Contents

contents

Contents

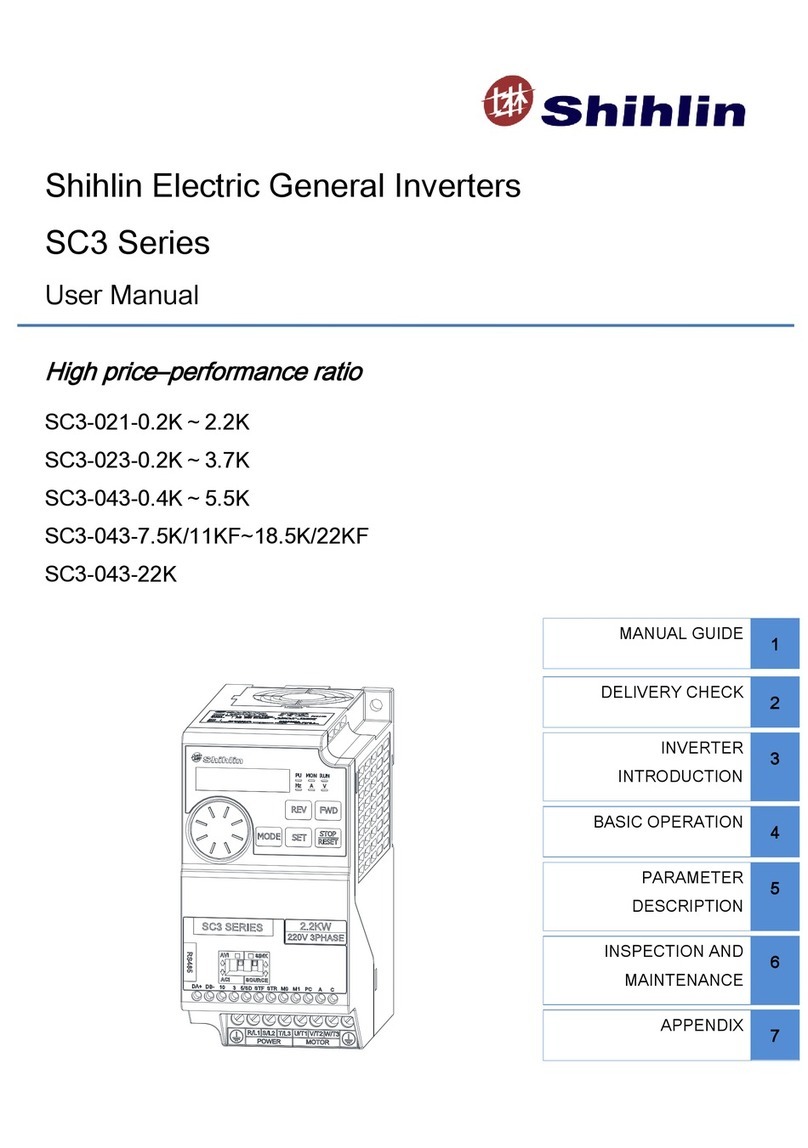

1. User Manual .................................................................................................................................................... 1

2. Delivery Check ................................................................................................................................................ 3

