The Reliable Automatic Sprinkler Co., Inc., 103 Fairview Park Drive, Elmsford, New York 10523

Model G6-80

Concealed Quick Response

Extended Coverage Light Hazard

Horizontal Sidewall Sprinkler

(SIN RA4762)

Bulletin 047

Bulletin 047

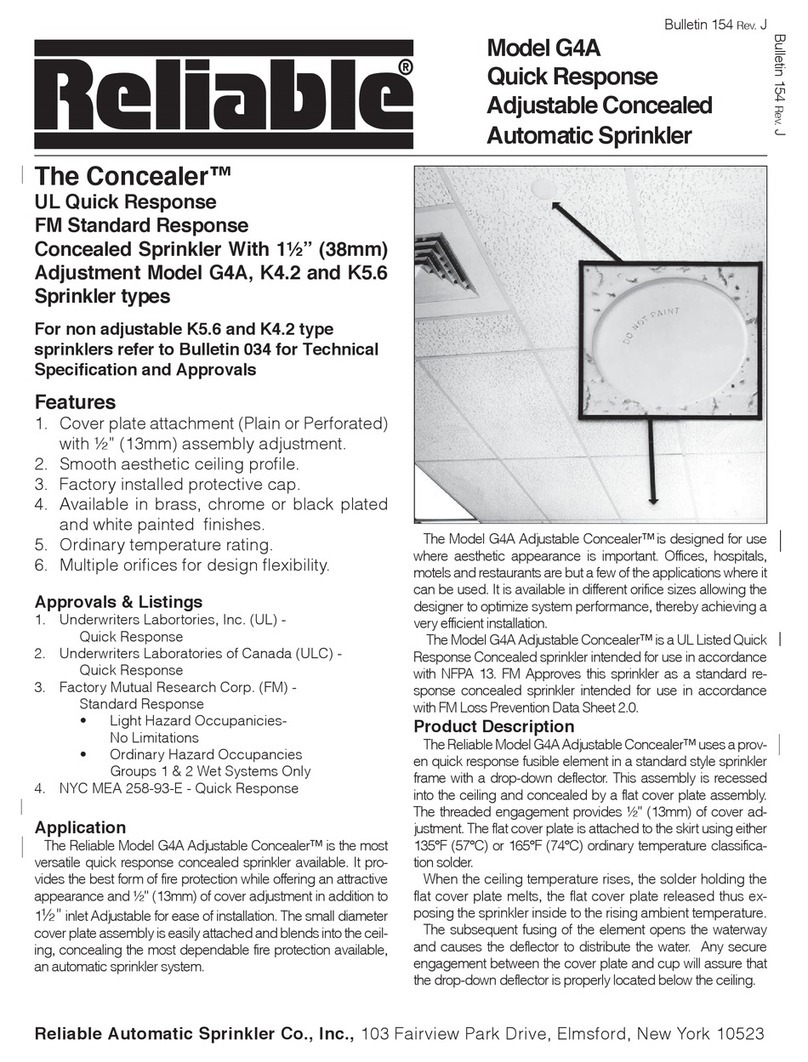

The Sidewall Concealer®

Coverage to 18 ft. x 22 ft. (5.5m x 6.7m),

16 ft. x 24 ft. (4.9m x 7.3m).

175 psi (12,0 bar) Rated.

Features:

1. Flat cover plate (Solid or Perforated) for optimized

finish mounting purposes.

2. 8.0 K Factor.

3. Sprinkler is approved for 175 psi (12,0 bar)

applications.

4. Quick response, extended coverage light hazard

Horizontal Sidewall.

5. Push-on/pull-off, sturdy convenient flat cover plate.

6. Sprinkler, shipped complete with factory installed

protective cap.

7. Sprinkler assembly and cover plate packaged

separately.

8. ¼” (6.3mm) adjustment.

9. Cover plate available in chrome, standard white

paint, special bronze, black paint or flat white

finishes.

Approval Organizations

1. Listed by Underwriters Laboratories Inc. and

UL certified for Canada (cULus).

Patents:

