HGM7220N/HGM7220S GENSET CONTROLLER USER MANUAL

HGM7220N/HGM7220S Genset Controller 2019-02-28 Version 1.0 Page 13 of 60

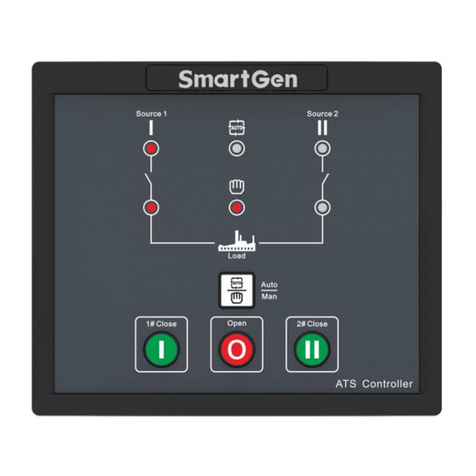

Operator controls load transfer ofATS via pressing button.

Mains Enable: When breaker open detection is disabled, (1) press generator button, open

breaker will output if generator is on-load; generator will be closed if load is disconnected; mains will

be opened if mains is on-load, and generator is closed after open delay is over; (2) press mains

button, if mains is on-load, open breaker output; if load is disconnected, mains will be closed; if

generator is on-load, generator will be opened, and mains will be closed after open delay is over.

If breaker open detection is enabled, mains on-load is changed to gens on-load. It is needed to

press mains and press generator after open delay, then generator is closed (directly

press gens close button, and none action occurs.). Gens on-load is changed to mains on-load, which

is the same as above.

Mains Disable: Press generator button, and if generator is not on-load, then generator

close outputs. Press generator and if generator is on-load, then generator open outputs.

5.1.2. AUTO SWITCHING PROCESS

Breaker is switched by automatic control if controller is in auto mode or stop mode.

a) In case input port is configured as close status auxiliary input,

Mains Enable:

When breaker open detection is enabled, mains on-load changes to generator on-load.After open

delay and transfer rest delay, in the process of open output, transfer failure is detected. When the

detection time is due, if open fails, then generator close does not occur, otherwise generator close

occurs. In the process of generator close, transfer failure is detected. When the detection time is due, if

close fails, then generator close is waited for. If transfer failure warning is enabled, then open/close

failures shall issue warning signals. For generator on-load transfers to mains on-load, it is the same

process as above.

When breaker open detection is disabled, mains on-load changes to generator on-load. After

open delay and transfer rest delay, generator close occurs. In the process of generator close, transfer

failure is detected. When the detection time is due, if close fails, then generator close is waited for. If

transfer failure warning is enabled, then warning signal is issued. For generator on-load transfers to

mains on-load, it is the same process as above.

Mains Disable:

When breaker open detection is enabled, mains on-load changes to generator on-load.After open

delay in the process of open output, transfer failure is detected.When the detection time is due, if open

fails, then open is waited for, otherwise open is completed. For generator off-load changing to

generator on-load, after close delay, in the process of close output, transfer failure is detected. When

the detection time is due, if close fails, then close is waited for, otherwise close is completed.

If transfer failure warning is enabled, then open/close failures shall issue warning signals.

When breaker open detection is disabled, generator on-load changes to generator off-load. After

open delay, open is completed. For generator off-load changing to generator on-load, after close delay,

in the process of close output, transfer failure is detected. When the detection time is due, if close fails,

then close is waited for, otherwise close is completed. If transfer failure warning is enabled, then close