Shimax MAC3 Series User manual

1

「

「「

「Notice」

」」

」

Pleaseensurethatthis manual is given to thefinaluser of the instrument.

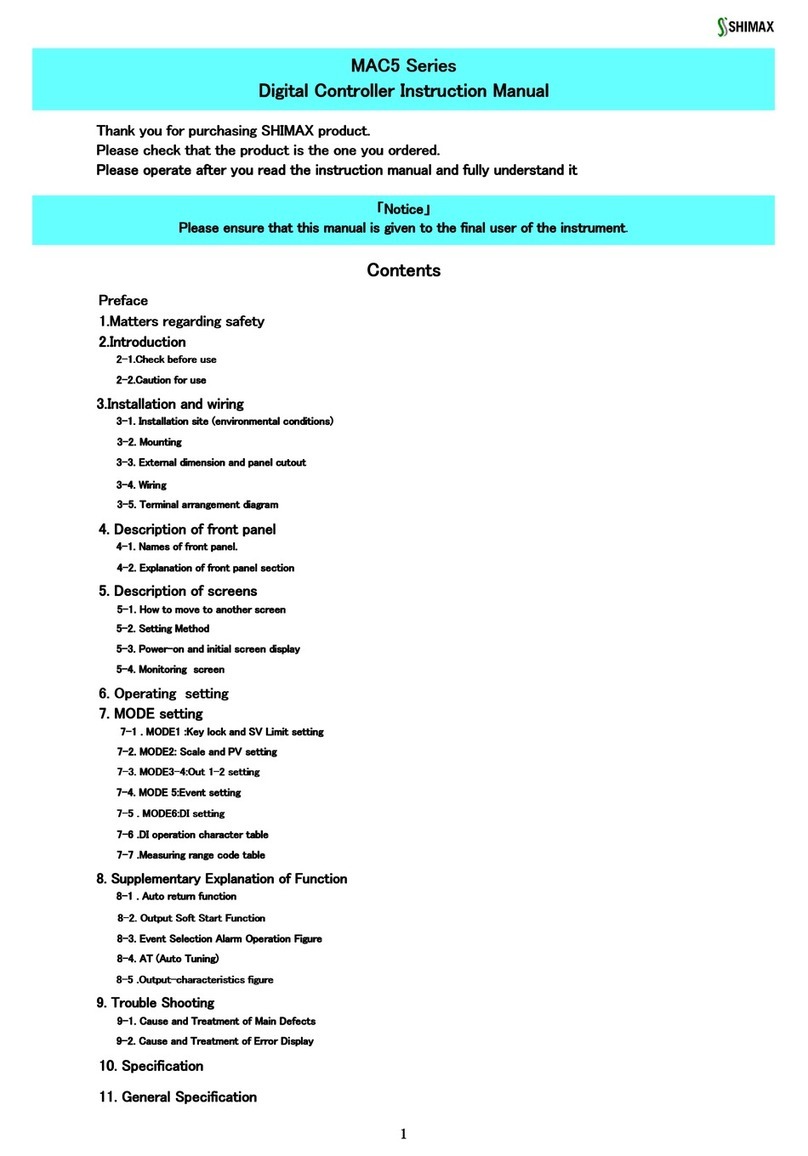

Contents

Page

Preface ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・2

1.Mattersregardingsafety・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・2

2. Introduction ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・2

2-1.Checkbeforeuse ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・2

2-2.Caution for use ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・2

3. Installationandwiring ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・3

3-1. Installation site(environmentalconditions)・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・3

3-2.Mounting・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・3

3-3.External dimension andpanelcutout ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・3

3-4.Wiring ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・3

3-5.Terminalarrangementdiagram ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・4

4. Description of front panel ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・4

4-1.Names offrontpanel ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・4

4-2.Explanationoffrontpanelsection ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・4

5. Description of screens ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・5

5-1.Howtomovetoanotherscreen ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・5

5-2.SettingMethod ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・5

5-3.Power-on andinitialscreendisplay・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・5

5-4.Explanationofeach screen・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・5

(1)Basicscreens・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・5

(2)FIX(constantvaluecontrol)settingscreens ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・7

(3)PROG(programcontrol)settingscreens ・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・・・・7

(4)Mode1screens・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・9

(5)Mode2screens・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・9

(6)Mode3screens・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・9

(7)Mode4screens ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・10

(8)Mode5screens ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・11

(9)Mode6screens ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・12

(10)Mode7screens ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・13

(11)Mode8screens ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・13

(12)Mode9screens ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・13

5-5.Measuringrangecodetable ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・14

6. SupplementaryExplanationofFunction・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・14

6-1. Autoreturnfunction・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・14

6-2.Output Soft StartFunction ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・14

6-3.EventSelectionAlarmOperation Figure・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・14

6-4. AT (AutoTuning) ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・14

6-5.2output-characteristicsfigure ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・14

7. Trouble Shooting ・・・・・・・・・・ ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・15

7-1.CauseandTreatment ofMainDefects ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・15

7-2.CauseandTreatment ofError Display・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・16

8. Specification ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・16

9. Programpatternsettingtable ・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・20

MAC3F-1 AE January, 2005

MAC3

MAC3MAC3

MAC3 Series

SeriesSeries

Series

Digitalcontroller InstructionManual

Thankyoufor purchasingSHIMAX product.Pleasecheck thatthe productisthe one youordered.

Pleaseoperateafter youread theinstruction manualand fully understand it.

2

Preface

This instruction manual is intended for those who will be involved in wiring, installation,

operationandroutinemaintenanceoftheMAC3.

This manual describes the care, installation, wiring, function, and proper procedures

regardingtheoperationofMAC3.

Keep thismanualonhandwhileusingthisdevice. Please followtheprovided guidance.

1.

Mattersregardingsafety

For matters regarding safety, potential damage to equipment and/or facilities and additional

instructionsareindicatedasfollows:

This mark indicates hazardous conditions that could cause injury or death of personnel.

Exerciseextreme cautionasindicated.

「

「「

「

WARNING」

」」

」

This mark indicates hazardous conditions that could cause damage to equipment and/or

facilities.Exercise extremecautionasindicated.

「

「「

「

CAUTION」

」」

」

Thismark indicatesadditionalinstructionsand/or notes.

「NOTE」

「

「「

「

WARNING」

」」

」

MAC3 isdesignedforcontrollingtemperature,humidity,andother physicalsubjectsingeneral

industrialfacilities.Itmust not beusedinany waythatmayadverselyaffectsafety, health,or

workingconditions.

「

「「

「

CAUTION」

」」

」

To avoid damageto the connected equipment, facilities or the product itself due to a fault of

thisinstrument, safety countermeasures must be taken beforeusage, suchas proper installation

ofthefuseandtheoverheatingprotectiondevice.Nowarranty,expressedorimplied,isvalidin

thecaseofusagewithout havingimplementedpropersafetycountermeasures.

「

「「

「

CAUTION」

CAUTION」CAUTION」

CAUTION」

Themarkontheplateaffixedtotheinstrument:

On the terminal nameplate affixed to the case of your instrument, the mark is printed.

Thisistowarn you of therisk of electrical shock which may resultif thecharger istouched

whileitisenergized.

The external power circuit connectedto the power terminal ofthisinstrument must havea

means of turning off the power,such asa switch or breaker. Install the switchor breaker

adjacent to theinstrument in a position which allows it to be operated with ease, and with

an indication that it isa means of turning off the power. Use a switch or breaker, which

meetstherequirementsofIEC127.

Fuse:

Since the instrument does not have a built-in fuse, do not forget to install a fuse in the

power circuit to be connected to the power terminal. The fuse should be positioned

between the switch or breaker and the instrument and should be attached to the L side of

thepowerterminal.

Fuse Rating:250VAC0.5A/mediumlaggedorlaggedtype.

Usea fuse which meetsthe requirements ofIEC127

Load voltage/current to be connected tothe output terminalandthe alarm terminal should

be within the rated range. Otherwise, the temperature will rise and shorten the life of the

productand/or resultinproblems withtheproduct.

Voltage/current that differs from input specification should not be connected to the input

terminal.Itmayshortenthelifeoftheproductand/orresult inproblems withtheproduct.

Input, output ofvoltage pulse, and output of electric current are not insulated. Therefore, do

notgroundanadjusted power terminal whena groundsensorisemployed.

A signal wire's common mode voltage to ground (signal wires other than contact output

includingpower supply and event) shouldbelessthan 30Vrms, 42.4Vpeak,and60VDC .

「

「「

「

CAUTION」

」」

」

All the wires for the interior distribution, except for communication and contact output (including

power supplyand event), should be lessthan30minlength.Whenthe wire'slength is 30mor more,

orinthe caseofoutdoor wiring,the suitablemeasureagainsta lightningsurgeisrequired.

EMC standard (IEC61326) classifies MAC3 into Class A apparatus. Electromagnetic interference

may occur when MAC3 is used at a business district or in the home. Please use after taking

sufficientmeasures.

2. Introduction

2-1. Checkbefore use

BeforeusingMAC3,please checkthemodel code,theexteriorappearanceand accessories. Also,

makesurethatthereare no errors, impairsand shortages.

Confirmationofmodelcode:Checkthattheproductyou orderedisbeingdeliveredproperly.

Check themodelcodeofthemainbodycaseagainstthe followingcodetable.

