Shinko Denshi HTR-80CE User manual

270011M21

T u n i n g F o r k A n a l y t i c a l B a l a n c e

HT/HTR-CE

Series

Operation Manual

SHINKO DENSHI CO., LTD.

IMPORTANT

To ensure safe and proper use of the balance, please read this

manual carefully.

After reading this manual, store it in a safe place near the balance, so

you can review it as needed.

PREFACE

Thank you for purchasing an HT/HTR Series electronic balance.

The HT/HTR Series is a new balance equipped with a high-precision tuning fork sensor

mechanism. It windshield is made of antistatic plastic, helping to reduce its weight, and the

balance is equipped with a variety of functions such as parts counting, percentage weighing,

gravimeter and limit functions that are helpful in weighing fixed amounts. This multifunctional

balance employs a user-friendly program, and the keys are arranged in a way that makes the

balance easy to operate. In addition, the fluorescent display is eye-friendly, and the balance’s

high-speed and stable performance improves your work efficiency.

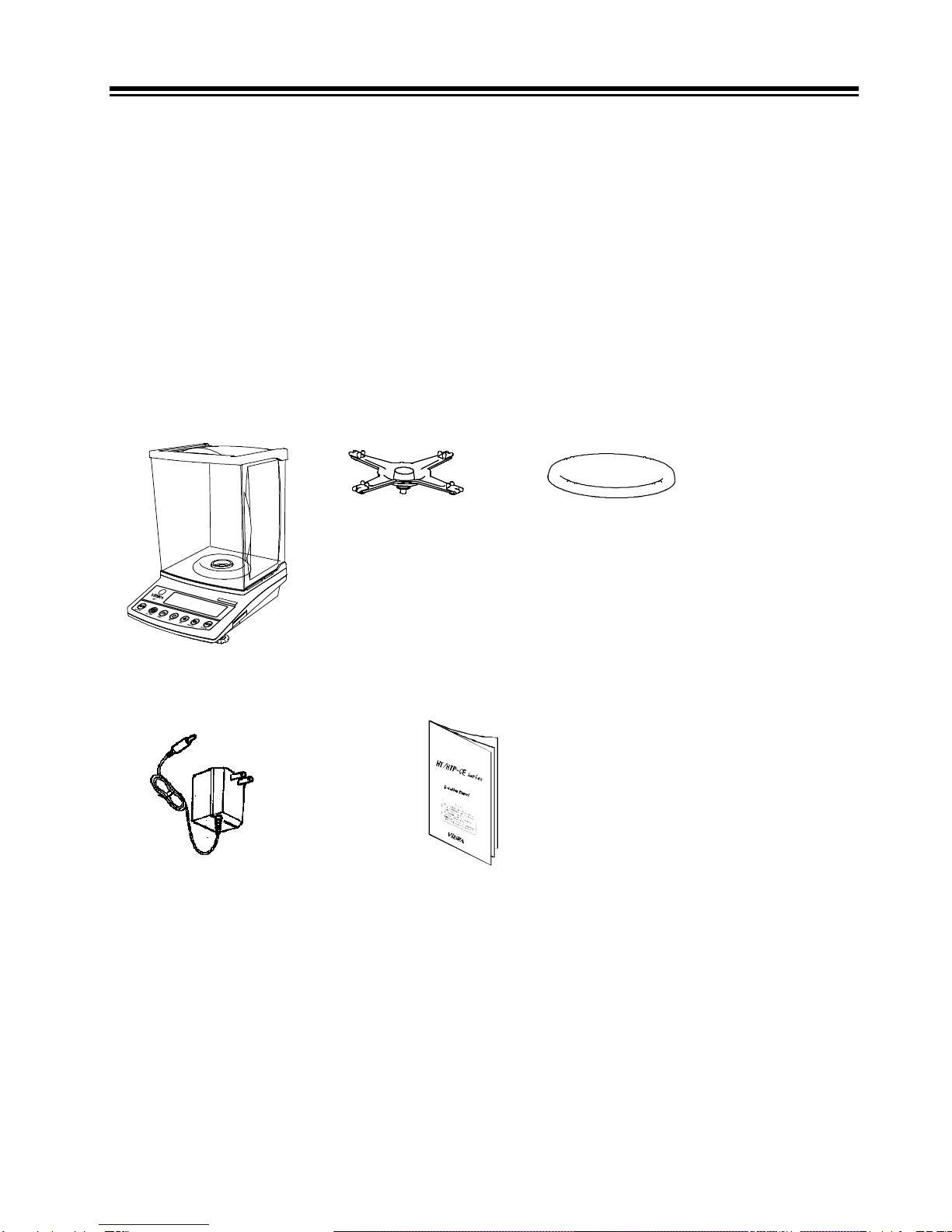

Check for the following accessories before use.