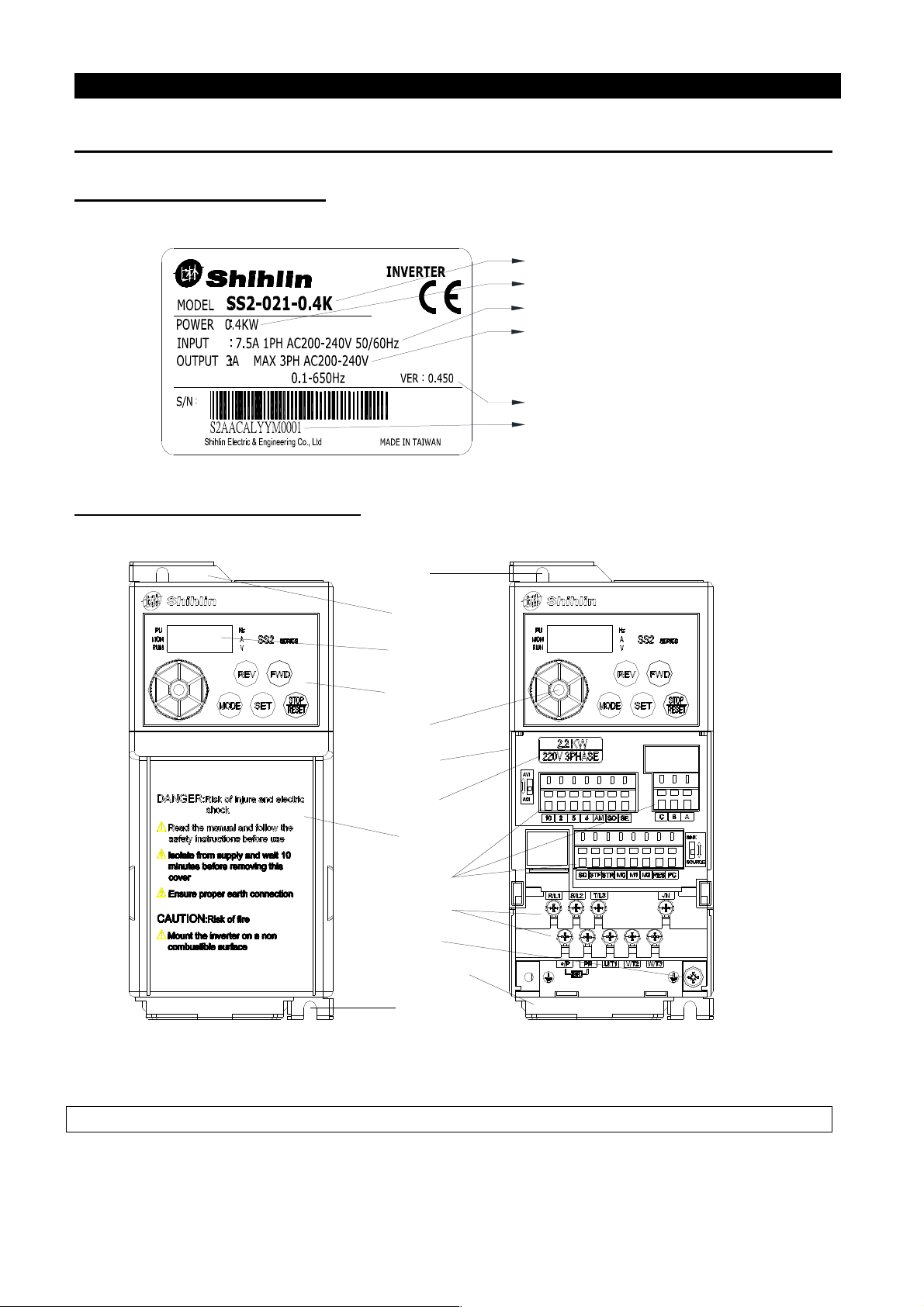

2.1 Nameplate Instruction ..................................................................................................................................................... 3

2.2 Type Instruction .............................................................................................................................................................. 3

2.3 Order Code Description .................................................................................................................................................. 3

3. Introduction of Shihlin Inverter .................................................................................................................... 4

