Sherman + Reilly Revolution Series User manual

Sherman+Reilly™RevolutionSeries

PLW‐200x

PilotLineWinder

Operator’sManual

ImportantSafetyNotice

BeforeusinganySherman+Reilly™equipment,operatorsmustreadandunderstandallproceduresand

safetyinstructions.Noteallsafetyinformationandspecificsafetyrequirementsasexplainedinthismanual.

Failuretofollowtheseinstructionscouldresultindamagetothemachine,seriouspersonalinjury,ordeath.

Advertencia

Porfavor,leaatentamentetodaslasinstruccionesoperacionalesydeseguridadantesdeoperaresta

maquinaria.Sinoentiendelasinstrucciones,porfavorconsulteasusupervisorantesdeutilizaresta

maquinaria.Elusoinadecuadodeestasinstruccionespuederesultarenlesionesgravesoenmuerte.

Savethisoperator’smanualforfuturereference.

ThismaterialiscopyrightedandproprietarytoSherman+Reilly™Inc.andisnottobereproduced,used,or

disclosedexceptinaccordancewithexpresswrittenpermissionfromSherman+Reilly™Inc.Informationis

providedforthepurposeofproductusageandmaintenancedescriptionsonly.Thedescriptionsand

specificationsinthismanualaresubjecttochangewithoutnotice,andtothebestofourknowledge,are

accurateatthetimeofprinting.Theinformationcontainedmaynotbespecifictoallmodelsorunits,and

mustnotbeconstruedaswarrantedcharacteristicsinthelegalsense.Theinformationdoesnotrelieveusers

fromthedutyofconductingtheirowninspectionsandevaluations.Theinformationcontainedrepresentsthe

bestpracticesforthesafestuseandmaintenanceofthemachine/unit,anddoesnotcovereverysituation.

Withregardtosituationsnotcoveredinthismanual,theoperatorisresponsibletoensurethesafeoperation

ofthemachineandshouldaskquestionsormakeinquiriesifuncertaintyexistspriortotheoperationofthe

machineorunit.Sherman+Reilly™Inc.reservestherighttocontinuallyimproveandexpandourproduct

line.Itisourpolicytoimproveourproductswheneveritispossibleandpracticaltodoso.Wereservethe

righttomakechangesorimprovementsatanytimewithoutincurringanyobligationtoinstallsuchchanges

onproductspreviouslysold.Asourproductsaresubjecttocontinualimprovement,wereservetherightto

amendtheproductspecifications,maintenancesteps,andallinformationcontainedinthismanual.Some

productimprovementsmayhavetakenplaceafterthismanualwaspublished.

CommunicationwiththeManufacturer

ForinformationaboutSherman+Reilly™products,contactusbyphoneat(423)756‐5300or800‐

251‐7780orviaemailathelp@sherman‐reilly.comorat400W.33

rd

Street,Chattanooga,TN37410;

www.sherman‐reilly.com.

NOTE:Productimagesshowninthisdocumentareforillustrationpurposesonlyandmaynotbeanexactrepresentationof

yourproduct.Actualproductmayvaryduetocontinualproductenhancementandimprovement.

©2018bySherman+Reilly™Inc.

400W33rdStreet

Chattanooga,TN37410USA

www.sherman‐reilly.com

Allrightsreserved

Sherman+Reilly™,Inc.

ATextronCompany

611324

RevB

TableofContents

1

INTRODUCTION....................................................................................................................................................1

T

ERMSOF

U

SE

.............................................................................................................................................................1

2

SAFETY.................................................................................................................................................................2

H

AZARD

O

VERVIEW

......................................................................................................................................................2

C

AUTION

S

YMBOLS

:......................................................................................................................................................3

O

PERATOR

S

AFETY

P

RECAUTIONS

....................................................................................................................................4

E

MPLOYER

S

AFETY

P

RECAUTIONS

....................................................................................................................................5

ChemicalSafety..............................................................................................................................................6

B

EFORE

S

TARTING

O

PERATIONS

......................................................................................................................................7

UnderstandtheMachine................................................................................................................................7

PreparationsforSafeOperation.....................................................................................................................7

Pre‐TowingChecklist.....................................................................................................................................10

IntheEventaFireOccurs.............................................................................................................................11

E

MERGENCY

S

TOP

P

ROCEDURE

.....................................................................................................................................12

UnauthorizedModifications.........................................................................................................................13

PrecautionsWhenRunningEngineInsideBuilding.......................................................................................13

InvestigateandConfirmJobsiteConditions..................................................................................................13

PrecautionsWhenWorkingonLooseGround..............................................................................................13

PositioningtheMachine...............................................................................................................................14

3

CONTROLS..........................................................................................................................................................15

G

ENERAL

O

VERVIEW

...................................................................................................................................................15

S

PECIFICATIONS

..........................................................................................................................................................16

T

ERMSTO

K

NOW

.......................................................................................................................................................17

O

PERATOR

C

ONTROLS

.................................................................................................................................................18

ControlPanelontheUnit..............................................................................................................................18

MasterPowerKeySwitch.............................................................................................................................18

EmergencyStopButton................................................................................................................................18

JoystickControl.............................................................................................................................................19

LevelwindHead.............................................................................................................................................19

TurretRotationControl.................................................................................................................................20

LevelwindControl.........................................................................................................................................20

LineTensionControl......................................................................................................................................21

EngineThrottleControl.................................................................................................................................21

DrumDriveCouplingControlLevers.............................................................................................................21

SafetyBrakeOverride...................................................................................................................................22

SystemGaugePressure.................................................................................................................................22

PayoutBrakePressureControlSwitches......................................................................................................23

PayoutBrakePressureGauges.....................................................................................................................23

S

YSTEM

C

ONTROL

S

CREEN

D

ESCRIPTIONS

.......................................................................................................................24

MainScreen..................................................................................................................................................24

EngineInformationScreen............................................................................................................................25

E

XTERIOR

H

YDRAULIC

C

ONTROLS

..................................................................................................................................26

HydraulicJackControls.................................................................................................................................26

4

HANDLINGANDOPERATION...............................................................................................................................27

P

RE

‐O

PERATION

I

NSPECTION

........................................................................................................................................27

S

TART

U

PAND

S

ET

U

P

P

ROCEDURE

...............................................................................................................................28

P

AYOUT

O

PERATIONS

..................................................................................................................................................29

PayoutOperations–Non‐Powered..............................................................................................................29

P

AYOUT

O

PERATIONS

–

P

OWER

A

SSISTED

.......................................................................................................................30

P

ULLING

...................................................................................................................................................................31

T

O

P

RE

‐

SETA

S

YSTEM

P

RESSURE

/

L

INE

T

ENSIONFOR

P

ULLING

...........................................................................................32

