3

Using this cut-off saw, or any other

high-speed power tool, can be

hazardous. As a result, you must

employ special safety precautions to

reduce the risk of injury or re.

Children and people who do not

understand this manual must not use

this unit.

Never allow other people or animals

to be near the unit when starting or

operating.

Never touch a rotating cut-off wheel.

Operate the unit only in a well

ventilated area.

Never operate the unit in a closed

area such as a room, warehouse or

tunnel. Running the unit in a closed

area may cause serious illness or

even death due to exhaust gas.

Never allow any people or animals

near exhaust gas.

Never inhale exhaust gas.

Never make unauthorized

modications or alterations to any of

the components of the unit, and never

operate the unit without the wheel

guard or mufer.

This unit is designed for one-man

operation and must be operated by

only one person.

Never operate the unit when you

are tired or under inuence of any

substance that could impair vision,

dexterity or judgement.

■

■

■

■

■

■

■

■

■

■

■

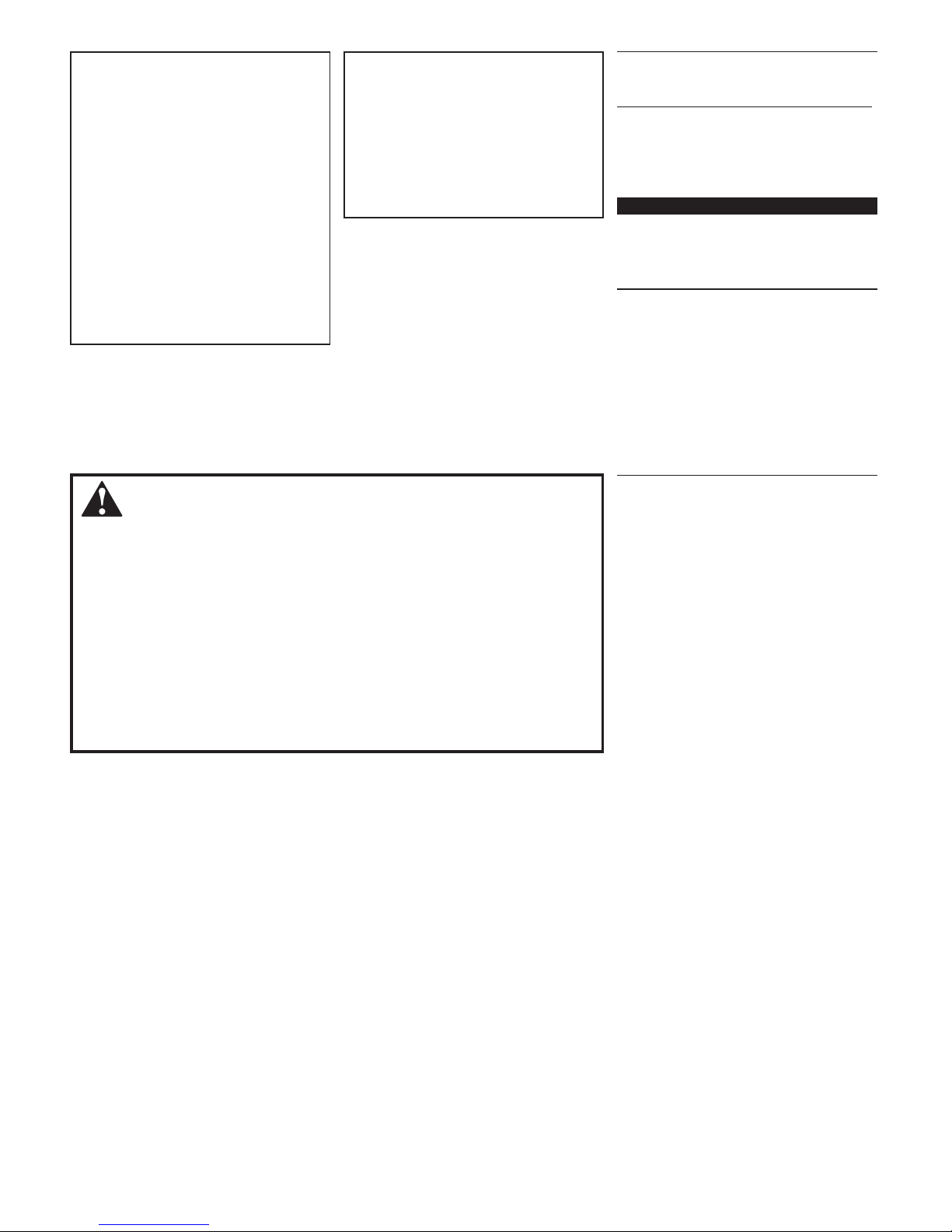

When operating the unit, always

wear snug-tting clothing, safety

gloves, safety non-skid footwear,

hearing protection, a dust-proof

mask, a helmet and goggles. Never

wear oppy clothing, shorts, sandals

or accessories that could become

entangled.