Example of modelcode

MAC3A-

MAC3A-MAC3A-

MAC3A- M

MM

MC

CC

C

F-

F-F-

F- E

EE

E

C-

C-C-

C- D

DD

D

H

HH

H

T

TT

T

R

RR

R

N

NN

N

1 2 3 4 5 6 7 8 9 10

11

Item

1.Series MAC3A-:96×96mmsizedigitalcontroller

MAC3B-:48×96mmsizedigital controller

2.Input M:multi,V:voltage,I:current

3.ControlOutput1 C:contact,S:voltagepulse,I:current(4~20mA),V:Voltage(0~10V)

4.Power Supply F-:90-264VAC,L-:21.6 -26.4VDC/AC

5.EventOutput N:none,E:EventOutput1・2(twopoints)

6.ControlOutput 2・EventOutput・OptionalSelectionofDI

N-:none,C-:contact,S-:voltagepulse,I-:current(4~20mA),V:Voltage(0~10V)

E-: Event Output3(one point), D-: externalcontrolinput(DI4) one point

7.DI N:none,D: external control input(DI1,2,3)threepoints8

8. CT Input N:none,H: CT Inputtwo points

9.AnalogOutput N:none,I: current(4~20mA)

10.Communication N: none, R:RS485

11.ProgramFunction N:none, P:equipped

Example of model code

MAC3D-

MAC3D-MAC3D-

MAC3D- M

MM

MC

CC

C

F-

F-F-

F- E

EE

E

C-

C-C-

C- D

DD

D

T

TT

T

N

NN

N

1 2 3 4 5 6 7 8 9

Items

1.Series MAC3C:72×72mmsizedigitalcontroller

MAC3D-:48×48mmsize digital controller

2.Input M:multi,V: voltage, I:current

3.ControlOutput1 C:contact,S:voltagepulse,I:current(4~20mA)V:Voltage(0~10V),

4.Power Supply F-:90-264VAC,L-:21.6-26.4VDC/AC

5.EventOutput N:none,E:EventOutput1・2(two points)

6.ControlOutput2・EventOutput・OptionalSelectionofDI

N-:none,C-:contact,S-:voltagepulse, I-:current(4~20mA)V:Voltage(0~10V)

E-: Event Output3(one point), D-: externalcontrolinput(DI4) one point

7.DI・CT Input N:none, D: externalcontrolinput(DI1,2,3)three points,H:CT Inputtwo points

8.AnalogOutput・Communication N:none,T:current(4~20mA),R:RS485

9.ProgramFunction N:none, P:equipped

Check ofaccessories

Instruction manual:1 set

「NOTE」: Please contactour agencies or business officesifyou have anyproblem.

Wewelcomeanykind ofinquirysuchasdefectoftheproduct, shortageofaccessory

andsoon.

2-2.Cautionforuse

(1) Do not operatethefront panel keys with hard or sharpobjects.

Donot failto touchkeyslightlywitha fingertip.

(2)Wipegentlywitha dryragandavoidusing solventssuchasthinner.

3.Installationandwiring

3-1. Installationsite (environmentalconditions)

「

CAUTION」

Donot usethisproductunderthefollowingconditions.

Otherwise,failure,damageand firemay occur.

(1) Where flammable gas,corrosive gas, oil mist or dust generateor growrife.

(2)Wherethetemperatureisbelow-10℃orabove55℃

(3)Wherethe humidityisover90%RH orwherecondensationoccurs.

(4)Wherehighvibration or impactoccurs

(5)Whereinductiveinterferencemayeasilyaffect theoperation.

Or,intheregion of strongelectriccircuitarea.

(6) Where waterdropsor direct sunlightexists.

(7)Wherethealtitudeisabove2,000m.

「NOTE」:Theenvironmentalconditions comply withtheIEC664.

InstallationcategoryisⅡandthe pollution degreeis2.

3

3-2. Mounting

(1)Machinethemounting holebyreferring tothepanel-cutillustrationinSection3-3.

(2)Applicablethicknessofthemountingpanelis1.2~ 2.8mm.

(3)As thisproductprovides mounting fixture, inserttheproductintothepanel.

3-3. Externaldimensionand panelcutout

MAC3 externaldimensions(unit:mm)

MAC3panelcutout(unit:mm)

MAC3A 96×96size

92

+0.8

-0

92

+0 . 8

-0

(9 6 ×N - 4)

+0 . 8

-0

96 以 上

92

+0 . 8

-0

96 以 上

In the case of horizontal proximityattachment by a single hole

N:

Number

MAC3B 48×96size

48 以 上

96 以 上

9 2+0.8

-0

45

+0.6

-0

( 48 × N - 3)

+0.6

-0

92+0 . 8

-0

In the caseof horizontal proximity attachment by a single hole

N:

Number

MAC3C 72×72size

MAC3D 48×48size

45

+0 . 6

-0

45

+0 . 6

-0

4 8 以 上

( 4 8 × N - 3 )

+0 . 6

-0

45

+ 0. 6

- 0

48 以 上

Inthe case of horizontal proximityattachment by a single hole

N:

Number

Note:Proximityattachment bya singleholeispossibleonlyinthe case ofhorizontaldirection.

When an apparatus that was attached in vertical direction is removed, a dedicated detachment

tool isrequired.

3-4.

3-4.3-4.

3-4.Wiring

「

「「

「

WARNING」

」」

」

◎Donotturnonelectricity while wiringtoavoidanelectricshock.

◎Donot touchaterminalor livepart whileturningonelectricity.

(1)Makesurethatwiring operation isproperly doneinlinewitha terminalwirediagramofsection3-5.

(2)Choosea suitablecompensationleadwireinthecaseofthermocoupleinput.

(3)Inthecase ofresistancebulbinput,resistancevalueofeachleadwiremust belessthan

5Ωandthatofthreelead wiresmust be equal.

(4)Donot wiresaninputsignallineinsideofanelectricwirepipeora ductsamewiththe

highvoltage line.

(5)Shieldwiring(singlepoint grounding) is effectiveagainst staticinductionnoise.

(6)Wiringtwistedatequalshortintervalsiseffectiveagainstelectromagneticinduction noise.

M

96

AC

3

MAC3A

MAC3B

MAC3B

MAC3D

96

69

96

48

66

96

72

69

72

48

48

66

4

3-5.

3-5.3-5.

3-5.Terminalarrangementdiagram

3-5.Terminalarrangement planofMAC3AandMAC3B

OUT2/EV3/DI4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

DI1

DI2

DI3

AO

+

-

EV2

EV1

INPUT

L

N

POWER

OUT1

90-264V AC

50/60Hz 9VA

COM

+

-

CT1

CT2

~

~

~

~

+

-

A

B

B

RS-485

+

-

+

-

CONTACT:240V AC 2A

SSR DRIVE:12V DC 20mA

CURRENT:4-20mA DC

CONTACT:240V AC 2A

SSR DRIVE:12V DC 20mA

CURRENT:4-20mA DC

EV3:240V AC 2A

240V AC 2A

240V AC 2A

L +

N -

POWER

21.6-26.4V DC

4W

50/60Hz 6VA

21.6-26.4V AC~

COM

VOLTAGE:0-10V DC

VOLTAGE:0-10V DC

「Note」: If input type is thermocouple or voltage, errors may occur when terminal 11 and

terminal12terminalare short-circuited

Terminalarrangement planofMAC3C

1

2

3

4

5

6

10

11

12

13

14

15

16

17

18

EV2

EV1

DI1

DI2

DI3

AO

+

-

COM

+

-

CT1

CT2

~

~

~

~

L

N

POWER

OUT1

90-264V AC

50/60Hz 9VA

OUT2/EV3/DI4

INPUT

+

-

A

B

B

CONTACT:240V AC 2A

SSR DRIVE:12V DC 20mA

CURRENT:4-20mA DC

+

-

+

-

CONTACT:240V AC 2A

SSR DRIVE:12V DC 20mA

CURRENT:4-20mA DC

EV3:240V AC 2A

240V AC 2A

240V AC 2A

COM

7

8

9

19

20

21

22

23

24

25

26

27

L +

N -

POWER

21.6-26.4V DC

4W

50/60Hz 6VA

21.6-26.4V AC~

VOLTAGE:0-10V DC

VOLTAGE:0-10V DC

「Note」: If inputtypeisthermocouple or voltage, errors may occur when terminal 8 and

terminal9terminalareshort-circuited

TerminalarrangementplanofMAC3D

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

EV2

EV1 DI1

DI2

DI3

AO

+

-

COM

+

-

CT1

CT2

~

~

~

~

L

N

POWER

OUT1

90-264V AC

50/60Hz 9VA

OUT2/EV3/DI4

INPUT

+

-

A

B

B

CONTACT:240V AC 2A

SSR DRIVE:12V DC 20mA

CURRENT:4-20mA DC

+

-

+

-

CONTACT:240V AC 2A

SSR DRIVE:12V DC 20mA

CURRENT:4-20mA DC

EV3:240V AC 2A

240V AC 2A

240V AC 2A

L +

N -

POWER

21.6-26.4V DC4W

50/60Hz 6VA

21.6-26.4V AC~

COM

VOLTAGE:0-10V DC

VOLTAGE:0-10V DC

「Note」:Ifinputtypeisthermocouple or voltage, errors may occur whenterminal 5 and

terminal 6 terminalareshort-circuited

4.

4.4.

4..Descriptionoffrontpanel

4-1.

4-1.4-1.

4-1.Namesoffrontpanel.

