Shaver HD-10 User manual

Hydraulic

Post Driver

Model HD-10 & HD-10-H

Shaver Manufacturing Company

103 South Washington Avenue, Graettinger, Iowa 51342

Phone: (712) 859-3293 — Fax: (712) 859-3294 — www.shavermfg.com

Safety

Operation

Maintenance

Repair

Troubleshooting

Parts

Operator’s Manual

Contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety Alert Symbols . . . . . . . . . . . . . . . . . . 3

Safety Icon Nomenclature . . . . . . . . . . . . . . 3

Safety Warnings . . . . . . . . . . . . . . . . . . . . . . . 4

General Safety . . . . . . . . . . . . . . . . . . . . . . . 4

Hazard Avoidance . . . . . . . . . . . . . . . . . . . . 4

Hydraulic Hoses . . . . . . . . . . . . . . . . . . . . . 5

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Product Information . . . . . . . . . . . . . . . . . . . 6

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . 6

Assembly Procedure . . . . . . . . . . . . . . . . . . . 7

Recommended Tools . . . . . . . . . . . . . . . . . . 7

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Main Carriage Channel . . . . . . . . . . . . . . . 9

Stabilizer Legs . . . . . . . . . . . . . . . . . . . . . 10

Base Plate . . . . . . . . . . . . . . . . . . . . . . . . 10

Hydraulic Valve . . . . . . . . . . . . . . . . . . . . 13

Safety Stop Adjustment . . . . . . . . . . . . . . 16

Rubber Debris Guard . . . . . . . . . . . . . . . 17

Safety Arm . . . . . . . . . . . . . . . . . . . . . . . . 18

Document Storage Tube . . . . . . . . . . . . . 21

Post Driver Operation . . . . . . . . . . . . . . . . . 21

Operational Safety Tips . . . . . . . . . . . . . . . 21

Operating Instructions . . . . . . . . . . . . . . . . 22

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . 22

Preparing to Drive a Post. . . . . . . . . . . . . 23

Driving a Post. . . . . . . . . . . . . . . . . . . . . . 24

Dismounting Post Driver . . . . . . . . . . . . . 27

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . 29

Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Service Procedures . . . . . . . . . . . . . . . . . . . 30

Three-Point Hitch/Post Driver Assembly . . 30

Main Carriage Channel Disassembly . . . . 31

Drive Cylinder Seal Replacement . . . . . . . 33

Main Carriage Channel Assembly. . . . . . . 35

Forward and Side Tilt Cylinder

Maintenance . . . . . . . . . . . . . . . . . . . . . . . 38

Cylinder Disassembly . . . . . . . . . . . . . . . 38

Cylinder Assembly. . . . . . . . . . . . . . . . . . 39

Three-Point Hitch/Post Driver Assembly . . 41

Service Parts . . . . . . . . . . . . . . . . . . . . . . . . 42

Driver Assembly. . . . . . . . . . . . . . . . . . . . . 42

Manual Base Plate Assembly . . . . . . . . . . 44

Hydraulic Base Plate Assembly . . . . . . . . 46

Three-Point Hitch Assembly . . . . . . . . . . . 48

Hydraulic Hoses . . . . . . . . . . . . . . . . . . . . 48

Safety Arm Assembly . . . . . . . . . . . . . . . . 48

Replacement Decals . . . . . . . . . . . . . . . . . 49

Document Tube . . . . . . . . . . . . . . . . . . . . . 49

Hydraulic Control Valves . . . . . . . . . . . . . . 50

Single Control Lever Valve. . . . . . . . . . . . 50

Triple Control Lever Valve . . . . . . . . . . . . 51

Drive Cylinder Assembly . . . . . . . . . . . . . . 52

Expanded View of Safety Lever

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Tilt Cylinder Assembly . . . . . . . . . . . . . . . . 53

Limited Warranty . . . . . . . . . . . . . . . . . . . . . 54

Warranty Card . . . . . . . . . . . . . . . . . . . . . . . 55

Safety

Most work related accidents are caused by

failure to observe basic safety rules or

precautions. An accident can often be

avoided by recognizing potentially hazardous

situations before an accident occurs. As you

assemble and operate the Shaver Post Driver,

you must be alert to potential hazards. You

should also have the necessary training, skills,

and tools to perform this assembly procedure.

