Shield SD1010 User manual

6www.shieldglobal.com

MODEL: SD1010, SD1015, SD1030, SD1032

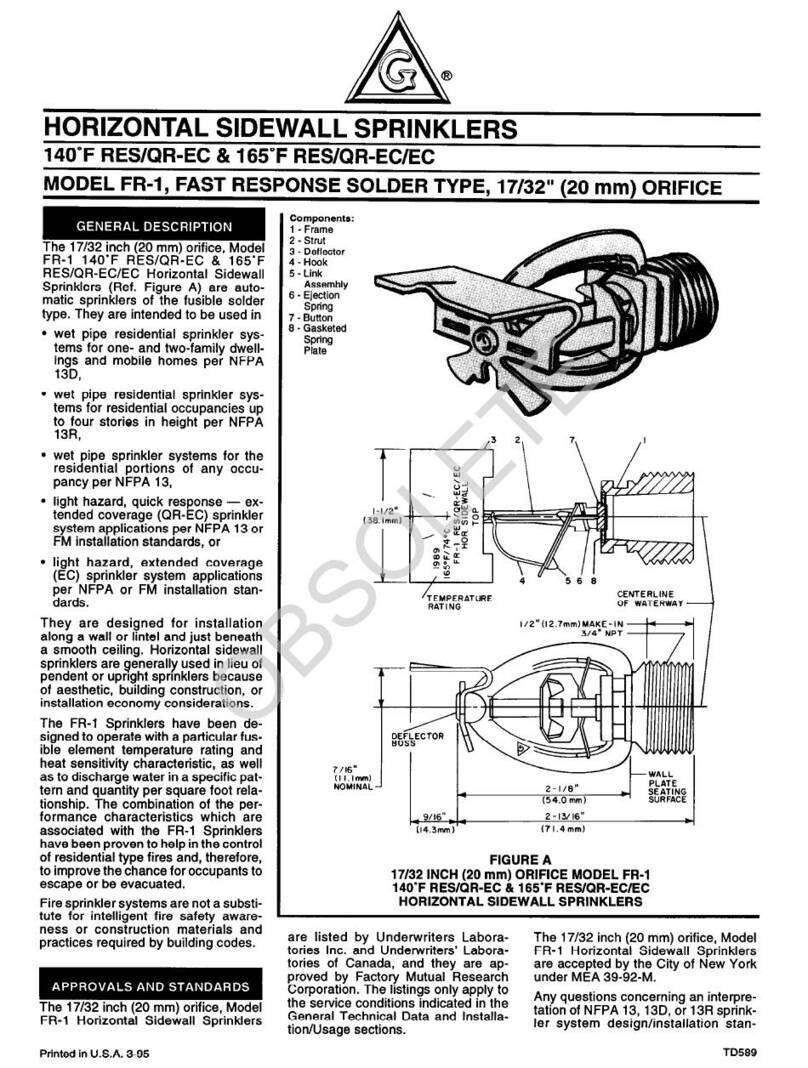

DESCRIPTION

The SHIELD Sprinklers, SD1010, SD1015, SD1030, SD1032

(Glass Bulb Type), Standard Orice, Upright, Pendent and

Recessed Pendent type, design incorporates state-of-the-art,

heat responsive, frangible glass bulb design (standard or quick

response) for prompt, precise operation.

The die cast frame is more streamlined and attractive than

traditional sand cast frames. It is cast with a hex-shaped wrench

boss to allow easy tightening from many angles, reducing assembly

effort. This sprinkler is available in various temperature ratings

and nishes to meet many design requirements. The recessed

pendent should be utilized with a recessed escutcheon which

provides up �” of adjustments. All Sprinklers are manufactured

using the time proven Belleville seal used exclusively by all major

manufactures to ensure long life and safe operation.

