Sherline Products 8-DIRECTION MILL Owner's manual

8-DIRECTION MILL

P/N 2000 (Metric P/N 2010)

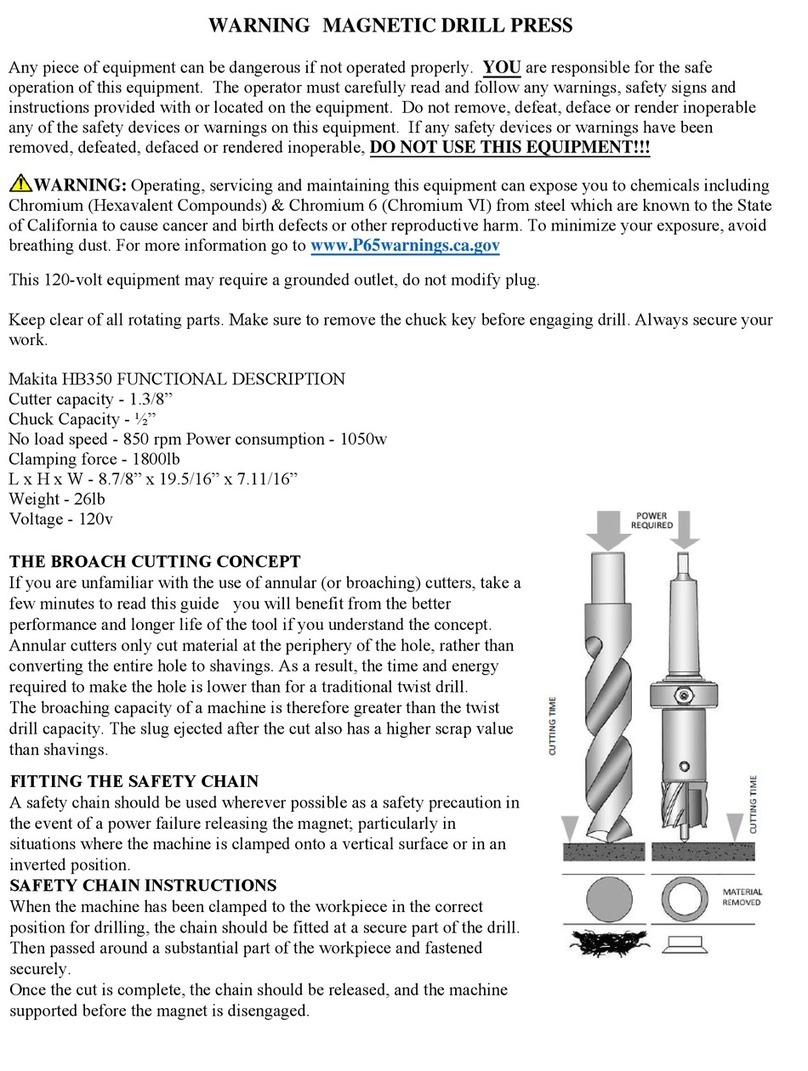

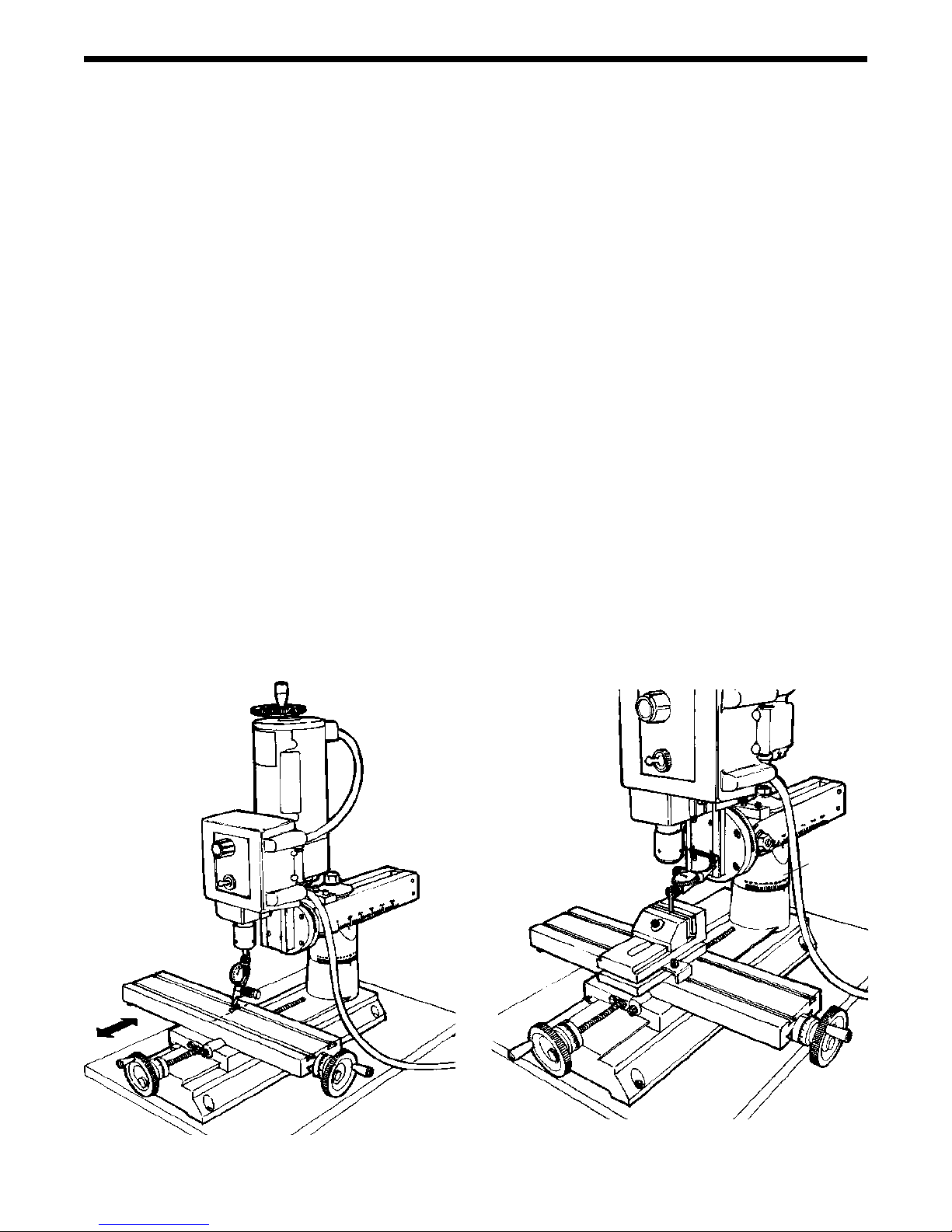

Using the multidirectional milling capabilities

The design of the 8-direction mill allows you to do

everythingthatcouldbedonewithpreviousmodelsofthe

Sherline mill plus much more. Now angled holes can be

drilledormillingoperationscanbecompletedfromalmost

any angle on parts mounted square to the table. The

increased swing and movement of the column allows

larger surfaces to be machined, eliminating the need for

thehorizontalmillingconversion.