Improper operation and maintenance of this

implement could result in a dangerous

situation that could cause injury or death.

Do not assemble, operate, or maintain

the Shaver Post Driver until you read and

understand the information contained in

this manual.

Safety precautions and warnings are

provided in this manual and on the

product. If these hazard warnings are

not heeded, bodily injury or death could

occur to you or to other persons.

2

Shaver Manufacturing Company cannot

anticipate every possible circumstance that

might involve a potential hazard. The

warnings in this supplement and on the

product are, therefore, not all-inclusive. If a

method of operation not specifically

recommended by Shaver Manufacturing

Company is used, you must satisfy yourself

that it is safe for you and for others. You

should also ensure that the implement will

not be damaged or be made unsafe by the

methods that you choose.

The information, specifications, and illustrations

in this supplement are based on the

information that was available at the time this

material was written and can change at any

time.

Safety Alert Symbols

TThheesafety alert symbol means

Attention! Become Alert! Your Safety

is Involved.

Hazards are identified by the “Safety Alert

Symbol” and are followed by the signal word

“WARNING”.

WARNING: Indicates a potentially hazardous

situation which, if not avoided, could result in

death or serious injury.

Potential damage situations are identified by the

signal words “IMPORTANT NOTICE”.

IMPORTANT NOTICE

Indicates that equipment or property damage

can result if instructions are not followed.

Safety Icon Nomenclature

Read the manual

Eye protection

Foot protection

Hand protection

Hearing protection

Inspect equipment

Two person operation

Warning decal alert

Bending hazard (hydraulic hose)

Crushing hazard

Crushing hazard (hand)

Do not weld

Electrocution hazard

Explosion hazard

High-pressure fluid hazard

Impact hazard (hydraulic hose)

Pressurized fluid

Projectile hazard (body)

Protective guards

Safety alert symbol

Slipping hazard

Tripping hazard

N

I

NG

AR

WARNING

3

44

Safety Warnings

General Safety

To avoid personal injury or death,

carefully read and understand all

instructions before attempting to

assemble and/or operate the Post

Driver. Do not operate or work on equipment

unless you read and understand the

instructions and warnings in this and all other

applicable manuals. Contact Shaver

Manufacturing Company. if any of the

instructions provided are unclear or not

understood. Proper care is your responsibility.

Always follow all State and Federal health and

safety laws and/or local regulations.

To help prevent personal

injury, protective

equipment must be worn

during Post Driver

assembly, operation, and

maintenance. Personal

protective equipment

should include, but not

be limited to, safety glasses, hearing

protection, protective gloves, and steel toe

footwear.

Personal injury can result

from slips or falls. DO

NOT leave tools or parts

laying around the work

area, and clean up all spilled fluids

immediately.

Hazard Avoidance

Inspect this equipment before each

use. Make sure all hardware is

tight. Always replace worn or

damaged parts before use.

To avoid personal injury or death,

do not operate the Post Driver by

yourself. Always have another

person to control the machine or

power source.

Make sure all decals are securely

attached to the Post Driver and are

legible at all times. Always read

and understand all decals before

working on or operating the Post Driver.

Make sure all lock-pins

and transport supports

are secured in place

before transporting or

storing the Post Driver..While transporting,

never ride on or permit others to ride on the

Post Driver..

Improper operating

procedures can create risk

for the operator and

bystanders. DO NOT use the

Post Driver before making sure no one will be

endangered.

To prevent personal

injury or death, be aware

of overhead electrical

lines when operating the

Post Driver. Electrocution can occur even

without direct contact with overhead power

lines. Proceed cautiously around electrical

lines and utility poles.

To prevent personal injury

or death, always check for

underground utilities,

such as electrical wires,

gas lines, and water pipes, before driving

posts. Contact local utility companies for

information on locating underground

utilities.

To avoid serious injury or

death, do not operate the

Post Driver on steep

slopes, as this can cause

a roll over.

To avoid personal injury,

always stand 45 degrees

to the right of the post

being driven while

operating the Post Driver.

N

I

NG

AR

WARNING

WARNING

WARNING

5

Potential pinch points.

Keep hands clear of Post

Driver while operating.

Never place hand(s) on

top of a post when inserting it into

the Post Driver. Always close the safety arm

before driving the post.

