When used in residential applications,

per NFPA 13, 130 or 13R, the 17132

inch (20 mm) orifice, Model FR-1 Hor-

izontal Sidewall Sprinklers must only

be installed and utilized in accordance

with the following described criteria

which are provided by the manufac-

turer.

These restrictions relate to

the general service conditions nec-

essary to sprinkler performance and

integrity,

the minimum amount of water which

must be discharged from an operat-

ing sprinkler,

the maximum area which can be

covered by the spray from an oper-

ating sprinkler,

installation requirements necessary

to the proper operational sensitivity

of the sprinklers,

preventing the wetting (i.e., cold sol-

dering) of the fusible Link Assembly

of a non-operated sprinkler, which is

adjacent tdone which has operated,

and

preventing the weakening followed

by the possible release of a

sprinkler’s fusible Link Assembly,

due to exposure to heat sources

other than abnormal fire.

NOTES

1.Residential Fire Sprinkler Sys-

tems should only be designed

and installed by those compe-

tent and completely familiar

with automatic sprinkler sys-

tem design, installation proce-

dures, and techniques.

2. Several criteria may apply to

the installation and usage of

each sprinklec Consequently,

it is recommended that the

sprinkler system designer re-

view and develop a working un-

derstanding of the complete

list of criteria, prior to initiat-

ing the design of the sprinkler

system.

3. Questions concerning sprink-

ler installation and usage cri-

teria, which are not covered by

the following instructions,

should be mailed to the atten-

tion of the Technical Data De-

partment. Include sketches

and technical details, as ap-

propriate.

4. In some instances, the require-

ments of this document may

concern specifications which

are more stringent and which

take precedence over those

specified in NFPA 13, NFPA

130, NFPA 13R, or by the au-

thority having jurisdiction.

General Service Conditions

When used in residential applications,

the FR-1 Sprinklers must only be in-

stalled and utilized

1. in wet pipe automatic sprinkler sys-

tems,

2. within residential portions of any oc-

cupancy per NFPA 13, within resi-

dential “Dwelling Units” per NFPA

13D, or within residential occupan-

cies per NFPA 13R.

3. at a maximum service pressure of

175 psi (12,l bar),

4. at a maximum ambient temperature

of 1OO’Fl38’C.

5. with all interconnecting system pip-

ing, as well as sprinklers maintained

at a minimum temperature of

4O’F/4’C, and

6. with water supplies which are sub-

stantially free of contaminants and

particles of a size greater than l/8

inch (3,2mm),

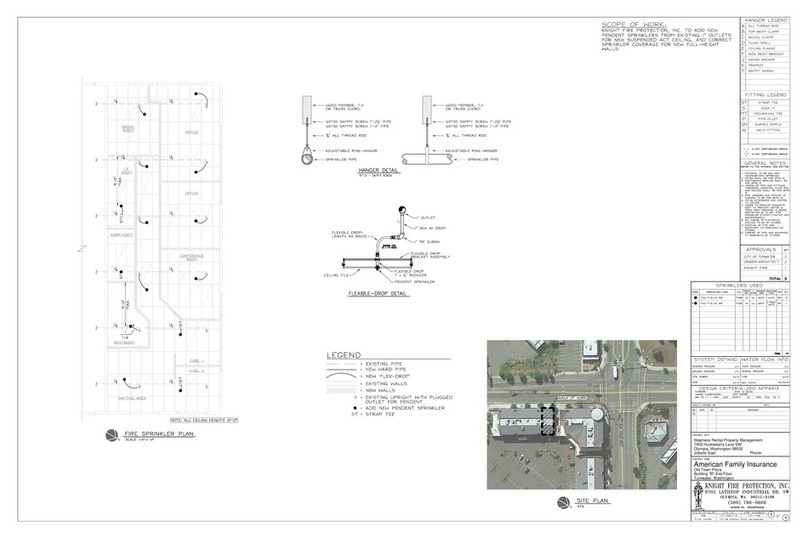

Hydraulic Design Criteria

The minimum required single and mul-

tiple sprinkler flow rates are given in

Table A-l as a function of the maxi-

mum allowable coverage areas. The

single sprinkler flow rate is the mini-

mum required discharge from the most

hydraulically demanding single sprink-

ler and, the multiple sprinkler flow rate

is the minimum required discharge

from each of the total number of “de-

sign sprinklers” (as specified in NFPA

13, 13D, or 13R).

NOTE

The number of sprinklers within

each compartment (as defined by

NFPA 13,130, or 13R), must be as

few as possible. Do NOT use more

sprinklers than necessary to

cover a particular space.

Spray Coverage Criteria

Each FR-1 Sprinkler must only be

used in accordance with one of the

designated width by length (W x L)

coverage criteria specified in Table

A-l. The nominal wetting pattern for

FR-1 Sprinklers at minimum required

multiple sprinkler flow conditions for a

16’ x 20’ (4,9 m x 6,1 m) coverage area

is illustrated in figure E.

Ceiling mounted obstructions such as

heating or air conditioning diffusers,

overhangs, and light fixtures must be

located above an elevation, as shown

in Figure F, where they will not inter-

fere with the proper distribution of

water by the sprinkler.

FR-1 Sprinklers may be installed along

overhangs or soffits that are a maxi-

mum of 6 inches (152 mm) wide (dis-

tance from wall) and, with a maximum

distance of 6 inches (152 mm) from the

centerline of the sprinkler waterway to

the bottom of the overhang/soffit.

NOTES

When installed along overhangs

or so#its, the deflector-to-mount-

ing surface distance must be a

minimum of 2 inches (51 mm) and

a maximum of 3 inches (76 mm)

(Ret: Figure B-l).