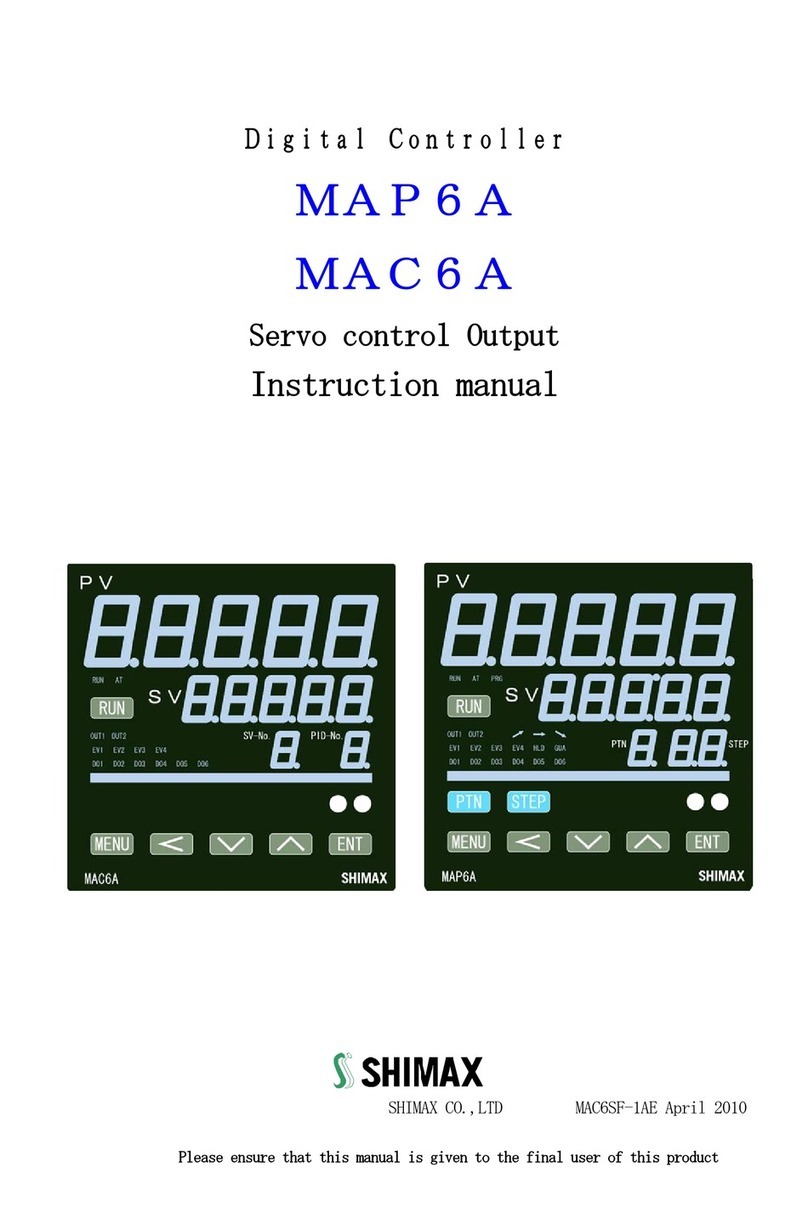

MAC3A 96×96size front MAC3C72×72size front

MAC3D 48×48size front MAC3B48×96 size front

4-2.Explanationoffront panelsection

① :Displayofmeasuredvalue(PV) (red)

Measured value(PV) andtypeofsettingisdisplayedoneachsettingscreen.

②:Displayoftarget value(SV) (green)

Target valueand set valueare displayedon eachsettingscreen.

③:MonitorLED

(1)RUN monitor LED RUN (green)

IfRUN isperformed with RUN key, operation mode1 screen, external control input (DI),and

communication, it lights up, and put out by standby (reset). It blinks, if a manual output is

choseninoutput monitoringscreenor externalcontrol input (DI).

(2)Programfunctionalmonitor LED PRG (green)

Lightsup at the time of program control's standby or flat part control. Puts out at the time of

FIXcontrolselection.

(3)AutotuningoperationmonitorLED AT (green)

If AT is chosen in ON or external control input (DI), blinks during AT execution. Lightsup

when ATisonstandby,andputsoutwithATautomaticterminationorrelease.

(4)controloutput1 monitorLED OUT (green)

At thetimeofa contact ora voltage pulseoutput,theitlightsupwith ONandlightsoff with

OFF.Lightsoffwith0%poweroutput,andlightsupwith100%power.

Andblinksinintermediateratio.

(5)Eventoutput monitorsLED EV1andEV2 (yellow)

Lightsupwhentheallottedeventoutput turnstoON.

(6)Controloutput 2/eventoutput3 monitorsLED OUT2/EV3 (yellow)

Whencontrol output2 ischosen, it operateslikecontrol output1 monitor LEDdoes.

Whenevent output3 ischosen,itoperateslikeeventoutput monitorLEDdoes.

④: Key-switchsection

(1)

(MENU)key

Pressthiskeytomoveontothenextscreenamong thescreens.

Press

(MENU)key for three secondsonthe basicscreen,then it jumpsto the

lead screen of Mode1. Press

keyfor threeseconds on thelead screen ofeach

Modescreens,thenitjumps tothe basicscreen.Press

keyforthreesecondson

the lead screen of FIX or PROG, then it jumps to the basic screen.When a

program control option is added, press

(MENU) key for three seconds on the

screenofoperationmode2,thenitjumpstothescreenofoperationMode1.

(2)

(DOWN)key

Press

(DOWN)key onetime,andtheshownvaluedecreasesbyonenumericalvalue.

One time press of

key decreases by one numerical value. By pressing the key

continuously, the valueas well consecutively decreases. A decimal point of the smallest digit

blinks at this time. This shows thata settingchange isinprogress.InPROG,usedasa shiftkey

between each step setting screens(Steps1-25) ,lead screen.Also used as a shift key between

leadscreenineachmodescreens.

(3)

(UP) key

Press

(UP)key onetime,and theshownvalueincreasesbyonenumerical value.

By pressing continuously, the value By pressing the key continuously, the value consecutively

increases. A decimal point of the smallest digit blinks at this time. This shows that a setting

change is in progress. In PROG,used as a shift key between each step setting screens (Steps

1-25), lead screen. Also usedasa shiftkeybetween lead screenin each mode screens.

(4)

(ENTRY/REGISTER)key

The setting data changed on each screen is determined (the decimal point of the minimum

digitisalsolightedoff).

When aprogramcontrol option is added,press

(ENT)keyforthreesecondsonthescreen

ofoperation mode1,thenitjumpstothe screenofoperationMode2.

Press

key for 3 seconds on the output monitoring screen,then the shift between manual

outputandautomaticoutputiscarriedout.

Press thekey for3 secondsonthe basicscreen,then it shifts to FIXor PROG head screen.

PushatFIX-PROGandeachmodescreens'leadscreen,thenshiftstosettingscreen.

(5)

(RUNOPERATION/STOP)key

Push for 3 secondsatSTBY (controlstop),thenFIXorPROG control starts.

Push for3 secondswhileFIX or PROG is in operation,thencontrolisstopped.

①

②

③

④

①

②

③

④

5

5. Description of screens

5. Description of screens5. Description of screens

5. Description of screens

5

55

5-

--

-1. How to move to another screen

1. How to move to another screen1. How to move to another screen

1. How to move to another screen

Basic Screen

3 seconds (constant value control) lead screen of setting screens or (Program control) lead screen of setting screens

3 seconds

Press the key for 3 seconds on a basic screen, then it shifts to the lead screen of (constant value control) setting screens, or to the lead screen of (program control) setting screens.

Press the key for 3 seconds on or the lead screen of setting screens, then it shifts to the basic screen..The shift is also possible when the program option is added and is chosen on the

operation mode 2 screen. The shift is possible when the program option is added and is chosen on the operation mode 2screen.

Basic Screens

Mode 1 ~ 9 screens

Basic Screen

Mode 1 lead screen Mode 2 lead screen Mode 9 lead screen

three seconds

three seconds

Operation mode 1 key lock PV offset correction

Every time you press the key on a basic screen, it shifts to each screen of the basic screens.

Press the key for 3 seconds on a basic screen, then it shifts to the lead screen of mode 1 screens.

Press the key on the lead screen of mode 1 screens , then it further advances to mode 2, and mode 3. (Notes: If no corresponding option is found, the mode 4 - 9 is skipped)

Press the key on the lead screen of mode 1 screens , then it further advances to mode 9, and mode 8. (Notes: If no corresponding option is found, the mode 4 - 9 is skipped)

Press the key for 3 seconds on the lead screen of mode 1~ 9 screens, then it shifts to the basic screen.

Press the key on the lead screen of mode 1~ 9 screens, then it shifts to the first setting screen of each screens.

Press the key on the the first setting screen of each screens, then it shifts to the next screen. Every time you press the key, it shifts to the next setting screen.

5

55

5-

--

-2. Setting Method

2. Setting Method2. Setting Method

2. Setting Method

To change settings, display an appropriate screen and change the setting (value or function) by pressing or key.

On the output monitor screen of basic screens, you can change the control output from "Automatic" to "manual" ,and save its change of setting. Display the output monitor screen, and then press key for

three seconds to shift from Automatic to Manual. Then by pressing or key, you can adjust to the desirable output value. In this case, no need to press key in order to determine the change of setting.

Press key for three seconds as well to shift back to Automatic. Excluding when a keylock is OFF, Automatic⇔Manual switchover does not work while STBY<RST> and AT are in operation.

In the case of two-output type, the switchover between automatic and manual is operatable through output 1 and output 2. The setting is altered simultaneously.

Output monitor Output monitor Output monitor

three seconds

or

Automatic screen RUN lamp lights up Manual screen RUN lamp blinks Manual screen RUN lamp blinks

5

55

5-

--

-3. Power

3. Power3. Power

3. Power-

--

-on and initial screen display

on and initial screen displayon and initial screen display

on and initial screen display

At power-on, the display section shows each screen of initial screens for one second , then moves on to the basic screen.

《Power-on》

All LED light up Input type Upper limit & lower limit of measuring range Out 1 type ※

※※

※ Out 2 type Basic screen

:Contact :Voltage pulse :Current ※

※※

※Output 2 Displays only optional addition.