A rst-time operator should obtain

practical instruction from a dealer or an

experienced user before using the unit.

To minimize the risk of sparks igniting

clothing while operating the unit, wear

clothing made of leather, wool, tightly-

woven cotton, or cotton treated with

ame-retardant.

Never use any cut-off wheel that is

not recommended in this manual.

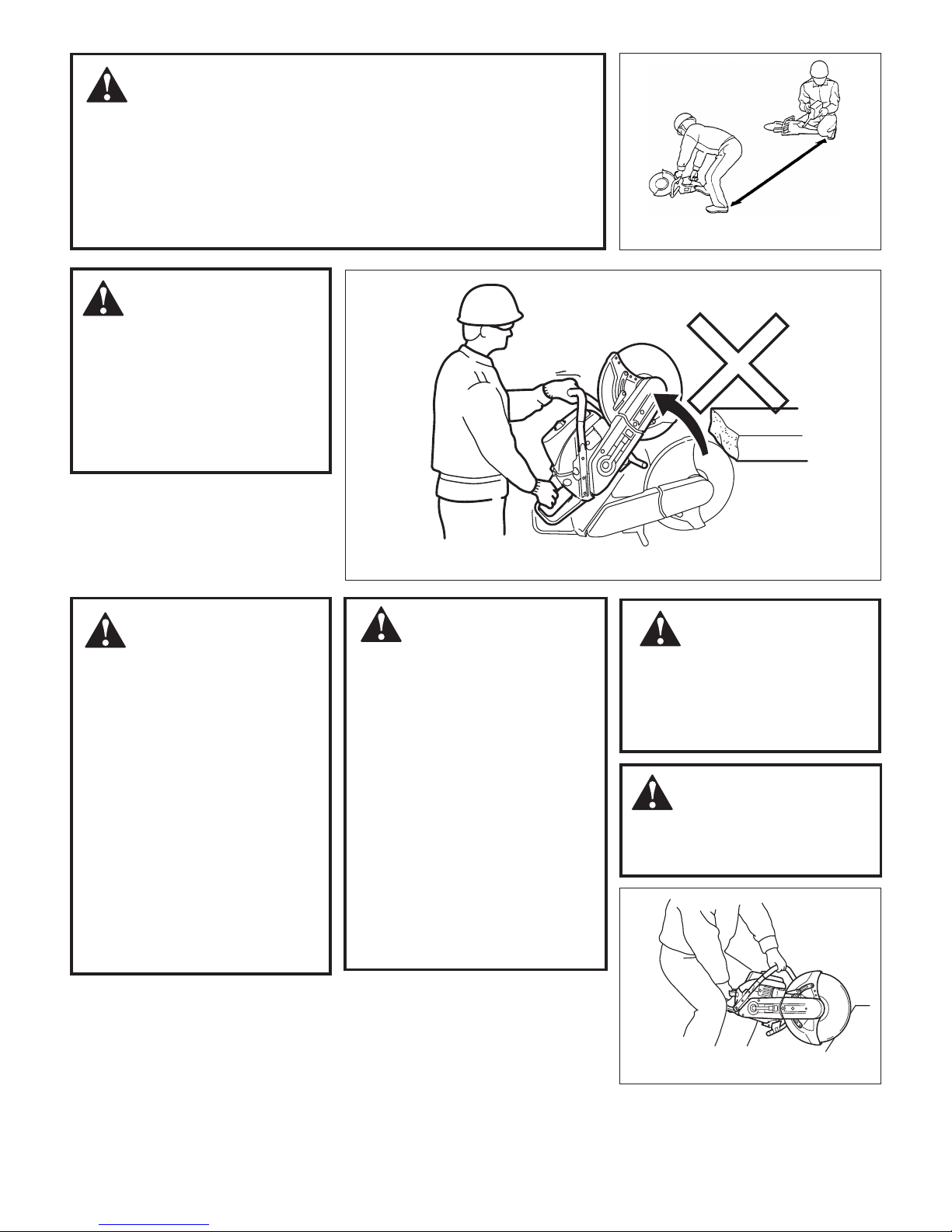

Do not start or operate the unit unless

you have a clear work area and

secure footing.