Unpacking and assembling a new 8-direction mill

The major components of your new 8-direction mill are

preassembled at the factory and are then packaged for

efficient shipping. After unpacking your shipping box,

you will then assemble the major components to ready

your mill for operation. The mill XY base must be

removedfromthe piece ofplywoodthat locates itduring

shipment. To make any adjustments to the handwheels,

backlash, gibs and so on, see the instruction manual that

isincludedwiththemill.Instructionsarealsofoundthere

for assembly of the headstock/motor/speed control unit.

Toassemblethemulti-directioncolumn,makereference

to the exploded view provided on the last page of these

instructions and complete the steps that follow:

1. Attach the round column base(P/N 5666)to the mill

base with the two 1/4-20 x 1-1/2" socket head cap

screwsprovided.

2. Screwthearmhold-downbolt(P/N5613)intothetop

oftheroundcolumnbaseandtightenwithanadjustable

wrench. Two flat indentations are provided for the

wrench to grip.

3. Sliptheroundcolumntop(P/N5655)overthepinand

rotateituntiltheflatsidesareparalleltothemillbase

withtheengravedindicatorlineonthesamesideasthe

X-axishandwheel.

4. Usingan11/16"or17mm*wrench,loosentheflange

nut holding the bed and swing arm together. Rotate

the bed away from the swing arm until they are at

approximately a 90° angle to each other. Retighten

the flange nut firmly to hold the column in this

SHERLINE

PRODUCTS

INCORPORATED 1974

SHERLINE PRODUCTS INC. ··

··

· 3235 Executive Ridge ··

··

· Vista ··

··

· California 92083-8527 ··

··

· FAX: (760) 727-7857

Toll Free Order Line: (800) 541-0735 ··

··

· International/Local/Tech. Assistance: (760) 727-5857 ··

··

· Internet: www.sherline.com

12/11/00,1of6

position. Discard the protective spacer that was

installed between the bed and arm during shipping.

*NOTE:A17mmwrenchusuallyworksonan11/16"hex

nutbutisaclosefit.Ifyour17mmwrenchistootightand

you don’t have any inch tools you will have to use an

adjustablewrench.

5. Set the swing arm over the column and align it

approximatelysquarewiththemillbaseandinabout

the center of its travel. Make sure the swing arm

registersontheflatsofthecolumntopandisproperly

seated.Whilestillholdingtheswingarmunitinplace,

setthehold-downwasher(P/N5620)overtheendof

the bolt. Put a flange nut on the end of the bolt and

tightenitagainstthehold-downwasherfirmlytolock

the swing arm in place. NOTE: There should be NO

LUBRICATION on the mating surfaces between

thearm andthe columnbase. Frictionbetween these

surfaces keeps the arm from moving during cuts.

6. Placethecolumnadjustmentblock(P/N5635)ontop

of the swing arm and attach it with two 10-32 x 5/8"

socket head cap screws at both ends. Adjust the

1"longcenterboltsothatitisjusttouchingtheflatin

the bottom of the relieved section in the top of the

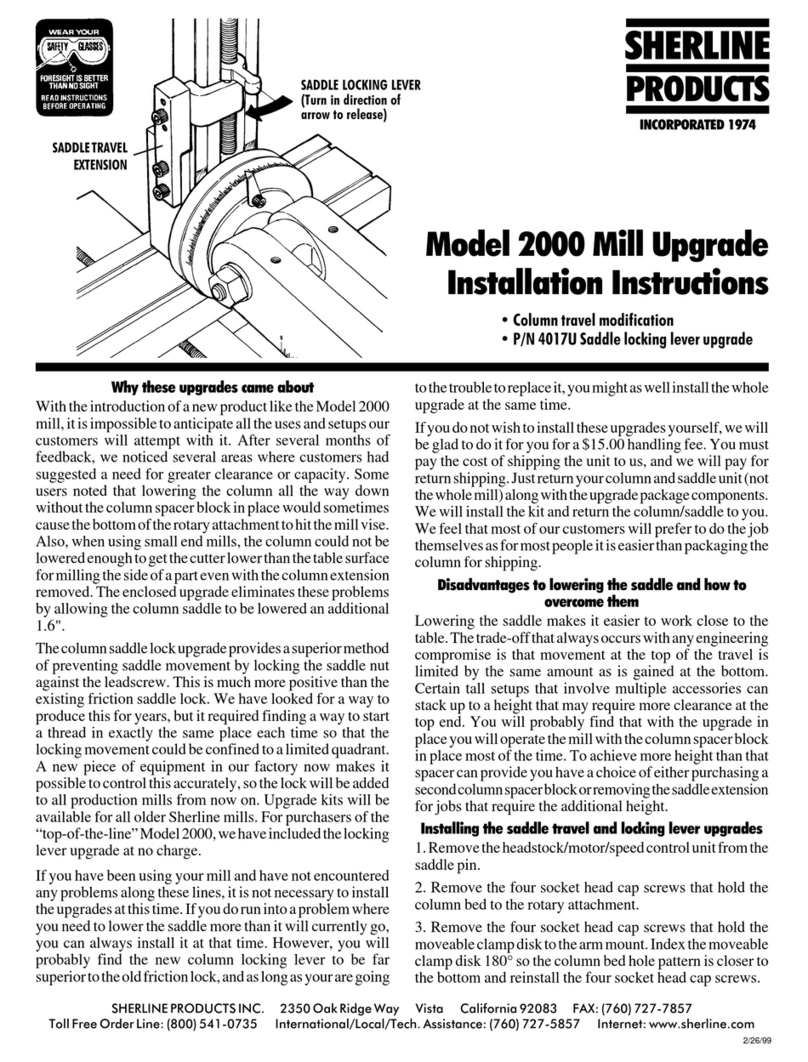

FIGURE 1—The axes of movement of a Sherline 8-

direction mill.

XY

Z

4

5

6

7

8

Note: This is a supplement to the instructions included in the Sherline

Assembly and Instruction Guide that comes with each new machine.

pivotknucklewhenthecolumnisinthe90°position.