If any items are found to be missing or damaged, immediately contact local dealer.

(1) Main Unit (2) Pan Base (3) Pan

(4) AC adapter (5) Operation manual

1

Contents

Contents.......................................................... 1

1Precautions Relating to Use.................... 3

2Names of Component Parts.................... 7

2.1 Main Unit...................................... 7

2.2 Operation Keys ............................ 8

2.3 Displayed Signs ........................... 9

3Installation of the Balance..................... 10

4Basic Operation..................................... 11

4.1 Power On/Off ............................. 11

4.2 Weighing .................................... 11

4.3 Zero Adjustment......................... 11

4.4 Tare (pan) .................................. 11

4.5 Set a Gross Weight.................... 12

4.6 Single-touch Response Setting . 12

4.7 Data Output................................ 13

4.8 Hanging Measurement .............. 13

5Function 1 ............................................. 15

5.1 Setting and Check ..................... 15

5.2 Description of Function 1 ........... 16

5.3 Specific Gravity Setting.............. 19

5.4 Limit/Addition Functions............. 19

5.5 Interface ..................................... 20

6Function 2 ............................................. 21

6.1 Calling and Setting..................... 21

6.2 Description of Function 2 ........... 21

7Weighing and Measurement Modes ..... 22

7.1 Weighing and Measurement

Modes ........................................ 22

7.2 Weighing Machine ..................... 22

8Parts Counting ...................................... 23

9Percentage Weighing............................ 25

9.1 Set a reference weight by

weighing an actual sample ........ 25

9.2 Set a reference weight by

entering a value ......................... 26

10 Unit Converting ...................................... 27

11 Gravimeter .............................................28

11.1 Measurement procedures for

specific gravity............................28

11.2 Entering water temperature or

the specific gravity of the media. 30

12 Addition Function ................................... 32

12.1 Cumulate Function .....................32

12.2 Net Addition Function .................33

13 Limit Function ........................................35

13.1 Setting the Limit Function........... 35

13.2 Judgment and Saving.................35

13.3 Display of Judgment Results...... 35

13.4 Judge by Absolute Values.......... 36

