2. SPECIFICATIONS WK

-2-

2.1 STANDARD SPECIFICATIONS

Current Output

4 to 20mA

OUTPUT RANGE

0 to 100µm pk-pk

0 to 125µm pk-pk

0 to 200µm pk-pk

0 to 250µm pk-pk

0 to 400µm pk-pk

4 to 20mA OUTPUT

CONVERSION

ACCURACY

±1.5 % of Full Scale Range

(From test signal input pin to current output)

MAX. LOAD

REGISTANCE

43.5 × (Vps-12) ( (Vps=Power supply voltage)

NOT-OK FUNCTION Current output : 3.6mA or less.

Not-OK condition : Open or short of sensor,

Outside of linear range.

Delay time to resume ; 2 to 3 seconds after

Not-OK condition is removed.

GAP Output

(Wave form output)

CALIBRATION

MATERIAL

JIS SCM440 FLAT (AISI 4140 equivalent )

LINEAR RANGE* 1.4mm (Gap : 0.3 to 1.7mm)

SCALE FACTOR* 7.87mV/µm

SCALE FACTOR

ERROR*

7.87mV/µm±6.5% typ.

(including interchangeability errors)

Step : 200µm, Target : 30 mm dia.

OUTPUT

IMPEDANCE*

10kΩ(It is calibrated load impedance at 10MΩ)

System

1. CALIBRATION MATERIAL

MODEL WK-142K 2-wire Vibration Transmitters are calibrated with

JIS SCM440 (AISI 4140 equivalent) flat surface (more than 15 mm

dia.).

It is not calibrated with any other target.

2. CONNECTOR ISOLATION, etc.

The connector connecting the sensor cable and the extension cable

shall be insulated with the attached insulation sleeve (transparent

shrink tube) or fluoro resin insulation tape.

The vinyl-insulating tape shall not be used, which may cause the

wiring trouble in the case of the temperature more than 80°C.

The connector shall not be located in the oil environment.

The oil penetration to cable through the connector may cause the

sensitivity change, due to the change of the cable capacitance.

3. MEGGER TEST OF SIGNAL CABLE

If megger test is made on the signal cable (2-wire shielded cable), be

sure to discharge the charged electric load before connecting the

cable to transmitter.

If this caution is not adhered the transmitter could be damaged.

4. WIRING BETWEEN GAP OUT TERMINAL AND EQUIPMENT

a). Non-grounding type equipment

Connect directly with coaxial cable within 3 meters long.

b). Grounding type equipment

Use an isolator between the transmitter and the equipment.

Use coaxial cable within 3 meters long between the transmitter

and the isolator.

5. SENSOR INSTALLATION

Not available for rainwater at out door use.

It may cause the sensitivity change and insulation down.

FREQUENCY

RESPONSE*

5Hz to 6,000Hz (+0dB, -3dB) at 900µm Gap

TEMPERATURE

RANGE OF

TRANSMITTER

Operating : 0 to 70°C(32 to 158°F)

Storage : -34 to +100°C(-29 to +212°F)

TEMPERATURE

RANGE OF SENSOR

AND EXTENSION

CABLE

Operating : -34 to +177°C (-29 to +350°F)

(Connector : Max. 125°C (257°F))

Storage : -34 to +177°C (-29 to +350°F)

(Connector : Max. 125°C (257°F))

RANGE OF

TEMPERATURE AT

EXPLOSION PROOF

CONSTRUCTION

CSA,ATEX :

0 to +70°C (Sensor, Ext. Cable &Transmitter)

RELATIVE HUMIDITY

95%RH (non condensing)