NOTE: If you remove the column adjustment block to

accommodate a backward tilt movement of the column,

makesureyoureplaceitwhenreturningthecolumntoan

upright position. It not only serves as a reference point

when returning the column to the 90° position, it also

keepsitfrom accidentally swingingdownand damaging

the table if the flange nut is loosened.

7. Slip the alignment key* into its keyway in the mill

saddle.Placetheheadstock/motor/speedcontrolunit

overthepinonthemillsaddleandoverthealignment

key.Tightenthesetscrewinthesideoftheheadstock

toholdtheentireunitinplace.Rechecktobesureyou

have tightened the flange nut on the shouldered bolt

pivotpinsecurelysothatalltheweightofthecolumn

is not resting on the column adjustment block bolt.

*NOTE: The alignment key is precision ground and will

onlyfitintothekeywaywiththegroundedgestowardthe

sides.

The mill is now ready to be positioned for use if you will

bedoingangledoperationsorreadytobesquaredupifyou

will be milling square parts. The following instructions

willexplainthestepsusedto“indicatein”theheadofthe

mill so it will be square to the table.

The additional challenges of dealing with

so many adjustments

Havingsomanyadjustablecomponentsoffersyoumany

more possibilities, but it also brings with it additional

challenges.You must make sure eachof theadjustments

is securely tightened before beginning your cut. Large

clamping surfaces are provided which offer plenty of

frictional area, so it is not necessary to overtighten the

lockingnutsandscrews.Also,asyouadjustyourmachine

closertotheextremesofitsmovement,itissuggestedthat

youtakelightercutstoreducethepossibilityofflexingor

vibration. Let common sense and experience be your

guidehere.

Obviously, the additional movements provided by an 8-

directionmillcolumnalsomeanmorewillbeinvolvedin

returningthespindletoasquarepositioninrelationtothe

table.Thisisthesameprocedurethatmustbeusedonfull

sizedmachinesthatoffersimilarmovements.Beingable

to square up a mill is one of the skills that must be

developed by any machinist. Using the laser engraved

markings and the adjustment block provided with your

Sherline mill will allow you to bring it back to a location

veryclosetosquare.Fromthereyouwillusedialindicators

to “indicate in” the head the final few thousandths of an

inch.Thefirstfewtimesyoudoitwillprobablytakesome

time. The more often you do it, the faster it will go.

Remember that alignment for small parts is less critical

thanifyour cutwillbe traversingalonger distance.How

accurately you must indicate in the head will be dictated

by the parts you will be making.

Precautions on overtightening

As with all adjustments on any machine, overtightening

can distort components or ruin the built-in accuracy of

yourmachine.Thisisparticularlytrueonsmallermachines

wherethepoweroftheoperatorismuchgreaterinrelation

tothesizeofthecomponentsthanitisonlargermachines.

It is possible to deform the T-slot, which results in a

worktable that isn’t flat. I believe that the people who

damage Sherline T-slots are the same people who break

theT-slotsonexpensivehardenedandgroundtools.You

havetodevelopa“touch”sothisdoesn’thappen.Itisvery

difficult to correctly square work up with the machine if

the table is damaged and the work is “rocking”.

MACHININGTIP:Useofatoolingplate(P/N3560)is

an inexpensive way to protect the surface of your mill

table while providing a flat, versatile clamping surface.

SQUARING UP YOUR MILL

Determining the level of accuracy you really need

Squaring up a multi-direction mill can be a chore if you

want“perfection”.Itisbesttodeterminehowaccuratethe

setupmustbebeforeyoustart.Thelargeraclosetolerance

part is the better the setup required. An error of .001"

(.025mm)perinch(25.4mm)wouldbeaverysmallerror

onapart.4"(10mm) long.However,apartthatis5"long

wouldhave an errorof .005".Thetype ofmachining that

isgoingtobe performedalsohasabearing onthequality

ofthesetup.Asanexample,adrilledholedoesn’tusually

requirethequalityofsetupthatwouldbeusedforabored

hole,(assumingtheholeisbeingboredforaccuracyrather

than for lack of a drill of the proper size). The amount of

workthatwillbedonewiththesetupshouldbeconsidered

too. If your setup is just to do one particular job you only

have to set it up close enough to do that job. If the setup

willaccommodate future operationsas well, it should be

adjusted to the tolerances of the most critical job. For

example,squaringupamillandvisetoworkonanumber

of precise parts is worth more of your attention than

settingupto drilloneclearance holeina noncriticalpart.

Limitations of the production process

Before starting you should realize that these mills are

relativelyinexpensivemachinetools.Theyhaveaccurately

milledslidesbutthesurfacesarenot ground. Toincrease

the accuracy of a Sherline tool only a percentage point

would dramatically increase the price. We try to give a

customerwhatweconsider“themostbangforthebuck”.

Why aren’t there alignment pins

to square up the machine?

If you are a novice to machining, you probably believe a

machineshouldbedesignedsothatacoupleofpinscould

be dropped into holes, squaring up the machine and

eliminating this whole process. After all, that is the way

they do it with woodworking machinery. The truth is the

tolerances that work well for wood cutting tools simply

aren’taccurateenoughformostmetalworkingtools.You

P/N 2000, 2 of 6

NOTE: Before installing the adjustment block squaring

fixture onto the swing arm, make sure there are no chips

or debris in the pocket of the arm mount or on the end of

theadjustment screw.

justcan’t hold thetolerancesrequired with“pins”.When

they fit tight enough to lock the head square to the table

youcan’tremovethemtodo work that isn’tsquare.They

become more of a problem than the problem they were

installed to eliminate. For example, an alignment or

assembly error of .010" in a wooden kitchen table will

neverbenoticed.Usuallytheflooritsitsonisnotevenflat.

It would be a waste of time and effort to make it more

accurate than it has to be. On the other hand, a cylinder

that has been bored out of square with the crankshaft in

an automobile engine could wear the entire engine at an

alarmingrate.Thepistongoesupanddownamilliontimes

in a normal day’s use. The additional cost in fuel and

shortened life demands accuracy. The Model 2000

Sherline mill allows you to provide this accuracy by

making the adjustments required to suit a particular job.

Start by getting the column close to

square with the table

Thefirst place tostart isto getthecolumn approximately

squarewiththetableusingthepointersandlaserengraved

scalesonthemachine.Thefirsttimeyousetitupyouwill

have to use a machinist’s square on the side-to-side

columnrotaryadjustmentasthepointerwillnothavebeen

"zeroed in" yet. None of these adjustments must be

extremely precise at this point because a finger type dial

indicatorwillbeusedtomakethefinal adjustments later.

