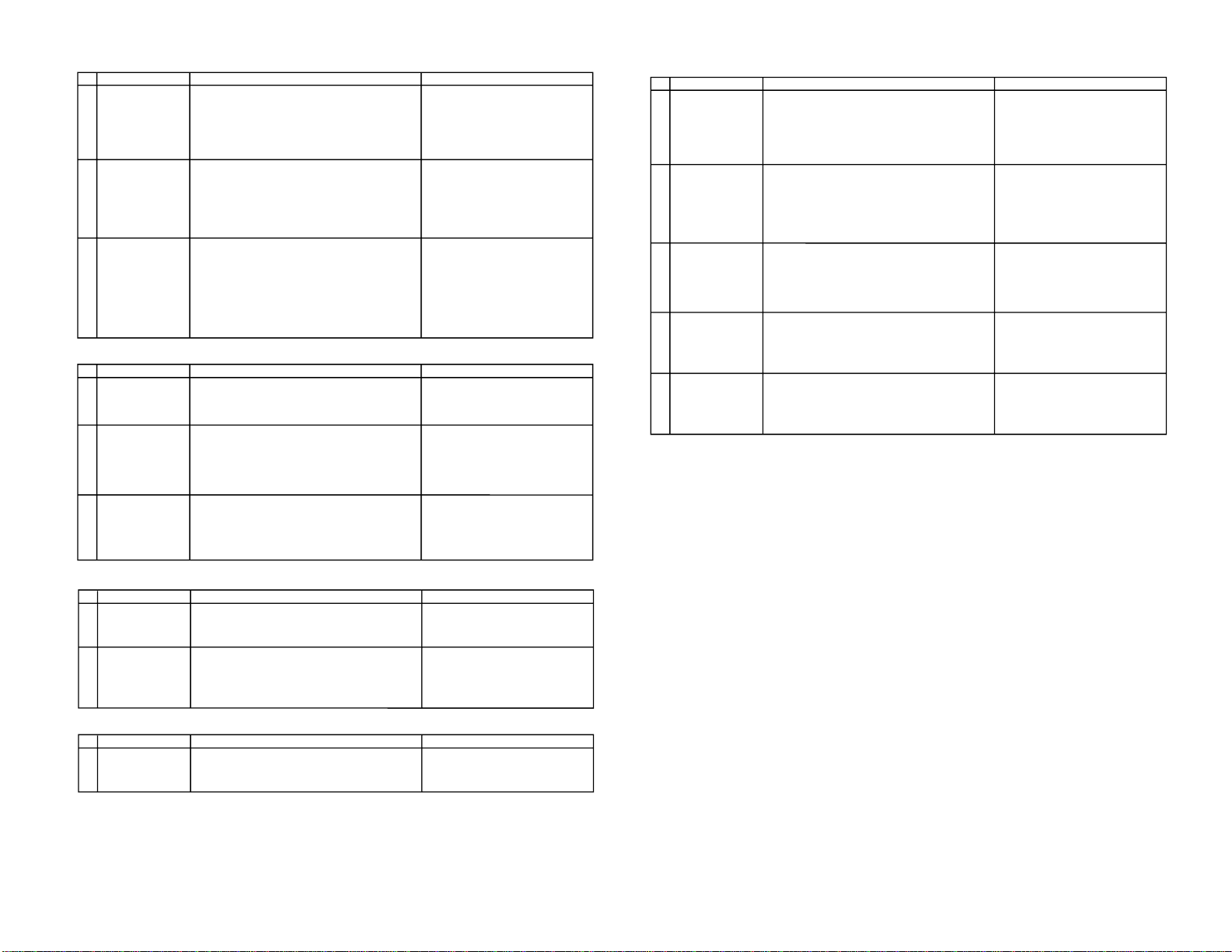

CHECKING FUNCTION OPERATION (2) (VIDEO & AUDIO) CONTINUED

NO

9

10

11

12

13

ADJUSTMENT POINT

COLOUR SYSTEM

SOUND SYSTEM

VOLUME

BALANCE

BASS

ADJUSTMENT CONDITION / PROCEDURE

(1) Receive the "PAL COLOUR BAR" signal, press the

COLOUR SYSTEM key to select modes except PAL,

check the COLOUR is not working properly.

Then, select the "PAL" mode. Check again its colour so

that it is working properly.

(2) Receive "SECAM COLOUR BAR" signal, press

COLOUR SYSTEM key to select modes except SECAM,

check the COLOUR is not working properly.

Then, select the "SECAM" mode. Check again its colour

so that it is working properly.

(3) Receive "NTSC 3.58 COLOUR BAR" signal, press

COLOUR SYSTEM key to select modes except NTSC

3.58, check the COLOUR is not working properly.

Then, select the "NTSC 3.58" mode. Check again its

colour so that it is working properly.

(4) Receive "NTSC 4.43 COLOUR BAR" signal thru AV,

press COLOUR SYSTEM key to select modes

except NTSC 4.43, check the COLOUR is not working

properly.

Then, select the "NTSC 4.43" mode. Check again its

colour so that it is working properly.

(1) Receive "PAL-D/K" signal, press the "SOUND SYSTEM"

to select B/G, I, M Check the sound output is not working

properly.

Select D/K and check the sound output to make sure it is

working properly.

(2) Receive "PAL-I" signal, press the "SOUND SYSTEM"

to select B/G, D/K, M Check the sound output is not

working properly.

Select I and check the sound output to make sure it is

working properly.

(3) Receive "PAL-B/G" signal, press the "SOUND SYSTEM"

to select I, D/K, M Check the sound output is not

working properly.

Select B/G and check the sound output to make sure it is

working properly.

(4) Receive "NTSC-M" signal, press the "SOUND SYSTEM"

to select I, D/K, B/G Check the sound output is not

working properly.

Select M and check the sound output to make sure it is

working properly.

(1) Receive "E-5ch Monoscope Pattern" signal.

(2) Press Volume Up/Down key to check whether the

VOLUME effect is OK or not.

(1) Receive "E-5ch Monoscope Pattern" signal.

(2) Press to Menu mode, then select Sound Mode and set

to select BALANCE.

(3) Press Volume Up/Down key to check whether the

Left-to-Right BALANCE effect is OK or not.

(1) Receive "E-5ch Monoscope Pattern" signal.

(2) Press to Menu mode, then select Sound Mode and set

to select BASS.

(3) Press Volume Up/Down key to check whether the

BASS effect is OK or not.

WAVEFORM OR OTHERS