5

55

5-

--

-4. Explanation of each scre

4. Explanation of each scre4. Explanation of each scre

4. Explanation of each scre

(1) Basic Screens

Basic Screen

Executed SV initial value:Sensor input 0

Linear input Lower limit of scaring range

Setting range:Sensor input Within measuring range

key Linear input With in scaring range

Within SV limiter besides

Targeted value (PV) is displayed on the upper row as four-digit ,and target d

value (SV) is displayed on the lower row also as four-digit. (Notes:hereinafter,

measured value and targeted value are referred to as"PV" and "SV")

At the time of FIX, execution SV is displayed and change of setting is possible.

PROG's SV is just displayed ,and change of setting is impossible.

Action Mode 1 screen

Initial value::(stanby)(Initial value at the time of constant value control)

(reset)(Initial value at the time of program control)

Setting range::() Control stop [Output OFF (0%)] operation

key conduct of control operation

Choose (RUN) by key. Decide by key, then Monitor LED's RUN lights up to

start control operation.

Choose ()by key、Decide by key, hen Monitor LED's RUN lights off

and becomes control stop [Output OFF (0%)] conducting.

Priority is given to DI when RUN is allotted to external control input. DI. Key operation cannot be

performed unless allotment is canceled.

When measuring range, a unit, scaling, and output characteristics are changed it is initialized and

() is displayed.

Press key for 3 seconds, then it shifts to Action mode2 screen,when the program control

option is added on this screen, FIX (constant value control) ←→PROG (program control)

switchover is possible choose.

Choose a program,then Monitor LED's PRG lights up.

Action mode1 screen Action mode2 screen

three seconds

three seconds

three seconds PRG LED lights up

Press key for 3 seconds on Action mode2 screen, then it returns to Action mode1 screen.

Action mode2 screen is not displayed without a program option.

When PROG is allotted to DI, DI is given priority. Key operation cannot be performed unless

allotment is canceled.

Press key on Action mode1 screen, then it shifts to output 1 monitoring screen.

6

Output 1 monitoring screen

manual output setting range: :0.0-100.0% (within output limiter)

At the time of automatic output,monitor display only.

key Refer to Item 5-2 about automatic ⇔ manual switchover,and setting method at the

time of manual operation.

A manual output is canceled when an operation mode is made into ().

When a power source is intercepted and re-switched on, it returns to the condition just before

intercepting.

When is allotted to DI, DI is given priority. Automatic ma ⇔ manual switchover

is not performed with key operation,and only the output value at the time of manual

operation can be changed.

Output 2 monitoring screen

Contents are the same with that of an output 1.

key Output 2 monitoring screen displays only when output 2 option is added.

CT1 current monitoring-screen

Current display range: 0.0-55.0A

Displays at the time of CT input option addition, and the current value detected by CT

sensor is displayed.

key Current value is displayed.

CT2 current monitoring screen

Contents are the same with that of an output 1.

key

Monitoring screen of step's remaining time period

:

::

: Displays while program is in operation if program option is added.

key Step № in progress and remaining time are displayed by turns.

(In ∞ setting, step № and are displayed by turns)

A remaining time and an elapsed time is switchable by pressing the key for 3 seconds.

(Switchover is interlocked with the number of times of next screen pattern.)

Decimal point of the minimum digit lights up in displaying elapsed time,

This screen is not displayed without a program option.Not displayed in the state of

program RST and FIX neither.

Monitoring screen for the remaining repeating time of pattern

Being displayed while program is in operation, when the program option is added,

On-going step № and the remaining repeating time of pattern are displayed by turns.

key (In ∞ setting, step № and are displayed by turns)

A remaining time and actually performed times are switchable by pressing the key

for 3 seconds. (Switchover is interlocked with front screen step time.)

The decimal point of the minimum digit lights up when actually performed times being displayed.

This screen is not displayed without a program option.Not displayed in the state of

Program RST and FIX neither.

PID № monitoring screen

Chosen PID № is displayed when FIX is in operation.

PID № chosen at each step and on-going step № are displayed by turns when PROG

key is in operation.

PID № of output 1 is displayed in the first digital, and PID № of output 2 is displayed in

the third digital. The third digital is shown as when there is no output 2 option.

This screen is not displayed in the state of STBY (RST).

HOLD (temporary stopping) execution screen

Initial value::

Setting range::、

While HOLD is executed, on the basic screen,SV value and is displayed by turns . If

switched while PROG is in operation , the operation temporary stops with

as of then step time and SV value. While HOLD is in execution , SV value and

is displayed by turns in basic screen.、

HOLD is used in order to perform AT in the middle of an inclination step or to compensate the

insufficient time of flat step.

Controls is performed with SV value at the time of stopping,while HOLD is in execution

HOLD is canceled if is chosen while HOLD is in execution. The remaining time

of the step is performed based on a program.

(skip)is unable to perform while HOLD is in execution.

When is allotted to DI, DI is given priority.

Execution and release of HOLD with key operation is unable to perform.

This screen is not displayed without a program option.Not displayed in the state of program

and FIX neither.

SKIP (skip) execution screen

Initial value::

Setting range::、

SKIP (skip) is the function that makes to end the on-going step compulsorily, and is to shift to

the following step. The next step starts instantly, if performed.

When SKIP is continuously performed, about 1 second interval is required from execution to the

next one.

Even if SKIP is allotted to DI, execution is able to perform with DI and key operation.

key SKIP cannot be performed while HOLD is in operation.

This screen is not displayed without a program option. Not displayed in the state of

program

and FIX neither.

AT (Auto Tuning) execution screen

Initial value::

Setting range::、

key

AT is performed by ON selection ,and canceled by OFF selection.

Not displayed at the time of STBY(RST), a manual output, and P(proportional band) =OFF.

Except in the setting of keylock OFF, AT is unable to perform in scale over.

(At the time of DI allotment,execution of AT by DI can be performed .)

Even in such a case,halfway release is performed on this screen.

Release of AT, STBY(RST), EV operating point, setting of keylock, and mode 5 ~

9screen are operateable with key.

Except in th setting of AT normal end, execution of AT is canceled compulsorily at the time

of STBY(RST) selection and AT release setup.

EV1 (event 1) operating-point setting screen

Initial value: upper limit absolute value measuring range Scaling upper limit

lower limit absolute value measuring range Scaling lower limit

upper limit deviation

key lower limit deviation

within deviation

outside deviation

CT1 or CT2

guarantee

Setting range: upper limit absolute value within measuring range within scaling limit

lower limit absolute value within measuring range within scaling limit

upper limit deviation ~ unit

lower limit deviation ~ unit

within upper-lower limit deviation ~ unit

outside upper-lower limit deviation ~ unit

CT1 or CT2 ~A

The operating point of the alarm type allotted to EV1 is set up.

No option, No display when , , , , ・ , ,

, , , and are allotted to EV1.

The operation mode of each deviation alarm is .

Effective at the time of automatic output.

Each deviation alarm serves as PV’s deviation to Execution SV.

Event operation other than each deviation alarm is always effective.

EV2 (event 2) operating-point setting screen

Initial value,setting range, contents are the same with EV1

key

EV3 (event 3) operating-point setting screen

Initial value,setting range, contents are the same with EV1

key

When EV3 option is added, event 3 is displayed as the same contents with EV 1 and 2,

irrespective of EV 1 and 2.

7

Latching release screen

Initial value::

Setting range:: release EV1

release EV2

key release EV3

release all EVs at a time

On the latching setting screen of each EV mode, № and which chose

are displayed. If latching is ,once EV is outputted, EV output state is maintained even

if EV is in the state of OFF. When EV is in a latching state, decimal point of the minimum

digit blinks, and it shows that release of EV is possible. If key is pressed, EV is released

and a decimal point lights off.

However, release is impossible when a state is in EV power range.

Return to basic screen

(2) FIX (constant value control) setting screens

At the time of no program option and with program option and is chosen on Action

mode2 screen of basic screens,lead screen of FIX setting screens is displayed when key is

pressed for 3 seconds.

If key is pressed for 3 seconds on lead screen, it returns to basic screen.

basic screen lead screen of FIX setting

three seconds

three seconds

FIX lead screen

No setting on this screen.

key Press key , then it shifts to the first setting screen SV1 setting screen.

SV1 setting screen

Initial value : At the time of sensor input 0

linear input time scaling lower limit

Setting range: sensor input time within measuring range

key linear input time within scaling range

Moreover, within limit of SV limiter.

When SV1 is Execution SV,being reflected in basic screen.

Being initialized when measuring range, unit, and scaling are changed.

SV1 output1 PID No. setting screen

Initial value : 1

Setting range:1, 2, 3

key When SV1 is Execution SV,PID№ that will be used for control of output 1

is chosen from 1~3.

SV1 output2 PID No. setting screen

Initial value:1

Setting range:1,2,3

key When SV1 is Execution SV,PID№ that will be used for control of output 2 is

chosen from 1~3.

Displayed when output 2 option is added.

SV2 setting screen

Initial value: same with SV1

Setting range: same with SV1

key

Displayed when SV2 is allotted to DI.When terminal of allotted DI short-circuits, it becomes

Execution SV.

When SV2 is Execution SV, it is reflected in basic screen.

Being initialized when measuring range, unit, and scaling are changed.

SV2 output 1 PIDNo. setting screen

Initial value:1

Setting range:1,2,3

Displayed when SV2 is allotted to DI.

key When SV2 is Execution SV,PID№ that will be used for control of output 1 is

chosen from 1~3.

SV2 output 2 PIDNo. setting screen

Initial value:1

Setting range:1,2,3

key Displayed when SV2 is allotted to DI.

When SV2 is Execution SV,PID№ that will be used for control of output 2 is

chosen from 1~3.

Displayed when output 2 option is added.