Removetheheadstock/motor/speedcontrolunitfromthe

saddle.Placeamachinist’ssquareonthetableandlineup

the front of the saddle to get the column approximately

square front to back. Then line up on the right side of the

saddle to get the column approximately square side to

side. Reinstall the headstock assembly.

Check for any built-in error in your machine

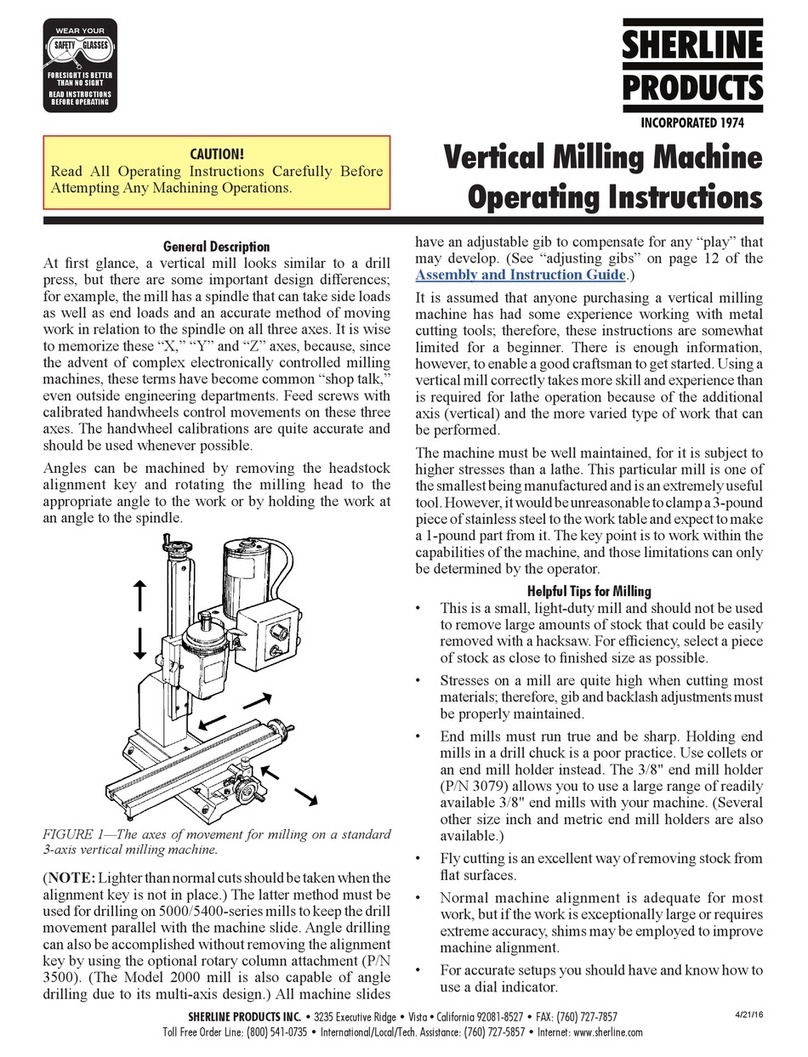

(SeeFigure2.)Tocheckthebuilt-inerrorofthemachine

useadialindicatormountedinthespindle.Movethetable

under spindle with the Y-axis handwheel and note the

error. This error will usually be around .001" to .002"

(.05mm) in 3" (76mm). (Remember the components are

not precision ground, they are precision milled.) When

squaring the head this error should be accounted for.

Rememberyouaresquaring the headandspindleto base

of the machine where the saddle travels, not the surface

of the table itself. The head doesn’t have to be square for

thisoperationaslongasyoudon’trotatethespindlesince

you are only checking for square in one direction.