Do not operate the machine for more

than two hours a day in total. Do not

operate it for more than ten minutes

continuously. Due to vibration,

excessive operation may cause you

white nger disease.

Never smoke or use re near the unit

or its fuel.

Since the mufer and exhaust gas

become very hot, make sure there

are no ammable substances near

the unit.

■

■

■

■

■

■

■

■

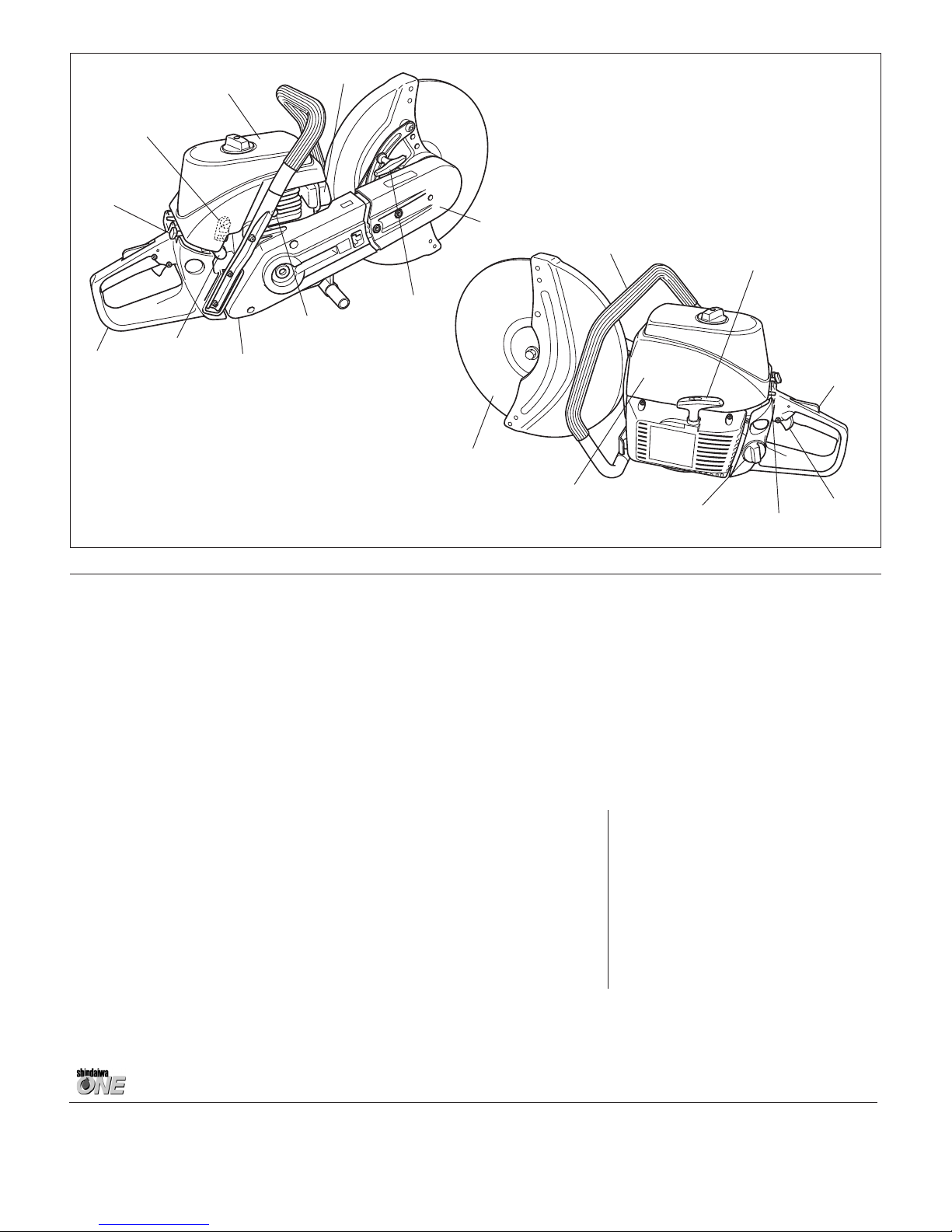

Never run the unit if you discover a

fuel leak.