13.5 Judge by Deviation Values......... 39

13.6 Bar Graph for the 2-point Scale .43

14 Calibration and Span Test for the

Balance..................................................44

14.1 Span Adjustment with Built-In

Weights....................................... 44

14.2 Span Adjustment with External

Weight ........................................44

14.3 Span Test with Built-In Weights . 45

14.4 Span Test with External Weight .45

14.5 Calibration of Built-In Weights.... 45

14.6 Entry of Weight Error..................47

14.7 Advice CAL and Full-automatic

Span Adjustment ........................48

14.8 Auto Repeatability

Measurement (ARM) ..................48

15 Date and Time Setup............................. 49

15.1 Time Setup .................................49

15.2 Date Setup..................................49

16 Various Functions .................................. 50

16.1 Auto Backlight OFF ....................50

16.2 Set Unit....................................... 50

16.3 Date Display ...............................50

16.4 Time Stamp Output ....................50

16.5 Direct Start..................................50

16.6 Interval Output Function .............51

16.7 Input of ID No. ............................52

2

17 Input/Output Functions.......................... 53

17.1 RS232C Output.......................... 53

17.2 Output to Peripherals................. 56

17.3 Type of Communication Texts ... 57

17.4 Output Data................................ 57

17.5 Input Commands........................ 61

17.6 Special Format Output............... 67

18 Use Printers .......................................... 69

18.1 Setting up the Printer ................. 69

18.2 Outputting calibration results ..... 69

18.3 Output of Measurement Data in

Compliance with ISO/GLP/GMP 69

19 Output in Compliance with

ISO/GLP/GMP .......................................70

20 Removing the Windshield Door ............. 73

20.1 Removing the Windshield Door.. 73

20.2 Caring for the balance ................ 73

21 Troubleshooting ..................................... 74

22 Specifications.........................................75

22.1 Basic Specifications ................... 75

22.2 Weighing Capacity and

Minimum Readability by Unit...... 76

23 Unit Conversion Table ...........................77

3

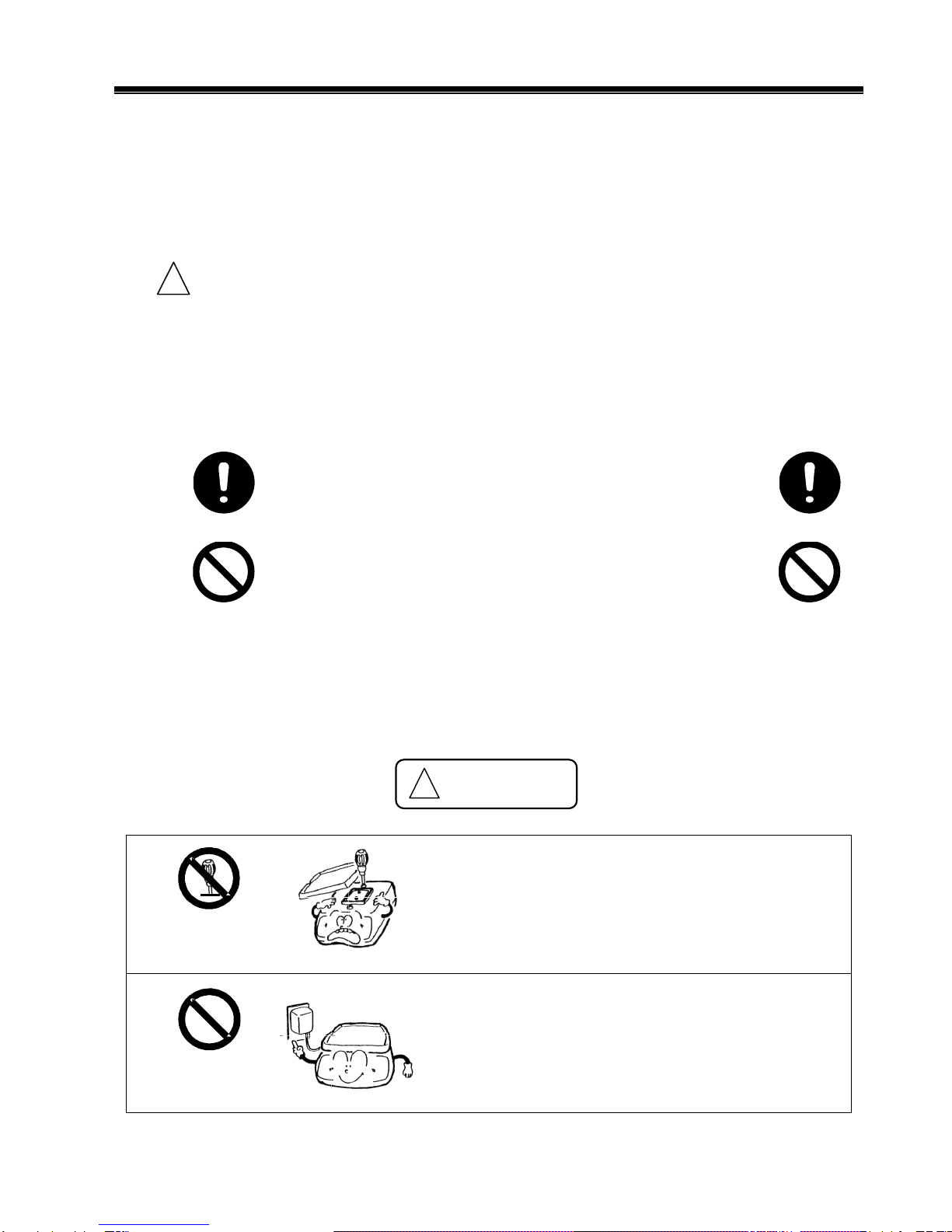

1 Precautions Relating to Use

This Section “Precautions Relating to Use” sets forth precautionary notes that the user

should observe in order to prevent physical injury to the user and/or damage to property.