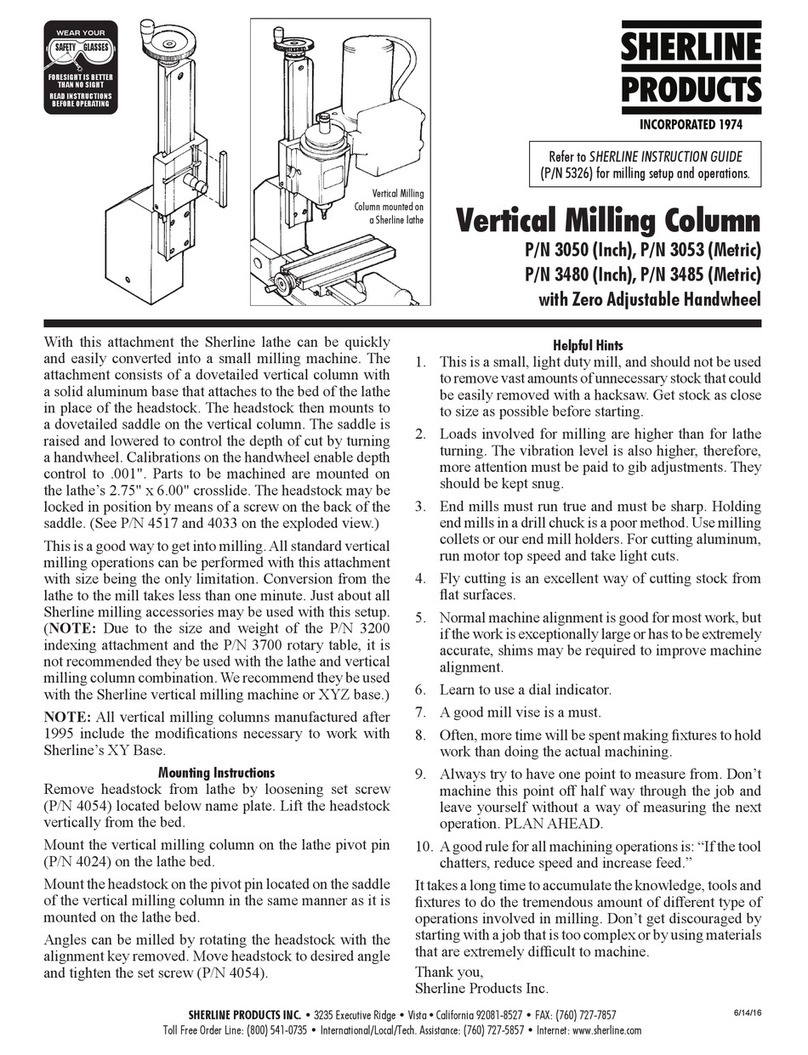

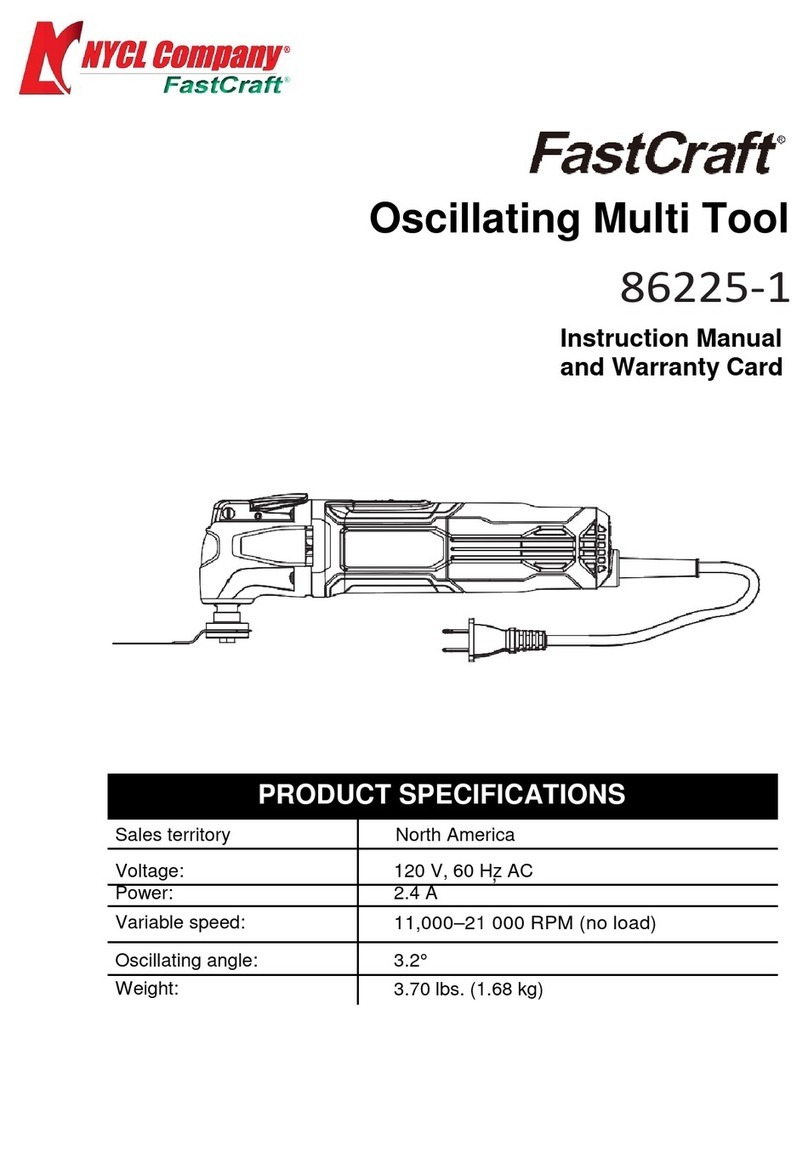

Squaring up the ram

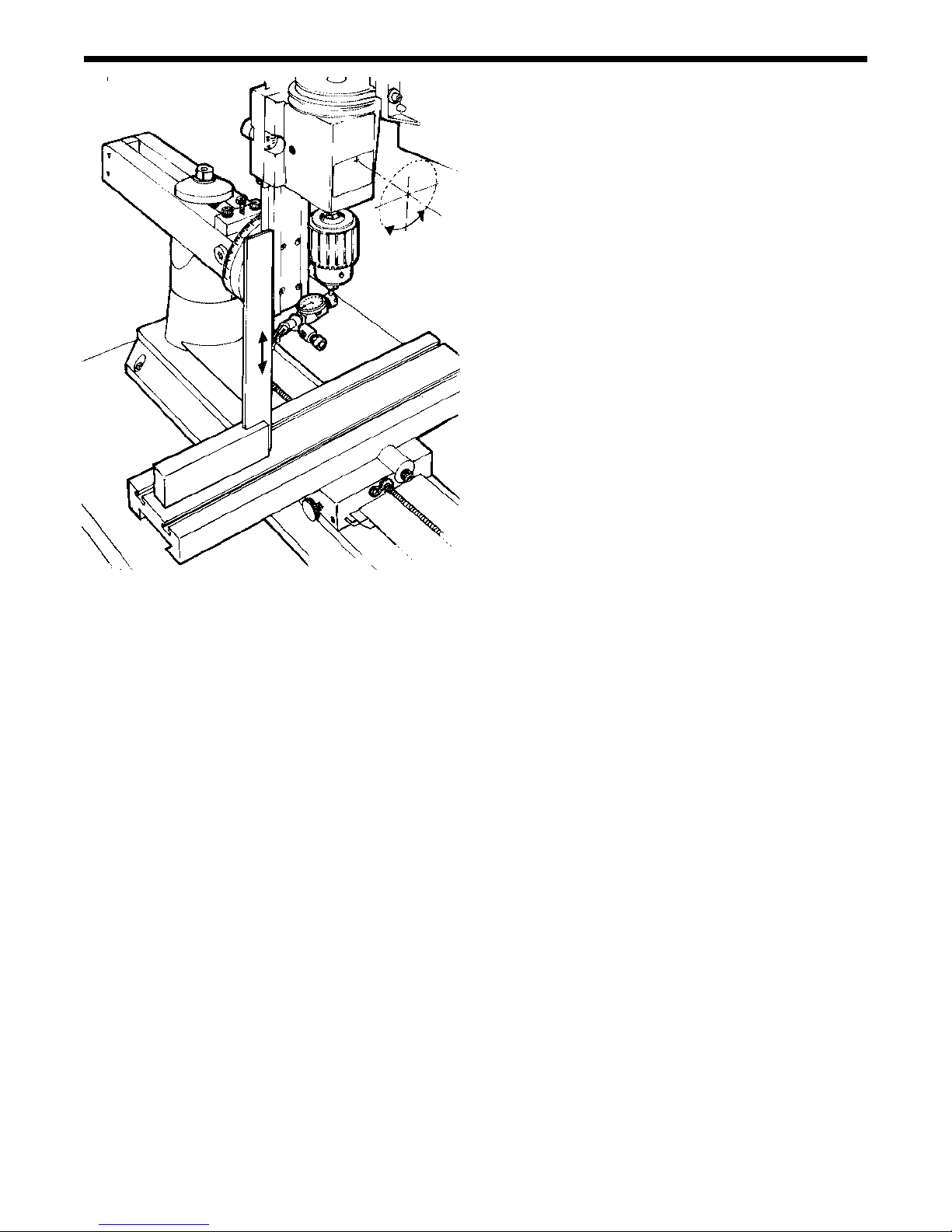

(See Figure 3.) The next decision to make is where the

spindleis tobe located.With allthe adjustmentsthat can

bemadewiththe8-directionmillyou’llprobablystartwith

the spindle located near the middle of the X/Y table

movements. Something that isn’t too obvious should be

considered now. If the ram (the two-bar slide that allows

youtomovetheheadinoroutandleftorright)isn’tsquare

withtheX-axis,therotatingcolumncalibrationswillhave

an error. To square up the ram, mount a dial indicator to

the worktable and move the X-axis back and forth while

readingtheleft and rightsurfacesofthe column bednear

thebottom.Thisonlyhastobedoneifyouwillberotating

the column and want to be able to rely on the angle

graduationreadings.Onceset, locktheramin place with

theflangenut.WithasteelscribeorX-Acto®knifeblade,

scribealineonthecolumnbaseoppositethe“zero”mark

on the angle scale for future reference.