SV3 setting screen

Initial value: same with SV1

Setting range: same with SV1

key Displayed when SV3 is allotted to DI.When terminal of allotted DI short-circuits,

it becomes Execution SV.

When SV3 is Execution SV, it is reflected in basic screen.

Being initialized when measuring range, unit, and scaling are changed.

SV3 output 1 PIDNo. setting screen

Initial value:1

Setting range:1,2,3

key Displayed when SV3 is allotted to DI..

When SV3 is Execution SV,PID№ that will be used for control of output 1 is

chosen from 1~3.

SV3 output 2 PIDNo. setting screen

Initial value:1

Setting range:1,2,3

key Displayed when SV3 is allotted to DI..

When SV3 is Execution SV,PID№ that will be used for control of output 2 is

chosen from 1~3.

Displayed when output 2 option is added.

SV4 setting screen

Initial value: same with SV1

Setting range: same with SV1

key Displayed when SV4 is allotted to DI..

When terminal of allotted DI short-circuits, it becomes Execution SV.

When SV4 is Execution SV, it is reflected in basic screen.

Being initialized when measuring range, unit, and scaling are changed.

SV4 output 1 PIDNo. setting screen

Initial value:1

Setting range:1,2.3

key Displayed when SV4 is allotted to DI..

When SV4 is Execution SV,PID№ that will be used for control of output 1 is

chosen from 1~3.

SV4 output 2 PIDNo. setting screen

Initial value:1

Setting range:1,2,3

key Displayed when SV4 is allotted to DI..

When SV4 is Execution SV,PID№ that will be used for control of output 2 is

chosen from 1~3.

Displayed when output 2 option is added.

Return to FIX lead screen

(3) PROG (program control) setting screens

Press key for 3 seconds, lead screen of the PROG setting screens is displayed,When program

option is added and is chosen on Action mode2 screen of basic screens.

If key is pressed for 3 seconds on lead screen, it returns to basic screen.

Basic screen lead screen of the PROG setting screens

three seconds

three seconds

Press Key for 1second it will move to Program pattern 2 screen, and Press key 1second

It will move to program pattern 1,2, 4,

The number of setting in the program pattern screen can be changed 1-4 to the number of program

pattern.(1=pattern 1,2= pattern 1 & 2, 4= pattaern 1 to 4)

Only the pattern you did program pattern setting screen will be indicated.

1second 1second 1second 1second

Please refer explanation

of program sequence

8

Program basic setting screens

Program basic setting screens Lead screen

No setting on this screen

Press key to shift to step 1 lead screen.

Press key to shift to step 40 lead screen.

key Press key to shift to the first setting screen start mode setting screen.

Start mode setting screen

Initial value: (PV)

Setting range: (SV)、(PV)

This setting screen can decide if the start set point of program control should be PV, or

key should be the start SV which is set on the next screen.

When PV is chosen, and when PV is closer to the set point of Step1 than start wasting

SV,time is omissible.

Start SV setting screen

Initial value : At the type of sensor input 0

linear input type scaling lower limit

Setting range: sensor input type within measuring range

key linear input type within scaling range

Moreover, within limit of SV limiter.

When SV is chosen on start mode setting screen, this screen's set value becomes start set point.

The basic screen SV display at the time of Program RST is the value set on this screen.

Termination step setting screen

Initial value: 40

Setting range: 1~40 steps

key Pattern termination step No, of program control is set.

Number of execution Setting screen for repeating of program pattern

Initial value:1

Setting range:1~9999 times、∞

key The number of execution of a program pattern is set.

Gurantee soak zone

Initial value:OFF

Setting range:OFF,1~2000 Digits(Time unit belong to the Time unit setting screen)

key In case deviation of step SV of level step PV remains,the step does not move to the

next step until PV reach to the SV.

Time unit setting screen

Initial value::(minute:second)

:

::

: Setting range: :、 :、 .

..

.

key This decides if unit of the execution time set up at each step is minute:

second ,hour: minute,or hour.

To program basic setting screens Lead screen

About PV start

In start mode,when PV is chosen, and when PV is closer to the set point of Step1 than start SV,

wasting time is omissible.

「example」:PV at the time of "RST is 30℃, Start SV is 0 ℃, Step 1's attainment SV 100 ℃,

Execution time of Step1 is 60 minutes

Start at start SV,attainment time is 60 minutes.

When starts at PV, 100-30=70℃ ,therefore 60 minutes x70%= 42 minutes = 18

minutes' shortening

However, depending on the spatial relationship between PV, Start SV, and attainment SV, it may become

SV start or Step1 may be skipped.

(1) case of SV start

PV≦S_SV(start SV) < 1_SV (step1 attainment SV)

PV≧S_SV>1 _SV

1_SV PV

S_SV

S_SV

PV 1_SV

Step 1 Step 2 Step 1 Step 2

(2)When Step 1 is skipped and progresses to Step 2

S_SV < 1_SV < PV

S_SV > 1_SV > PV

PV=1_SV

PV S_SV

abbreviation

1_SV 1_SV

S_SV PV abbreviation

Step 1 Step 2 Step 1 Step 2

Step 1 setting screens~ Step 40 setting screens

Screen sequence of step 1 setting screens ~ step 40 setting screens are as follows.

・・・・

・・・・

1 second ・・・ 1 second

1 second ・・・ 1 second

1 second ・・・ 1 second

1 second ・・・ 1 second

In each step setting screen, next to number, for Steps 1~9 , for 10~ 19 for 20~ 29 ,30

~39 and 40 are assained to distinguish each of them.

( Step 1 SV = , step 12SV = , step 23SV= , and step 34 )

If the key is pressed at each step lead screen, it shifts to SV setting screen of each step.

If the key is pressed on SV setting screen, it shifts to execution time setting screen of each step.

After that, if key key is pressed,then it shifts to output 1PID№, output 2PID№, and lead screen.

Moreover, it is if key is pushed for 1 second on each setting screen,it advances to the next Step №'s

same setting item screen.

(1_SV→2_SV・・・→0 SV→1_SV)

Step 1 is explained, since all the setting content of each step are same.

Step1 SV setting screen

Initial value : At the time of sensor input 0

At the time of linear input scaling lower limit

Setting range : At the time of sensor input within measuring range

key At the time of linear input scaling within the limits

Within limit of SV limiter,and yet

Attainment set value of Step 1 is set.

Being initialized when measuring range, unit, and scaling are changed.

Step 1 execution-time setting screen

Initial value: 00:01

Setting range: 00:00 to 99:59 (minute: second, hour : minute)

0.1-999.9 (hour) and ∞(infinity)

key Execution time of Step 1 is set.

Step1 output1 PIDNo. setting screen

Initial value:1

Setting range:1~3

PID№ used in Step1's control output 1 is chosen.

key

Step1 output 2 PIDNo. setting screen

Initial value:1

Setting range:1~3

key PID№ used in Step1's control output 2 is chosen.

Displayed when output 2 option is added.

To step1 lead screen

9

(4) Mode 1 screens

Mode 1 lead screen

Press key for 3 seconds on basic screen, then displayed

key No setting on this screen. Press the key, then it shifts to the first setting screen,

keylock setting screen.

Keylock setting screen

Initial value:

Setting range:、、、、

key

Only change of Execution SV (basic screen) and keylock is possible.

Possible to change numerical value value manualy ,and key lock level

Only change of a keylock is possible.

Only change of a keylock is possible It can be locked key

Notes: Even when keylock is set as 1 and 2, manual output value is possible to change.

SV limiter lower limit setting screen

Initial value: measuring range lower limit

Setting range: measuring range lower limit value~measuring range upper limit value-1

key And (SV display turn off)

Lower limit value of target value is set .

When upper limit value is smaller than lower limit value, the value compulsorily becomes

lower limit value +1.

When you choose pressing at lower limit value ,the SV display turn off at

basic screen. But it will turn on at the setting screen.

SV limiter upper limit value setting screen

Initial value: measuring range upper limit

Setting range:SV limiter lower limit value +1~ measuring range upper limit value

key

Setting upper limit value of target value is set.

Return to mode1 lead screen.

(5) Mode 2 screens

Mode 2 lead screen

Press key in mode1 lead screen, or press key in mode3 lead screen,

then being displayed.

key If key is pressed, it shifts to the first setting screen PV offset correction screen.

PV offset correction (PV bias) setting screen

Initial value:0

S etting range:-500~500 Digits

key

Used for correction of input errors such as sensor.

If offset correction is performed, control is also performed with the corrected value

PV gain correction setting screen

Initial value:0.00

Setting range: ±5.00%

key Maximum input value is corrected within limit of ±5.00% of measuring range.

If corrected, inclination of spang changes in straight line which connects zero point and

correction maximum value.

PV filter setting screen

Initial value:0

Setting range: 0 ~ 9999 seconds

key When input change is violent or noise is overlapped, used in order to ease the influences.

In 0 second setting, filter does not function.

Mesuring range setting screen

Initial value: multi , voltage , current

Setting range: Chosen from 5-5.measuring range code table.

key

Combination of input type and measuring range is set by code.

Temperature unit setting screen

Initial value:

Setting range:、

key

The temperature unit at the time of a sensor input is set up from

(℃) , ()

.

Not displayed when the linear input is chosen.

Input scaling lower limit value setting screen

Initial value:0.0

Setting range: -1999 ~ 9989 digits

key

Scaling lower limit value at the time of linear input is set up.

Input scaling upper limit value setting screen

Initial value:100.0

Setting range: -1989 ~ 9999 digits

key Scaling upper limit value at the time of linear input is set up.

NOTE:Suppose that the difference between a lower limit value and upper limit value is 10

or less,or over 10,000. In this setting, upper limit value is compulsorily changed

into that of +10 or ± 10000 count. Upper limit value cannot be set as lower limit

value of +10 count or less,or that of over 10,000 count.

