6(62)

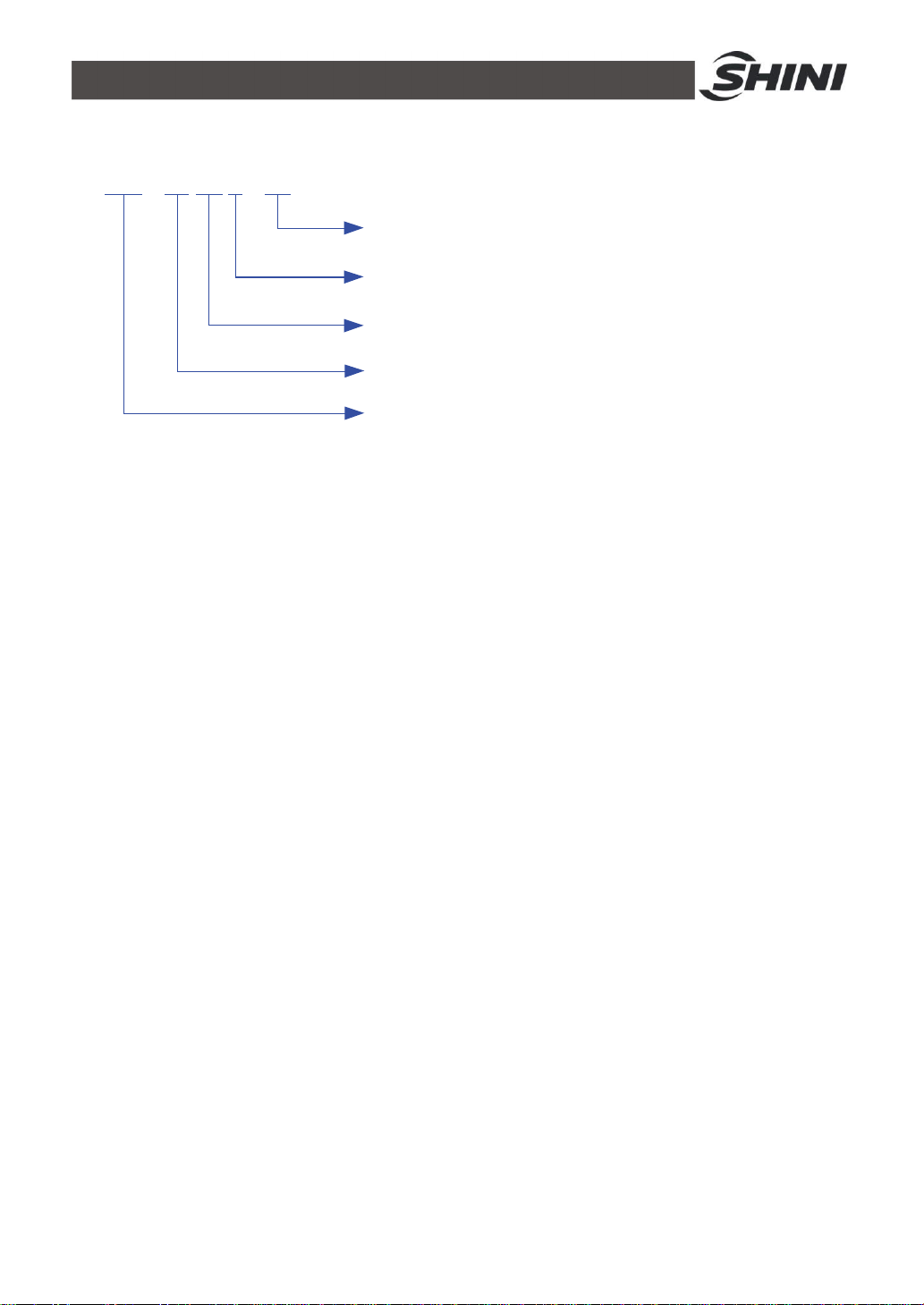

Picture1-1 Dimensions..................................................................................13

Picture2-1 WorkingPrinciple.........................................................................18

Picture2-2 SafetySystem..............................................................................19

Picture2-3 EmergencyStop Switch...............................................................20

Picture2-4 SafetySystem..............................................................................20

Picture2-5 AssemblyDrawing.......................................................................21

Picture2-6 CuttingChamber..........................................................................24

Picture2-7 BladeRest...................................................................................25

Picture2-8 Transmission Parts......................................................................26

Picture2-9 FeedBox, FeedPortandMaterialStopper..................................27

Picture2-10 StorageBox...............................................................................28

Picture2-11 MainBody..................................................................................29

Picture2-12 MainCircuit (400V)....................................................................30

Picture2-13 ControlCircuit 1(400V)..............................................................31

Picture2-14 ControlCircuit 2(400V)..............................................................32

Picture2-15 ComponentsLayout (400V).......................................................33

Picture2-16 MainElectricalCircuit (230V).....................................................35

Picture2-17 ControlCircuit 1(230V)..............................................................36

Picture2-18 ControlCircuit 2(230V)..............................................................37

Picture2-19 ComponentsLayout (230V).......................................................38

Picture2-20 ElectricalComponentsDescription............................................40

Picture3-1 InstallationSpace........................................................................42

Picture3-2 InstallationPlace..........................................................................43

Picture3-3 InstallationofBearingand BladeRest 1......................................43

Picture3-4 InstallationofBearingand BladeRest 2......................................44

Picture3-5 InstallationofBearingand BladeRest 13...................................44

Picture3-6 InstallationofGearMotorand Coupling.......................................44

Picture3-7 InstallationofRotatingBladeandFixed Blade1.........................45

Picture3-8 InstallationofRotatingBladeandFixed Blade2.........................45

Picture3-9 InstallationofRotatingBladeandFixed Blade3.........................46

Picture3-10 Installation of FeedBox, Feed Port and StorageBox1.............46

Picture3-11 Installation of FeedBox, Feed Port and StorageBox2.............47

Picture3-12 Installation of FeedBox, Feed Port and StorageBox3.............47

Picture4-1 Openthe Feed Box......................................................................49