2

Assembly / Disassembly Instructions (continued)

E. Press the mechanical seal seat (15) into the housing with the white ceramic seal face or gray silicon carbide face toward the

impeller. Lubricate the outside of the seat boot with a water soluble lubricant or soapy water for easier assembly. Oil or grease

must not be used as it will prevent the rubber cup assembly from properly gripping the housing. The seat should be inspected

to ensue that the cup did not become partially dislodged during the assembly procedure.

F. Slide the housing over the shaft and body assembly. Fasten the three bolts (12) and torque them to 25 ft-lbs.

G. When applicable replace the drive gear assembly. Slide the thrust washer (20) onto the outer bearing. Place the key (19) in the

shaft, then slide the gear (16) on the shaft. Replace the washer (18) then tighten the nut (17) onto the shaft. While supporting

the drive gear, torque the nut to 270 ft-lbs.

H. Lubricate the inter rubber portion of the mechanical seal (11) with a water soluble lubricant or soapy water and slide the seal

onto the shaft, with the carbon or silicon carbide portion of the mechanical seal toward the seal seat. Oil or grease must not be

used as it will prevent the mechanical seal from properly gripping the shaft.

I. Place the washer (10) onto the shaft and against the mechanical seal (see below to identify the proper washer) and then using

external snap ring pliers, install the retaining ring (9) into the groove in the shaft to compress the mechanical seal.

Seal Washer Selection

When replacing the mechanical seal, it is necessary to ensure the proper seal washer is used to avoid damage to the pump. It is

recommended that all pumps be upgraded with the silicon carbide mechanical seal 23837, except for pump number G1810, which

can only be fitted with the 23512 seal. Use the following to determine which washer to use:

• When using the silicon carbide mechanical seal 23837 for replacement, determine the proper spacer to use from the chart

below. Silicon carbide is characterized by the charcoal gray colored seal and seat faces, as opposed to carbon on ceramic,

which would be black on white.

• Exceptions to the chart

oIf the pump is to be fitted with the new shaft and bearing assembly listed on the chart on page 3 (24000, 24001, 24002,

and 24003), use the 19866 washer. These shaft and bearing assemblies can only be used with the 23837 silicon

carbide mechanical seals.

oReplacement of the seal with the carbon on ceramic mechanical seal 19878 can only be performed on older units with

the original shaft and bearing assemblies still in place. Use the 19866 spacer in such cases. Use of the 19878 seal with

the current production units (G18061-01, G18071-01, and G18081-01) or with older units fitted with the new shaft and

bearing assemblies will cause damage to the pump.

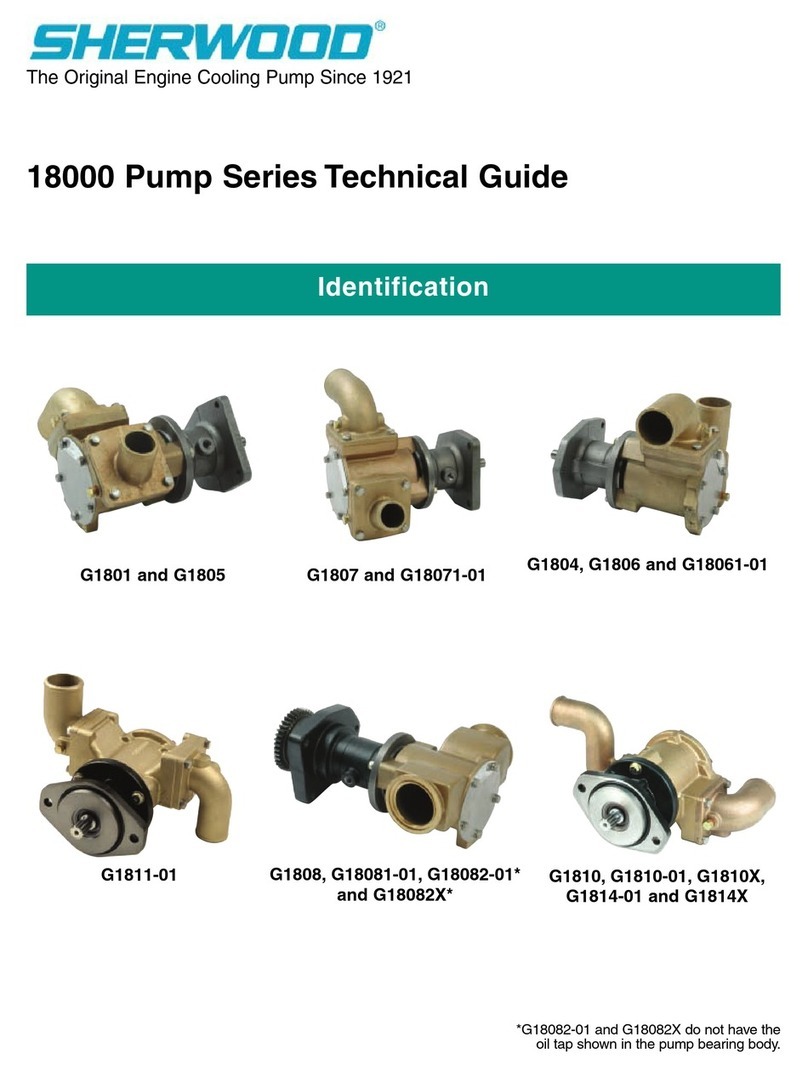

Pump Number 23837 Seal

Spacer Number *

G1801 23840

G1804 23840

G1805 23840

G1806 23840

G18061-01 19866

G1807 23840

G18071-01 19866

G1808 23840

G18081-01 19866

G1810 N/A

* Note: the 19866 spacer is .060" thick and the 23840 is .260" thick.

J. Install the wearplate (7) with the hole in the plate lined up with the slot in the housing. Install the quad ring (4) into the housing

and on top of the wearplate.

K. Create the cam assembly by connecting the cam halves (6) together and installing the pin (8) into the cam liner. A dab of

grease can be used to hold the pin in place during installation. Place the cam assembly into the housing, ensuring that the pin

aligns with the slot in the housing.

L. Insert the impeller (5) in the housing using a twisting motion. Ensure that the impeller blades are bent in the same direction as

upon removal (dependent on the pump model – see illustration on page 3 for details). For ease of installation apply a silicon

lubricant to the impeller. Caution: DO NOT USE A PETROLEUM BASED LUBRICANT (petroleum product will cause damage

to the impeller).

Note: if the pump is fitted with a silicon carbide seal,

it must be replaced with the 23837 silicon carbide

seal to prevent damage.