E

MERGENCY

M

ANUAL

O

VERRIDES

/

[L

IMP

H

OME

]

M

ODE

................................................................................................33

P

OST

‐O

PERATION

I

NSPECTION

C

HECKLIST

.......................................................................................................................34

5

QUICKSTARTGUIDE...........................................................................................................................................35

6

SYSTEMCONTROLINFORMATION.......................................................................................................................39

SetUpScreen–SecurityLevel0....................................................................................................................39

E

RROR

M

ESSAGES

......................................................................................................................................................40

EngineErrorCodes........................................................................................................................................40

D

IESEL

P

ARTICULATE

F

ILTER

(DPF)

R

E

‐G

ENERATION

I

NFORMATION

.....................................................................................41

EngineDPFErrorCodes.................................................................................................................................42

DPFandEngineIndicators............................................................................................................................42

T

ROUBLESHOOTING

Q

UICK

T

IPS

....................................................................................................................................43

S

ERVICE

&

R

EPAIR

......................................................................................................................................................44

O

VERHEAD

S

WIVEL

,

G

RIP

,

AND

R

OPE

S

AFETY

..................................................................................................................45

Safety

1

1

Introduction

TermsofUse

Itisimportantthateverymachineisoperatedinasafemanner.Toproperly,safelyoperatethismachine,itis

requiredthatoperatorsandservicepeoplereadandunderstandtheinformationinthisandtheengine

manufacturer’smanual.ANYONEworkingaroundthemachineshouldreadthesafetyprecautionsinthe

manuals.Beawareeachwarningandprecautionistohelpprotectagainstinjury.Takingunnecessaryrisks

andignoringwarningsistheprimarycauseofpersonalinjuryandfatalaccidentsintheworkplace.Ifyouhave

anyquestionsregardingoperationorsafetyofaprocedureorsituationregardingtheoperationsofthisunit,

feelfreetocontacttheSherman+Reilly™CustomerServiceat800‐251‐7780orviaemailathelp@sherman‐

reilly.com.

Publicationofthismanualandthesafetyprecautionsinitdoesnotinanywayrepresentanall‐inclusivelist.It

istheownerandoperator’sresponsibilitytomakesurethemachineisoperatedinaccordancewithallstate

andlocalsafetyrequirementsandcodes,includingallapplicableOSHA‐(OccupationalSafetyandHealth

Administration)andEPA‐(EnvironmentalProtectionAgency)regulations,aswellasANSI‐(American

NationalStandardsInstitute)accreditedstandards.

Shouldaproblemorunsafeconditionarise,shutthemachinedownusingthenormalshut‐downprocedure.

Intheeventofanemergency,usetheemergencystopproceduredescribedinthismanual,andthennotify

theproperauthoritiesorfollowyouremployer’sprescribedprocedureforanemergency.

Sherman+Reilly™stronglyrecommendsthatonlypersonswhohaveafullunderstandingoftheprovided

manualandwhoareknowledgeableintheuseofoverheadlinepullingandtensioningmachines,includingall

applicablelaws,regulations,andsafetystandards,beallowedtooperatethismachine.Therearesignificant

hazardsinherenttotheuseofthismachine;therefore,alloperatorsshouldbeeducatedonallfunctions,

procedures,andsafetymeasuresoutlinedinthismanualpriortotheiruseormaintenanceofthismachine.

Sherman+Reilly™stronglyrecommendsthatonlypersonnelthatareliterateintheEnglishlanguageand

whoverballyunderstandtheEnglishlanguagebeconsideredasoperatorsorservicepersonnelforthis

machine.

Sherman+Reilly™alsorecommendsfollowingapplicableguidancepublishedbytheInstituteofElectrical

andElectronicsEngineers(IEEE),andspecificallyIEEEStandard524–GuidetotheInstallationofOverhead

TransmissionLineConductors(IEEE524‐2016orsubsequent).

Thismanualwaspreparedtohelptheownerandoperatoruseandservicethemachineinasafemanner.

Responsibilityforsafetyduringoperationandservicerestswiththeperson(s)performingthework.Being

alertofsurroundingsandobservingallsafetyprecautions,andallratingrequirementsandstandardsis

requiredtohelpreducethepossibilityofanaccident.Thismanualisofnovalueiftheoperatordoesnotread

andunderstandtheinstructionsandprecautions‐beforestartingortryingtooperatethemachine.

Theoperatormustbeawareofthemachine’scapacitiesandlimitations.Itistheoperator’sresponsibilityto

watchforsituationsandconditionswhichcouldaffectthenormalperformanceofthemachineandthesafety

oftheoperating/workenvironment.

Sherman+Reilly™unitsarepowered,hydraulicallyactuatedmachines.Thismachinehasvariablespeedand

linetensioncontrols;however,ifpullingmultipleconductorsusingarunningboard,thetotallinepullapplied

fromallconductorsmustnotexceedthecapacityofthemachine.