Input scaling Decimal point position Setting screen

Initial value: the first place after decimal point (0.0)

Setting range: no decimal point 0~the third place after decimal point(0.000)

Decimal point position of input scaling is set .

key

NOTE: The screen of input scaling serves as a monitor at the time of a sensor input.

Setting change cannot be performed.

Return to mode 2 lead screen.

(6) Mode 3 screens

Mode 3 lead screen

No setup

If key is pressed, it shifts to the first setting screen, output 1 proportional band

key setting screen. In this screens, PID which can be used in output 1, 1~3 related Items

and soft start of output 1,and proportional period output characteristics are set up.

Output 1 PID1 proportional-band (P) setting screen

Initial value:3.0%

Setting range:OFF, 0.1 ~ 999.9%

key

When performing auto tuning, no necessity for a setting basically.

If OFF is chosen, it becomes ON-OFF (two positions) operation.

Output 1 PID1 Integral time (I) setting screen

Initial value: 120 seconds

Setting range: 0FF, 1~6000 seconds

key

When performing auto tuning, no necessity for a setting basically.

This screen is not displayed at the time of ON-OFF operation.

Becomes P operation or PD operation in I=OFF setting.

Output 1 PID1 Derivative time (D) setting screen

Initial value: 30 second

Setting range: 0FF, 1~3600 seconds

key

When performing auto tuning, no necessity for a setting basically.

This screen is not displayed at the time of ON-OFF operation.

Becomes P operation or PI operation in D=OFF setting.

Output1 PID1 manual reset setting screen

Initial value:0.0

Setting range: -50.0~50.0%

key

The offset correction at the time of I=OFF ( P operation,PD operation]) is performed.

This screen is not displayed at the time of ON-OFF operation.

Output 1 PID1 differential-gap setting screen

Initial value: 5

Setting range: 1 ~999 unit

key

The differential gap at the time of ON-OFF operation is set.

Displayed at the time of P=OFF ( ON-OFF operation) setup.

10

Output1 PID1 minimum limiter setting screen

Initial value:0.0

Setting range: 0.0~99.9%

key Output lower limit value of output 1 PID1 is set up.

Note: At the time of STBY (RST) and scale over output,

limiter value is disregarded.

Output 1 PID1 maximum limiter setting screen

Initial value:100.0

Setting range: output limiter lower limiter values +0.1~100.0%

key Upper limit value of output 1 PID1 is set .

Output 1 PID2 proportional band (P) setting screen

Initial value:3.0%

Setting range: OFF, 0.1~ 999.9%

key Content is the same with output 1 PID1.

Output 1 PID2 integral-time (I) setting screen

Initial value: 120 seconds

Setting range: 0FF, 1~6000 seconds

key Contents is the same with output 1 PID1.

Output 1 PID2 derivative-time (D) setting screen

Initial value: 30 seconds

Setting range: 0FF, 1~ 3600 seconds

key

Contents is the same with output 1 PID1.

Output 1 PID2 manual reset setting screen

Initial value: 0.0

Setting range: -50.0~50.0%

key Contents is the same with output 1 PID1.

Output 1 PID2 differential gap setting screen

Initial value: 5

Setting range: 5~999 unit

key Contents is the same with output 1 PID1.

Output 1 PID2 minimum limiter setting screen

Initial value:0.0

Setting range:0.0~99.9%

key Contents is the same with output 1 PID1.

Output 1 PID2 maximum limiter setting screen

Initial value: 100.00

Setting range: output limiter lower limit value +0.1~100.0%

key Contents is the same with output 1 PID1.

Output 1 PID3 proportional band (P) setting screen

Initial value: 3.0%

Setting range:OFF, 0.1~ 999.9%

key

Contents is the same with output 1 PID1.

Output 1 PID3 integral-time (I) setting screen

Initial value: 120 seconds

Setting range: 0FF, 1~ 6000 seconds

key

Contents is the same with output 1 PID1.

Output 1 PID3 derivative time (D) setting screen

Initial value: 30 seconds

Setting range: 0FF, 1~3600 seconds

key

Contents is the same with output 1 PID1.

Output 1 PID3 manual reset setting screen

Initial value:0.0

Setting range:-50.0~50.0%

key Contents is the same with output 1 PID1.

Output 1 PID3 differential gap setting screen

Initial value:5

Setting range:1~999 unit

key Contents is the same with output 1 PID1.

Output 1 PID3 minimum limiter setting screen

Initial value: 0.0

Setting range: 0.0~99.9%

key Contents is the same with output 1 PID1.

Output 1 PID3 maximum limiter setting screen

Initial value: 100.0

Setting range: output limiter lower limit values +0.1~100.0%

key Contents is the same with output 1 PID1.

Output 1 soft starting time setting screen

Initial value: OFF

Setting range:OFF, 0.5~120.0 seconds (setting resolution 0.5 second)

This is the function that eases change of output at the time of a power-on and startup.

key Does not function at the time of OFF setup.

Output 1 proportional periodic time setting screen

Initial value: Contact output 30.0 seconds

Voltage pulse output 3.0 seconds

key Setting range: 0.5~120.0 seconds (setting resolution 0.5 second)

Proportional periodic time of output 1 is set.

Not displayed when output 1 is current.

Output 1 characteristics setting screen

Initial value:

Setting range:、

key Characteristics of control output is chosenfrom (heating characteristics)

and (cooling characteristics)

Return to mode 3 lead screen

(7) Mode 4 screens

Mode 4screens is the setup screens of output 2 option. Not displayed when option is not added.

Mode 4 lead screen

No setup

Press key , then it shifts to the first setting screen,output 2 proportional band 1

key setting screen.

On this screen, PID1~3 related items that can be used in output 2,

soft start of output 2,and proportional period output characteristics are set.

Output 2 PID1 proportional band (P) setting screen

Initial value:3.0%

Setting range:OFF, 0.1~ 999.9%

key

Contents is the same with output 1 PID1.

Output 2 PID1 integral-time (I) setting screen

Initial value: 120 seconds

Setting range: 0FF, 1~ 6000 seconds

key Contents is the same with output 1 PID1.

Output 2 PID1 derivative-time (D) setting screen

Initial value: 30 seconds

Setting range: 0FF, 1~3600 seconds

key Contents is the same with output 1 PID1.

Output 2 PID1 dead-band setting screen

Initial value:0

Setting range: -1999~5000 unit

key

Output 2's operation zone to output 1 is set with dead- band.

Output 2 PID1 differential-gap setting screen

Initial value:5

Setting range: 1~999 unit

key Contents is the same with output 1 PID1.

Output 2 PID1 minimum limiter setting screen

Initial value: 0.0

Setting range: 0.0~99.9%

key Contents is the same with output 1 PID1.

11

Output 2 PID1 maximum limiter setting screen

Initial value:100.0

Setting range: output limiter lower limit values +0.1~100.0 %

key Contents is the same with output 1 PID1.

Output 2 PID2 proportional-band (P) setting screen

Initial value:3.0%

Setting range: OFF, 0.1~ 999.9%

key

Contents is the same with output 1 PID1.

Output 2 PID2 integral-time (I) setting screen

Initial value: 120 seconds

Setting range: 0FF, 1~6000 seconds

key Contents is the same with output 1 PID1.

Output 2 PID2 derivative-time (D) setting screen

Initial value: 30 seconds

Setting range: 0FF, 1~3600 seconds

key Contents is the same with output 1 PID1.

Output 2 PID2 dead-band setting screen

Initial value:0.0

Setting range:-50.0~50.0%

key Contents are the same as output 2PID1 dead-band setting screen.

Output 2 PID2 differential-gap setting screen

Initial value: 5

Setting range: 1~999 digits

key

Contents is the same with output 1 PID1.

Output 2 PID2 minimum limiter setting screen

Initial value: 0.0

Setting range: 0.0~99.9%

key Contents is the same with output 1 PID1.

Output 2 PID2 maximum limiter setting screen

Initial value:100.0

Setting range:output limiter lower limit values+0.1~100.0 %

key Contents is the same with output 1 PID1.

Output 2 PID3 proportional-band (P) setting screen

Initial value:3.0%

Setting range:OFF, 0.1~999.9%

key

Contents is the same with output 1 PID1.

Output 2 PID3 integral-time (I) setting screen

Initial value: 120 seconds

Setting range: 0FF, 1~6000 seconds

key

Contents is the same with output 1 PID1.

Output 2 PID3 derivative-time (D) setting screen

Initial value: 30 seconds

Setting range: 0FF, 1~3600 second

key Contents is the same with output 1 PID1.

Output 2 PID3 dead-band setting screen

Initial value:0.0

Setting range:-50.0~50.0%

key Contents are the same as output 2 PID1 dead-band setting screen.

Output 2 PID3 differential-gap setting screen

Initial value:5

Setting range: 1~999 digits

key Contents is the same with output 1 PID1.

Output 2 PID3 minimum limiter setting screen

Initial value:0.0

Setting range: 0.0~99.9%

key Contents is the same with output 1 PID1.

Output 2 PID3 maximum limiter setting screen

Initial value:100.0

Setting range: output limiter lower limit values+0.1~100.0%

key Contents is the same with output 1 PID1.

Output 2 soft starting time setting screen

Initial value:OFF

Setting range:OFF, 0.5~120.0 seconds (setting resolution 0.5 second)

key

Contents is the same with output 1.

Output 2 proportional periodic-time setting screen

Initial value: Contact output 30.0 seconds

Voltage pulse output 3.0 seconds

key Setting range: 0.5~120.0 seconds (setting resolution 0.5 second)

Contents is the same with output 1.

Output 2 characteristics setting screen

Initial value:

Setting range:、

key Contents is the same with output 1.