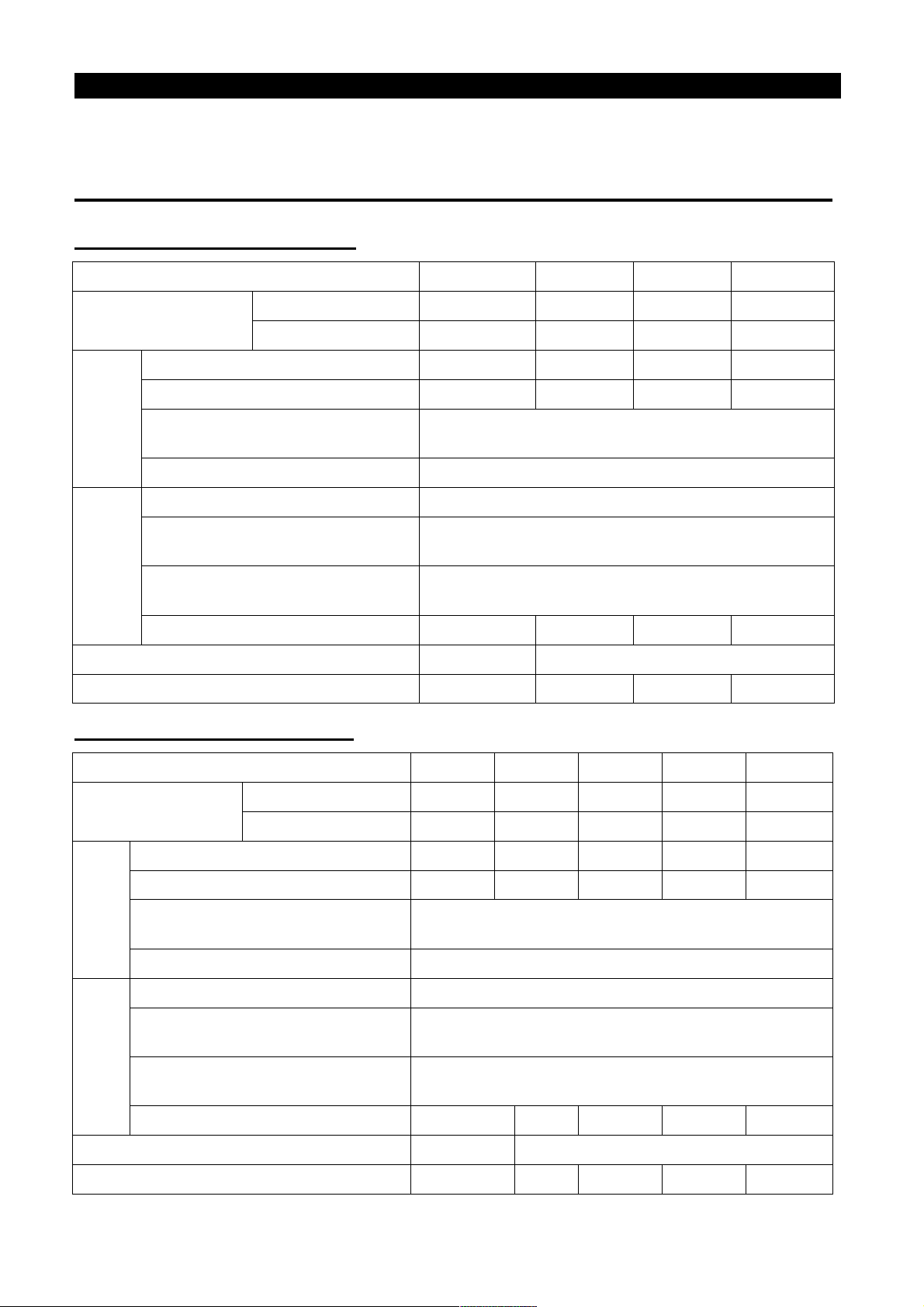

3.1 Electric Specification .................................................................................................................................................... 4

3.2 Common Specification (Inverter Characteristics) ...................................................................................................... 6