P/N 2000, 3 of 6

FIGURE 2—Checking for built in error in the table

travel along the Y-axis

FIGURE 3—Squaring up the ram parallel to the Y-axis.

The indicator can be held with a chuck on the table or a

mill vise as shown here.

WHEN SQUARE,

SCRIBE ZERO

REFERENCE

MARK HERE

Squaring the column with the X-axis

(See Figure 4.) The column should next be squared with

theX-axis.Thisisaccomplishedwithanindicatormounted

inthespindle.Havethefoursockethead capscrewsused

to clamp the column rotation tight enough to keep the

columnfromrotating,butnotsotightthatyoucan’tmove

itwitha lighttapfrom a plasticmalletto thecolumnbed.

Becausethe axis that allows you to tiltthe columnin and

out hasn’t been squared yet you should only read the

indicatoratthesameY-axislocationontheworktablethat

you used before. Offset the indicator at an angle in the

spindle so that when the spindle is rotated it describes

about a 2" to 3" circle on the table. Take readings at the

extreme left and right positions. Adjust the column with

light taps until there is little difference in the readings at

either extreme. I wouldn’t try to get it perfect yet, just

close enough so there isn’t a gross error.

FIGURE 4—Squaring the left to right rotation of the

column with the X-axis

Squaring the column with the Y-axis

(See Figure 5.) Loosen the flange nut on the horizontal

pivot pin so that the column can be moved using the

adjustment screw in the alignment block but there is no

slop in the assembly. The tilt is harder to set because the

spindle doesn’t rotate at the pivot point, but once you

understandthis,thetaskbecomessimpler.Thealignment

block adjustment screw helps make fine adjustments in

thisdirectioneasy.Withtheblockinplaceandtheflange

nutloosetheentireassemblyiskeptfromfallingforward

by the adjusting screw. This block can be left in place

unless the ram is completely retracted or the column is

tiltedbackatananglethatinterfereswiththeblock.With

theindicatorstillheldinthespindle,takereadingsparallel

with the Y-axis near the front and rear edges of the table.

Raise or lower the column with the alignment block

adjusting screw until the readings are the same front and

rear.Remember the location of thepivot pointand allow

for it.

Example:

If the indicator reading is larger at the front of the table

than the back, then that means the column must be tilted

back. Say your reading is “0” at the back and .010"

(.25mm) at the front. If you tipped the column back until

theindicatorreadzeroatthefront,thereadingattheback

would not remain at “0” but would now be a negative

reading.This iscaused because the pivot point is located

far enough behind the spindle so that both front and rear

measuring points are still in front of it. Swinging the

column back actually raises both points. The front point

raises more than the back point, but both do go up. You

will have to keep tilting the column back and measuring

until you get the same reading front and back. This may

requiremoremovementthatyoufirstthoughtbasedonthe

differencebetweentheinitialmeasurements.

Fine tuning the headstock alignment

(See Figure 6.) It is time to make the final adjustments to

therotatingcolumn,butfirstI’lladdalittlemoreconfusion

toyourlife.RememberwhenIsaidthatalignmentpinsare

somewhatuselesstolineupamachine?Well,asmuchas

I hate to admit it, in a sense we already have one. It is the

alignmentkeythatholdstheheadstockassemblysquareto

thecolumnsaddle,which ismountedonthe column bed.

Removal of this key is what allows you to pivot the

headstockontheSherlinelathesandmills.Itisoneofthe

featuresthatmakeourmachineseasytouse,versatileand

very adaptable. It is also another thing you have to

consider when searching for “perfect” alignment. If you

havemorethan onekey,don’t mixthemup because they

arematchedduringassemblytofitascloselyaspossible.

I have found the best way to deal with this potential

P/N 2000, 4 of 6

ADJUST FORE/AFT MOVEMENT

WITH CENTER ADJUSTMENT

SCREW ON ALIGNMENT BLOCK

LOCK ADJUSTMENT

IN PLACE WITH

11/16" FLANGE NUT

FIGURE5—Squaringtheforeandaftpivotmovementof

the column with the Y-axis

P/N 2000, 5 of 6

problemistopushtheheadsquareagainstthekeybefore

tighteningtheconepointscrewthatlockstheheadstockin

place.Ifyoueverwanttocheckalignmentofthekeytothe

column bed, mount a dial indicator in the spindle. Raise

and lower the head while reading the vertical edge of a

precisionsquare.Adjusttherotatingcolumnuntilthereis

no error as the indicator moves up and down the square.

Now read the table with the indicator. If the slot and key

areperfectthereshouldn’tbeanyerror,butin mostcases

therewillbeasmallamount.Thiscanusuallybeeliminated

by taking advantage of what play does exist in the

alignment key and slot. With the cone point set screw

loosened slightly, tap the headstock with a plastic mallet

to take out play in the direction you want to go. Then

retighten the set screw.

Making final adjustments

Therotatingcolumnandtiltingadjustmentscanbefinalized

so the indicator reads “0” as the spindle is rotated,

however the error we measured when checking the table

flatness could be accounted for now if need be. If the

pointeron the backof therotary column diskdoesn't line

upwiththezeromark,loosenthescrewholdingitinplace

and reset it to indicate zero for future reference.

Yourmachine isnow “indicatedin” andready touse. As

you get a feel for your machine and go through this

adjustmentprocedurea fewtimes,the timeittakes to get

good results will decrease. Being able to accurately

indicateinamillisoneoftheskillsthatmustbedeveloped

by any machinist who plans on making accurate parts.

FIGURE6—Finetuningtheheadstockrotationalignment

with a machinist’s square and dial indicator

Thoughtheadjustmentsonlargermachinesmaybemade

in slightly different ways, the skills and procedures you

learn here can be applied to other machines as well.

