WEAR YOUR

FORESIGHT IS BETTER

THAN NO SIGHT

READ INSTRUCTIONS

BEFORE OPERATING

SAFETY GLASSES

SHERLINE PRODUCTS INC. •3235 Executive Ridge •Vista •California 92081-8527 •FAX: (760) 727-7857

Toll Free Order Line: (800) 541-0735 •International/Local/Tech. Assistance: (760) 727-5857 •Internet: www.sherline.com

6/14/16

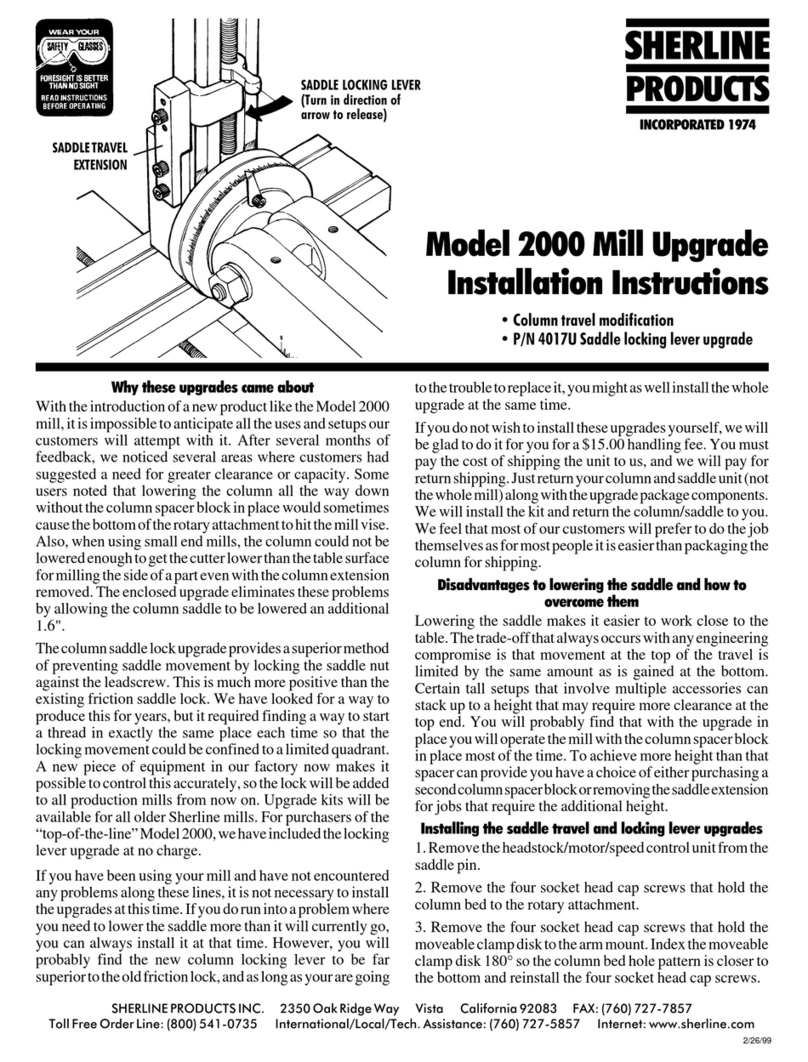

Vertical Milling Column

P/N 3050 (Inch), P/N 3053 (Metric)

P/N 3480 (Inch), P/N 3485 (Metric)