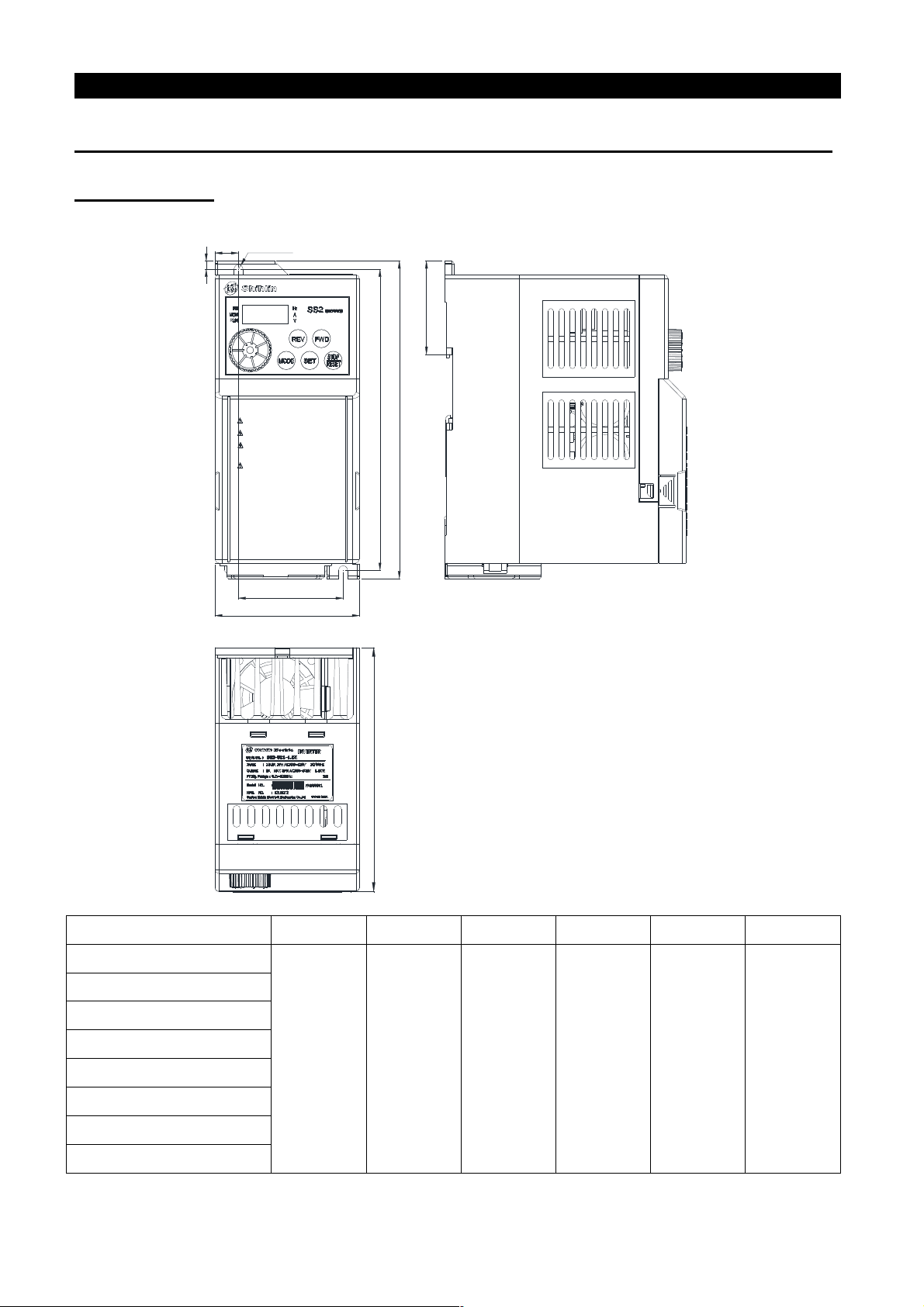

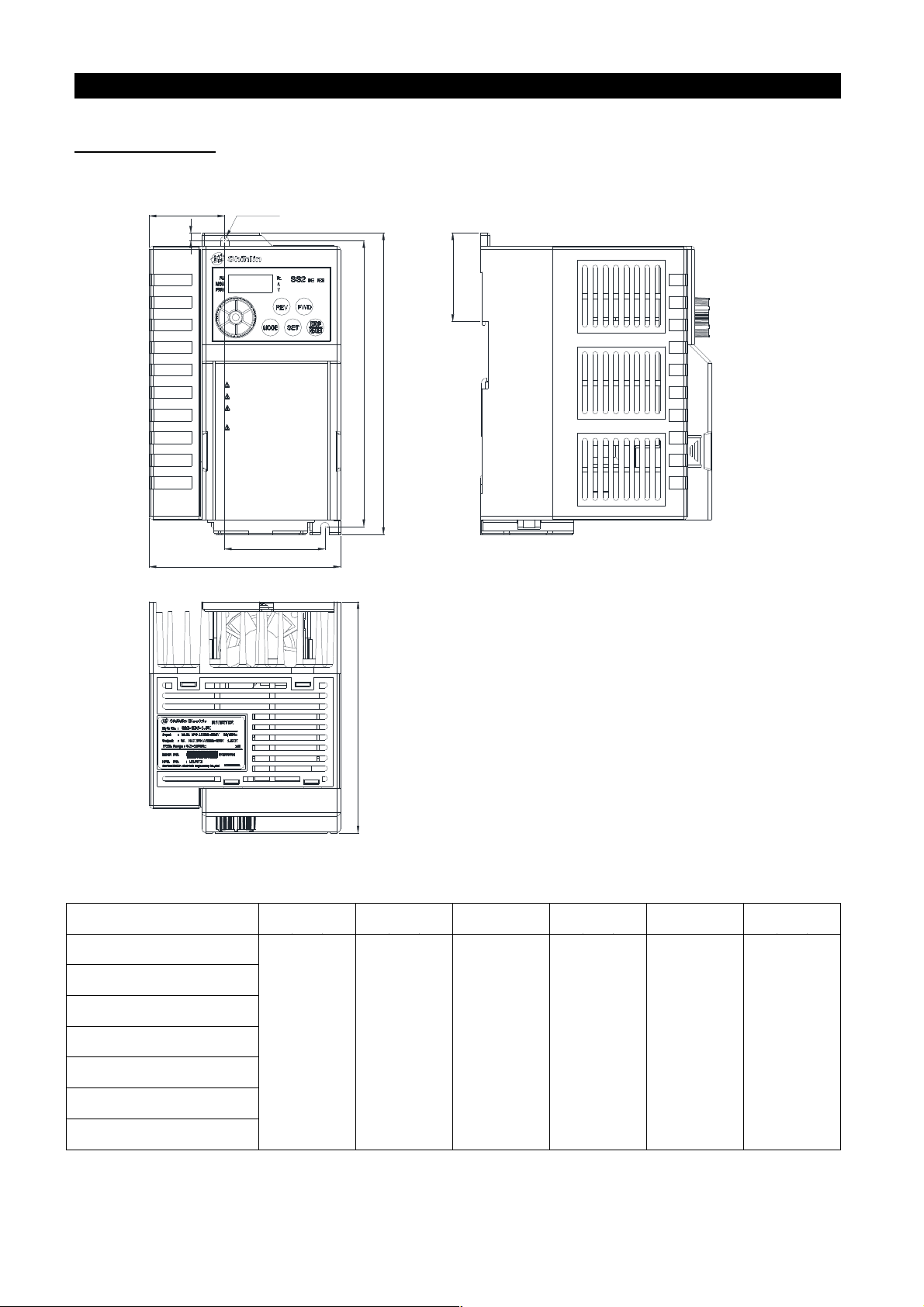

3.3 Mechanical Dimensions ................................................................................................................................................