To avoid personal injury

do not attempt to clean,

adjust, or lubricate the

Post Driver while it is in

motion.

The rubber debris guard helps

shield the operator from flying

debris that may be generated

during post driving. To avoid

personal injury, make sure the rubber debris

guard is securely attached to the Post Driver

before driving posts.

To avoid personal injury or death,

do not modify the Post Driver by

welding, drilling, or grinding. Do

not expose to extreme heat, such

as from a torch.

The main carriage channel

assembly is tall and heavy. To

avoid tip over, resulting in serious

injury or death, leave the overhead

lifting device attached to the main carriage

channel while assembling components.

To avoid serious injury or death, the

safety arm must be installed after the

Post Driver has been mounted on a

machine, or the freestanding Post

Driver has been secured to prevent tipping.

Hydraulic Hoses

Avoid damaging hydraulic hoses.

Avoid sharp bends and kinks when

routing hydraulic hoses. Using a

bent or kinked hose will cause

severe back-pressure. Sharp bends and

kinks can internally damage the hose,

leading to premature hose failure, resulting

in personal injury.

Do not drop heavy objects on

hoses. A sharp impact may cause

internal damage to the hose.

Applying pressure to a damaged

hose may cause it to rupture, resulting in

personal injury.

Mismatched couplings

and hoses can cause the

coupling to violently

disconnect from the hose

when placed under pressure; separating

with sudden, extreme force which can result

in property damage, personal injury, or

death.

Replace a hose if any of the following

conditions are present:

- End fittings that are damaged or leaking

- Outer coverings that are chafed or cut

- Wire shields that are exposed

- Outer coverings that are ballooning

- Flexible part of the hoses that are kinked

- End fittings that are displaced

Pressure can be trapped

in a hydraulic system.

Trapped pressure can

cause sudden movement

of an attachment. Use caution when

disconnecting hydraulic lines or fittings.

High-pressure oil that is released can cause

a hose to move violently while spraying oil.

Escaping high-pressure fluid can

penetrate the skin, causing serious

injury. Relieve pressure before

unhooking hoses. Check/tighten

all connections before activating hydraulics.

Never use your hand to check for leaks.

WARNING

WARNING

WARNING

6

Introduction

The Shaver Manufacturing Company would

like to congratulate you on your purchase of

the Shaver Hydraulic Post Driver. You have

selected the best Post Driver in its class. The

clean design and uncomplicated working

principle have made Shaver the largest selling

Post Driver in the country.

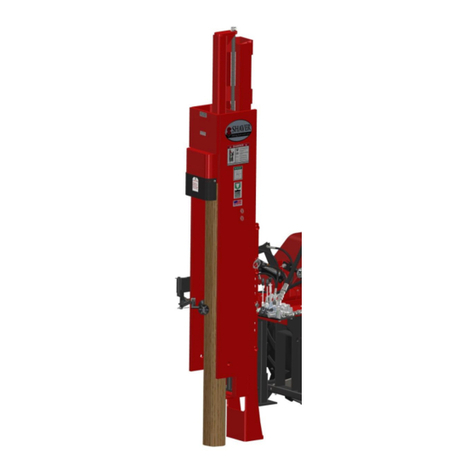

The Shaver HD-10 (manual tilt adjustment) and

HD-10-H (hydraulic tilt adjustment) Hydraulic

Post Driver is a durable piece of equipment

that, with regular maintenance, will provide

many years of service.

This manual provides information regarding

assembly, operation, and maintenance. It is

important to read and become familiar with

this manual before assembling or operating

the Shaver Hydraulic Post Driver.

NOTE: For other valuable information on farm

equipment operation and safety, refer to the

following resources.

•Farm Equipment Manufacturers

Association (FEMA)

http://www.farmequip.org/home

•National Ag Safety Database

http://www.cdc.gov/nasd/

Product Information

Record Shaver product information here. The

model number and serial number are found on

the metal tag attached to the drive ram.