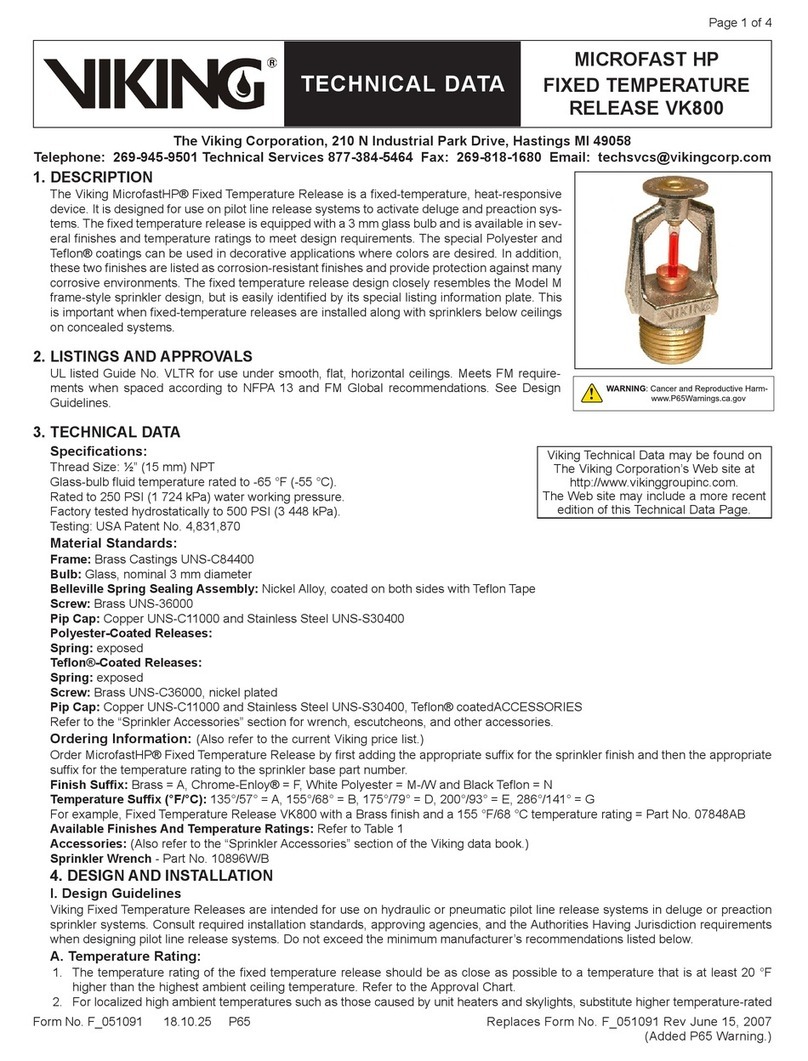

SPRINKLER OPERATION

The operating mechanism is a frangible glass bulb which contains

a heat responsive liquid. During a re, the ambient temperature

rises causing the liquid in the bulb to expand. When the ambient

temperature reaches the rated temperature of the sprinkler, the

bulb shatters. As a result, the waterway is cleared of all sealing

parts and water is discharged towards the deector. The deector

is designed to distribute the water in a pattern that is most

effective in controlling the re.

MAXIMUM COVERAGE

Standard spray coverage is up to: Light Hazard = 225 square

feet(20.9 sq.m); Ordinary Hazard = 130 square feet(12.1 sq.m) per

NFPA 13.

