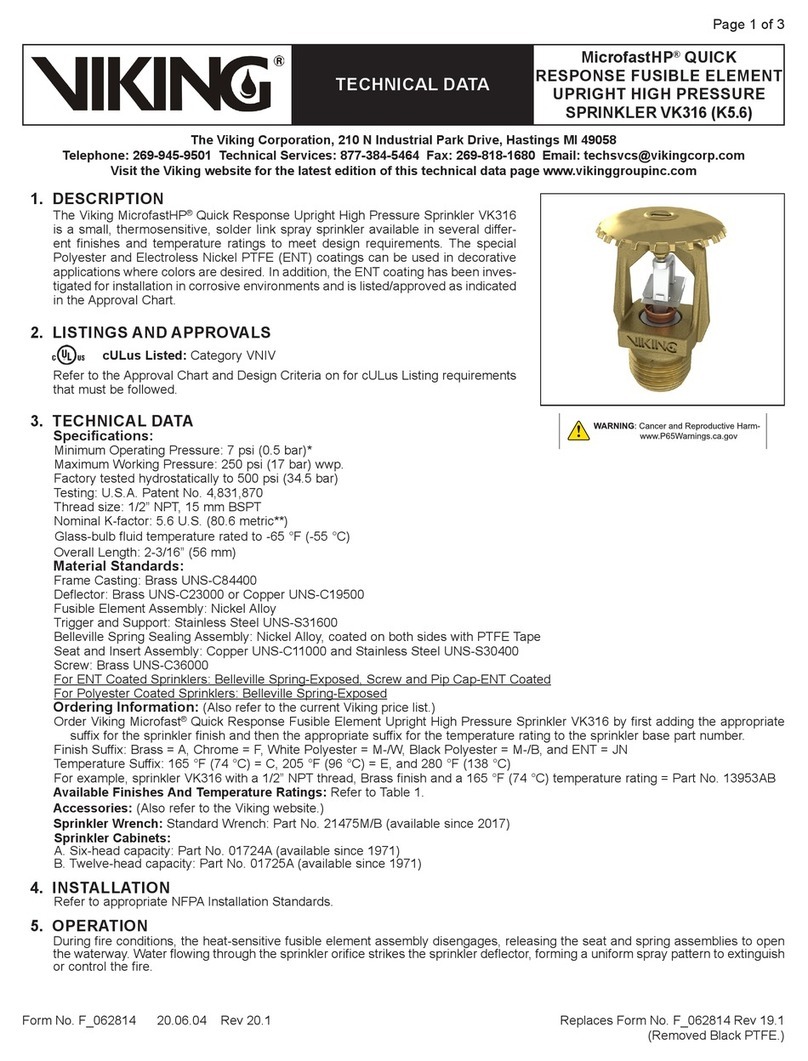

TECHNICAL DATA

The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058

T

elephone:

269-945-9501

T

echnical

Services:

877-384-5464

Fax:

269-818-1680

Email:

[email protected]FREEDOM®RESIDENTIAL

SPRINKLER

INSTALLATION GUIDE

Form No. F_080190 18.10.25 Rev 16.1.P65

DESIGN CRITERIA

For Systems Designed to NFPA 13D or NFPA 13R: Apply the listed areas of coverage and minimum water supply requirements shown in

the approval charts on the residential sprinkler data pages. The sprinkler flow rate is the minimum required discharge from each of the total

number of design sprinklers as specified in NFPA 13D or NFPA 13R.

For Systems Designed to the latest edition of NFPA 13: The number of design sprinklers is to be the four most hydraulically demanding

sprinklers. The minimum required discharge from each of the four sprinklers is to be the greater of the following:

• The flow rates given in the approval charts on the data pages for NFPA 13D and NFPA13R for each area of coverage listed, or

• Calculated based on a minimum discharge of 0.1 gpm/sq. ft. over the “design area” in accordance with sections 8.5.2.1 or 8.6.2.1.2 of NFPA 13.

The greatest dimension of the coverage area cannot be any greater than the maximum areas of coverage shown on the data pages.

Flow Rates

All residential sprinklers manufactured on or after July 12, 2002 are listed with a single minimum flow rate. Where rooms have more than one sprinkler,

multiple-sprinkler calculations are still required, but the first sprinkler and any additional sprinkler or sprinklers must be calculated flowing at identical mini-

mum flow rates, based on the area of sprinkler coverage, using the minimum flow and pressure listed for the sprinkler model used.

