1. Specification

Input ............................................See ordering information.

Feedback Resistance ...................100Ω~ 2kΩrandam/3-wire

Output .........................................Relay contact or Triac (SSR)

Output Rating/Contact Protection

Relay contact..........................240V AC, 1A (inductive load)/

CR Absorber

Triac (SSR) ............................

20 ~ 120V AC, 1A (inductive load)/

CR Absorber + varistor

Hysteresis...................................

Approx. 0.5% fixed of input signal range

Deadband (DB) ...........................

1 ~ 10% variable of input signal range

Dead Time...................................Approx. 0.2 sec.

(Chattering prevention)

Zero & Span Adjustment ............0% (ZERO): 0 ~ 20% variable

100% (SPAN): 70 ~ 100% variable

Output Action Display ................M2-M1/LED green lighting

M2-M3/LED red lighting

Operating Ambient Temperature

.....-10 ~ +50°C

Operating Ambient Humidity .....

90% RH max. (no dew condensation)

Storage Temperature...................-20 ~ 65°C

Power Supply..............................See ordering information.

Power Consumption....................Approx. 4 VA

Insulation Resistance

Between the input and power supply terminals: 500V DC, 100MΩ min.

Between the output and power supply terminals:

500V DC, 100MΩ

min.

Dielectric Strength

Between the output and power supply terminals: 1 min. at 1000V AC

Material.......................................ABS resin molding

External Dimensions...................80 (H) x50 (W) x130 (D) mm

Installation ..................................11P Plug-in

Weight.........................................Approx. 350g

(Exclusively used for AC load)

2. Ordering Information

ITEMS CODE SPECIFICATIONS

1. SERIES

EM51- Plug-in type servo controller

1

1 ~ 5mA DC, Receiving Impedance

: 250Ω

2

4 ~ 20mA DC, Receiving Impedance

: 62Ω

2. INPUT 3 0 ~ 10V DC, Input Resistance

:

200kΩ

5 Potentiometer 100Ω~ 2kΩ, 3-wire type

9 Others (Please consult before ordering.)

Y

Contact 240V AC, 1A (inductive load)/

with CR Absorber

3. OUTPUT

RContact 240V AC, 1A (inductive load)/

without CR Absorber

S

Triac 20 ~ 120V AC, 1A (inductive load)

(Motor Supply Voltage: 20 ~ 120V AC)

13-

100 ~ 110V AC ±10%, 50/60Hz

14-

110 ~ 120V AC ±10%, 50/60Hz

4. POWER SUPPLY 15-

200 ~ 220V AC ±10%, 50/60Hz

16-

220 ~ 240V AC ±10%, 50/60Hz

99-

Others (Please consult before ordering.)

5. REMARKS 0 Without

9

With (Please consult before ordering.)

