3

MFP023-E52-B

Mar. 2006

Contents may be changed for improvements without notice.

Copyright© SHIMADEN CO., LTD. All rights reserved.

FP23 2-input

Quick Reference

http://www.shimaden.co.jp/ For questions, please contact

YOUR LOCAL AGENT or

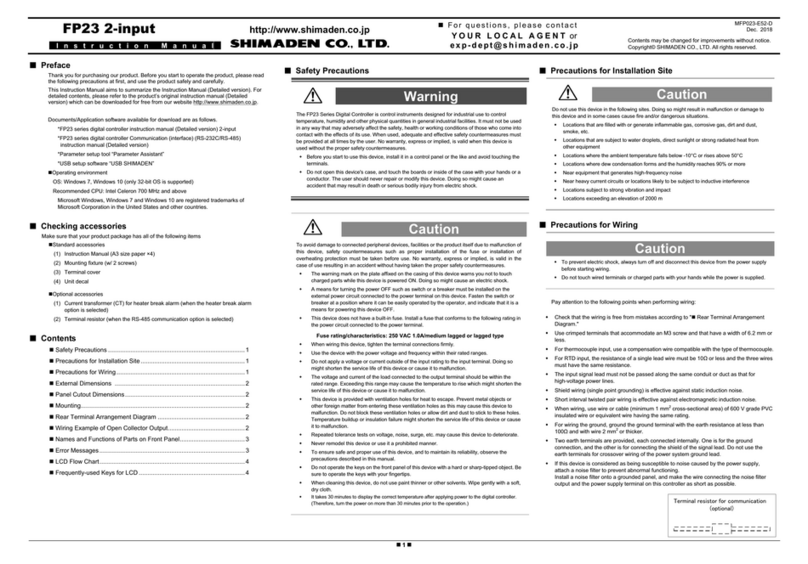

Names and Functions of Parts on Front Panel

If the instrument is 2-loop specification, it has three kinds of display mode. The display mode

can be switched to another by pressing

DISP

key on the front panel.

1PV display

For 2-loop;

Display mode 1: Displays the current measured value (PV) or an error message of CH1.

Display mode 2: Displays the current measured value (PV) or an error message of CH2.

Display mode 3: Displays the current measured value (PV) or an error message of CH1.

For other than 2-loop;

Displays the measured value (PV) or an error message.

2SV display

For 2-loop;

Display mode 1: Displays the target set value (SV) of CH1.

Display mode 2: Displays the target set value (SV) of CH2.

Display mode 3: Displays the current measured value (PV) of CH2.

For other than 2-loop;

Displays the target set value (SV).

Note

When it is under Display mode 1, CH1 PV value is shown on the PV display,

and CH1 SV value is shown on the SV display.

When it is under Display mode 2 (when CH2 lamp lights), CH2 PV value is

shown on the PV display, and CH2 SV value is shown on the SV display.

When it is under Display mode 3 (when PV lamp lights), CH1 PV value is

shown on the PV display, and CH2 PV value is shown on the SV display.

3LCD display (21 characters x 4 lines, max.)

For 2-loop, the following “CH1” information is displayed under Display mode 1 or 3, and the

following “CH2” information is displayed under Display mode 2.

Pattern/step No. display

Displays the pattern/step No. in the Program mode.

In the FIX mode, "F" is displayed at the PTN field and "- - -" is displayed at the STEP field.

"- - - " at the STEP field goes out during control execution (RUN) in the FIX mode.

Output (OUT) display

The control output value is displayed by a numerical value and a bar graph as a

percentage (%).

Channel (CH1 or CH2)

Displays the current channel for the data as one of the parameter values (2-loop

specification only).

IN1/IN2 PV

Displays the PV values of INPUT1/INPUT2 (2-input specification only).

CH1/CH2 actions

Displays the actions of the channel that is not displayed on LED indicators. (2-loop

specification only).

Program monitor display

Displays the program status monitor.

Remaining step time display

Displays the remaining step time during program operation.

Pattern graph display

Displays the pattern (step) graph during program operation.

Screen title display

Displays the screen group title in the respective screen group top screen.