TECHNICAL SPECIFICATION

RATINGS

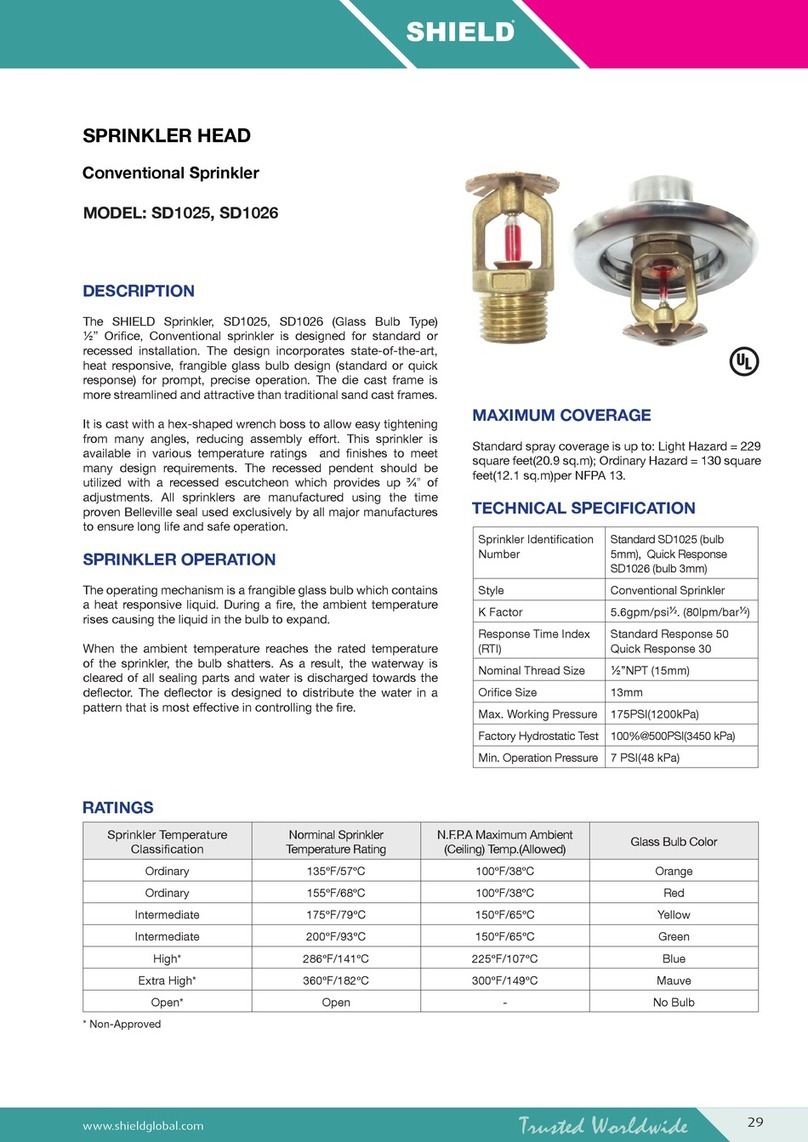

SPRINKLER HEAD

Upright, Pendent & Recessed Pendent Sprinklers

Sprinkler Identication

Number

Standard SD1015, SD1010

(bulb 5mm), Quick Response

SD1030, SD1032 (bulb 3mm)

Style Upright Sprinkler SD1015,

SD1032, Pendent &

Recessed Pendent

SD1010, SD1030

K Factor 5.6gpm/psi½. (80lpm/bar½)

Response Time Index

(RTI)

Standard 50

Quick Response 30

Nominal Thread Size ½”NPT(15mm)

Orce Size 13mm

Max. Working Pressure 175PSI(1200kPa)

Factory Hydrostatic Test 100%@500PSI(3450 kPa)

Min. Operation Pressure 7 PSI(48 kPa)

Sprinkler Temperature

Classication

Norminal Sprinkler

Temperature Rating

N.F.P.A Maximum Ambient

(Ceiling) Temp.(Allowed) Glass Bulb Color

Ordinary** 155ºF/57ºC 100ºF/38ºC Orange

Ordinary 155ºF/68ºC 100ºF/38ºC Red

Intermediate 175ºF/79ºC 150ºF/65ºC Yellow

Intermediate 200ºF/93ºC 150ºF/65ºC Green

High* 286ºF/141ºC 225ºF/107ºC Blue

Extra High* 360ºF/182ºC 300ºF/149ºC Mauve

Open* Open - No Bulb

* Non-Approved

**UL Listed only.

7

www.shieldglobal.com

PART LIST

DISCHARGE CURVE

SD1015 SD1010 SD1030 SD1032

1. Frame 2. Deector 3. Cap 4. Cap Seat 5. Load Screw 6. Seal 7. Bulb

8www.shieldglobal.com

WARNINGS

The SHIELD sprinklers must be installed and maintained

in compliance with this document. Depressurize and drain

the piping system before attempting to install, remove,

or adjust any Sprinklers. Failure to do so may impair the

performance of these sprinklers. The owner is responsible

for maintaining the re protection system and devices in

operation.

WRENCH DESCRIPTION

The Sprinkler Wrench is a tool specically designed for

installing SHIELD Sprinklers. These special wrenches must

be used to provide the proper leverage when tightening

the sprinkler and to minimize slippage during installation.

Any other wrench may damage the sprinkler.

INSTALLATION

All SHIELD Sprinklers must be installed according to

NFPA 13 Standards. Deviations from these requirements

and standards or any alteration to the sprinkler itself will

void any warranty made by manufacturer. In addition,

installation must also meet local government provisions,

codes and standards as applicable.