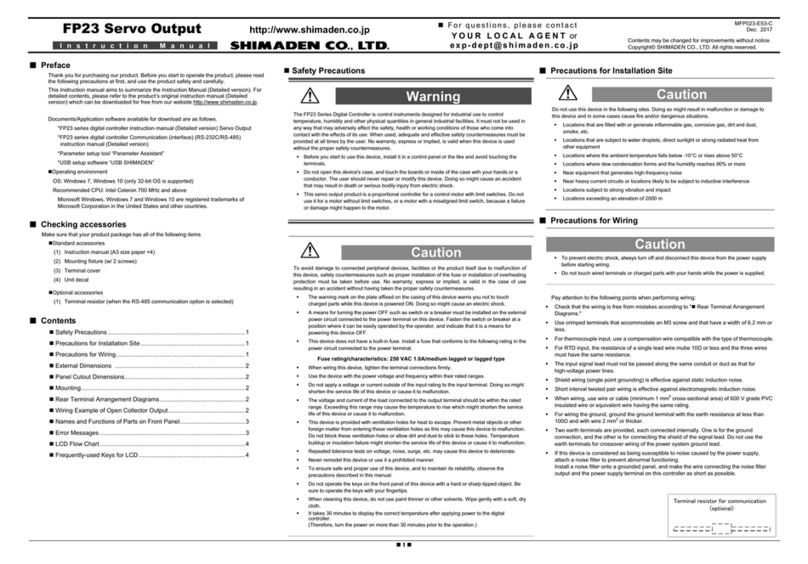

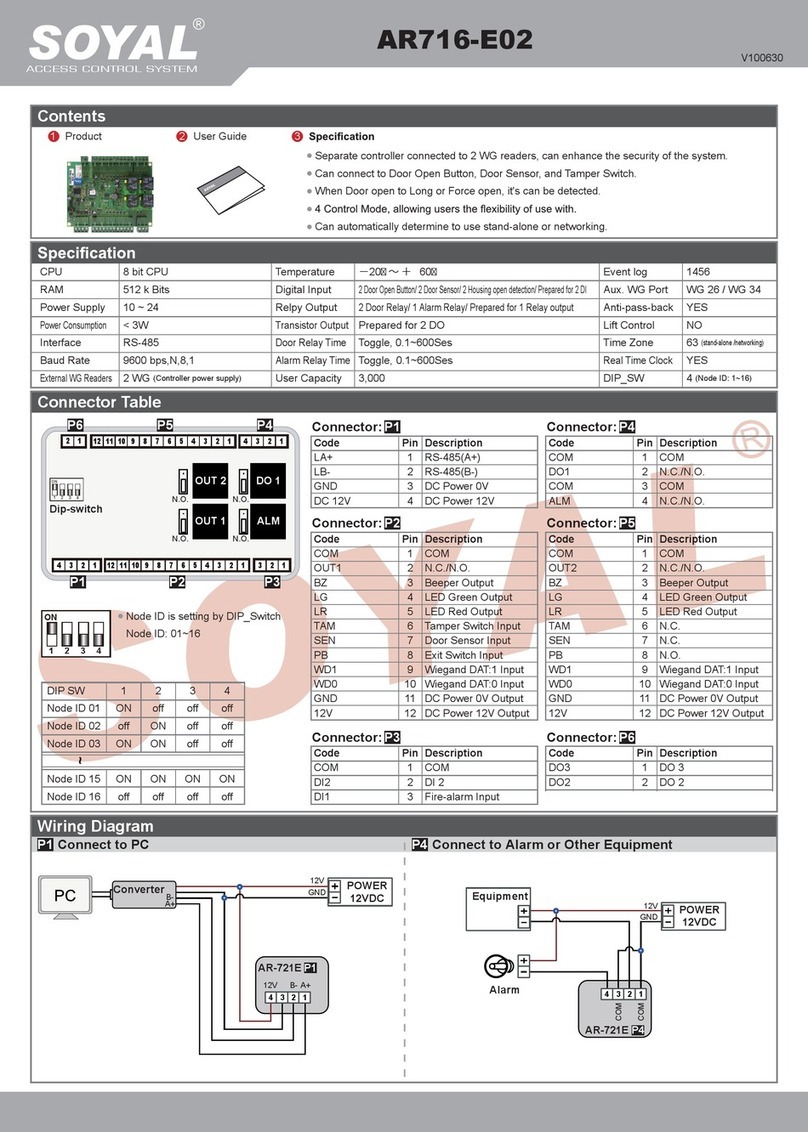

5. Terminal Arrangement

3. Installations

Do not use this device in the following sites to avoid any trouble since

use in such circumstances may generate severe harmful influence on

its performance or its useful life, or lead to other shortcomings:

1. Locations that are filled with or generate corrosive gas or inflam-

mable gas

2. Locations where high temperature/humidity is present

3. Locations where direct sunlight or radiant heat such as that from

an electric furnace is present

4. Locations where any vibration or shock may be experienced

4. External Dimensions & Panel Cutout

6. Wiring

1. Wiring should be routed according to the indications located on

the terminal face plates.

Do not apply too much force when tightening the terminal screw.

2. Keep wiring away from strong electrolyte circuits, or use shield-

ing wire to protect the feedback resistance wire from the input

signal/control motor.

3. If you inadvertently connect the motor power supply to the feed-

back resistance circuit of the control motor, the potentiometer will

burn.

4. Connection terminal symbols found on control motors may vary

depending on their manufacturer. Refer to the instruction man-

ual supplied by the manufacturer in question for clarification.