Safety

2

2

Safety

HazardOverview

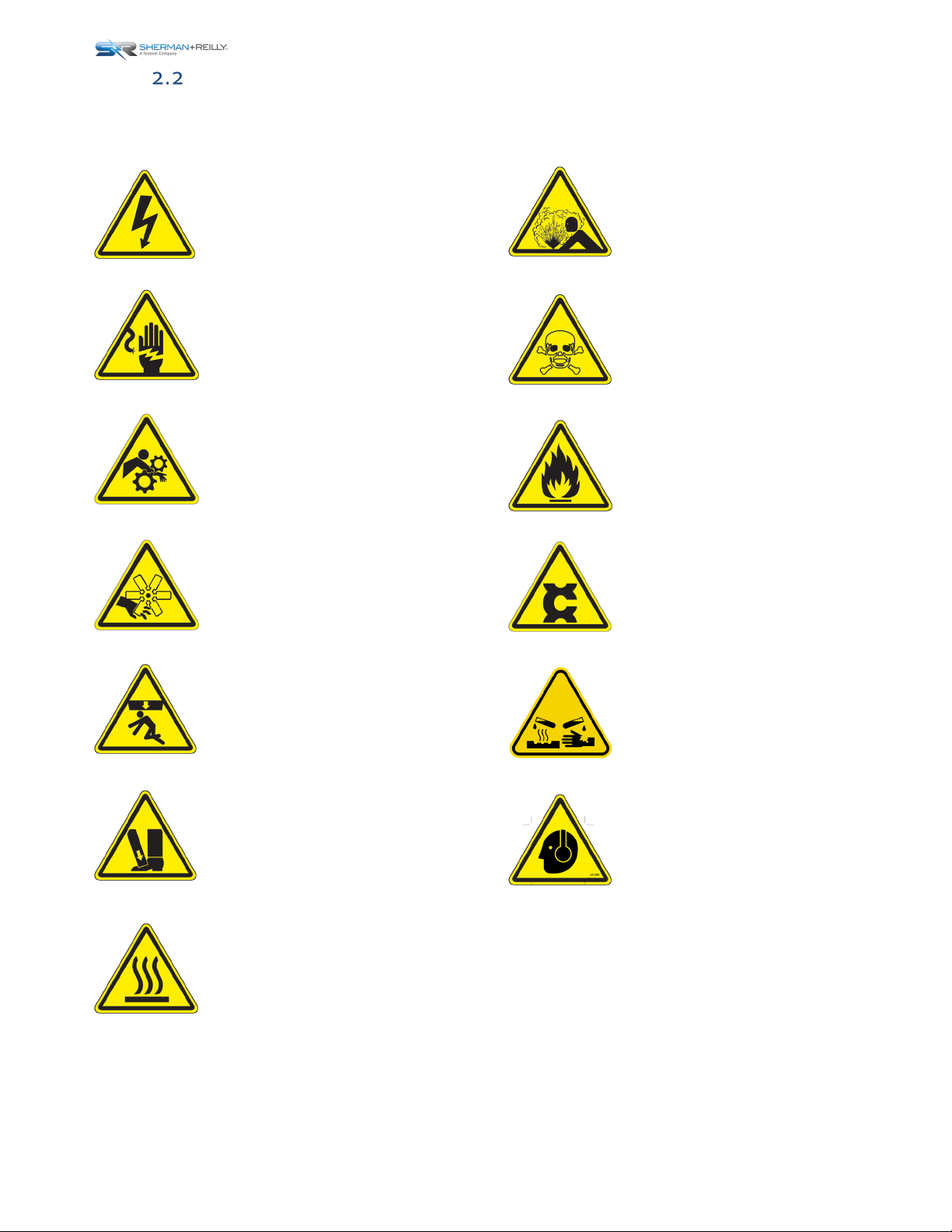

Familiarizeyourselfwiththefollowingsafetysymbolsbeforeoperatingmachinery.

CommonISOsymbolsandANSIstylesafetyalertcolorsareusedtoalertthereaderoroperatorofpotential

hazardsorinformation.

Pleasepayattentiontoallsafetywarninglabelsandinformationplacardspostedonthemachine,

components,andtrailerassembly.Theselabelsandplacardsarenotallinclusiveandareprovidedtosimply

assistinidentifyingareascontainingpotentialhazardswhilealsoprovidinginformationregardingequipment

specificationsandlimitations.Pleaseseebelowforexamples.

Thesesafetyalertsymbolsareusedto

alertyoutopotentialhazards.

IndicatesanimminentlyhazardoussituationwhichWILL

resultindeathorseriousinjuryifnotavoided.

IndicatesapotentiallyhazardoussituationwhichCOULD

resultindeathorseriousinjuryifnotavoided.

IndicatesapotentiallyhazardoussituationwhichMAY

resultinminorormoderateinjuryandpropertydamageif

notavoided.Itmayalsobeusedtoalertagainstunsafe

practices.

IndicatesapotentiallyhazardoussituationwhichMAY

resultinpropertydamageifnotavoided.Itmayalsobe

usedtoalertagainstunsafepractices.

CAUTION

NOTICE

WARNING

DANGER

CAUTION:Whenwashingdowntheunit:

Useonlyfreshwaterforcleaning.

Donotusehighpressurespray.

Donotspraywaterdirectlyattheinstrumentpanel,oranyelectricalcomponents,

electricalfittings,hydraulicfittings,hydraulicpistons,orhydraulicmanifolds.

Donotspraywaterintothecoolingairintakeortheengineairintake.

Donotwashahotorrunningengine.Usecompressedairtocleantheengineandradiator

finstoreducethepotentialforcorrosionandmoisturecontamination.

Safety

3

CautionSymbols:

CommonISOsymbols.Notallsymbolsapplytoall

machines

Highvoltagehazard

Electricalshockhazard

Pinchpointand/or

entanglementhazard

Cuttingand/orcrushinghazard

Crushingofbodyhazard

CrushingofToesorFootHazard

HotSurfaceHazard

RiskofExplosionHazard

ToxicHazard

FlammableMaterialHazard

CarcinogenHazard

Corrosive

HearingProtectionRequired

Safety

4

OperatorSafety

Precautions

DonotattempttooperateanySherman+

Reilly™equipmentwithoutproper

instruction,includingreadingand

understandingtheprovidedmanual.

Donotplaceanypartofthebodyintoa

potentialpinchpoint.Themachineshould

beturnedoffandlockedoutinaccordance

withOSHAregulationsbeforeattempting

tocorrectaproblem,workonthe

machine,orperformpreventive

maintenance.

Obeyandenforceallwarningsincluding

OSHArequirementsandANSIstandards.

Neverallowanyonetorideontheunit

whileitisbeingtowed.

Alwayswearpropersafetyequipmentas

requiredbyemployer.

Neverbypasssafetyswitchesoroperate

equipmentwithfaultysafetydevices.

Besureallguardsandaccesscoversarein

placeandsecuredwhenthemachineis

beingoperated.

Beawareofpeopleintheworkareawho

maybeatriskduringoperation.

Knowallemergencyshutdown

procedures.

Donotobstructcontrolsorfire

extinguisherandmakesurefire

extinguisherisfullycharged.

Neveroperateequipmentwhileunderthe

influenceofanysubstancewhichcould

impairabilityorjudgment.

Donotoperateequipmentifworkabilityis

impairedbyfatigue,illness,orother

causes.

Alwaysuseemployerapprovedgrounding

procedureswhenoperatingthemachine.

Neverusehandstocheckforhydraulic

systemleaks.Hydraulicfluidescaping

underpressurecancausepersonalinjury.

Avoidcontactwithpumps,cylinders,

hoses,enginecomponents,andexhaust

system.

Donotrefuelunitwhiletheengineis

runningorhot.

Keepallbodyparts,toincludeheadand

limbs,awayfromallmovingparts.

Refertoenginemanufacturer’smanualfor

alladditionalsafetyprecautionswhich

relatetoengineoperationandservice.

Knowlocationandfunctionofallcontrols,

gauges,instruments,andprotective

devices.

Neveruseunittotoworwinchanother

vehicle.

Neverusecontrolsorhosesforhandholds.

Donotexceedunitspecificationsand

limitations,toincludeweight.

Knowwheretogethelpintheeventofan

emergencyorinjury.

Whentowingthismachine/unittrailer,the

drivershouldusecautionandadjustspeed

basedonroad,weather,andterrain

conditions,aswellasapplicablelawsand

speedlimits.