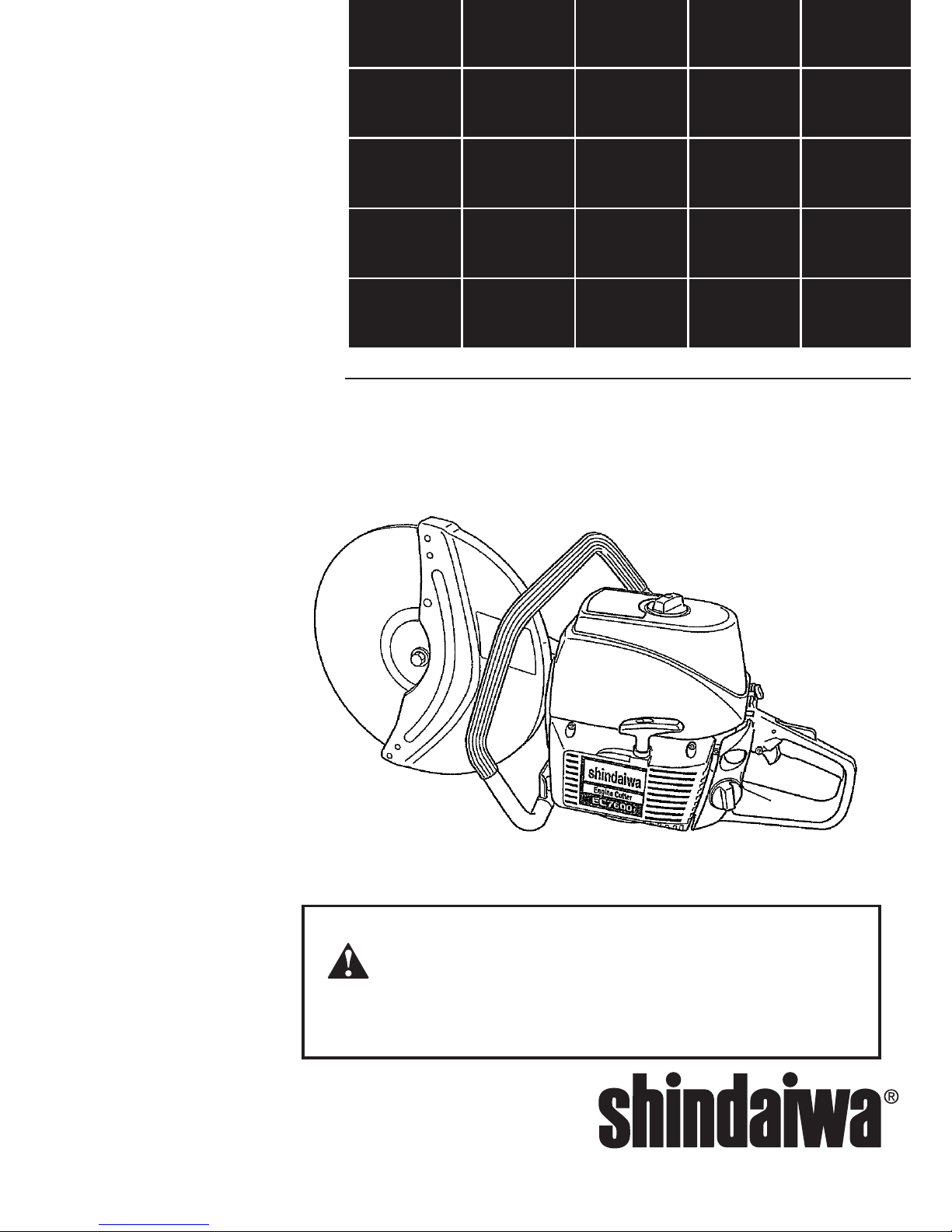

Make sure all the components are

in place and the bolts are securely

fastened.

Make sure the cut-off wheel is

securely fastened and is not

damaged. Never use a cut-off wheel

with cracks, distortion, or one that is

unbalanced.

Make sure the belt tension is properly

adjusted and the wheel guard, belt

guard and clutch cover are securely

assembled.

Always inspect the front handle, rear

handle and wheel guard before use,

and never use the unit if the parts are

damaged.

Before cutting into a material,

familiarize yourself with the risks

associated with dust, fumes, or

mists that may be generated during

operation. Make sure you provide

adequate protection against harmful

emissions. A high-performance

respirator and/or water attachment

may be required.