Model Number

Serial Number

Date Purchased

Dealer Name

Specifications

HD-10 & HD-10-H Post Driver

Approximate Length 1100 in (254 cm) collapsed

148 in (376 cm) extended

Approximate Width 244 in (111.8 cm)

Approximate Depth 233 in (88.8 cm)

Shipping Weight 694 lbs (315 kg) manual base

714 lbs (324 kg) hydraulic base

Effective Weight of 725 lbs (329 kg)

Spring Powered

Driving Ram

Impact (at full stroke) 71,500 lbs (32,432 kg)

Main Carriage Channel

Tilt Front/Back 15°/15°

Tilt Side/Side 15°/15°

Guide Blocks 4 (2 per side)

Mounting Options Tractor (rear/front) and skid steer

Three-Point Hitch Category II and III

Hydraulic Requirements 12 GPM at 1500 PSI

(45 LPM at 10,342 kPa)

Post Size

Maximum Width 8.75 in (22.2 cm)

Maximum Length 10 ft (3.0 m)

1Driving ram and main carriage channel. Overall height will

vary, depending on mounting position and tractor.

2With stabilizer legs attached to three-point hitch weldment.

Assembly Procedure

Recommended Tools

The basic tools needed to assemble and

maintain the HD-10 and HD-10-H Post Driver

are shown below. Additional specialized tools

may be required.

HD-10 and HD-10-H Recommended Tools

No. Description Qty

T1 Mallet or Hammer 1

T2 Straight Edge 1

T3 1-1/8 Inch Combination Wrench 1

T4 1-1/16 Inch Combination Wrench 1

T5 15/16 Inch Combination Wrench 1

T6 3/4 Inch Combination Wrench 1

T7 11/16 Inch Combination Wrench 1

T8 5/8 Inch Combination Wrench 1

T9 9/16 Inch Combination Wrench 1

T10 1/2 Inch Combination Wrench 1

T11 7/16 Inch Combination Wrench 1

T12 Paste-Type Thread Sealant AR

T13 1-1/2 Inch Combination Wrench 1

T14 1/2 Inch Drive Impact Gun 1

T15 1-1/2 Inch Impact Socket 1

1-1/16 Inch Impact Socket 1

T16 3/8 and/or 1/2 Inch Drive Socket Set

(9/16, 5/8, 11/16, 3/4, 15/16, 1 Inch ) AR

T17 1/2 Inch Drive Ratchet 1

T18 3/8 Inch Drive Ratchet 1

HD-10 and HD-10-H Recommended Tools (continued)

No. Description Qty

T19 Heavy-Duty Retaining Strap 1

T20 Heavy-Duty Seal Picks 1AR

T21 9/16 Inch Deepwell Impact Socket 1

1/2 Inch Deepwell Impact Socket 1

T22 9/16 Inch Impact Socket 1

5/8 Inch Impact Socket 1

11/16 Inch Impact Socket 1

3/4 Inch Impact Socket 1

T23 Heavy-Duty Snap Ring Pliers 11

— Soft Brass or Wood Drift 1(not shown) 1

1Required for cylinder seal replacement.

AR - As Required

7

Unpacking

Due to the size and weight of the

Post Driver, two people are required

for the assembly procedures.

The Post Driver is shipped in several sections:

the driving ram assembly, base plate

assembly, short channel bracket, hose and

valve carton, safety arm carton, and on model

HD-10-H, the tilt cylinder carton.

Before starting the unpacking

procedure, make sure the

overhead lifting device or material

handling device (forklift) has

adequate lifting capacity. Follow all safety

recommendations when unpacking the Post

Driver. Some components are heavy and

can cause serious injury or death if not

adequately supported during removal and

assembly.

For ease of assembly, unload the Post Driver

components in the area where they will be

assembled. Choose a large, hard surface

area that can safely support the weight of the

assembled Post Driver and is accessible by

the machine it will be mounted on.

Assembly

NOTE: Refer to the Service Parts section of

this manual for a photo and description of all

the parts.

The HD-10 main carriage channel has

provisions for mounting the short carriage

channel bracket in three positions.

• Six middle bolt holes - three-point hitch

(most common position).

• Six upper bolt holes - tractor front mount.

• Six lower bolt holes - for driving

10 ft (3.0 m) tall posts only - three-point

hitch or front tractor mount.

The HD-10 and HD-10-H are shipped with the

carriage channel bolts installed in the middle

mounting position.