U.S. Patent No. 6,374,919, other Patents pending

Product Description

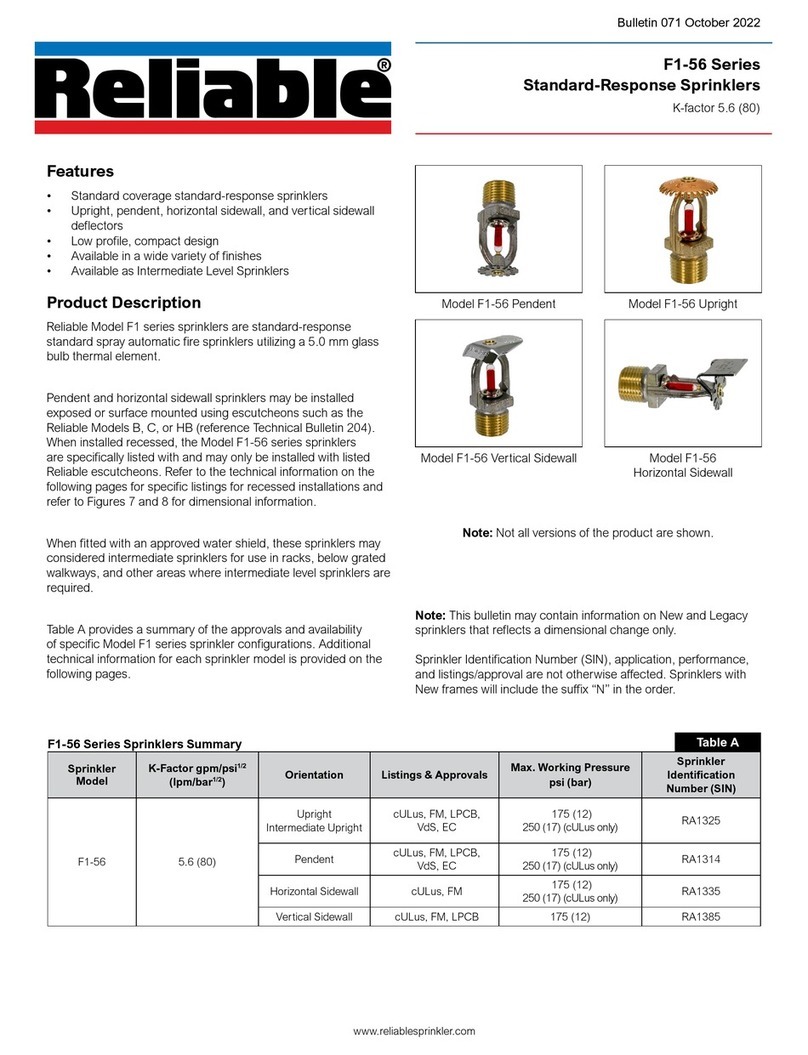

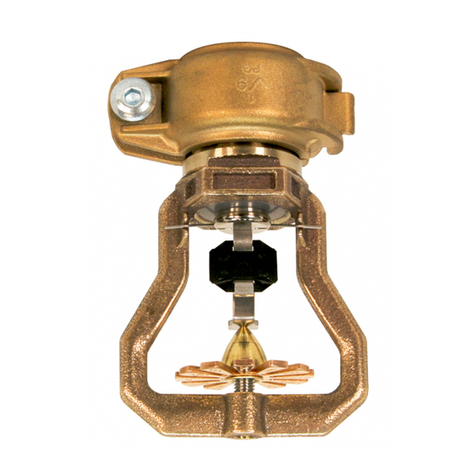

The Reliable Model G6-80 Concealed Quick Response

Extended Coverage Horizontal Sidewall Sprinkler is an at-

tractive, concealed sprinkler assembly that utilizes a push-

on/pull-off cover plate assembly. The sprinkler assembly is

shipped with a protective cap.

The flat cover plate is attached to the skirt using 135°F

(57°C) ordinary temperature classification solder. The sprin-

kler is easily installed into the sprinkler fitting using the Model

G6 Sprinkler Wrench.

When the ambient temperature rises, the solder holding

the cover plate melts, allowing the release of this part and

thus exposing the sprinkler inside to the rising ambient tem-

perature.

The Model G6-80 utilizes a Quick Response soldered link.

This quick response enables the sprinkler to apply water to a

fire sooner than standard sprinklers of the same temperature

rating.

This sprinkler is listed for a maximum service pressure of

175 psi (12,0 bar).

Application and Installation

The Model G6-80 sprinkler is intended for installation in

light hazard occupancies in accordance with NFPA 13. This

sprinkler is especially well-suited for use in student dormito-

ries, hotels, hospitals and care facilities.

Model G6-80 Concealed Horizontal Sidewall sprinklers

utilize a sprinkler assembly with spring loaded deployable

deflector feature. The assembly is completed by the instal-

lation of the attractive, 135°F (57°C) push-on/pull-off cover

plate assembly, which provides ¼” (6.3mm) of adjustment.

Apply a Teflon* - based thread sealant to the sprinkler

threads. After a 2 5/8” (66.7mm) diameter hole is cut in the

wall, the sprinkler is easily installed and properly oriented

with the Model G6 Wrench, as follows:

Do not remove factory installed plastic protective cap since

it is sized to fit inside the G6 wrench. Note that the sprinkler

can only mate when the sprinkler’s deflector orientation tab

(Fig. 1) is aligned with wrench’s key-way. G6 wrench is pro-

vided with bubble level pad and TOP marking, features that

assure proper orientation of the internally retained horizontal

sidewall deflector. Final leveling can be done after leak proof

joint is obtained with a minimum to maximum torque of 10 to

20 ft-lbs (13,4 to 26,8 N.m). Do not attempt to compensate

for improper rough in dimensions of fitting by over tighten-

ing the sprinkler assembly, but readjust the sprinkler fitting

instead. Leave the protective cap on to assure sprinkler pro-

tection while the wall is plastered, wallpapered or painted.

Concealed cover plate/cup assemblies are listed only for

use with specific sprinklers. The use of any other concealed

cover plate/cup assembly with the Model G6-80 Horizontal

Sidewall Sprinkler or the use of this dedicated concealed

cover plate assembly on any sprinkler with which it is not

specifically listed will void all guarantees, warranties, listings

and approvals.

* DuPont Registered Trademark