Do not use the cut-off saw to cut

or disturb asbestos or products

containing or wrapped in asbestos.

If you believe you might be cutting

asbestos, contact your supervisor.

■

■

■

■

■

■

■

Safety Precautions

WARNING!

Before Operation

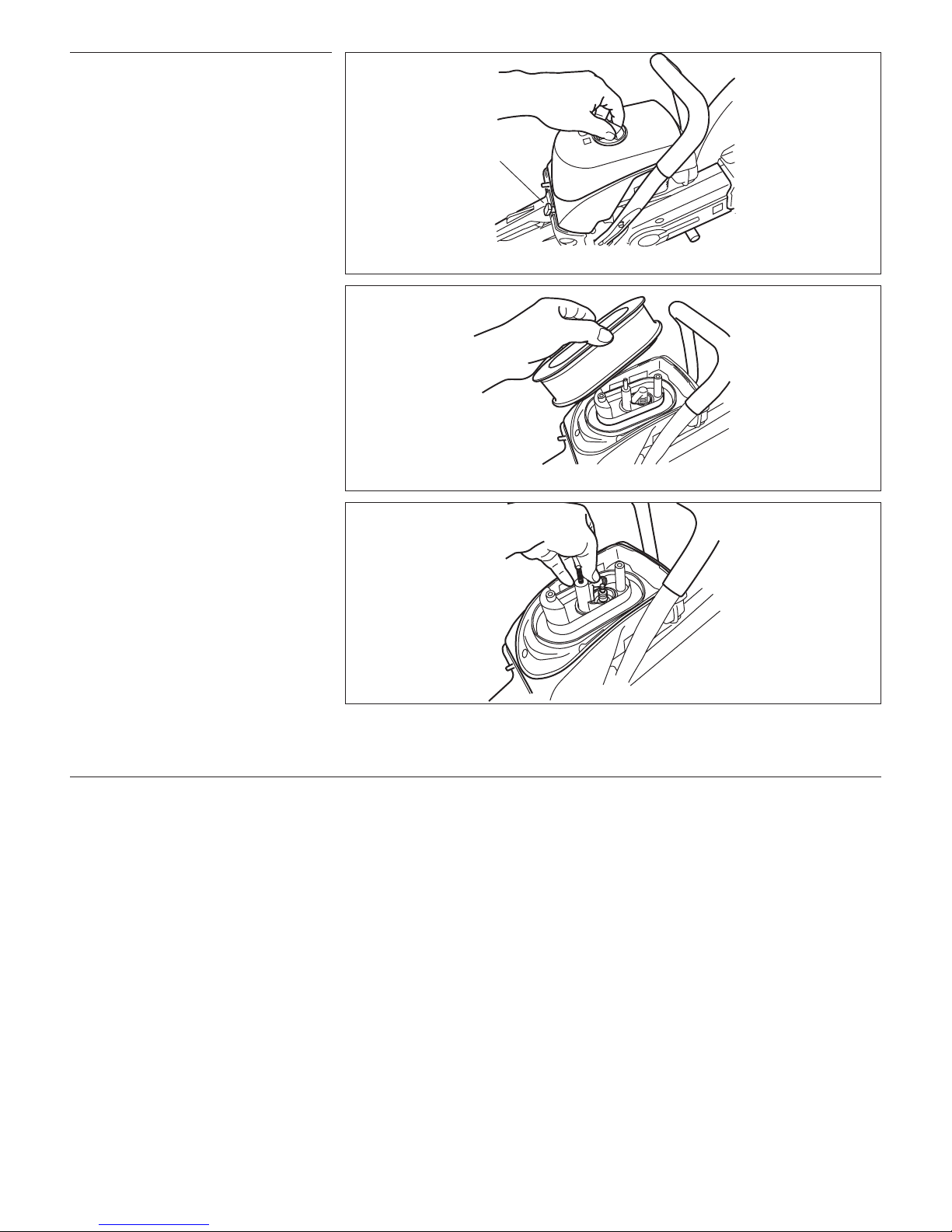

Mixing fuel and engine fueling must

be done outside, and where no other

combustibles are nearby.

Open the fuel cap slowly to release

any possible build-up of pressure.

■

■

Never refuel when the unit is hot.

Allow to cool before refueling.

Never fuel when the engine is

running.

■

■

After fueling, wipe all spilled fuel.

Cutting metal may cause sparks from

the cut-off wheel and may ignite spilled

fuel which could result in serious injury.

■

WARNING!

Fueling the Unit