The Post Driver assembly procedure consists

of the following subsections:

1.Main Carriage Channel

2.Stabilizer Legs

3.Base Plate

4.Hydraulic Valve

5.Safety Stop Adjustment

6.Rubber Debris Guard

7.Safety Arm

8.Document Storage Tube

WARNING

WARNING

8

Main Carriage Channel

1.With road lock pin (B8) installed in lower

hole of drive ram (A1), use a suitable

overhead lifting device to raise (stand up)

main carriage channel (B1).

(A1) Drive Ram. (B1) Main Carriage Channel.

(B8) Road Lock Pin.

The main carriage channel

assembly is tall and heavy. To

avoid tip over, resulting in serious

injury or death, leave the overhead

lifting device attached to the main carriage

channel while assembling components.

2.Install appropriate short channel bracket

(D1, D2) using bolts (D3) and lock washers

(D4) (6 each). Tighten completely.

NOTE: Hydraulic short channel bracket (D2)

shown. Manual short channel bracket (D1)

installation is the same.

(D1) Manual Short Channel Bracket (not shown).

(D2) Hydraulic Short Channel Bracket (shown).

(D3) Bolt. (D4) Lock Washer.

3.Remove road lock pin (B8) from lower hole

in drive ram (A1). Use spring tension to

help raise main carriage channel (B1) and

insert road lock pin (B8) in upper hole (tool

storage position) in drive ram (A1). Install

Lynch pin (B9), not shown, to secure road

lock pin.

(A1) Drive Ram. (B1) Main Carriage Channel.

(B8) Road Lock Pin.

WARNING

9

Stabilizer Legs

1.Place three-point hitch weldment (K1)

upside down on the floor. Install stabilizer

leg brackets (K2), with stabilizer legs (K7)

installed, over the cross tube, as shown.

Tighten two leg bracket bolts (K3) to secure

the brackets to the cross tube.

(K1) Three-Point Hitch Weldment. (K2) Leg Bracket.

(K3) Leg Bracket Bolt. (K7) Stabilizer Leg.

2.Set stabilizer leg (K7) height at 8” (20.3 cm)

measured from three-point hitch weldment

(K1) cross tube to the stabilizer leg base

plate, as shown. Tighten the stabilizer leg

lock bolts.

(K1) Three-Point Hitch Weldment. (K2) Leg Bracket.

(K7) Stabilizer Leg.

NOTE: If a different set of holes was used to

mount channel bracket (D1 or D2), the height

of the legs will need to be adjusted

accordingly.

3.Turn over three-point hitch weldment (K1)

and set it on stabilizer leg (K7) base plates,

as shown.

(K1) Three-Point Hitch Weldment. (K7) Stabilizer Legs.

Base Plate

NOTE: Hydraulic base plate (F2) installation is

shown. Installation of manual base plate (E2)

is similar.

IMPORTANT NOTICE

Hydraulic system fittings that require a thread

sealant must be installed with a paste-type

sealer only. Do not use a tape-type sealer, such

as Teflon Tape, as this can contaminate the

system and voids the valve warranty.

1.Remove the carriage bolts, washers, and

nuts from hydraulic base plate (F2). Save

the hardware for reuse.

10

2.Install hydraulic base plate (F2) on three-

point hitch weldment (K1), as shown.

Install carriage bolts, washers,

lockwashers, and nuts removed in Step 1.

Center the base plate on the three-point

hitch and tighten the hardware securely.

(F2) Hydraulic Base Plate. (K1) Three-Point Hitch

Weldment.

3.Locate tilt cylinders (F3, F4). Install four

hose assemblies (H5) using paste-type

thread sealant (T12) on the fittings. Tighten

the hose fittings securely.

(F3) Forward Tilt Hydraulic Cylinder. (F4) Side Tilt

Hydraulic Cylinder. (H5) Hydraulic Cylinder Hose

Assembly.

4.Install hydraulic cylinders (F3, F4) on

hydraulic base plate (F2), along with safety

lever (F9, F10), as shown. Secure with

Lynch pins (included).

NOTE: Side tilt cylinder (F4) is secured with

cylinder mounting pins (F7, F8). Forward tilt

cylinder (F3) and safety lever (F9, F10) are

secured with cylinder mounting pin (F7) and

channel mounting pin (D6).

(D6) Channel Mounting Pin. (F2) Hydraulic Base Plate.