Consult the appropriate standards and the Authorities Having Jurisdiction to determine the number of sprinklers to hydraulically calculate to verify ad-

equate water supply for multiple-sprinkler operation.

Operating Pressure: The minimum operating pressure of any sprinkler shall be the minimum operating pressure specified by the listing, or 7 psi (0.5

bar), whichever is greater. The maximum allowable operating pressure is 175 psi (12 bar).

Areas of Coverage

If the actual area of coverage is less than the listed area of coverage, use the minimum water supply for the next larger area of coverage listed. DO NOT

interpolate. Residential sprinkler systems must be hydraulically calculated according to NFPA standards to verify that the water supply is adequate for

proper operation of the sprinklers. Hydraulic calculations are required to verify adequate water supply at the hydraulically most remote single sprinkler

when it is operating at the minimum gpm and psi listed for single-sprinkler operation for the sprinkler model used.

Viking residential sprinklers may be listed for more than one area of coverage. Suggested practice in selecting area of coverage is to select the one

that can be adequately supplied by the available water supply and still allow for the installation of as few sprinklers in a compartment as possible while

observing all guidelines pertaining to obstructions and spacing. This maximizes the use of the available water supply, which is often limited on residential

fire protection systems. After selecting an appropriate area of coverage, sprinklers must be spaced according to guidelines set forth in the installation

standards.

Definition of “COMPARTMENT”: A space completely enclosed by walls and a ceiling. Openings to an adjoining space are allowed, provided the open-

ings have a minimum lintel depth of 8 in. (203.2 mm) from the ceiling.

Spacing Guidelines

For guidelines concerning spacing of Viking residential sprinklers near beams, obstructions, heat sources, and sloped ceilings [slopes more than a

2/12 (9.5°) pitch], refer to the Viking residential sprinkler data pages and installation guide, the appropriate NFPA standard, and the Authority Having

Jurisdiction. NOTE: Sloped, beamed, and pitched ceilings could require special design features such as larger flow, or a design for more sprinklers to

operate in the compartment, or both.

Distance from Walls: Install not more than one-half the listed sprinkler spacing nor less than 4” (102 mm) from walls, partitions, or obstructions as

defined in the standards.

Minimum Sprinkler Spacing: The minimum distance between residential sprinklers to prevent cold soldering (i.e., the spray from one operating sprink-

ler onto an adjacent sprinkler that could prevent its proper activation) is 8 ft. (2.4 m).

Maximum Sprinkler Spacing: Locate adjacent sprinklers no farther apart than the listed spacing.

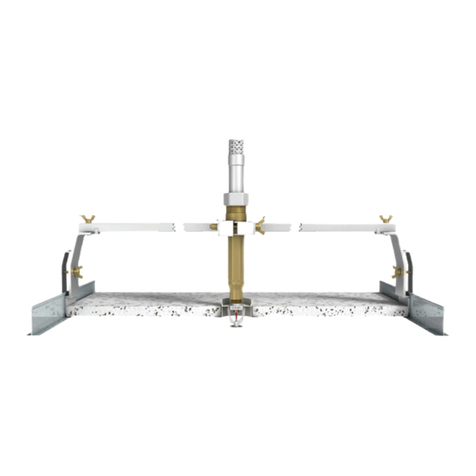

Deflector Position: Install frame style residential pendent sprinklers with the deflector between 1” and 4” (25.4 mm to 102 mm) below smooth ceilings,

unless the sprinkler data page indicates otherwise. Install pendent sprinklers in the pendent position only, with the deflector oriented parallel with the ceiling

or roof.

Refer to the individual listings in the residential sprinkler data pages for horizontal sidewall sprinkler deflector or sprinkler centerline distance below

the ceiling. Install horizontal sidewall sprinklers in the horizontal position only below smooth ceilings, with the leading edge of the deflector or element

assembly oriented parallel with the ceiling.

IMPORTANT: Always refer to Bulletin Form No. F_091699 - Care and Handling of Sprinklers. Also refer to the ap-

propriate sprinkler data page. Viking sprinklers are to be installed in accordance with the latest edition of Viking

technical data, the appropriate standards of NFPA and any other similar Authorities Having Jurisdiction, and also

with the provisions of governmental codes, ordinances, and standards, whenever applicable. Final approval and

acceptance of all residential sprinkler installations must be obtained from the Authorities Having Jurisdiction.

Sprinkler RES3