The nature of problems that may result in the event of improper operation, and

consequential effects on the quality and performance of the balance, are indicated under

the two categories of “Caution” and “Recommended,” and explained using symbols.

! Caution

This is a category to indicate improper handling that may

cause physical injury or severe damage to property. Be

sure to follow the directions for safe use to avoid serious

consequences.

Recommended This term indicates steps that the user should take to

ensure the quality and reliability of the balance.

Meanings of Symbols Each symbol is accompanied by an instruction.

Mandatory Symbol

Indicates a “mandatory” action that should

be executed without fail.

Example

Check Level

Prohibitive Symbol

Indicates a “prohibited” action that must

not be executed.

Example

Do Not Use

Do not disassemble or modify the unit.

• Could cause malfunction.

• In case of malfunction do not disassemble the

unit. Contact our local dealer.

Only AC power should be used.

Only use the dedicated AC adapter.

• Use of other types of power or adapters may

result in heat generation or malfunction of the

balance.

!Caution!

Do Not Deviate

from Ratings

Do Not

Disassemble

4

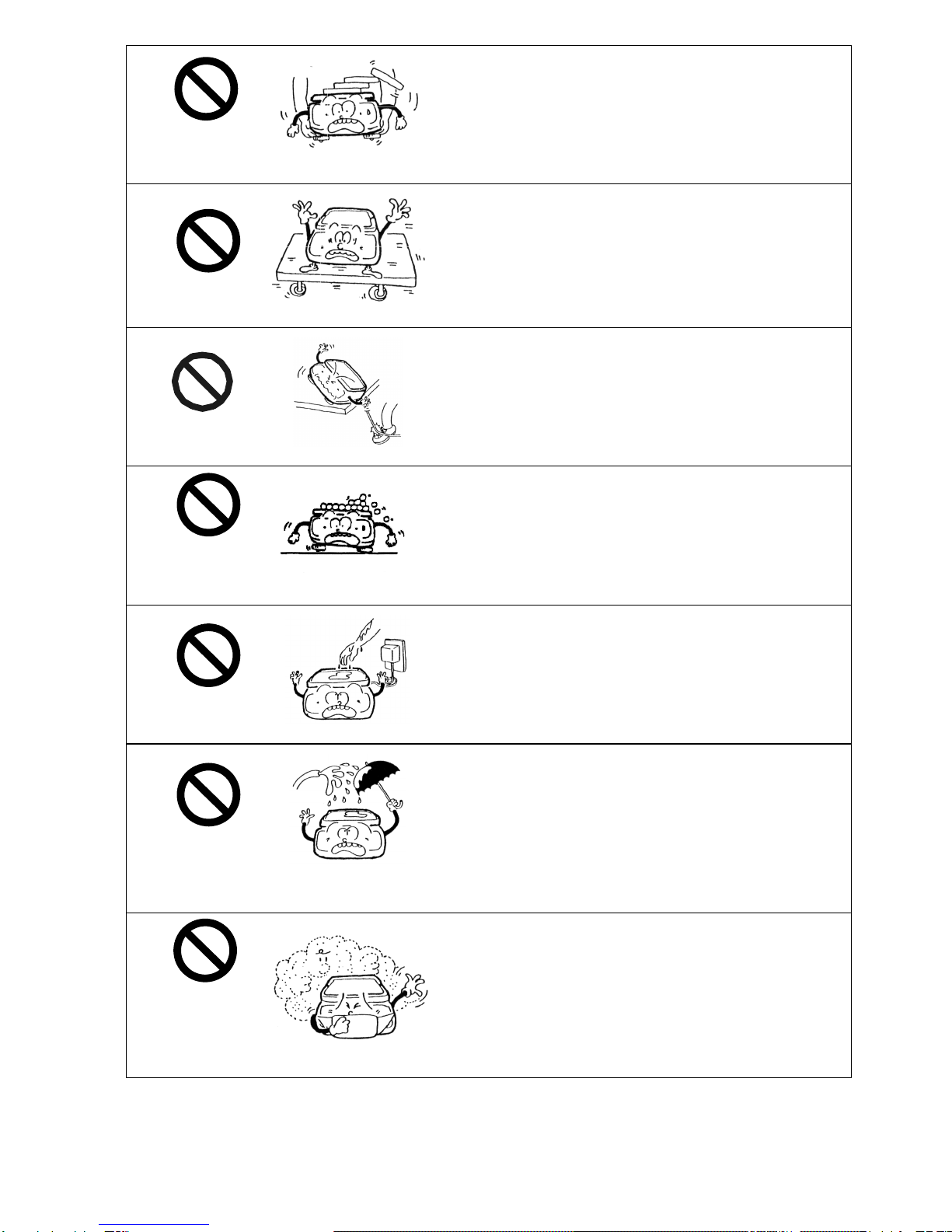

Do not move the balance when a sample is

loaded.

• The loaded sample may fall off the pan and cause

an injury.

Do not place the balance on an unstable base

or use the balance in a location where it may

be subjected to shock.

• The loaded sample may fall off the pan.

• Accurate measurement may be rendered

impossible.

Do not lay the AC adapter cable on the surface

of the passage.

• Somebody may trip on the cable, causing the

balance to fall off, thereby causing injury and/or

damage to the balance.

Do not use the balance with its adjusters

lifted.

• The balance will become unstable, preventing

accurate measurement.

Do not touch the AC adapter or the balance

with wet hands.

• Could result in an electrical shock.

Do not expose the balance to rain or water.

• Could cause an electrical shock or short circuit.

• The balance will corrode and malfunction.

Do not use the balance in a dusty

environment.

• Could cause an explosion or fire.

• Could cause a short circuit or interfere with the

balance’s electrical conductivity, causing it to

malfunction.