(F3) Forward Tilt Hydraulic Cylinder. (F4) Side Tilt

Hydraulic Cylinder. (F7) Long Cylinder Mounting Pin.

(F8) Short Cylinder Mounting Pin. (F9, F10) Safety Lever.

11

The main carriage channel

assembly is tall and heavy. To

avoid tip over, resulting in serious

injury or death, leave the overhead

lifting device attached to the main carriage

channel while assembling components.

5.Install the hydraulic base plate on the short

channel bracket.

a. Get assistance to position hydraulic

base plate (F2) in front of hydraulic

short channel bracket (D2).

b. Manually extend forward tilt cylinder

and install upper channel mounting pin

(D6) through short channel bracket

(D2) and safety lever (F9). Make sure

safety lever link (F9) is installed on

upper channel mounting pin (D6), as

shown. Secure with Lynch pins

(included).

c. Start lower channel mounting pin (D6)

in lower short channel bracket, as

shown.

(D2) Short Channel Bracket. (D6) Short Channel Bracket

Mounting Pin. (F2) Hydraulic Base Plate. (F9) Safety

Lever Link.

d. Use a suitable floor jack to support the

three-point hitch weldment.

e. Loosen stabilizer leg lock bolts (K8),

and adjust floor jack up or down to

align base plate pivot pin hole with

short channel (D2) lower mounting

hole.

f. Install lower channel mounting pin (D6)

and secure with Lynch pins. Tighten

the two stabilizer leg lock bolts and

remove the floor jack.

(D2) Hydraulic Short Channel Bracket.

(K8) Stabilizer Leg Lock Bolts.

WARNING

12

NOTE: If using manual base plate (E2)

assembly, adjust forward tilt crank (E11) and

side tilt crank (E3) to align channel mounting

pin holes. Install lower channel mounting pin

(D6) first and then upper channel mounting

pin. Secure pins with Lynch pins (included).

(D6) Channel Mounting Pin. (E2) Manual Base Plate.

(E3) Side Tilt Crank. (E11) Forward Tilt Crank.

Hydraulic Valve

The customer must supply suitable hydraulic

quick disconnect fittings for connecting

pressure supply hose (G17) and return hose

(G20) to the tractor or power supply hydraulic

system.

IMPORTANT NOTICE

Hydraulic system fittings that require a thread

sealant must be installed with a paste-type

sealer only. Do not use a tape-type sealer, such

as Teflon Tape, as this can contaminate the

system and voids the valve warranty.

1. Assemble the hydraulic control valve.

Single lever control valve (G1) for manual

base plate or triple lever control valve (H1)

for hydraulic base plate.

a. Remove the plugs from the hydraulic

control valve. Apply paste-type thread

sealant (T12) to pipe threads and

install hydraulic fittings (G16, G18,

G19, G21), and on triple lever control

valve, four tilt cylinder hose fittings

(H3). Refer to photographs for correct

placement and orientation.

(G1) Manual Tilt Base Control Valve.

(H1) Hydraulic Tilt Base Control Valve.

(G16) Swivel Fitting:

3/4” O-Ring Male to 1” Female NPT.

(G19) 90° Swivel Fitting:

1-1/16” O-Ring Male to 1/2” Female.

(G21) 90° Swivel Fitting:

3/4” Male to 1” NPT Female with

Adapter Fitting:

1-1/16” O-Ring Male to 3/4” NPT Female.

(H3) 90° O-Ring Swivel Fitting (with restrictor):

7/8” Male to 1/4” Female.

13

b. Assemble control valve linkage. Install

lever(s) (G5), control valve safety lever

(G7), return spring (G10), and lever

linkage (G11, G12, G23), as shown.

Secure with cotter pins (G13). Refer to

photographs for correct placement and

orientation.

(G1) Manual Tilt Base Control Valve.

(H1) Hydraulic Tilt Base Control Valve.

(G5) Control Valve Lever(s). (G7) Control Valve Safety

Lever. (G10) Safety Lever Return Spring. (G11) Clevis

Pin. (G12) U-Link. (G13) Cotter Pin(s). (G23) Flat Link.

(H1) Hydraulic Valve Control Lever Linkage.

(G5) Control Valve Lever(s). (G10) Safety Lever Return

Spring. (G11) Clevis Pin. (G12) U-Link.