Using the column spacer block

In normal use the column spacer block will not be

required.However, ifyou are working on alarger partor

yoursetup requires moreclearance undertheswing arm,

the spacer block can be installed to raise the column an

additionaltwoinches.(Installationwillbe made easierif

you first remove the headstock/motor unit to reduce the

weightofthecolumn.)Toinstallthespacerblock,remove

theflangenutontopofthecolumnhold-downbolt,andlift

off the hold-down washer so that the entire column top

andswingarmassemblycanbeliftedoffofthehold-down

bolt.Screwtheextensionboltonto the endofthecolumn

bolt and tighten with an adjustable wrench. Slide the

column spacer over the bolt and reinstall the column top

and swing arm assembly. Reinstall the headstock/motor

unit.

Lowering the headstock for working close to the table

Toworkdownclosetothetableonthinstockortorunan

end mill past the edge of the table, the column may be

loweredby placingthe columntop (P/N 5655) above the

swing arm instead of below it. Remove the flange nut,

hold-down washer and swing arm. Place the swing arm

overthehold-downboltdirectlyontopofthecolumnbase

(P/N 5666). Place the column top back onto the hold-

downboltupsidedownandreplacethehold-downwasher

and flange nut. Although you cannot use the alignment

lines to help square up the head, this makes for a very

strong and stable setup.

Engineering compromises

I’malwaysat odds withmyselfwhenI writeinstructions

on complicated procedures. By giving you this much

informationIknowthatImaybesolvingaproblemforone

customer by making them aware of it. At the same time I

am probably confusing another customer who would

never have noticed the problem because of the type of

work that the mill or lathe is being used for. I don’t want

to create a customer who spends all his time trying to

achieveperfectalignment for workthatdoesn'trequire it

and ends up never using the machine. Engineering is

alwaysacompromise.Idealwiththis fact with eachnew

productthatIdesign.Whileourmachinesaren’taccurate

enoughforsomecustomers,theyarestilltooexpensivefor

others. I hope you are pleased with the new capabilities

thismulti-directionmillcanbringtoyourshop.Ithinkyou

willfindthecombinationof features offersagoodvalue.

Joe Martin, President and Owner

Sherline Products Inc.

HEADSTOCK PIVOTS ON

SADDLE PIN. EVEN WITH

ALIGNMENTKEYINPLACE,

SLIGHT ADJUSTMENT CAN

BE MADE TO GET

HEADSTOCK PERFECTLY

SQUARE..

NOTE: This instruction sheet is a supplement to the

SherlineAssemblyandInstructionGuidethatcomeswith

eachnewmachine.Forsafetyrules,operatinginstructions

and information on the other components of the Model

2000 mill, consult that publication. It also includes basic

instructionsonmetalworkingthatwillbehelpfulfornew

machinists.