Do Not Move

Do Not Drop

Do Not Leave

Afloat

Do Not Touch

with Wet Hand

Do Not Expose

to Water

Do Not Use

Do Not Expose

to Dust

5

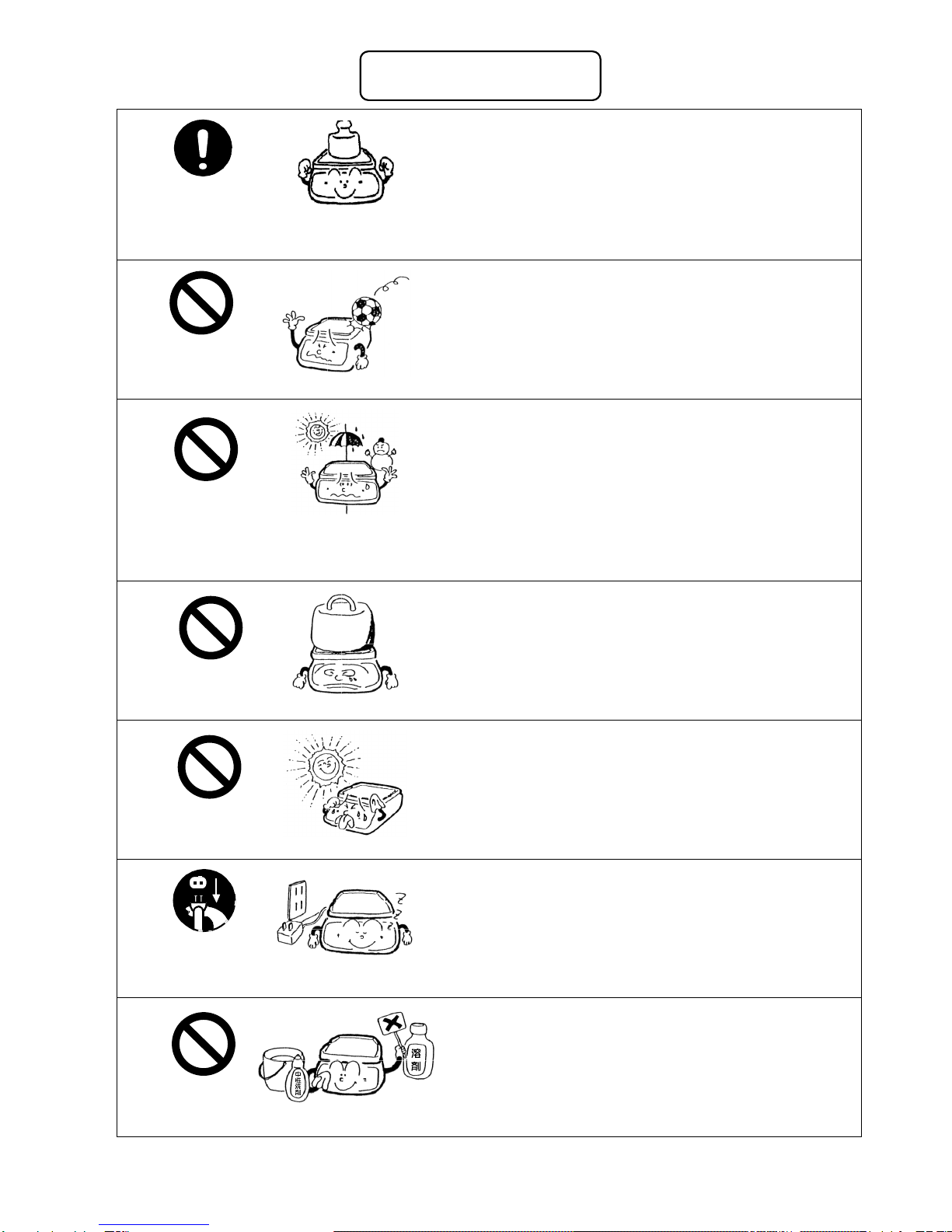

Calibrate the balance after installation or

relocation.

• Measurement values may contain errors,

preventing accurate measurement from being

conducted.

Avoid applying excess force or impact to the

balance.

• Place the sample to be measured on the balance

carefully to prevent breakage or malfunction.

Do not use the balance in a location were it may

be subjected to abrupt changes in ambient

temperature or humidity.

• Accurate measurement may be rendered

impossible.

• Use the balance in an ambient temperature range

of 10°C to 30°C and with 80% or lower relative

humidity.

Do not leave the balance overloaded. (When it

is overloaded, (o-Err) is displayed.)

• Take down the loaded sample immediately to

prevent breakage or malfunction.

Do not use the balance in a location where it is

subject to direct sunlight.

• The indications would be illegible.

• An internal temperature increase in the balance

may lead to inaccurate measurement.

If the balance is to be unused for an extended

period of time, unplug the adapter.

• This conserves power and prevents deterioration.

Do not use volatile solvents for cleaning.

• The body may be distorted.

• To clean the unit of stains, use a piece of dry cloth

or cloth soaked in a small quantity of neutral

detergent.

Recommended

Calibrate Balance

Do Not Apply

Force

Do Not Overload

Do Not Use

Do Not Use

Do Not Use

Unplug Adapter

6

Do not use the balance in a location where it

may be subject to air from an air-conditioning

unit.

• Extreme changes in the ambient temperature may

result in inaccurate measurements.

Do not use the balance on a soft floor.

• When loaded with a sample, the balance may tip or

move, preventing accurate measurements from

being conducted.

Do not use the balance when it is tilted.

• When the balance is tilted, an error may be caused,

preventing accurate measurement from being

conducted. Place the balance on a level surface.