(G13) Cotter Pin(s). (G23) Flat Link.

2. Install the hydraulic valve on short channel

bracket (D1, D2) using three 5/16-18 x 3”

valve mounting bolts (G2), washers (G3),

and nuts (G4). Do not over-tighten the

hardware, which can warp valve body.

NOTE: Single lever hydraulic valve shown.

Installation of three lever hydraulic valve is the

same.

(D1) Hydraulic Short Channel Bracket. (D2) Manual

Short Channel Bracket, shown. (G2) Bolt. (G3) Washer.

(G4) Nut.

IMPORTANT NOTICE

The hydraulic valve and cylinder(s) can be

damaged by contamination (dirt and debris)

from the oil in the tractor or power source.

Ensure the oil is clean and properly filtered

before connecting the Post Driver to a hydraulic

power source. Failure to follow oil cleanliness

standards voids the Shaver Post Driver

warranty.

14

3. Attach the hydraulic hoses.

(G15) Valve to Drive Ram Hose. (G17) Pressure Supply

Hose. (G20) Return Hose.

a. Apply paste-type thread sealant (T12)

to hose fitting threads and install hose

(1” I.D. x 35”) (G15) between hydraulic

control valve (G1 or H1) and drive

cylinder assembly (C1). Tighten the

hose fittings securely.

(C1) Drive Cylinder Assembly. (G1) Control Valve

(Single Lever), not shown. (G15) Valve to Drive Ram

Hose. (H1) Control Valve (triple lever).

b. Connect threaded fitting on pressure

hose (1/2” x 120”) (G17) to control

valve (G1 or H1) swivel fitting.

c. Connect threaded fitting on return hose

(1” x 120”) (G20) to control valve

(G1 or H1) swivel fitting.

(G1) Single Lever Control Valve, not shown.

(G17) Pressure Hose. (G20) Return Hose.

(H1) Triple Lever Control Valve.

NOTE: The hydraulic control valve for manual

base plate (E2) has a single control lever.

Installation of supply, return, and drive ram

hoses are the same.

15

IMPORTANT NOTICE

If the tilt cylinder hoses are attached differently

than shown, the control of the drive ram will not

be as described in this manual.

d. Hydraulic base plate only. Attach

forward tilt cylinder hoses (H5) between

forward tilt cylinder (F3) and triple lever

control valve (H1), as shown.

(F3) Forward Tilt Cylinder. (H1) Triple Lever Control

Valve. (H5) Tilt Cylinder Hoses.

e. Hydraulic base plate only. Attach side

tilt cylinder hoses (H5) between side tilt

cylinder (F4) and triple lever control

valve (H1), as shown.

(F4) Side Tilt Cylinder. (H1) Triple Lever Control Valve.

(H5) Tilt Cylinder Hose.

Safety Stop Adjustment

To avoid serious injury, inspect the

control valve safety stop before

using the Post Driver the first time

and/or before each daily use.

Adjust the safety stop as needed, per the

following procedure. Make sure all control

valve hardware is tight. Always replace worn

or damaged parts before use.

The control valve safety stop prevents

unintentional activation of the Post Driver

control valve and must be functional at all

times.

If the Post Driver is operational, make sure the

machine/power source is OFF, parking brake

is set, road lock pin is installed, and all

hydraulic pressure is released (zero pressure).

1. Attempt to push main hydraulic control

valve lever (G5) forward (away from

operator) without squeezing (pulling) yellow

tipped control valve safety lever (G7).

(G5) Main Hydraulic Control Valve Lever. (G7) Control

Valve Safety Lever.

2. If main hydraulic control valve lever (G5)

CAN move forward more than 1/4”, the

safety stop must be adjusted.

WARNING

16

17

3. To adjust the safety stop, do the following:

a. Squeeze the control valve lever and the

control valve safety lever together to

expose the safety lever stop setscrew.

b. Insert a 1/8” Allen wrench and adjust

the setscrew outward

(counterclockwise) slightly. Remove

the Allen wrench and repeat Step 1.

Adjust the Safety Stop Setscrew.

c. If necessary, repeat Step 3a and

Step 3b until the setscrew prevents

more than 1/4” of forward movement of

the control valve lever.

NOTE: Do not “over adjust” the setscrew.