Donotmakephysicalcontactwithropeor

cableasitentersorleavesthemachineor

drum.

Topreventthepossibilityofelectrocution,

donotenterorleavetheunitwhileitis

operatingorallowanyonetotouchorlean

onthemachinewheninuse.

Avoiddirectinhalationofengineexhaust

gases.

Safety

5

EmployerSafetyPrecautions

Thisguidelineisintendedtoassistowners,employers,jobsitesupervisors,andoperatorsinensuringthatthe

equipmentisoperatedinasafemanner.Eachjobsitemayhaveadditionalsituationsandconditionswhich

needconsideration.Informationinthismanualappliestoalltheoperatorschargedwiththeuseand/or

maintenanceofthemachine.Thismanualisnotatrainingmanual.Thismanualmustbekeptwiththe

machinefortheentirelifethemachineinordertobeavailabletoallpotentialusersandoperators.

Monitortheoperatorstobesuretheyobserveandpracticesafetyproceduresandoperatethesupport

equipmentasoutlinedinthismanual.

Establisharegularinspectionprogramwhichincludesmalfunctionreports,inspection,andservicerecords.

Thisinspectionshouldcoverthemachinecondition,adjustment,andensureallsafeguardsareinplaceand

functional.Additionally,allpre/post‐operationinspectionsshouldbeconductedatprescribedintervals.

Makesurethatanymalfunctionorbreakdownaffectingthesafeoperationoftheequipmentisproperly

correctedorrepairedbeforereturningthemachinetoservice.

Theemployermustprovidetrainingandinstructioninchemicalsafetyandsafemethodsofworkbefore

assigningworkerstooperate,service,orrepairthemachineandequipment.Arecordoftrainingdates,

employeenames,andleveloftrainingshallbemaintained.Onlypersonswhohaveafullunderstandingofthe

providedmanual‐(providedinEnglishonly),andwhoarecompetentintheuseofoverheadpullingand

tensioningmachines;toincludeallapplicablelaws,regulations,andsafetystandards,shouldbeallowedto

operatethismachine.Therearesignificanthazardsinherenttotheuseofthismachine,thereforeall

operatorsshouldbeeducatedonallfunctions,procedures,andsafetymeasuresoutlinedinthismanual‐prior

totheiruseormaintenanceofthismachine.

Employermustutilizealock‐out/tag‐outprocedurewhichcomplieswithOSHAStandard,Part1910.147,Title

29oftheCodeofFederalRegulationsorsubsequent.Thisproceduremustincludecontrolofallkeys.

Theemployershouldspecificallyinspectallsafetyequipmentandprotectivedevicesontheequipmentto

ensuretheyarenotbypassedordisabled.Operationofequipmentshouldnotbepermittedunlessallsafety

devicesareinplaceandfunctional.Theemployershouldmeetallappropriateinformationdisseminationand

protectionrequirementsfortheworkers.

Operatorsandmaintenance/servicepersonnelshouldtakeappropriateprecautions,toincludewearingall

(PPE)‐PersonalProtectionEquipment,priortotheoperation,maintenance,orserviceofthemachine.

Operatorsshouldwearsuitableclothingtoreducethepossibilityofentanglementinthemachinesmoving

parts.Operatorsshouldnotwearchainsorotherjewelryforthesamereason.

Safety

6

ChemicalSafety

Exposuretochemicalsduringnormaloperationofthemachineislimited;however,chemicalexposuremaybe

encounteredthroughpreventivemaintenanceandrepair.Operatorsandmaintenance/servicepersonnel

shouldtakeappropriateprecautions,toincludewearingall(PPE)‐PersonalProtectionEquipment,priortothe

operation,maintenance,orserviceofthemachine.AllMaterialSafetyDataSheets(MSDS’s)orSafetyData

Sheets(SDS’s)forOEMchemicalspresentuponinitialmanufacture/shipmentofmachinecanbemade

availableuponrequesttoSherman+Reilly™.

Anyadditionalchemicalsintroducedtothemachineorusedinconjunctionwithmaintenanceorrepairofthe

machinearerequiredbyfederalregulationstohaveaMSDS/SDSavailable,andaretheresponsibilityofthe

operator’semployerortheorganizationprovidingthemaintenance.Allchemicalhandlinganddisposal

shouldbedoneinaccordancewithenvironmental,federal,state,andlocallawsandregulations.Sherman+

Reilly™isnotliableforthemishandling,misuse,orimproperdisposalofchemicals,withregardtotheuseor

maintenanceofSherman+Reilly™machinesorequipment.

Allresponsibilities,includingbutnotlimitedto:handlinganddisposalofchemicals,availabilityand

maintenanceofMSDS’s/SDS’s,labelingofchemicalcontainers,andtrainingofemployeesandoperators,

shouldbefulfilledinaccordancewiththeHazardCommunicationAct,HazardousMaterialsTransportation

Act,OccupationalSafetyandHealthAdministration’sHazardCommunicationStandard‐(29CFR)Part

1910.1200,andallapplicableEnvironmentalProtectionAgencyStandardsandRegulations‐(additional

standardsmayapply).ForfurtherinformationonsafetystandardsregardingchemicalsseeOSHAandEPA

websites.

Safety

7

BeforeStartingOperations

Onlytrainedandauthorizedpersonnelcanoperateandmaintainthemachine.

Followallsafety,precautions,andinstructionsinthismanualwhenoperatingorperforminginspectionor

maintenanceonthemachine.

Ifyouarenotfeelingwell,ofifyouareundertheinfluenceofalcoholormedication,yourabilitytosafely

operateorrepairyourmachinemaybeseverelyimpaired,puttingyourselfandeveryoneelseonyourjobsite

indanger.

Whenworkingwithanotheroperatorifwiththepersonontheworksitetrafficduty,discussthecontentofthe

operationbeforehandandusethedeterminedsignalswhenperformingtheoperation.

UnderstandtheMachine

o Beforeoperatingthemachine,readthismanualthoroughly.Ifthereisanyplaceinthismanualthat

youdonotunderstand,askthepersoninchargeofsafetyforexplanation.

o Ifyoufindanyprobleminthemachineduringoperationormaintenance(noise,vibration,smell,

incorrectgauges,smoke,oilleakage,etc.,oranyabnormaldisplayonthewarningdevicesor

monitor),reporttheproblem(s)tothepersoninchargeandtakethenecessaryaction.Donotoperate

themachineuntiltheproblemhasbeencorrected.