The system piping must be properly sized to insure the

minimum required ow rate at the sprinkler. Check for the

proper model, style, orice size and temperature rating

prior to installation. Install sprinklers after the piping is in

place to avoid mechanical damage, replace any damaged

units. Wet pipe systems must be protected from freezing.

Upon completion of the installation, the system must be

tested per recognized standards .In the event of a thread

task, remove the unit, apply new pipe joint compound or

tape, and reinstall.

ADDITIONAL

Recessed Sprinkler - To install the escutcheon plate,

align with it and push or thread over the sprinkler body

into the upper support piece, until the outer edge of the

escutcheon meets the mounting surface.

INSTALLATION SEQUENCE

Step 1 - The unit must be installed in the upright position for

the Upright Sprinklers, and in the Pendent position for the

Pendent Sprinkler, Pendent Recessed Sprinkler.

Step 2 - Use only a non-hardening pipe joint compound or

tape seal. Apply only to the male threads.

Step 3 - Hand tighten the sprinkler into tting.

Step 4 - For Upright and Pendent Sprinklers, use a

standard wrench. Tighten the unit into the tting. A lead-tight

joint requires only 7 to 14ft.lbs (9.5 to 19.0Nm) of torque. A

tangential force of 14 to 28 ft.lbs (62.3 to 124.5N) delivered

through a 6”(150mm) handle will deliver adequate torque.

Once torque level reach over 21ft.lbs (28.6Nm) it may

distort the orice seal, resulting in leakage. For exposed

piping systems, the sprinkler should be oriented so the

frame arms are parallel with the branch line pipe.

CAUTION

Do not over-tighten or under-tighten the sprinkler to

compensate for inaccurate escutcheon plate adjustment.

Protection clips are used to protect its bulb. Please have

clip on at all times during transportation.

MAINTENANCE

Sprinklers must never be altered after manufacture. Any

alteration such as painting and coating will directly harm

the sprinkler and cause malfunctions.

Sprinkler in contact with corrosive products should be

replaced if they cannot be cleaned completely.

Visual inspections are recommended after installation.

After installation, a close-up inspection annually will

sufce.

Inspection and maintenance of re protection system is

the responsibility of the owner. It is recommended that

automatic sprinkler system be inspected and tested

according to local and/or national regulations.

