ŶŶ

1

http://www.shimaden.co.jp

For questions, please contact

YOUR LOCAL AGENT or

MSRS0-E53-A

Oct. 2018

Contents may be changed for improvements without notice.

Copyright© SHIMADEN CO., LTD. All rights reserved

SRS0 Series

Instruction manual

Preface

Thank you for purchasing Shimaden product. Before using this product, make sure that you read thoroughly

the precautions on safety, installation site and wiring in order to use it safely and correctly.

This manual contains the requisite minimum information. For parameter value, initial value, and other details,

please refer to the Digital Controller SRS1/3/4/5 Series Instruction Manual (Detailed Version).

The Digital Controller SRS1/3/4/5 Series Instruction Manual (Detailed Version) may be downloaded free from

the company website http://www.shimaden.co.jp.

Accessories check

The controller has undergone sufficient quality control inspections, but you should check the specification

code/appearance and make sure you have all the accessories to ensure nothing is missing or damaged.

࣭SRS0 digital controller: 1 unit

࣭Instruction manual (A3 size paper × 2): 1 copy

࣭Unitseals: 1set

Safety precautions

Warning

The SRS0 Series are control instruments designed for industrial use to control temperature, humidity and

other physical values. You should either take appropriate safety measures or avoid using this product for

control purposes where failure could have a serious effect on human life. The manufacturer shall not be liable

for accidents that result from use without taking appropriate safety measures.

ƔThe digital controller should be used so the terminal elements in the control box, etc., are not touched by humans.

ƔDo not remove the controller from its case or insert your fingers or electric conductors inside the case.

Doing so could result in electric shock or accident involving death or serious injury.

ƔBe sure to turn off power before wiring. Failure to do so could result in electric shock.

ƔAfter wiring, do not touch terminal elements or other charged parts while conducting electricity.

Failure to do so could result in electric shock.

Consent on use

The warranty period for SRS0 Series is one year after the purchase. In principle, avoid use of the product

under the following places/conditions. Should you use the controller under the following places/situations,

be sure to use it with the proper rating and level of performance and make sure to use the controller

correctly while taking appropriate safety measures in order to avoid accidents.

ƔOutside

ƔPlaces exposed to chemical contamination, electrical disturbance, and/or mechanical stress

ƔPlaces which are not specified as an appropriate installation site in the instruction manual or catalog

ƔWhen used for nuclear facilities, air facilities, space facilities, railway facilities, vehicle facilities, medical

equipment, and facilities which are controlled by separate regulations

ƔFacilities in which failure of the product would constitute a danger to human life or property

ƔWhen used in application or facilities which require a high level of safety

Caution

If there is danger of damage to any peripheral device or equipment due to failure of the controller, you should

take appropriate safety measures such as mounting a fuse or overheating prevention device. The manufacturer

shall not be liable for an accident that results from use without taking appropriate safety measures.

ƔController labels and alert mark ·

Alert marks ·are printed on the terminal label of the case.

ou could receive an electrical shock if you

touch charged parts. The alert mark is provided to call your attention to this danger.

ƔProvide a switch or breaker as a means of cutting off power for external power circuit connected to the powe

terminal of the controller. Mount a switch or breaker near the controller where the operator can access it

easily and label it as an electrical breaker for the controller. Use a switch or breaker that conforms to

requirements of IEC60947.

ƔFuses

The controller does not have a built-in fuse. Be sure to mount a fuse on the power circuit connected to the

power terminal. Provide a fuse between the switch or breaker and the controller. Mount on the L side of the

power terminal.

Fuse rating/characteristics: 250 V AC, 0.5 A/medium time-lagged type or time-lagged type

Use a fuse that conforms to requirements of IEC60127.

ƔVoltage/current of load connected to the output terminal and EV terminal should be within the rating.

Using voltage/current that exceeds the rating could shorten the life of the controller by raising the

temperature and could result in equipment failure. For rating, see “11. Specifications.”

ƔDo not apply voltage/current other than rated input to the input terminal. Doing so could shorten product life

and lead to equipment failure. For rating, see “11. Specifications.”

ƔDo not allow the ventilation holes to become clogged with dust, etc. Doing so could shorten the life of the

product due to temperature rise or insulation deterioration and could result in equipment failure or fire.

ƔRepeating endurance tests such as dielectric strength, noise resistance and surge resistance could

negatively affect the controller.

ƔThe user should absolutely not modify or use the controller in any other way than it was intended.

ƔIt takes 30 minutes to display the correct temperature after applying power to the digital controller.

(Therefore, turn the power on more than 30 minutes prior to the operation.)