with Zero Adjustable Handwheel

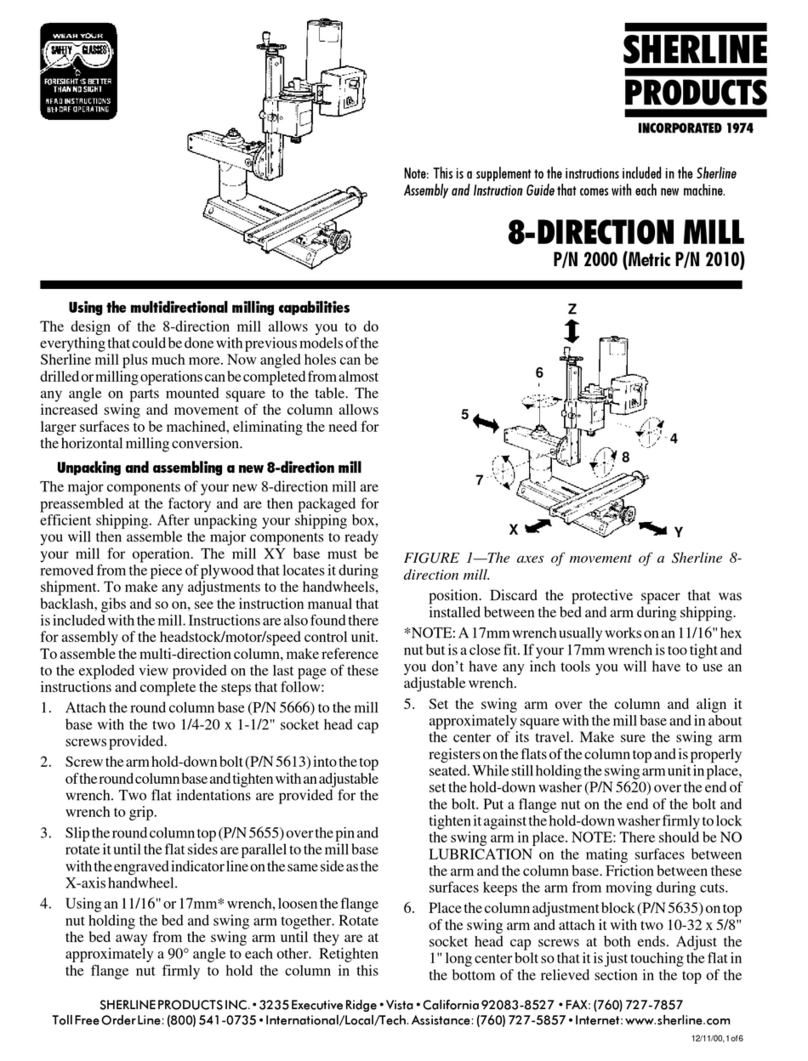

With this attachment the Sherline lathe can be quickly

and easily converted into a small milling machine. The

attachment consists of a dovetailed vertical column with

a solid aluminum base that attaches to the bed of the lathe

in place of the headstock. The headstock then mounts to

a dovetailed saddle on the vertical column. The saddle is

raised and lowered to control the depth of cut by turning

a handwheel. Calibrations on the handwheel enable depth

control to .001". Parts to be machined are mounted on

the lathe’s 2.75" x 6.00" crosslide. The headstock may be

locked in position by means of a screw on the back of the

saddle. (See P/N 4517 and 4033 on the exploded view.)

This is a good way to get into milling. All standard vertical

milling operations can be performed with this attachment

with size being the only limitation. Conversion from the

lathe to the mill takes less than one minute. Just about all

Sherline milling accessories may be used with this setup.

(NOTE: Due to the size and weight of the P/N 3200

indexing attachment and the P/N 3700 rotary table, it is

not recommended they be used with the lathe and vertical

milling column combination. We recommend they be used

with the Sherline vertical milling machine or XYZ base.)

NOTE: All vertical milling columns manufactured after

1995 include the modications necessary to work with

Sherline’s XY Base.

Mounting Instructions

Remove headstock from lathe by loosening set screw

(P/N 4054) located below name plate. Lift the headstock

vertically from the bed.

Mount the vertical milling column on the lathe pivot pin

(P/N 4024) on the lathe bed.

Mount the headstock on the pivot pin located on the saddle

of the vertical milling column in the same manner as it is

mounted on the lathe bed.

Angles can be milled by rotating the headstock with the

alignment key removed. Move headstock to desired angle

and tighten the set screw (P/N 4054).

Helpful Hints

1. This is a small, light duty mill, and should not be used

to remove vast amounts of unnecessary stock that could

be easily removed with a hacksaw. Get stock as close

to size as possible before starting.

2. Loads involved for milling are higher than for lathe

turning. The vibration level is also higher, therefore,

more attention must be paid to gib adjustments. They

should be kept snug.

3. End mills must run true and must be sharp. Holding

end mills in a drill chuck is a poor method. Use milling

collets or our end mill holders. For cutting aluminum,

run motor top speed and take light cuts.

4. Fly cutting is an excellent way of cutting stock from

at surfaces.

5. Normal machine alignment is good for most work, but

if the work is exceptionally large or has to be extremely

accurate, shims may be required to improve machine

alignment.

6. Learn to use a dial indicator.

7. A good mill vise is a must.

8. Often, more time will be spent making xtures to hold

work than doing the actual machining.

9. Always try to have one point to measure from. Don’t

machine this point o half way through the job and

leave yourself without a way of measuring the next

operation. PLAN AHEAD.

10. A good rule for all machining operations is: “If the tool

chatters, reduce speed and increase feed.”

It takes a long time to accumulate the knowledge, tools and

xtures to do the tremendous amount of dierent type of

operations involved in milling. Don’t get discouraged by

starting with a job that is too complex or by using materials

that are extremely dicult to machine.

Thank you,

Sherline Products Inc.

Refer to SHERLINE INSTRUCTION GUIDE

(P/N 5326) for milling setup and operations.

Vertical Milling

Column mounted on

a Sherline lathe