Sprinkler Wrench

9

www.shieldglobal.com

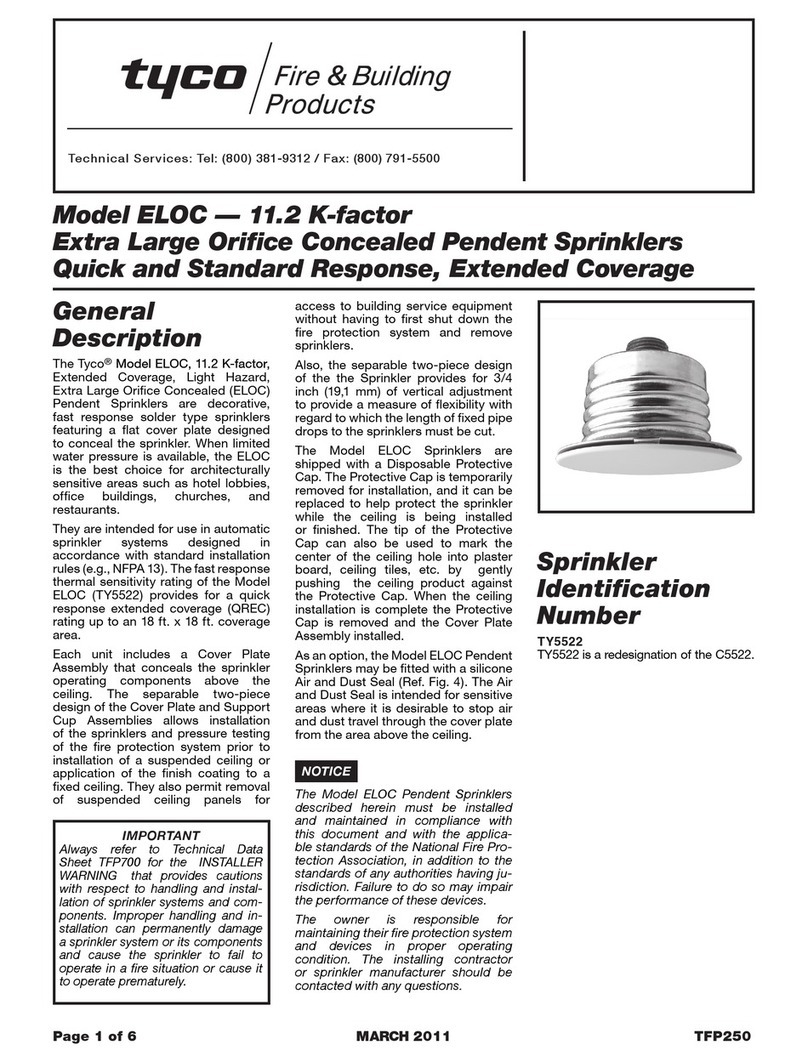

DISTRIBUTION PATTERNS

K5.6 PENDENT SPRINKLER

DISTRIBUTION PATTERNS - TRAJECTORY

K5.6 UPRIGHT SPRINKLER

DISTRIBUTION PATTERNS - TRAJECTORY

10 www.shieldglobal.com

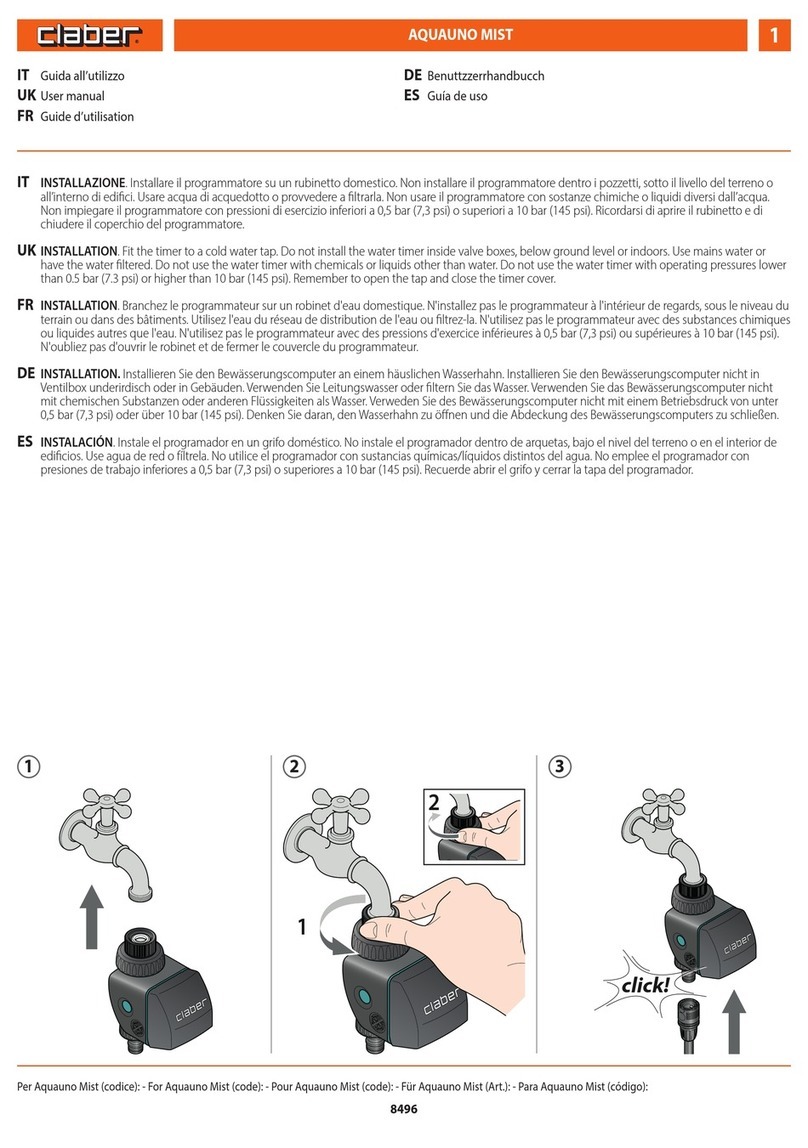

DIMENSIONS

UPRIGHT SPRINKLER PENDENT SPRINKLER

RECESSED PENDENT SPRINKLER

Maximum Extension Maximum Recess

Other manuals for SD1010

1

This manual suits for next models

3

Table of contents

Other Shield Irrigation System manuals