Return to mode 4 lead screen.

(8) Mode 5 screens

Mode 5 screens is the setup screens of event option. Not displayed when option is not added.

Mode 5 lead screen

No setup.

Press key , it shifts to the first setting screen, event 1 operation-mode setting screen.

key

Event 1 operation-mode setting screen

Initial value:

Setting range: Chosen from event type character table.

key

Event type allotted to event 1 is chosen from character table.

Event type character table

Character

Type Character

Type

No allotment Control loop alarm 2

Upper limit absolute value

alarm Step signal

Lower limit absolute value

alarm ・ Pattern termination signal

Scale over alarm Program termination signal

Maximum deviation alarm

Hold signal

Minimum deviation alarm Program signal

Within deviation alarm Up slope signal

Without deviation alarm Down slope siganal

RUN signal Gurantee signal

Control loop alarm 1

※ Being initialized if measuring range, scaling, and unit are changed.

※ Deviation alarm is possible to output at the time of RUN+AUTO.

In other events, output is always possible.

Event 1 differential-gap setting screen

Initial value:5Digits

Setting range: 1~999 Digits

key ON-OFF differential gap of event 1 is set .

Not displayed, when the event 1 mode are as follows.、、、、

、、、、.

Change in measuring range, scaling, unit, and the event 1 mode make it initialize.

Event 1 standby operation setting screen

Initial value::

key Setting range::、、

:No standby operation、 : standby-operation only at the time of a power-on.

:Standby-operation in the following cases. ;At the time of power-on.

When each alarm's operating point is changed,

When deviation alarm's SV is performed,

When RUN/STBY (RST) is switched,

When AUTO/MAN is switched.

Not displayed, when the event 1 mode are as follows. ;、、、、

・ 、、、、.

Change in measuring range, scaling, unit, and the event 1 mode make it initialize.

12

Event 1 latching setting screen

Initial value:

Setting range:、

key

When latching is set as , once event is output, even if event is OFF state event output

state is held. Not displayed when event 1 mode is .

Being initialized if measuring range, scaling, and unit are changed.

Event 1 output characteristics setting screen

Initial value:

Setting range:、

key Output characteristics event 1 is chosen from : normal open,

: normal closing.

Not displayed when event 1 mode is .

Note: If is chosen,relay turns to ON about 1.8 seconds later when power source is

switched on,and turns to OFF in event output range.

Event 2 mode setting screen

Initial value:

Setting range: Chosen from event type character table.

key Type allotted to event 2 should be chosen from character table.

Change in measuring range, scaling, unit, and the event 1 mode make it initialize.

Event 2 differential-gap setting screen

Initial value: 5digit

Setting range:1~999 digit

key The same as event 1.

Event 2 standby operation setting screen

・ Initial value:

Setting range:、、

key The same as event 1.

Event 2 latching setting screen

Initial value::

Setting range::、

key The same as event 1.

Event 2 output characteristics setting screen

・ Initial value::

Setting range::、

key The same as event 1.

Event 3 mode setting screen

Notes: Apart from event 1-2, event 3 is displayed when being added as additional option.

Initial value:

Setting range: Chosen from event type character table.

key Type allotted to event 2 should be chosen from character table.

Change in measuring range, scaling, unit, and the event 1 mode make it initialize.

Event 3 differential-gap setting screen

Initial value: 5 digit

Setting range: 1~999 digit

key The same as event 1.

Event 3 standby operation setting screen

Initial value:

Setting range:、、

key The same as event 1.

Event 3 latching setting screen

Initial value:

Setting range:、

key The same as event 1.

Event 3 output characteristics setting screen

Initial value:

Setting range:、

key The same as event 1.

Return to mode 5 lead screen

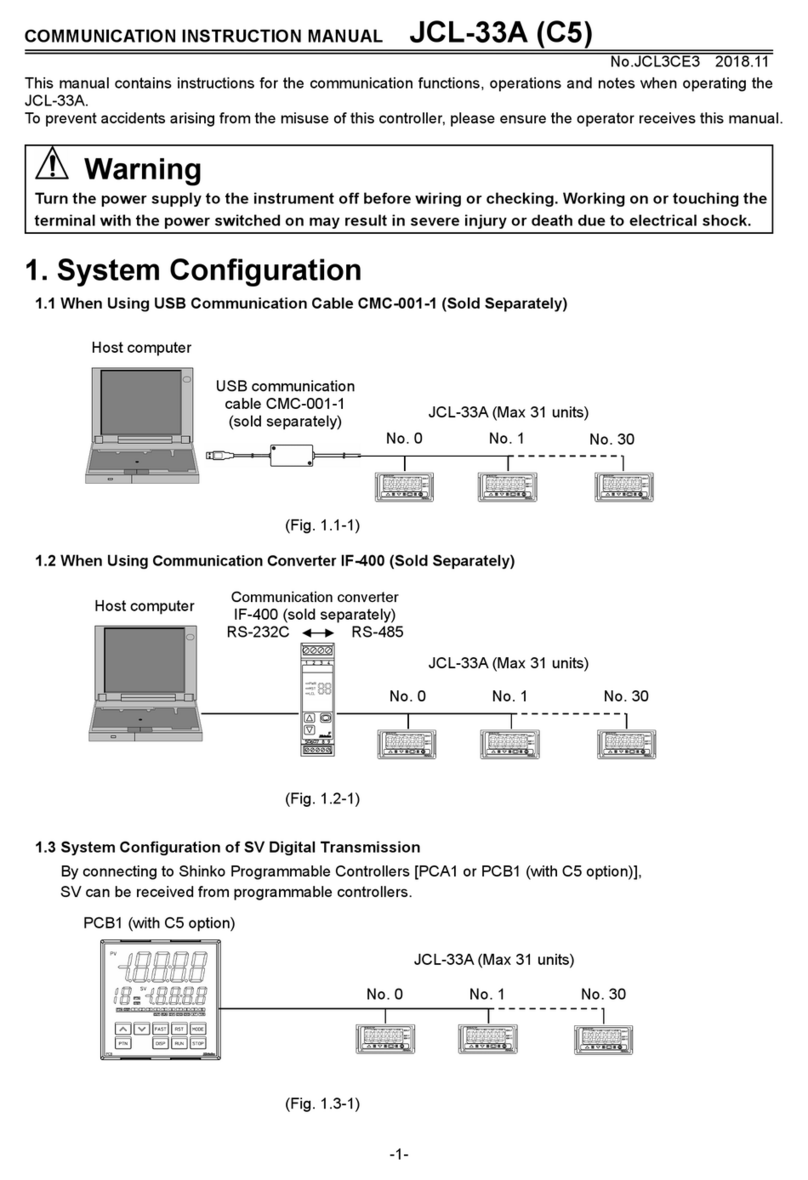

(9) Mode 6 screens

Mode 6 screens is the setup screens of external control input (DI) option.

Not displayed when option is not added.

DI input is a no-voltage contact or open collector

Mode 6 lead screen

Press key , it shifts to the first setting screen, DI1 mode setting screen.

key

In MAC 3D (48x48), when option of CT OUTPUT is added,

DI 1~DI3 cannot be chosen and not displayed.

DI 1 mode setting screen

Initial value:

Setting range: chosen from DI operation character table

key

Choose DI operation that is allotted to DI 1 from character table.

DI 2 mode setting screen

Initial value:

Setting range: chosen from DI operation character table

key

Choose DI operation that is allotted to DI 2 from character table.

DI 3 mode setting screen

Initial value:

Setting range: Chosen from DI operation character table.

key

Choose DI operation that is allotted to DI 3 from character table.

DI 4 mode setting screen

Notes: Apart from DI 1-3, DI 4 is displayed when being added as additional option.

Initial value:

Setting range: Chosen from DI operation character table.

key

Choose DI operation that is allotted to DI 4 from character table.

Return to mode 6 lead screen

DI operation character table and restrictions concerning DI

DI operation character table

DI character Operation type Input

detection

Contents

No allotment

2st SV level With closed DI terminal Execution SV = 1st SV

2nd SV level With closed DI terminal Execution SV = 2nd SV

3rd SV level With closed DI terminal Execution SV = 3rd SV

4th SV level With closed DI terminal Execution SV = 4th SV

control RUN level RUN with closed DI terminal, STBY with open one.

program level Program with closed DI terminal.

Constant value with opened.

manual inpu t level Manual with closed DI terminal,auto with open one.

auto tuning edge AT-start with rise edge.

hold level Program's time stops temporarily.

skip edge Shift to the next program's step.

Pattern 1 level Choose pattern 1 with close DI rerminal

Pattern 2 level Choose pattern 2 with close DI rerminal

Pattern 3 level Choose pattern 3 with close DI rerminal

Pattern 4 level Choose pattern 4 with close DI rerminal

latching release edge All latching are released by rise edg.

super key lock level Super keylock with closed DI terminal.

Release with opened.

*When ~ are conducted during AT execution, they are performed at the time of AT

termination.

*When ~ are allotted to to each DI, priority is given to --- in order.

* can be performed at the time of a RUN-automatic output.

*When is allotted to, release in the middle of AT operation is carried out by off-key operation chosen in

AT screen.

*While AT is performed, if STBY (RST) or a manual output is performed, AT is released.

*Even when a keylock is not OFF,conducting of DI is effective.

*The same operation other than is impossible to allot to DI1-DI4 at a time.

*Operation allotted to DI takes priority over DI.. Key operation cannot be performed.

*Execution of DI operation is possible to perform. But neither release of AT nor numerical change of SV and

manual output is possible to perform.*In DI input, 5VDC 0.5mA per point is impressed.Use endurable

switch, transistor and so on. ・Wiring distance of DI should be less than 30m

30m30m

30m.

13

(10) Mode 7 screens

The Mode 7 screens is the setup screens of analog output option.