Make sure the setscrew easily falls into place

behind the lip on the control valve when it is

released quickly (1/8” gap at the setscrew).

Gap Between Setscrew and Valve Body.

Rubber Debris Guard

1. Locate rubber debris guard (A4), guard

mounting strap bracket (A5), and bag

containing hardware and caution tag

(A6, A7, A8, and A9).

(A4) Rubber Debris Guard. (A5) Guard Mounting Strap

Bracket. (A6) Caution Tag. (A7) Bolt. (A8) Lock Washer.

(A9) Nut.

2. Attach rubber debris guard, mounting

strap, and caution tag on drive ram (A1)

with guard mounting bolts, lock washers,

and nuts, as shown.

NOTE: To avoid damage to the rubber debris

guard, do not over-tighten the mounting

hardware.

(A1) Drive Ram.

Safety Arm

To avoid serious injury or death,

the safety arm must be installed

after the Post Driver has been

mounted on a machine, or the

freestanding Post Driver has been secured

to prevent tipping.

1. Locate safety arm assembly parts and

hardware.

(I2) Safety Arm Frame. (I3) Frame Mounting Bolt.

(I4) Self Locking Nut. (I5) Swing Arm Handle.

(I6) Roller Bracket. (I7) Rollers. (I8) Roller Retainer Roll

Pin. (I9) Roller Bracket Nut. (I10) Latch Spring.

(I11) Spring Retainer Flat Washer. (I12) Swing Arm

Handle Cover. (I13) Lynch Pin.

2. Attach safety arm frame (I2) to outside of

short channel bracket (D1 or D2) with two

3/4-10 x 2” frame mounting bolts (I3) and

self locking nuts (I4), as shown. Tighten

nuts securely.

(D1) Manual Short Channel Bracket. (D2) Hydraulic

Short Channel Bracket (not shown). (I2) Safety Arm

Frame. (I3) Frame Mounting Bolt. (I4) Self Locking Nut.

3. Assemble rollers (I7) onto roller bracket (I6)

and secure with two roller retainer roll pins

(I8), as shown.

(I6) Roller Bracket. (I7) Roller. (I8) Roller Retainer Roll

Pin.

WARNING

18

19

4. Apply a light film of a good quality grease

to the pivot shaft and attach roller bracket

(I6) to swing arm handle (I5) with roller

bracket nut (I9). Tighten nut until seated

and then loosen 1/4 to 1/2 turn.

NOTE: Roller bracket (I6) must swivel freely

on swing arm handle (I5).

(I5) Swing Arm Handle. (I6) Roller Bracket. (I9) Roller

Bracket Nut.

5. Attach one end of latch spring (I10) to

swing arm handle (I5), as shown. Secure

with spring retainer flat washer (I11) and

Lynch pin (I13).

(I5) Swing Arm Handle. (I10) Latch Spring. (I11) Spring

Retainer Flat Washer. (I13) Lynch Pin.

6. Install the swing arm assembly.

a. Apply a light film of a good quality

grease to the pivot shaft on swing arm

handle (I5).

b. Start the pivot shaft into the main

bracket tube, as shown. Slide the open

spring eye over the main bracket

anchor rod.

NOTE: Swing arm handle (I5) will be below

safety arm frame (I2) bracket stop at this

point.

c. Secure spring with flat washer (I11)

and Lynch pin (I13).

(I11) Flat Washer. (I13) Lynch Pin.

19

To avoid serious injury or death,

the safety arm must be installed

after the Post Driver has been

mounted on a machine, or the

freestanding Post Driver has been secured

to prevent tipping.

7. Pull swing arm handle around toward the

Post Driver I-beam until the swing arm

clears (swings past) safety arm frame (I2)

bracket stop.

8. Tap swing arm shaft up through safety arm

frame tube.

9. Install Lynch pin (I13) to secure the swing

arm to the safety arm frame.

10. Verify the swing arm handle opens against

safety arm frame (I2) stop bracket and

closes against back wall of drive ram (A1)

I-beam.

(A1) Drive Ram. (I2) Safety Arm Frame.

NOTE: When driving a fence post, the swing

arm rollers must contact and hold the fence

post in position, as shown.

WARNING

2020

This manual suits for next models

1

Table of contents

Other Shaver Industrial Equipment manuals