PreparationsforSafeOperation

PreparationsforSafetyRelatedEquipment

o Besurethatallguards,covers,andsafetydevicesareintheirproperposition.Repairthem

immediatelyiftheyaredamaged.

o Understandtheapplicationofsafety‐relateddevicesandusethemproperly.

o Neverremoveanysafety‐relateddevices.Alwayskeepthemingoodoperatingcondition.

o WearWell‐FittingClothsandPersonalProtectiveEquipment(PPE).

o Donotwearlooseclothesoranyaccessoriesthatcouldcatchthecontrolleversorprotrudingparts,

andcouldcausethemachinetoengageunexpectedly.

o AlwayswearappropriatePPE:hardhat,safetyshoes;protectiveeyeglasses,earplugs,gloves,and/or

faceshield,dependingonthework.

o Longhairhangingdowncouldbecomeentangledinthemachine.Tiethehairupandbecarefulthatit

isnotcaughtinthemachine.

o Checkthatallpersonalprotectiveitemsfunctionproperlybeforeusingthem.

KeeptheMachineClean.

o Wipeoffanymudoroilfromthemachine.Alwayskeepthemachineclean.

o Ifwatergetsintotheelectricalsystem,itcouldcausesystemsmalfunctionswhichcouldcausethe

unittoengageunexpectedlyandcouldcauseseriouspersonalinjuryordeath.Whenwashingthe

machinewithwaterorsteam,donotallowthewaterorsteamtocomeintodirectcontactwith

electricalcomponents.

o Donotusehigh‐pressurewatertocleantheunit.Donotspraywaterdirectlyontoelectricalfittings,

hydraulicfittings,hydraulicpistons,orhydraulicmanifolds.Wipeoffanydirtfromelectricaland

hydraulicfittingsandcomponentswithsoftcloth.

Safety

8

PrecautionsforInsidetheCab

o Donotleavetoolsormachinepartslyingaroundinsidetheoperator’scab.Iftoolsorpartsgetintothe

controldevices,itmayobstructoperationandcausethemachinetomoveunexpectedly,resultingin

seriouspersonalinjuryordeath.

o Donotuseacellularphonewhenoperatingthemachine.Thismayleadtomistakesinoperationand

maybecauseseriouspersonalinjuryordeath.

o Neverbringanydangerousobjectssuchasflammableorexplosiveitemsintothecab.

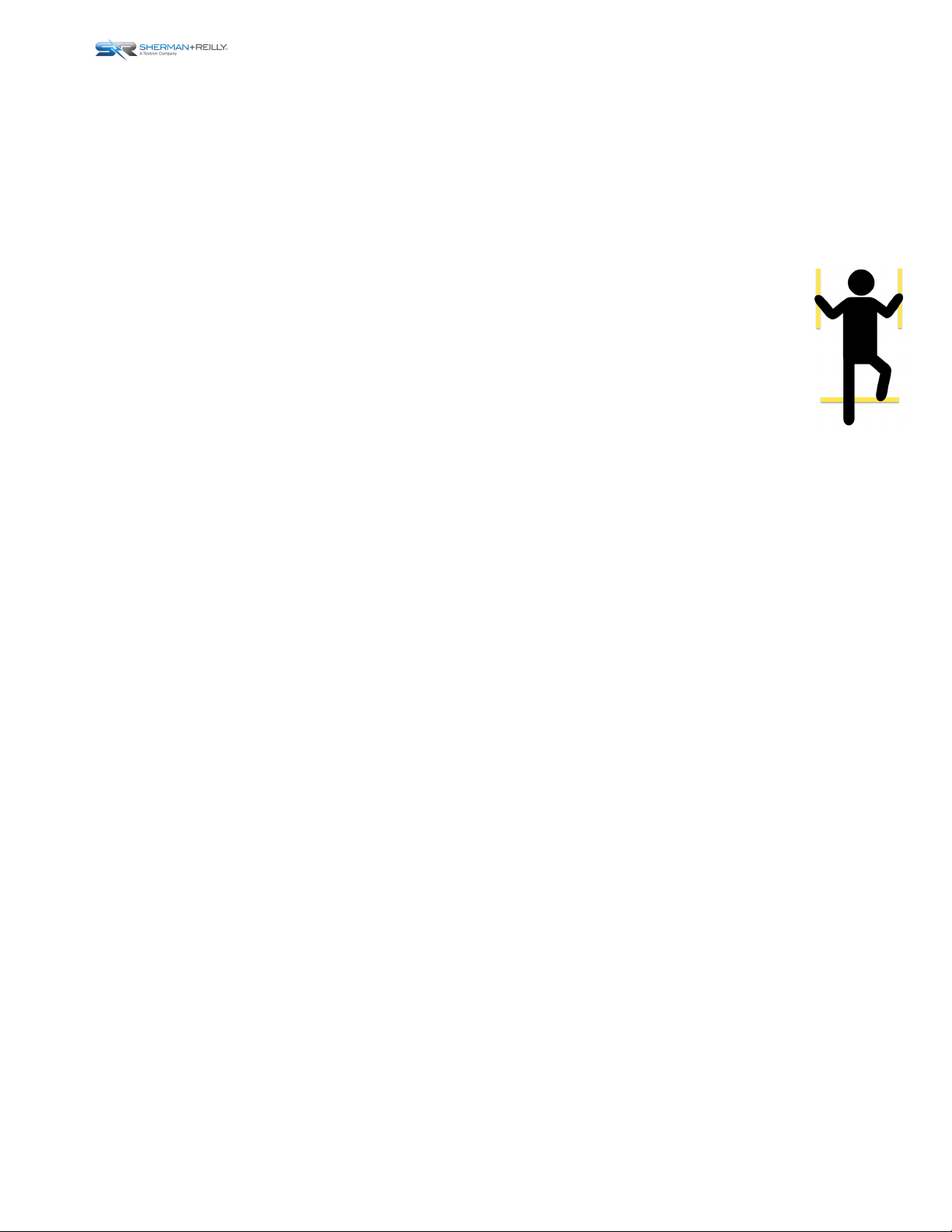

UseHandrailsandStepwhenGettingonorOffMachine.

Topreventpersonalinjurycausedbyslippingorfallingoffthemachine,alwaysobservethe

following:

o Alwaysfacethemachineandmaintainatleastthree‐pointcontact(bothfeetandonehand

orbothhandsandonefoot)withthehandrailsandstepstoensurethatyousupport

yourself.

o Beforegettingonandoffthemachine,checkthehandrailsandstepsifthereisanyoil,

grease,ormudonthem.Wipeitoffimmediatelysoasnottoslip.Inaddition,tightenany

looseboltsonthehandrailsandsteps.Ifthehandrailsandstepsaredamagedordeformed,

theyneedtoberepairedimmediately.

o Donotgripthecontrolleversorlockleverwhengettingonoroffthemachine.

o Neverclimbontheenginehoodorcoverswheretherearenonon‐slippads.

o Neverjump‐offorleapfromtheMachine–unlessnecessarytoavoidelectricalshock.