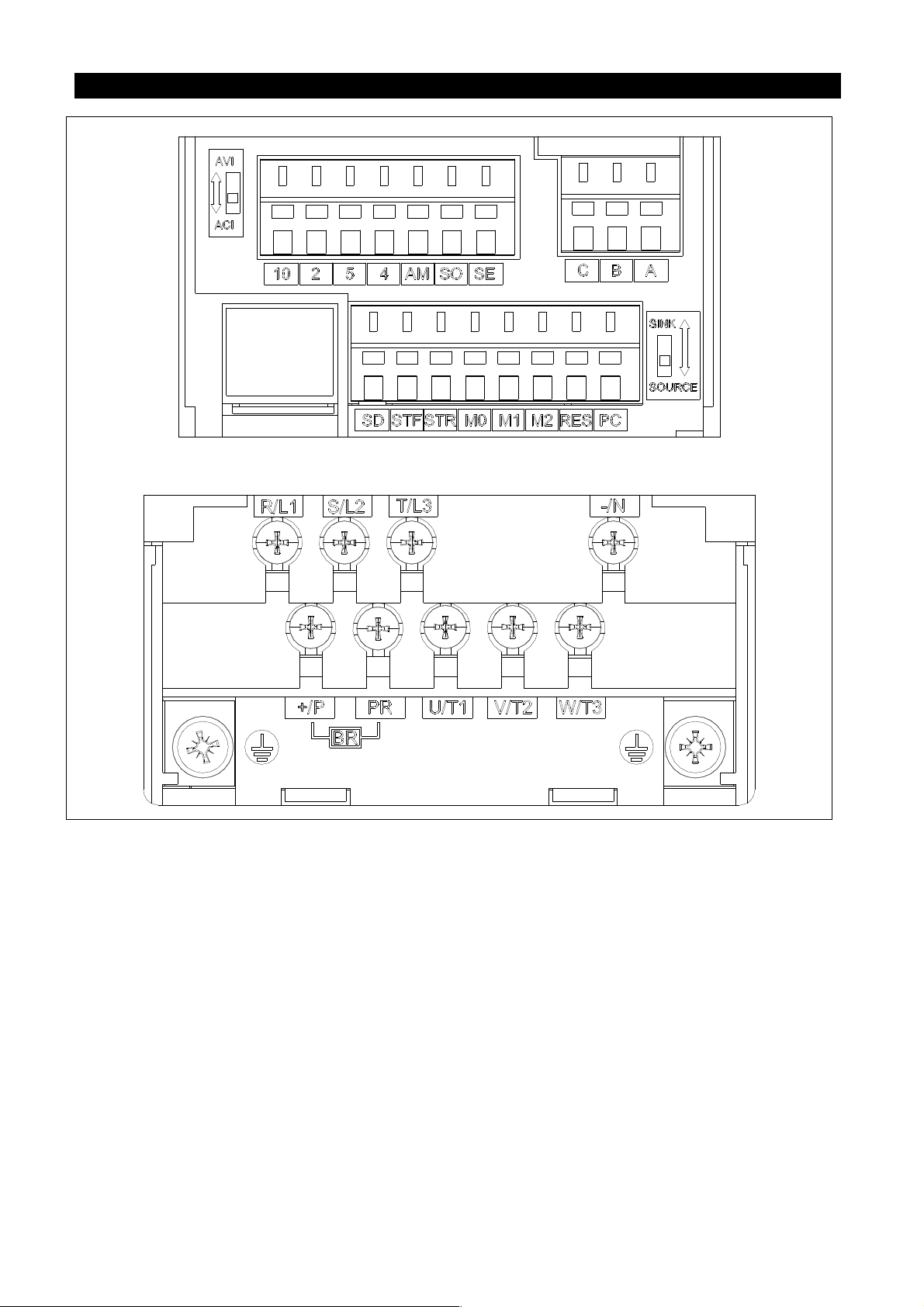

3.4 Name of Each Part ...................................................................................................................................................... 10