Setup parameter display

Parameters can be selected and displayed by front key operation.

4Front panel key switches

The following key combination operations are available in screens from 0-1 to 0-7.

5LED indicators

Note that for 2-loop specification, each RUN, HLD, MAN, FIX, EXT, AT lamp shows different

channel information depending on the Display mode.

For 2-loop;

Display mode 1: Displays the action status of CH1.

Display mode 2: Displays the action status of CH2.

Display mode 3: Displays the action status of CH1.

For other than 2-loop;

Displays the action status.

Status lamps

RUN green Lights during program execution.

HLD green Lights when the program is paused. Blinks when the pause has

caused by an input error.

MAN green Blinks when control output is set to manual operation (MAN).

FIX green Lights in the FIX mode.

EV1 orange Lights during EV1 action.

EV2 orange Lights during EV2 action.

EV3 orange Lights during EV3 action.

DO1 orange Lights during DO1 action.

DO2 orange Lights during DO2 action.

DO3 orange Lights during DO3 action.

DO4 orange Lights during DO4 action.

DO5 orange Lights during DO5 action.

EXT green Lights when start pattern No. selection (PTN2bit, PTN3bit, PTN4bit,

PTN5bit) are set to DI5 to DI8.

COM green Lights during communication (COM) mode.

AT green Blinks during execution of auto tuning, and lights during standby.

OUT1 green When control output is current or voltage output, the brightness of

this lamp changes according to fluctuation of Control Output 1, and

during contact or SSR drive voltage output, this lamp lights when

Control Output 1 is ON and goes Out when Control Output 1 is OFF.

OUT2 green When control output is current or voltage output, the brightness of

this lamp changes according to fluctuation of Control Output 2, and

during contact or SSR drive voltage output, this lamp lights when

Control Output 2 is ON and goes Out when Control Output 2 is OFF.

Monitor lamps (2-input specification only)

CH2 green Lights when CH2 PV/SV values are displayed on PV/SV display

respectively.

PV green Lights when CH2 PV value is displayed on SV display.

Error Messages

Code Cause

ROM error

RAM error

EEPROM error

Input 1 A/D error

Input 2 A/D error

Hardware error

The error codes on the left are displayed on the PV

display.

These indicate that all outputs turn OFF or become 0%.

If any of the messages are displayed, repair or

replacement is required. Immediately turn the power

OFF, and contact your dealer.

The PV value exceeded the measuring range

lower limit (-10%FS).

The PV value exceeded the measuring range

higher limit (+110%FS), RTD-A burnout, or

thermocouple burnout.

One or two RTD-B burnout, or all leads of the

RTDs burnout.

Action of this device in this case is PV moving

excessively towards the higher limit.

Reference junction compensation (-20°C) is at

the lower limit. (thermocouple input)

Reference junction compensation (+80°C) is at

the higher limit. (thermocouple input)

When a PV input-related

abnormality is detected

during execution of control

on this device, the error

codes on the left are

displayed on the PV display.

Check input or the heater

lead. If the input or the

heater lead is not in error

and there is another

probable cause, contact

your dealer.

HB_HH The heater current

exceeds 55.0A.

When a heater current abnormality is detected during

execution of control on this device this error code is

displayed on the LCD.

DISP

Displays the basic screen. Switches the Display mode.

GRP

Changes the screen group. Or, returns to the screen group top screen.

SCRN

Switches the parameter display screen in a screen group.

Selects the parameter to set up or change. The parameter to be changed is

indicated by the cursor (►).

Moves the digit in set numerical values.

Decrements parameters and numerical values during setup.

Increments parameters and numerical values during setup.

ENT

Registers data or parameter numerical values.

STEP

At a reset, increments the start step No. in the basic screen. (

ENT

must be

pressed to register.)

PTN

At a reset, increments the start pattern No. in the basic screen. (

ENT

must be

pressed to register.)

ENT

+

PTN

Hold (HLD) operation

ENT

+

STEP

Advance (ADV) operation

Infrared

LED indicators

LCD display

PV display

SV display

Interface

Front panel

key switches

RUN HLD MAN FIX EV1 EV2 EV3 D01 D02 D03 D04 D05 EXT COM