PrecautionstoPreventFire

o Donotbringanyopenflameclosetoflammablesubstancessuchasfuel,oil,coolant,orwindow

washerfluid.Thereisadangerthattheymaycatchfire.

o Donotsmokeoruseanopenflamenearfuelorotherflammablesubstances.

o Shutdowntheenginebeforeaddingfuel.

o Donotleavethemachinewhenaddingfueloroil.

o Tightenallthefuelandoilcapssecurely.

o Becarefulnottospillfuelonoverheatedsurfacesoronpartsoftheelectricalsystem.

o Afteraddingfueloroil,wipeupanyspilledfueloroil.

o Putgreasyragsandothercombustiblematerialsintoasafecontainer.

o Whenwashingpartswithoil,usenon‐flammableoil.Donotusedieselfuelorgasoline.

o Donotweldoruseacuttingtorchtocutanypipesortubesthatcontaincombustibleliquids.

o Determinewell‐ventilatedareasforstoringoilandfuel.Keeptheoilandfuelinthespecifiedplaceand

donotallowunauthorizedpersontoenter.

o Whenperforminggrindingorweldingworkonthemachine,moveanyflammablematerialstoasafe

placebeforestarting.

o Removeanydryleaves,chips,piecesofpaper,dust,oranyothercombustiblematerialsaccumulated

oraffixedaroundtheengineexhaustmanifold,muffler,battery,orcowling.

o Topreventfiresfromspreadingsparksorburningparticlesfromotherfires,removeanycombustible

materialssuchasdryleaves,chips,piecesofpaper,oranyothercombustiblematerialsaccumulated

onthemachineorinsidetheenginecowling.

o Shortcircuitsintheelectricalsystemcancausefires.Checktoseethatallpowercablesandwirings

areingoodcondition.Keepallelectricalconnectionsclean.Barewireorfrayedinsulationcancausea

dangerouselectricalshockandpersonalinjury.

o Keepalltheelectricwiringconnectionscleanandsecurelytightened.

o Checkthewiringeverydayforloosenessordamage.Reconnectanylooseconnectorsorrefasten

wiringclamps.Repairorreplacedamagedwiring.

o Checkthatallthehoseandtubeclamps,guards,andcushionsaresecurelyfixedinposition.Iftheyare

loose,theymayvibrateduringoperationandrubagainstotherparts.Thereisdangerthatthismay

leadtodamagetothehosesandcausehigh‐pressureoiltospurtout,leadingtofireandserious

personalinjury.

Safety

9

Precautionsregardinghighlyheatedexhaustgas

o ThemachineisequippedwithDieselParticulateFilter(hereafterDPF).DPFisadevicetopurifythe

sootintheexhaustgas.Exhaustgastemperaturemayincreaseduringthefiltercleaning/purification

process(regeneration/ReGen).Donotbringanycombustiblematerialclosetotheoutletofthe

exhaustpipe.Beawareofnearbycombustiblematerialsthatmaybeinadvertentlyheatedbyexhaust

gases.(SeeSectionaboutDPFCodes).

o Whenthereisbrush,trees,dryleavesorothercombustiblematternearthejobsite,beawarethatthe

DPFregenerationmaypresentafirehazard.ThesystemcanbesettodisableDPFReGenif

necessary.

Precautionsregardingsensitiveelectricalcomponentsandwelding

o Themachineisequippedmultipleelectroniccontrollersandelectronicallyactuatedhydraulics.

Electricalsurgestothemachinecandamagethesensitiveelectroniccontrols.

o Donotweldontheunitwithoutdisconnectingthebatteries

andallelectroniccontrollers.Locatetheweldgroundingwire

asabsolutelynearaspossibletoweldingpoint.

o ContactSherman+Reillyforinstructionalsupplementregarding

weldingontheunit.

o Electricalcomponentsdamagedbyweldingarenotcovered

underwarranty.

Precautionsregardingcorrosion

Regularlyinspecttheunitforcorrosion.Tohelppreventrustontheunit,itisimportanttoregularlyapplya

corrosioninhibitor/lubricantlikeTC‐11™CorrosionInhibitororequivalenttoexposedmetalaswellas

fairleadrollersandpins.Iftheunitisstoredoutdoors,acorrosioninhibitingproductshouldbereappliedevery

6months.Theproductshouldalsobereappliedifavisualinspectionindicatesthatsurfaceareasareno

longerglossy.Thefrictionbetweentheropesandthesurfaceofthereelandrollerscanacceleratethe

degradationofanycorrosioninhibitingcoating,therefore,thereelandrollersshouldbeexaminedaftereach

usetodetermineifreapplicationwouldbebeneficial.

Precautionsregardingrope,ropeeyes,grips,andswivels.

Allmechanicalcomponentsaresubjecttowear.WorncomponentsdonothavethesameMaximumLoad

Limitratingasdonewcomponents.Thetotalresponsibilityfortheinspection,maintenance,lubrication,and

continueduseisentirelyuptothepurchaser/user.Remember,visualinspectionmaynotbesufficientand

examinationmethodssuchasX‐ray,ultrasonictesting,magneticparticleinspection,dielectricresistanceand

others,mightberequiredtoestablishthepresentintegrityoftheproduct.Externalfactorswillaffectthe

longevityoftheproduct.Thereisnodefinedtimeperiodfortheusefullifeofanyoftheseproducts.

Checktoseethatyourequipmentisbeinginspectedandtestedinaccordancewithallapplicable

governmentalrulesandregulationsandOriginalEquipmentManufacturer(OEM)guidance.Shouldany

productsbecomewornandinneedofrepair,theresponsibilityfortheactualrepairworkwillbebornesolely

bythepartymakingsuchrepairs.ItisrecommendedthattheOEMbecontactedshouldtherebeany

questionswhatsoeverrelatingtoarepair.

ContactinformationfortheOriginalEquipmentManufacturers(OEM)fortheperipheralequipment:grips,

swivels,wire,andrope‐providedwithSherman+Reilly™equipmentisprovidedatthebackofthismanual.

ThiscontactinformationisprovidedasacourtesybySherman+Reillyinanefforttokeependuserswell

informedofthemaintenanceandsafetyrequirementsforthisequipment.Forthelatestinformationonany

ofthisaccessoryequipmentcheckwiththeOriginalEquipmentManufacturer.

Safety

10

Pre‐TowingChecklist

1. ___Makecertaintowvehiclehasthecapacityandratingtotowmachinesafely.