POWER SUPPLY

VOLTAGE

12 to 35VDC

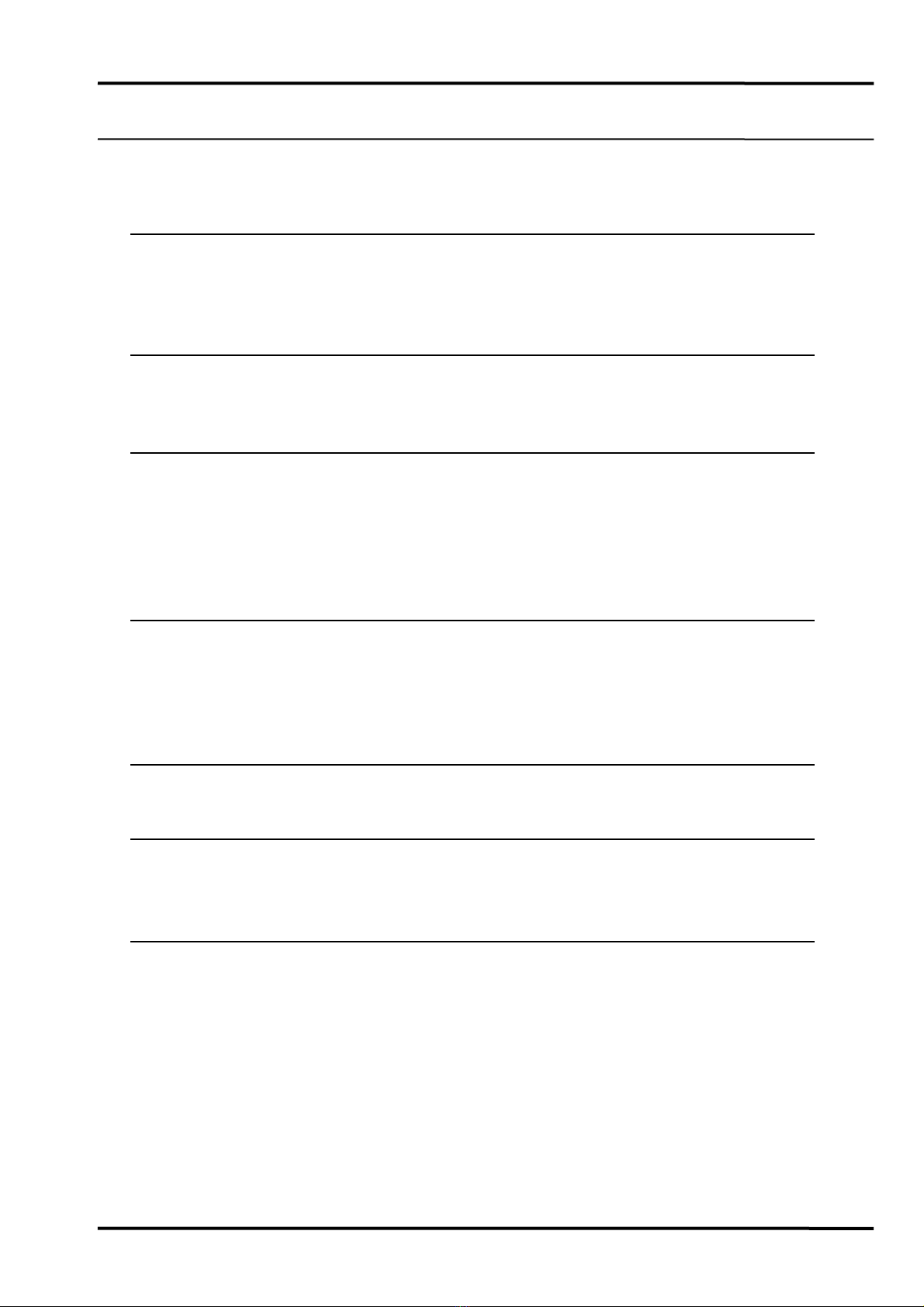

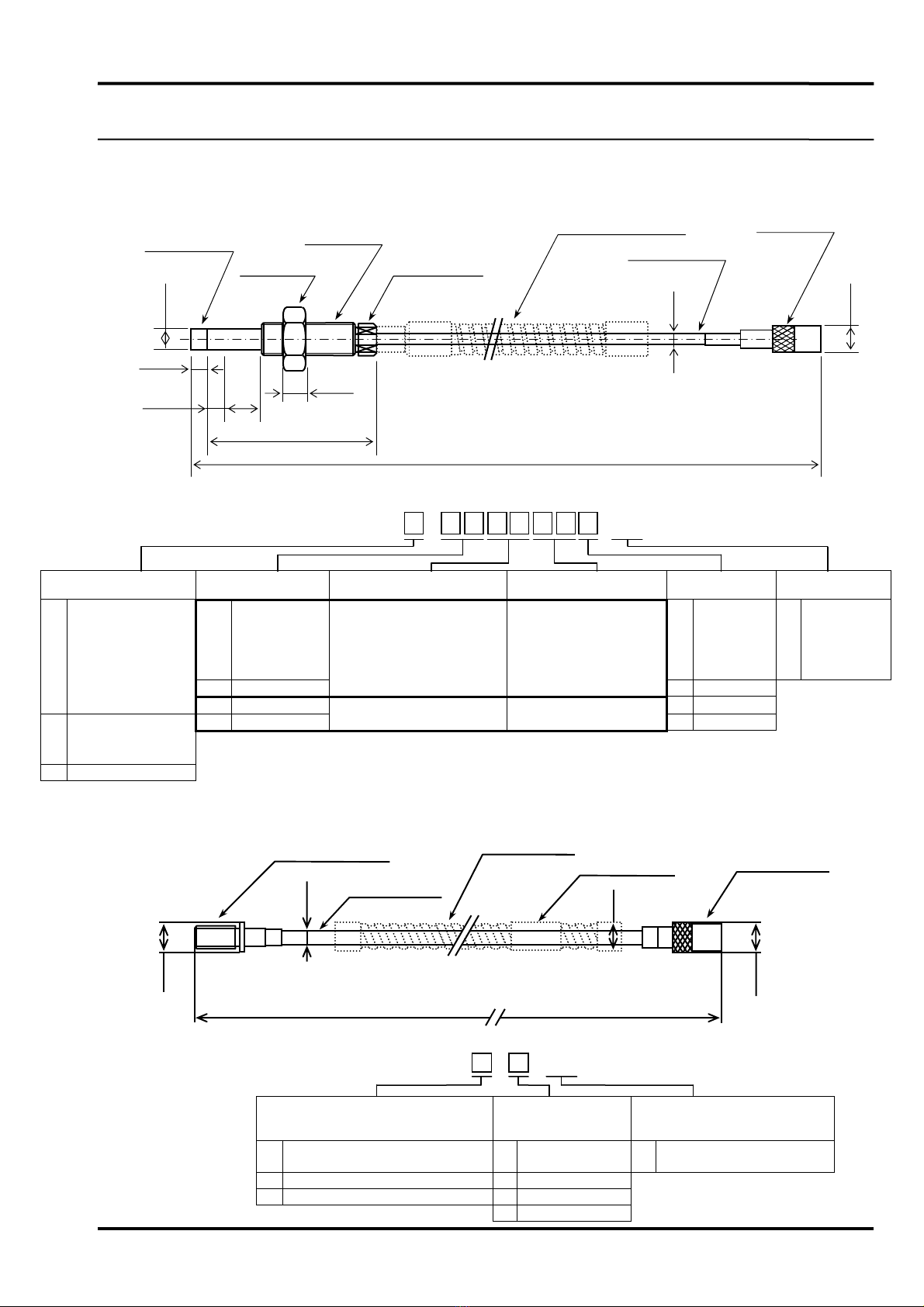

SENSOR TIP

DIAMETER

Approx. 5.5mm (0.217 inch) dia.

CABLE DIAMETER Approx. 2.7mm (0.106 inch) dia.

CONNECTOR

DIAMETER

Approx. 7.1mm (0.280 inch) dia.

SYSTEM CABLE

LENGTH

5m or 7m

TRANSMITTER SIZE (L) 100mm × (W) 74 mm × (H) 50 mm

(3.94 in) (2.91 in) (1.97 in)

Mass : Approx. 530g (1.2 lb)

*The above specifications apply at 25°C with 24VDC power supply and

SCM440 (AISI 4140 equivalent) steel flat target.

Other

SPECIFICATIONS NOTICE

CONFIGURATION

WL Sensor WW Extension Cable

WK Transmitter

Connecto

System Cable Length : 5m or 7m

30101E1.9