Use of overhangs and soffits

wider than 6 inches (152 mm) is

permitted if additional sprinkler

protection is provided for the

area below the overhanglsoffit.

The FR-1 Sprinklers must NOT be lo-

cated

a. along a wall/partition having a re-

cessed range oven, countertop, or

alcove,

b. along a wall/partition having an ad-

joining wood or coal burning stove,

or

c. along a wall/partition containing a

fireplace or wall oven.

NOTE

The spray from the FR-1 is distrib-

uted radially outward from the

sprinkler deflector. Sprinklers

must be located such that there

will NOT be any blind spaces

shielded from spray by partitions

or a portion of the dwelling struc-

ture.

Operational Sensitivity Criteria

The FR-1 Sprinklers must only be in-

stalled

1.

2.

3.

4.

5.

beneath level ceilings,

beneath solid ceilings having a

smooth or textured surface,

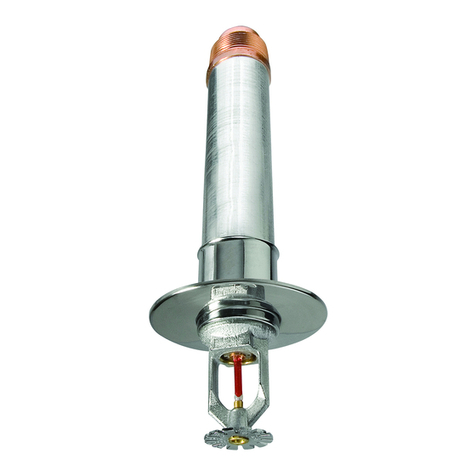

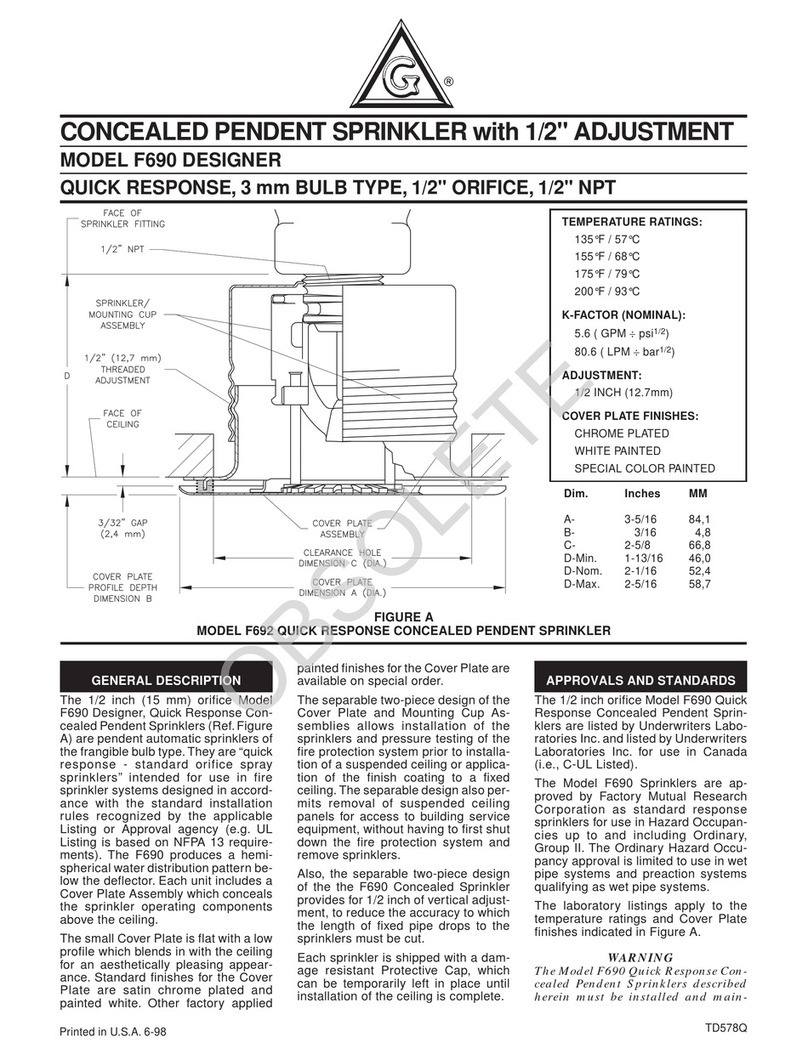

with a deflector-to-mounting surface

distance of 2 to 6 inches (51 to 152

mm) for wall mounting and 2 to 3

inches (51 to 76 mm) for soffit

mounting (Ref. Figure B-l),

with a deflector to ceiling distance of

4 to 8 inches (100 to 200 mm) (Ref.

Table A-l), and

at least 4 inches (102 mm) away

from an inside or outside corner.

The FR-1 Sprinklers must NOT be

used

a. beneath soff its,

b. above or below open-gridded type

suspended ceilings, or

c. with beams, joists, or ducts located

within the sprinkler coverage areas.

NOTE

Beams, joists, or ducts may be lo-

cated with their centerlines along

the boundaries separating ac(ja-

cent sprinkler coverage areas.

It is recommended that as part of the

sprinkler system design, the designer

review the dwelling plans and, where

appropriate, advise the owner or his

representative as to the following.

I. Lintels of at least 5 inches (127 mm)

in height and preferably 8 inches

(203 mm) should be used over all

passageways from one space to an-

other, in order to reduce the possibil-

ityof sprinkler operations outside the

fire area.