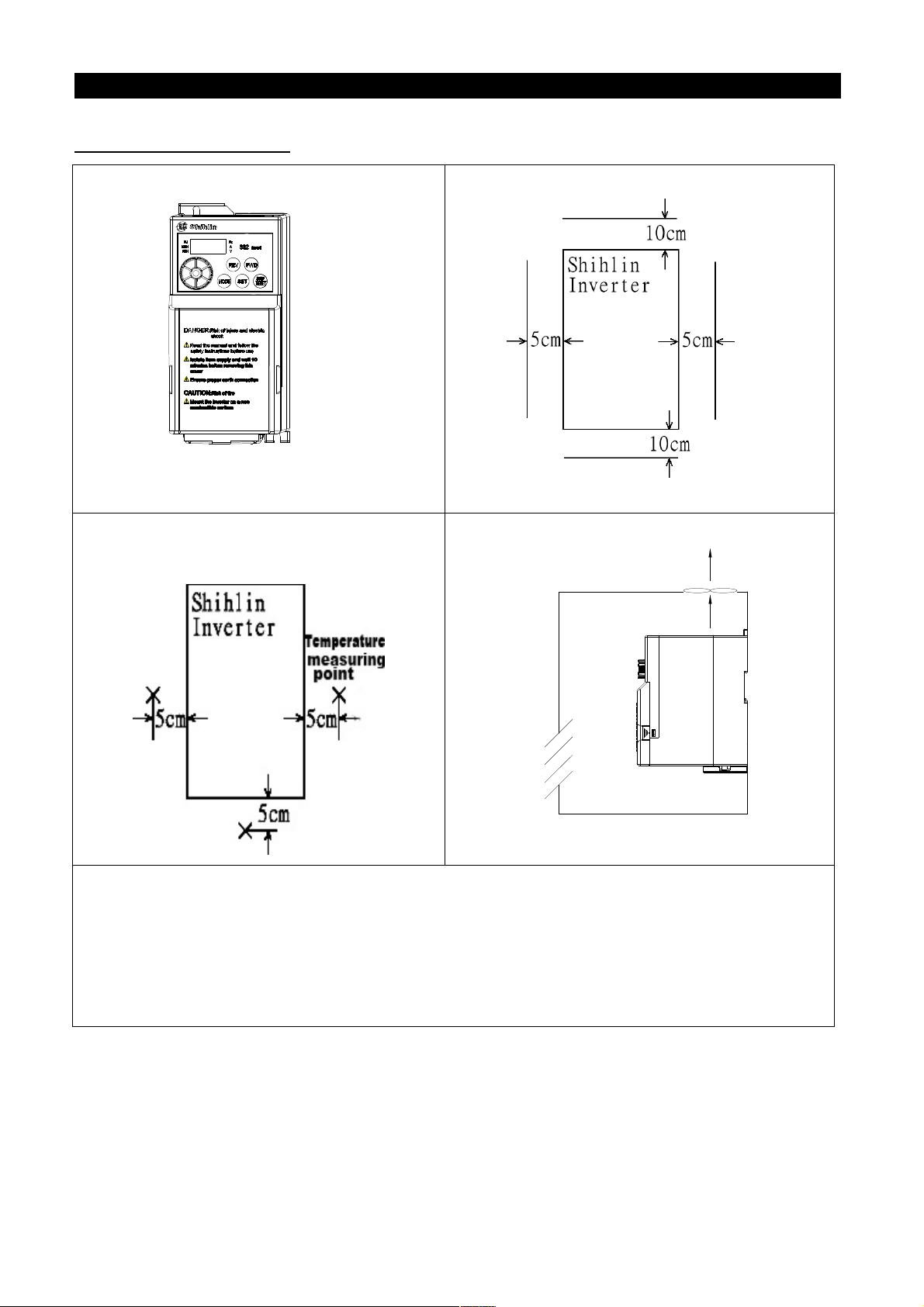

3. Installation and Wiring ............................................................................................................................................... 12

3.6 Selection of Peripheral Equipments .......................................................................................................................... 25

4. Primary peration ....................................................................................................................................... 31

4.1 Operation Modes of the Inverter ............................................................................................................................... 31

4.2 Basic Operation Procedures for Different Modes .................................................................................................... 36

4.3 Operation ..................................................................................................................................................................... 40

5. Parameter Description ................................................................................................................................. 42

.1 Torque Boost (P.0, P.46) V/F .................................................................................................................................. 45

.2 Range of the Output Frequency (P.1, P.2, P.18) ........................................................................................................ 46

.3 Base Frequency and Base Frequency Voltage (P.3, P.19, P.47) ................................................................................ 47

.4 Multi-speed (P.4~P.6, P.24~P.27, P.142~P.149) .......................................................................................................... 4

. Acceleration/Deceleration Time (P.7, P.8, P.20, P.21, P.44, P.4 ).............................................................................. 49

.6 Electronic Thermal Relay Capacity (P.9) .................................................................................................................. 51

.7 DC Injection Brake (P.10, P.11, P.12) ......................................................................................................................... 51

.8 Starting Frequency (P.13) ........................................................................................................................................... 52

.9 Load Pattern Selection (P.14, P.98, P.99, P.162~P.169) ............................................................................................. 53

.10 JOG Mode (P.1 , P.16) .............................................................................................................................................. 56

.11 Stall Prevention (P.22, P.23, P.66) ............................................................................................................................. 56

.12 Output Frequency Filter Constant (P.28) ................................................................................................................ 57

.13 Acceleration/deceleration Curve Selection (P.29, P.2 ~P.2 8) ............................................................................. 5

.14 Regenerative Brake (P.30, P.70) ............................................................................................................................... 61

.1 Soft-PWM Selection (P.31) ....................................................................................................................................... 61

.16 Communication Function (P.32, P.33,P.34, P.36, P.48~P. 3, P.1 3~P.1 4) ............................................................ 62

.17 Communication Running and Speed Command(P.3 ) ..................................................................................... 79

.18 Speed Display (P.37, P.2 9) ....................................................................................................................................... 0

.19 Voltage Signal Selection and Target Frequency (P.38, P.73, P.139~P.141) ............................................................ 1

.20 The Input Signal across Terminal 4- and the Target Frequency (P.17, P.39) ..................................................... 5

.21 Multi-function Output (P.40, P.64, P.74, P.8 , P.120 and P.187) ............................................................................ 6

.22 Up-to-frequency Sensitivity (P.41) ........................................................................................................................... 9

.23 Output Frequency Detection (P.42, P.43) ................................................................................................................ 90

.24 AM Terminal (P. 4~P. 6, P.190, P.191) .................................................................................................................... 91

.2 Restart Function (P. 7, P. 8, P.1 0) V/F ........................................................................................................... 92