Caution for Operation

MADE IN JAPAN

https://shinanoinc.com

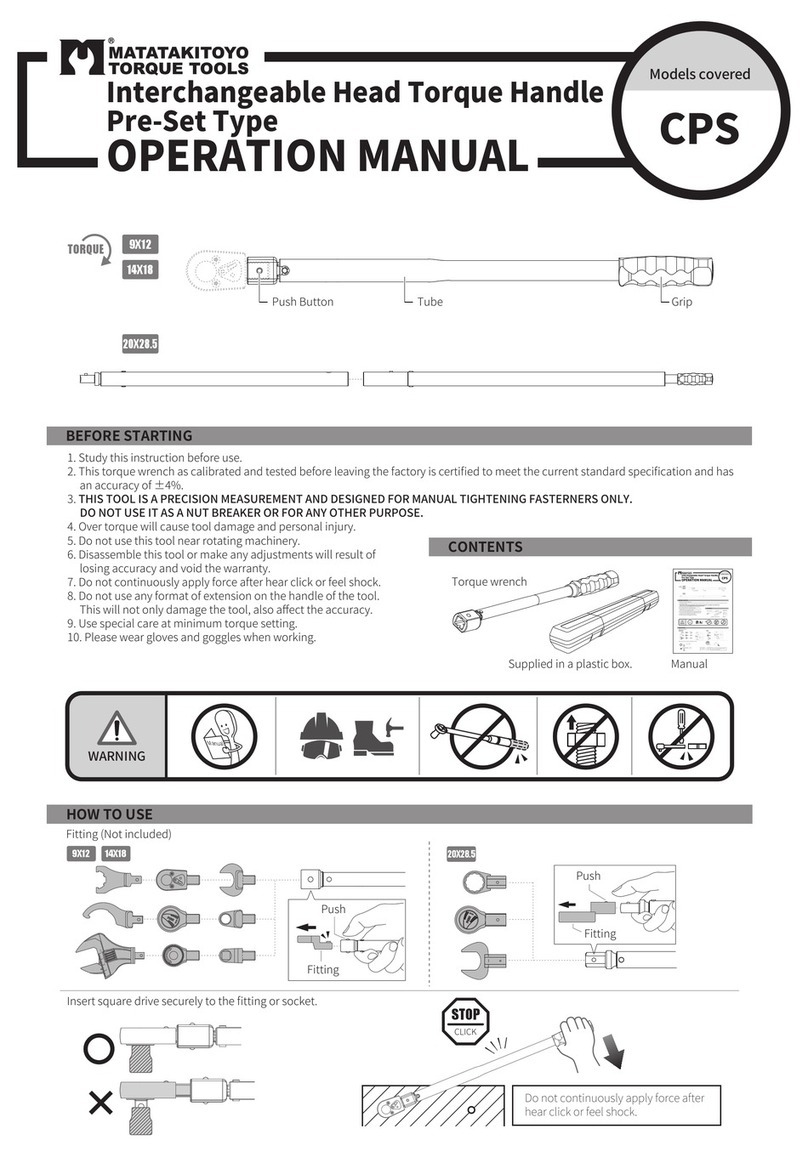

SI-4900

SI-4910

Model

Number

Avg.Air

Consumption

CFM (L/S)

1.00/(2.20) < 2.5 1.3/(0.6)

1.0/(3/64)

1.0/(3/64)

φ5/φ6.5

φ6.5×2

1.00/(2.20) < 2.5 1.3/(0.6)

Cutting. cap

mm/(in.)

Panching Cap Weight

kg/(lb)

Vibration

m/s2

AIR SUPPLY

Pressure at the working

Max Hose Length

Lubrication Daily

Lubricating oil

10m

(30ft)

0.63MPa

(90PSI 6.3bar)

1.First, remove the air hose.

2.Remove two screws at the oil inlet in

the head of the body, using the 3mm

Hex. wrench.

Note: To remove the screws, be careful not to

miss the O-ring.

3.Then, supply oil from either oil inlet so

as to fill up the tank.

Note: Be sure to employ #30 to #40

hydraulic oil.

The air tool is a very precious tool. Be careful not to drag or drop the air tool as much as possible.

Avoid idling run of the air tool for a long time.

Avoid overloading operation, because it is dangerous to use the air tool beyond the capability.

Open the tool within the air pressure 0.63MPa(6.5/cm2).If operated in hight pressure,the maximum

allowance speed will be exceeded, which may result in samage of components.

If the tool power is down during punching work the failure may almost cause due to oil shortage. Supply oil according to

the procedures as shown below.

Screw

Oil inlet

O-ring

Specifications

How to inject hydraulic oil