2. ___Inspectpintleeyeforexcessivewear,corrosion,crackedweldsorstructuraldamage.Checkthebolts

holdingthepintleeyeinplace.

3. ___Inspecttowvehiclehitchandensurehitch.

4. ___Makesuretrailerbrakesareoperable.

5. ___Makesuretheunitissafefortowingwithtiresingoodconditionandproperlyinflated.

6. ___Makesuretherearenotools,objects,ortrashitemswhichcouldfalloffduringtransport

7. ___Chockwheelsonbothsidesofthemachine/unittrailer,thenstartmachine/unitengine‐

(SeeOperatorControlsandStart‐UpProcedure).

8. ___Makesuretherightandleftoutriggerjacksarefullyretracted

‐(SeeJackControls).

9. ___Openthetowvehiclehitchandbackvehicleintoposition.Settowvehicleparkingbrake.

10. ___Slowlyretracttrailertonguejacksothatthepintleeyerestscorrectlyinhitchstrikeplate.

11. ___Ensurethehitchissecured.Connectthesafetychains.Thesafetychainsshouldbecrossedandshort

enoughtopreventthetonguefromdiggingintotheground,shouldtheunitunintentionallybecome

disconnected.Thechainsshouldbenolongerthannecessarytoallowslackforturning–crossingthechains

providesdirectionalcontrol.

12. ___Afterthetrailerissecuredtothevehicle,stopthemachine/unitengine,andremovethekeyfromthe

ignitionkeyswitch.

13. ___Connecttheelectricalplugtothetowvehicleandcheck:

a. Clearancelights

b. BrakeLights

c. TurnSignals

d. Brakes

14. ___Removeandstorethewheelchocks.

15. ___Removevinyldrum/ropecoversbeforetransporting.

Note:Thesecoversarenottransportationcoversandshouldbehandledaccordingly.

Safety

11

IntheEventaFireOccurs

MostSherman+Reilly™equipmentcomesstandardwithafireextinguishermountedsomewhereonthe

equipmentforquickaccessbytheoperator.However,shouldafireoccurwithS+Requipment;theoperator

shouldonlyutilizetheprovidedfireextinguisher,iftrainedinitsuse,ifsafetodoso,ifinaccordancewith

employerpolicy,andinthesedescribedsituations:

a. Tosaveyourownlife,ifinjeopardyfromfire.

b. Tosavesomeoneelse’slife,ifinjeopardybecauseofafire‐butonlyifsafetodoso.

c. Toputoutsmallequipmentfirestoavoidfurtherdamagetoequipmentorpreventadangerousexplosion,

butonlyifsafetodoso.

TurnthestartingswitchtoOFFposition,andstoptheengineoruseoneoftheEmergencyStop

buttonstoshutdown.

Usethehandrailsandstepstoescapefromthemachine.

Donotjumpoffthemachine,unlessnecessarytoavoidelectricalshock;thereisthedangeroffalling,

whichcouldcauseseriouspersonalinjury.

Thefumesgeneratedbyafirecontainharmfulelementsthatareunhealthywheninhaled.Donot

breathethefumes.

CAUTION:Operatorsshouldexercisecautionwhenattemptingtoputoutfires,astheprovided

extinguisherisonlyintendedtosuppresssmalllocalizedfires,andisnotintendedtoputoutor“fight”

largescalefires,shouldoneoccur.

Withthepresenceofflammablefluidsandotheroperationalenvironmentfactors,evensmallfirescan

growoutofcontrolquickly‐operatorsmustmaintainawarenessofthesefactors.

Propertrainingmustalsobeprovidedbyemployerbeforeengaginginanyfirefightingefforts.Shoulda

fireoccurwithSherman+Reilly™equipment,theoperatorshouldnotusetheequipmentuntilithasbeen

inspectedforsafetyandapprovedtobereturnedtoservice‐regardlessofthesizeofthefire.

Safety

12

EmergencyStopProcedure

Intheeventofanemergency,theoperatormustbeawareofhowtoshutdownthemachinesoastoavoid

anyadditionalinjuriesorequipmentdamage.Intheseemergencysituations,thelivesoflineman,work

crews,surroundingbystanders,aswellastheoperatormaybecomeatrisk‐dependentupontheseverityof

thesituation.Asanoperatorinthesesituations,thelevelofoperatingknowledgeandproficiencycanbe

tested.Thesefactorsalonemakethisprocedureoneofthemostimportanttoknow.

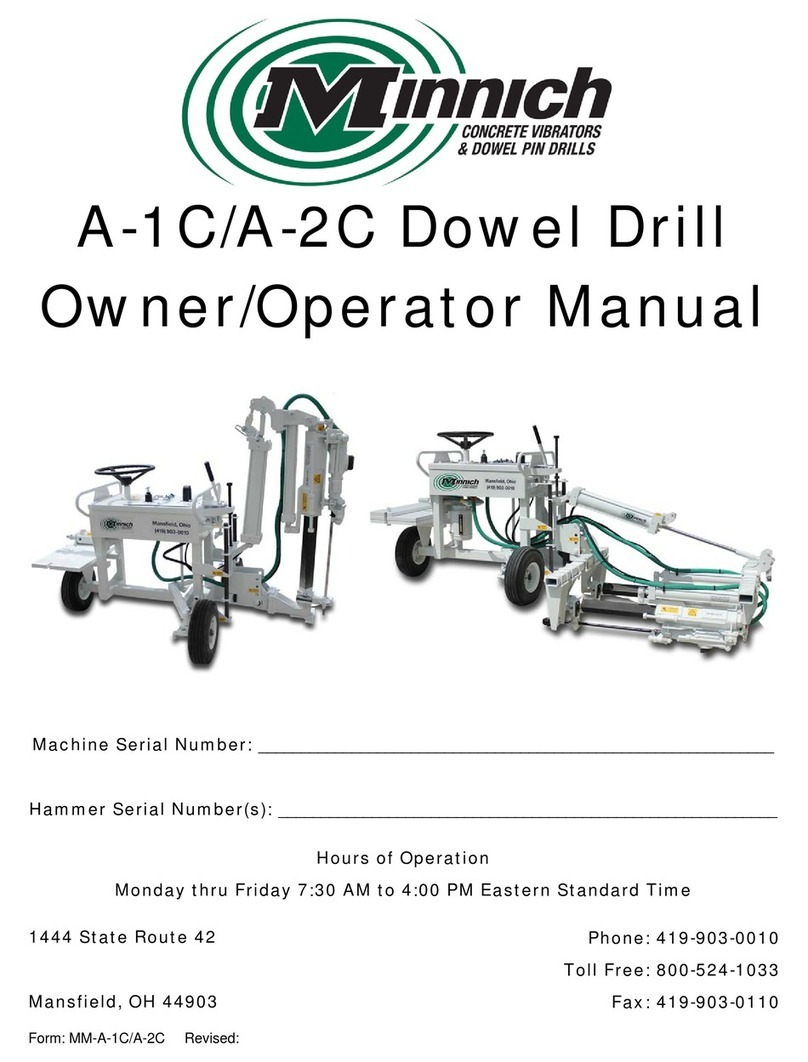

1. Thefirststepofanemergencyshutdownduringoperationsistode‐energize

thedrivesystem/engineandstopallequipmentrotationandpowerasquickly

aspossible.ThisisdonebypushingoneoftheinstalledEmergencyStop

Buttonslocatedonsidesofthemachineoronthecontrolpanel.Knowthe

locationoftheseE‐stopswitches.