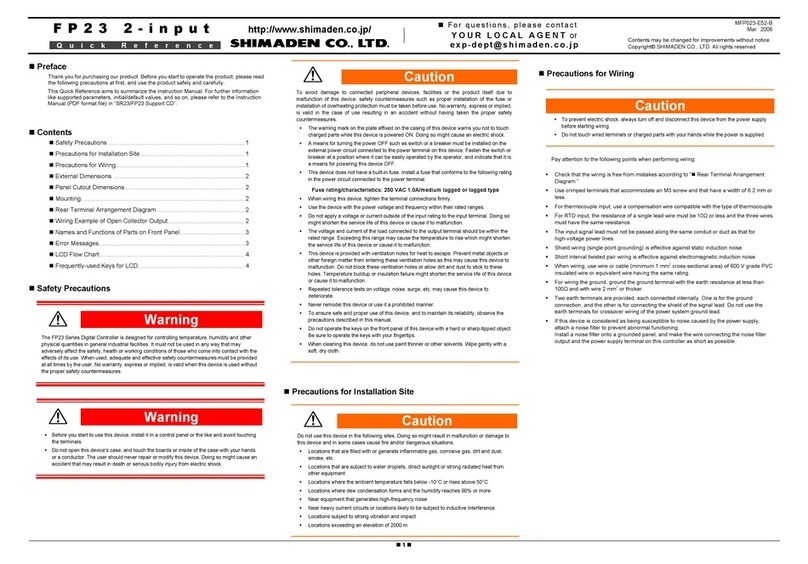

Wiring

Take the following precautions when wiring:

ƔWire in accordance with the “Terminal layout.” After wiring, check and make sure the wiring is correct.

ƔCrimp-type terminals fit M3 screws. Use crimp-type terminals that are no wider than 6 mm.

ƔFor thermocouple input, use a compensating lead wire that matches the type of thermocouple.

ƔFor RTD input, resistance for lead wires should be a maximum of 10ȍper wire. All 3 wires should have the

same resistance.

ƔInput signal wires must not be accommodated with a strong electric circuit in the same conduit or duct.

ƔUsing shielded wiring (single point grounding) is effective for static induction noise.

ƔMaking input wiring short and twisting at regular intervals is effective for electromagnetic induction noise.

ƔFor power supply, use wiring or cable with sectional area of at least 1 mm² that offers the same or higher

performance as 600 V vinyl insulated wiring.

ƔSecurely fasten the terminal element screw. Fastening torque: 0.5 N·m (5 kgf·cm)

ƔIf the instrument appears to be easily affected by power supply noise, use a noise filter to prevent

malfunctioning. Mount the noise filter on the grounded panel and make the wire connection between the

noise filter output and power line terminals of the controller as short as possible.

Terminal layout

SRS1

SRS3/SRS4/SRS5

Installation site (environmental conditions)

Caution

Do not use the controller in the following locations. Doing so could lead to equipment failure, damage or fire.

ƔPlaces exposed to flammable or corrosive gases, oil mist, or excessive dust that could cause insulation

to deteriorate.

ƔPlaces subject to strong vibration or impact

ƔPlaces near strong electrical circuit or places subject to inductive interference

ƔPlaces exposed to water dripping or direct sunlight

ƔPlaces where the controller is struck directly by air from heater or air conditioner

The controller is designed to be used under the following conditions.

Observe the following environmental conditions:

ƔIndoor use

ƔMax. elevation: 2000 m

ƔAmbient temperature: -10–50°C

ƔAmbient humidity: Max. 90%RH, no dew condensation

ƔTransient over voltage category: II

ƔPollution class: 2 (IEC 60664)

External dimensions and panel cutout

ƔCut a hole for mounting the controller in the panel by referring to external dimensions and panel cutout.

ƔThe panel thickness should be 1.0–3.5 mm.

ƔThe controller is provided with tabs for mounting. Insert as is from the front surface of the panel.

ƔSRS0 Series controllers are designed for mounting on a panel: Be sure to mount the controller

on a suitable panel.

ƔIf mounted in series, provide ventilation so ambient temperature does not exceed 50°C due to

temperature rise caused by heat generation.

SRS1

SRS3

SRS4

SRS5

Caution

In order to maintain safety and function, do not remove the case from the controller.

If the case of the controller has to be removed for replacement/repair, contact your nearest Shimaden agent.

Min. 60

45 +0.8

-0

92 +0.8

-0

+0.8

-0

9+0.8

-0

45 +0.6

-0 (48 × N - 3) +1.0

-0

If mounted horizontally

N = Number of units

Min. 130

+0.8

-0

92 +0.8

-0

Min. 130

(48 × N - 3)+1.0

-0

45 +0.6

-0

+0.6

-0

4+0.6

-0

Min. 60

Unit: mm

Panel cutout

Min. 130

Unit: mm

Unit: mm

Unit: mm

Min. 130

4

9

9

If mounted horizontally

N = Number of units