P/N 2000, 6 of 6

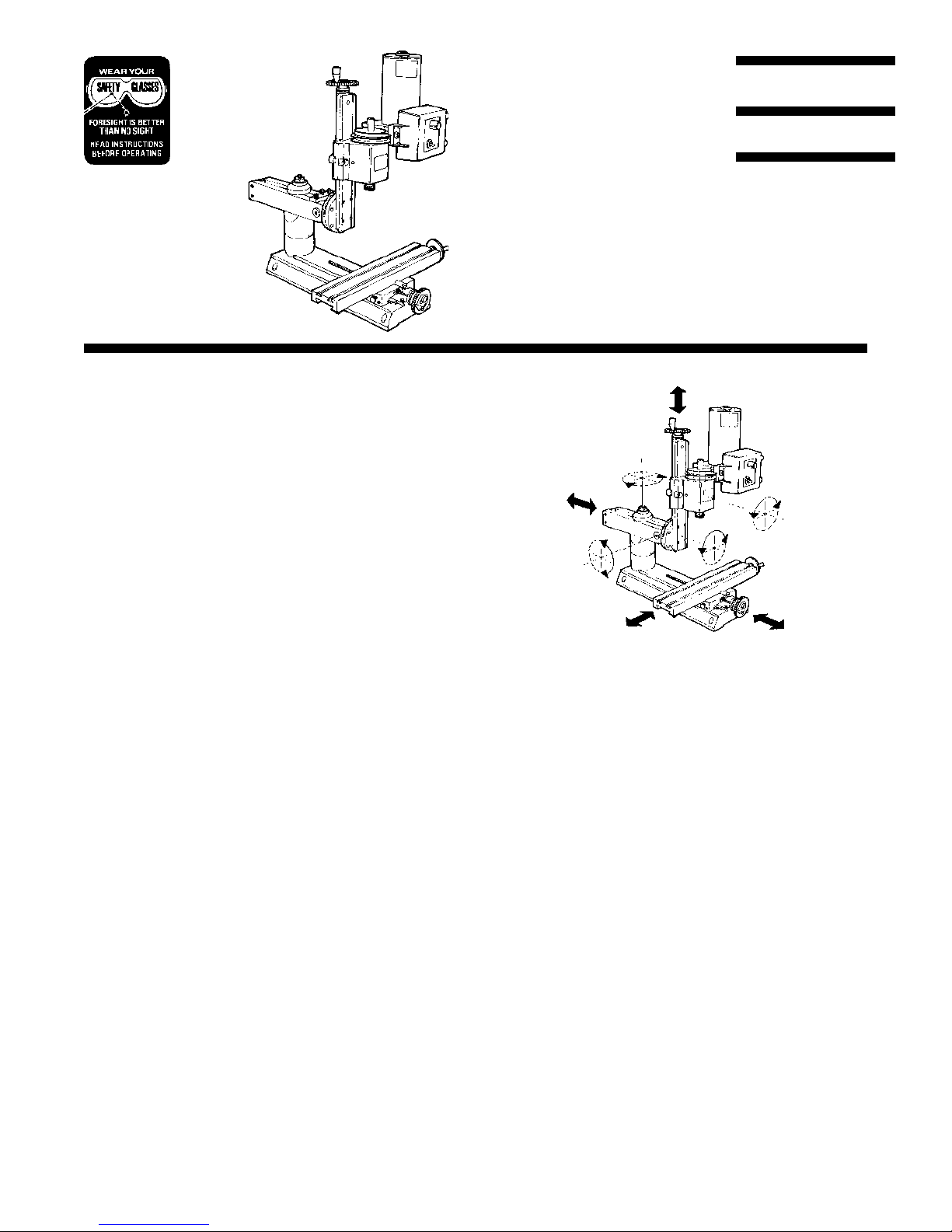

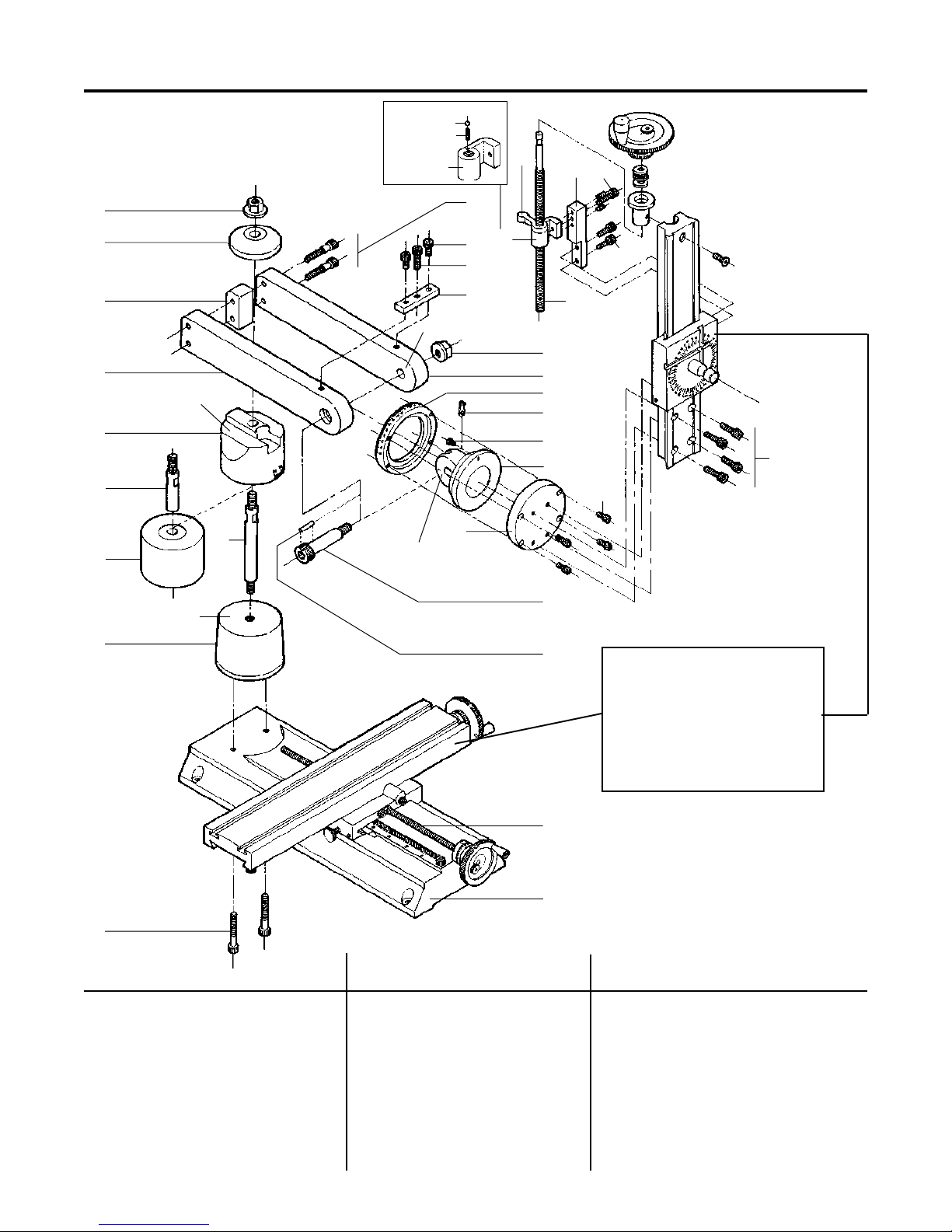

1

3

10

72

6

26

4

5

9

11

11 12

13

14

15

16

20

21

8

22

25

18

19

17

23

24

NOTE

For part numbers of table, column bed,

saddle and headstock/motor/speed

control portions of mill, see exploded

view in the Sherline Assembly and

Instruction Guide that came with your

mill.

EXPLODED VIEW AND

PARTS LISTING

SHERLINE MODEL 2000 MILL COLUMN

27

28 29 25

26

REF NO.

NO. P/N REQ. DESCRIPTION

1 35160 1 Graduated Clamping Ring

2 35170 1 Moveable Clamping Disk

3 40340 1 10-32 x 1" SHCS

4 40330 2 10-32 x 5/8" SHCS

5 56240 2 1/4-20 x 1-1/2" SHCS

6 56010 1 #2000 Mill Base (Metric P/N 5602)

7 56130 1 Arm Hold-down Bolt #2000

8 56200 1 Arm Hold-down Washer #2000

9 56210 1 3/8-16 x 2" Shouldered Bolt

10 56220 1 Swing Arm side #2000

REF NO.

NO. P/N REQ. DESCRIPTION

11 56230 2 Flange Nut

12 50220 2 1/4-20 x 1-3/4" SHCS

13 56330 1 Swing Arm side #2000

14 56350 1 Column Adjustment Block

15 56400 1 Arm Spacer Block #2000

16 56440 1 Arm Mount #2000

17 56450 1 Index Tab

18 50211 1 8-32 x 1/4” Button Head Screw

19 56470 1 3/32” x 1/2” Dowel Pin

20 56550 1 Model 2000 Column Top

REF NO.

NO. P/N REQ. DESCRIPTION

21 56700 1 Model 2000 Column Base

22 56160 1 Y-axis leadscrew (Metric P/N 5615)

23 56110 1 Extension bolt

24 56770 1 Column spacer

25 40690 5 10-32 x 3/4” SHCS

26 40670 6 10-32 x 1/2” SHCS

27 40177 1 Saddle nut w/ ball (Metric P/N 41177)

28 40175 1 Saddle locking lever (Metric P/N 41175)

29 40176 1 Saddle travel extension

30 45011 1 Z-axis leadscrew (Metric P/N 45161)

30

SADDLE NUT DETAIL

SADDLE NUT

(Asby.–40177/41177)

SPRING, P/N 22630

1/8" BALL, P/N 40178

NO LUBRICATION HERE

NO LUBRICATION HERE

NO LUBRICATION HERE

NO LUBRICATION HERE

Table of contents

Other Sherline Products Power Tools manuals

Popular Power Tools manuals by other brands

Huskie Tools

Huskie Tools SL-750 Operation manual

Gesipa

Gesipa taurus 1 Operating manual with spare parts list

Parkside

Parkside PBSG 95 C3 Translation of the original instructions

Metabo

Metabo STEB 70 Quick Original instructions

Skil

Skil 4570 Operating/safety instructions

EINHELL

EINHELL BT-HA 2000 operating instructions