Not displayed when option is not added.

In MAC 3D (48x48),when communication option isadded,it is impossible to choose and display.

Mode 7 lead screen

When key is pressed, it shifts to the first setting screen,analog output mode

key setting screen.

Analog output mode setting screen

Initial value: (does not output)

Setting range: PV

key execution SV

control out put 1

control out put 2

CT OUTPUT 1

CT OUTPUT 2

, , is displayed when option is added.

Data type allotted to analog output are chosen.

Analog output scaling lower limit value setting screen

Initial value: the following table

Setting range: the following table

key

Lower limit value of range allotted to analog output is set up.

However, AS_L<AS_H Lower limit value is given priority

Analog output scaling upper limit value setting screen

Initial value: the following table

Setting range:the following table

key

Upper limit value of range allotted to analog output is set up.

However, AS_L<AS_H Lower limit value is given priority

Lower limit value takes priority, therefore upper limit value cannot be set below the value of

lower limit value +1. When a lower limit value is set more than upper limit value, upper limit value

is push to the level of lower limit value +1.

Analog output limiter lower limit value setting screen

Initial value: 0.0

Setting range:0.0~100.0%

key

The lower limit value of analog output value (4-20mA) is set up by %.

For example, output value of a lower limit value in each setup are:8mA(25.0),

12mA(50.0), 16mA(75.0) and 20mA(100.0 ) respectively.

Analog output limiter upper limit value setting screen

Initial value:100.0

Setting range: 0.0~100.0%

key

Upper limit value of analog output value (4-20mA) is set up by %.

If set as the same value as ・ and ・ , it is fixed to the value.

Return to mode 7 lead screen

Note: An analog output limiter can be made into reverse scaling.

Example: Output range :0℃ (4mA)~ 1200℃ (20mA) can be 0℃ (20mA) ~ 1200℃ (4mA).

Set AL_L as 100% and AL_H as 0.0%.

(11) Mode 8 screens

Mode 8 screens is the setup screens of CT OUTPUT option.

Not displayed when option is not added.

In MAC 3D (48x48),when DI 1~3 are added,it is impossible to choose and display.

Mode 8 lead screen

Press key , it shifts to the first setting screen, CT1 mode setting screen.

key

Initial value:

Setting range:、、、

key 、、

Object detected by CT (current) sensor is chosen.

In the case of a current output, is not displayed.

is not displayed without current output or output 2 option.

and are not displayed without any option, respectively.

CT1 delay time setting screen

Initial value:0.5

Setting range: 0.5~30.0 seconds

key When control loop abnormal alarm is allotted to event,delay time from switchover of

operation (ON-OFF) to detection start is set up.

CT2 mode setting screen

Initial value:

Setting range:、、、

key 、、

The same as CT1 mode setting screen.

CT2 delay time setting screen

Initial value: 0.5

Setting range: 0.5~30.0 seconds

key The same as CT1 delay time setting screen

Return to mode 8 lead screen

About control loop abnormal alarm

When the targeted output of a control loop abnormal alarm is ON, if current detected by CT is lower

than the allotted event's operating point(Setting Value of a basic screens, event operating point setting

screen)

alarm output is issued as breaking alarm.

When the targeted output is OFF, if detected current is higher than the allotted event's operating point

(short-circuit, earth fault, etc.)

(12) Mode 9screens

Mode 9screens is the setup screens of communication (RS-485) option.

Not displayed when it isnot added. See the attached Communication Instruction Manual (in the

appendix : "at the time of communication option added") about communication,

MODE Settingrange Initial value

PV sensor input withinmeasuringrange measuringrangelowerlimitvalue

SV linearinput withinscalingrange scalinglower limit value

OUT1,0UT2 0.0~99.9 0.0

CT1,CT2 0.0~49.9 0.0

MODE Settingrange Initial value

PV sensorinput withinmeasuringrange measuringrangeupper limit value

SV linearinput withinscalingrange scalingupperlimit value

OUT1,0UT2 0.1~100.0 100.0

CT1, CT2 0.1~50.0 50.0

14

5

55

5-

--

-5.

5. 5.

5. measuring rangecode

measuring rangecodemeasuring rangecode

measuring rangecode table

table table

table

MeasureingRange

InputType Code UnitCode

(℃) UnitCode

(

)

R

0 ~1700 0 ~3100

K

-199.9~400.0 -300 ~700

K

0 ~1200 0 ~2200

K

0.0~300.0 0 ~ 600

K

0.0~800.0 0 ~1500

J

0 ~600 0 ~1100

J

0.0~600.0 0 ~1100

T

-199.9~200.0 -300 ~400

E

0 ~700 0 ~1300

S

0 ~1700 0 ~3100

*5U

-199.9~

200.0

-300 ~400

N

0 ~1300 0 ~2300

*1B

0 ~1800 0 ~3300

*3Wre5-26

0 ~2300 0 ~4200

Thermo

Couple

*4PLⅡ

0 ~1300 0 ~2300

-200 ~600 -300 ~1100

-100.0~200.0 -150.0~400.0

0.0~100.0 0.0~200.0

-50.0~50.0 -60.0~120.0

-100.0~300.0 -150.0~600.0

-199.9~300.0 -300 ~600

-199.9~600.0 -300 ~1100

0 ~230 0 ~450

-200 ~500 -300 ~900

-100.0~200.0 -150.0~400.0

0.0~100.0 0.0~200.0

-50.0~50.0 -60.0~120.0

-100.0~300.0 -150.0~600.0

-199.9~300.0 -300 ~600

-199.9~500.0 -300 ~900

*6

*6

ResistanceBulb Pt100

*6

*6

0 ~230 0 ~450

M

u

l

t

i

I

n

p

u

t

Volatage(mV)*70~10

0~100

*7-10~10

0~20

0~50

Voltage(V) 1~5

0~5

-1~1

0~1

0~2

0~10

Current(mA) 4~20

0~20

Scaling Range:-1999~9999Digit

Span:10~10000Digit

Change ofdecimalpoint’spositionispossible

(nodecimalpont、0.1,0.01,0.001)

thermo couple B,R,S,K,E,J,T,N:JIS/IEC

resistance bulb Pt100:JIS/IEC

JPt100: former JIS

*1 thermo couple Accuracy is not guaranteed below B:400℃ (752).

*2 thermo couple In K, T, U,accuracy is±0.5%FS for 0~-100℃ (-148 ) and

±1.0%FS if it is below-100℃

*3 thermo couple Wre 5-26: Product of Hoskins Mfg. co.,

*4 thermo couple PLⅡ: Platinel

*5 thermo couple U:DIN43710

*6 resistance bulb accuracy of Pt/JPt±50.0℃, 0.0~100.0℃ is ±0.3%FS.

*7 voltage(mV) 0~10mV,accuracy of 0~10mV is ±0.3% of input range.

* Setup of factory shipment is Multi input: thermo couple 0-1200℃

Voltage input :1-5V 0.0-100.0

Current input : 4-20mA 0.0-100.0

6. Supplementary Explanation of Function

6. Supplementary Explanation of Function6. Supplementary Explanation of Function

6. Supplementary Explanation of Function

6

66

6-

--

-1.

1. 1.

1. A

AA

Auto

uto uto

uto r

rr

retur

eturetur

eturn function

n functionn function

n function

When there is no key operation 3 minutes or more,on the screen except for basic screen and each

monitoring screen, screen automatically shifts to basic screen. (Auto return).

6

66

6-

--

-2. Output Soft Start Function

2. Output Soft Start Function2. Output Soft Start Function

2. Output Soft Start Function

This is the function to increase the control output gradually with set-up time at the time of

power-on,

STBY→RUN, and normal return from scale over. This is effective for controlling the excessive

current to loads, such as a heater.

1) Soft- start functions in the following conditions.

・At the time of the power-on in automatic operation, STBY(RST)→RUN, and normal return from

scale over.

・Setup of proportional band (P) is other than OFF

・Soft starting time is not OFF

6

66

6-

--

-3. Event Selection Alarm Operation Figure

3. Event Selection Alarm Operation Figure3. Event Selection Alarm Operation Figure

3. Event Selection Alarm Operation Figure

The figure of alarm operation figure allotted to event 1~3 is shown.

: Lower limit absolute value alarm :Upper limit absolute value alarm

ON operation ON operation

▲ ▲

△: SV ▲: Alarm operating point setting value

:Upper limit deviation alarm :Lower limit deviation alarm

ON operation

Differential gap Differential gap

△ ▲ ▲ △

:Without deviation alarm :Within deviation alarm

ON operation

ON operation

▲ △ ▲ ▲ △ ▲

: Scale over

ON operation

-10% 0% ←PV→ 100% 110%

6

66

6-

--

-4. AT (Auto Tuning)

4. AT (Auto Tuning)4. AT (Auto Tuning)

4. AT (Auto Tuning)

・If AT is performed by FIX (constant value control)、AT monitor LED blinks and light is put out by

termination or intermediate release.

・When auto tuning is ended in inclination step or chosen all PID(s) , it is in standby state until one

pattern is completed. then lights up, then puts out when one pattern is completed.

・When AT is not completed within 1 pattern, AT conducting is released when one pattern is

completed.

・Even in inclination step, AT is performed if it is in HOLD state.

・AT at the time of 2 output specification is as follows.

At the time of heating / cooling operation and cooling / heating operation = OUT1, OUT2

common - PID value

At the time of heating / heating operation and cooling / cooling operation, only OUT1 performs

AT.

OUT 2 output while performing AT is 0% or output limiter lower limit value.

6

66

6-

--

-5.

5. 5.

5. 2 o

2 o 2 o

2 output

utpututput

utput-

--

-characteristics figure

characteristics figurecharacteristics figure