2. IftheEmergencyStopButtonispushedduringoperationsandother

machines/operatorsarebeingutilizedintandemorsyncwithyourmachine,

notifythemasquicklyaspossiblethatanemergencyhasoccurredandadvise

tohaltrotations.

3. Quicklyassesssituationandassistanyinjuredpersonneltogetfreefrom

hazards‐onlyifsafetodoso.

4. Notifyproperauthoritiesandgethelp.

5. Followallemployeremergencyprocedures.

Safety

13

UnauthorizedModifications

Sherman+Reilly™willnotberesponsibleforanypersonalinjuries,productfailures,physicallossor

damage,orimpactstotheenvironmentresultingfrommodificationsmadewithoutwritten

authorizationfromSherman+Reilly™.

AnymodificationsmadewithoutwrittenauthorizationfromSherman+Reilly™cancreatehazards.

Beforemakinganymodifications,consultSherman+Reilly™.

AnymodificationsmadewithoutauthorizationfromSherman+Reilly™willvoidanywrittenor

impliedwarranty.

PrecautionsWhenRunningEngineInsideBuilding

Theengineexhaustgascontainssubstancesthatmaydamageyourhealthandevencausedeath.

Startoroperatetheengineinaplacewherethereisgoodventilation.Iftheengineormachinemust

beoperatedinsideabuildingorunderground,wheretheventilationispoor,takestepstoensurethat

theengineexhaustgasisremovedandthatamplefreshairisbroughtin.

InvestigateandConfirmJobsiteConditions

Onthejobsite,therecanbevarioushiddendangersthatmayleadtoseriouspersonalinjuryordeath.

Beforestartingoperations,alwayscheckthefollowingtoconfirmthatthereisnodangeronthe

jobsite:

Alwaysbecarefulwhenperformingoperationsnearmaterialssuchasshingledroofs,drytimber,dry

leaves,ordrygrassbecausetheyareeasilycombustibleandmaycausefire.

Checktheterrainandconditionofthegroundatthejobsite,anddeterminethesafestmethodof

operation.Donotoperateinadangerousareawherelandslidesorfallingrockmayoccur.

Ifwaterlines,gaslines,orhigh‐voltageelectricallinesmaybeburiedunderthejobsite,contactthe

appropriateauthoritytoidentifytheirlocations,andtakecarenottodamageanyoftheselines.

Inparticular,ifyouneedtooperateonanactiveright‐of‐way,protectpedestrianandcarsby

designatingapersonforjobsitetrafficdutyorbyinstallingfencesaroundthejobsite.

PrecautionsWhenWorkingonLooseGround

Avoidoperatingthemachineneartheedgeofcliffs,bluffs,roadedges,anddeepditches.Theground

maybeweakinsuchareas.Ifthegroundshouldcollapseundertheweightorvibrationofthe

machine,thereisahazardthatthemachinemayfallortipover.Rememberthatthesoilisweakin

theseareas,especiallyafterheavyrain,blasting,orearthquakes.

Whenworkingonembankmentsornearexcavatedditches,thereisahazardthattheweightand

vibrationofthemachinewillcausethesoiltocollapse.Beforestartingoperations,takestepsto

ensurethatthegroundissafeandtopreventthemachinefromrollingoverorfalling.

Safety

14

PositioningtheMachine

Thedriver/operatorshouldpositiontheunitinasuitablelocationwhereitwillbefreefromobstructionsand

clearofanyapparenthazards.Foroverheadpulling,theunitshouldbeapproximatelythreetimes(3X)the

distanceoftheleadblockheight.

Example:Iftheleadblockis40feethigh,itisrecommendedthattheunitbe

positionedapproximately120feetfromthebaseofthepolewheneverpossible.By

allowingthedistancetotheleadblockasspecified,thisreducesthedirectdownward

forcesthatwouldbecreatedother‐wise.Insomesituations,however,itmaynotbe

possibletoachievethesedistances.(seenotebelow).

Theunitshouldbeleveledasmuchaspossible,centeredontheleadblock,andparalleltothelinebeingpulled

priortobeginningoperations.

Theoperatormustchockthetrailerwheelspriortooperationsandanytimethevehicleisparked.All

appropriategrounding,anchoring,andprotectiveequipmentmustbeinstalledandsecuredtomachineprior

tooperations.

WARNING:DONOTOVERSTRESSTHEHITCHANDTRAILERTONGUE.Thetrailerframeisnot

designedtoliftorsupporttheweightofthepullingvehicle.Iftheunitistoremainconnectedtothe

towingvehicle,extremecautionshouldbetakentoassurethatthepintle‐eyehitchdoesnotliftthetowing

vehicleinconjunctionwithlevelingandliftingwiththetrailer’shydraulicjacks.Overloadingthepintle‐eye

hitchconnectionandtrailertonguecancausestructuraldamagetothetrailerframe.Sherman+Reillywill

notberesponsibletodamagetothetrailercausedbyverticalliftingstresscausedbydownwardforceson

thepintleeyeconnection.

CAUTION:Alljacksshouldbeextendedforstabilization,andthemachinemustbeleveledpriorto

conductingoperations.

NOTE:Insomesituations,(i.e.,duetoroughterrain),itmaynotbepossibletoachievesafedistancesfrom

theleadblock.Insuchsituations,operatorsshouldestablishasmuchdistanceaspossiblefromthelead

blockandremainawareoftheincreaseddownforcesduringoperations.

Other manuals for Revolution Series

1

This manual suits for next models

1

Table of contents

Popular Construction Equipment manuals by other brands

felton industries

felton industries SELG4T4R Assembling instructions

Tadano

Tadano GR-1600XL-2 Service manual

GÜDE

GÜDE GPR 800 E Translation of the original instructions

Portable Winch

Portable Winch 600MH user guide

Minnich

Minnich A-1C-48 Owner's/operator's manual

Haufftechnik

Haufftechnik HSI150 DFK installation instructions