Do Not Use

Check Level

Do Not Use

7

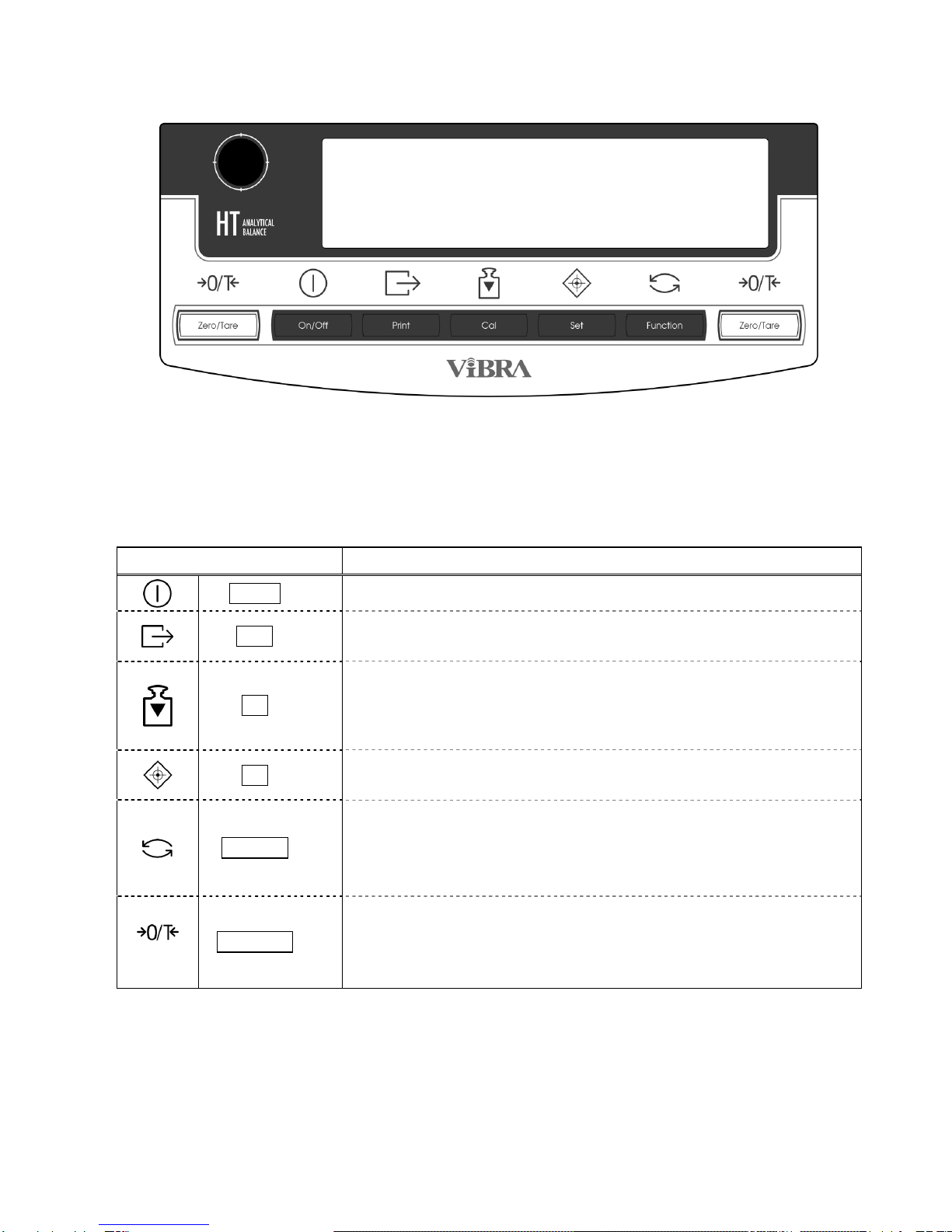

2 Names of Component Parts

2.1 Main Unit

Windshield (door)

Pan

Windshield ring

Level

Operation ke

y

Liquid crystal display

RS-232C connector

(D-SUB9P)

Connector for peripheral

devices

(DIN8P)

* Replace the connector cap

when not using AC power.

AC adapter connector

Adjuster

(Adjustable leg)

Fixed leg

Cover of hanging

hook

8

2.2 Operation Keys

Operation key Function

On/Off key Turns the balance on or off.

Print key Starts output.

Pauses the setting and input operation.

Cal key

[Short press] Switches to the span adjustment and span test

modes.

[Continuous press] Starts automatically repeatable

measurements.

Set key [Short press] Toggles the response mode.

[Short press] Stores the settings.

Function key

[Short press] Toggles the weighing modes.

[Short press] Used to enter numerical values.

[Short press] Used to select a function to set.

[Continuous press] Calls functions.

Zero/Tare key

[Short press] Used for zero-setting or sets the display to

zero by tare range.

[Short press] Used to enter numerical values.

[Short press] Used to select a function.

9

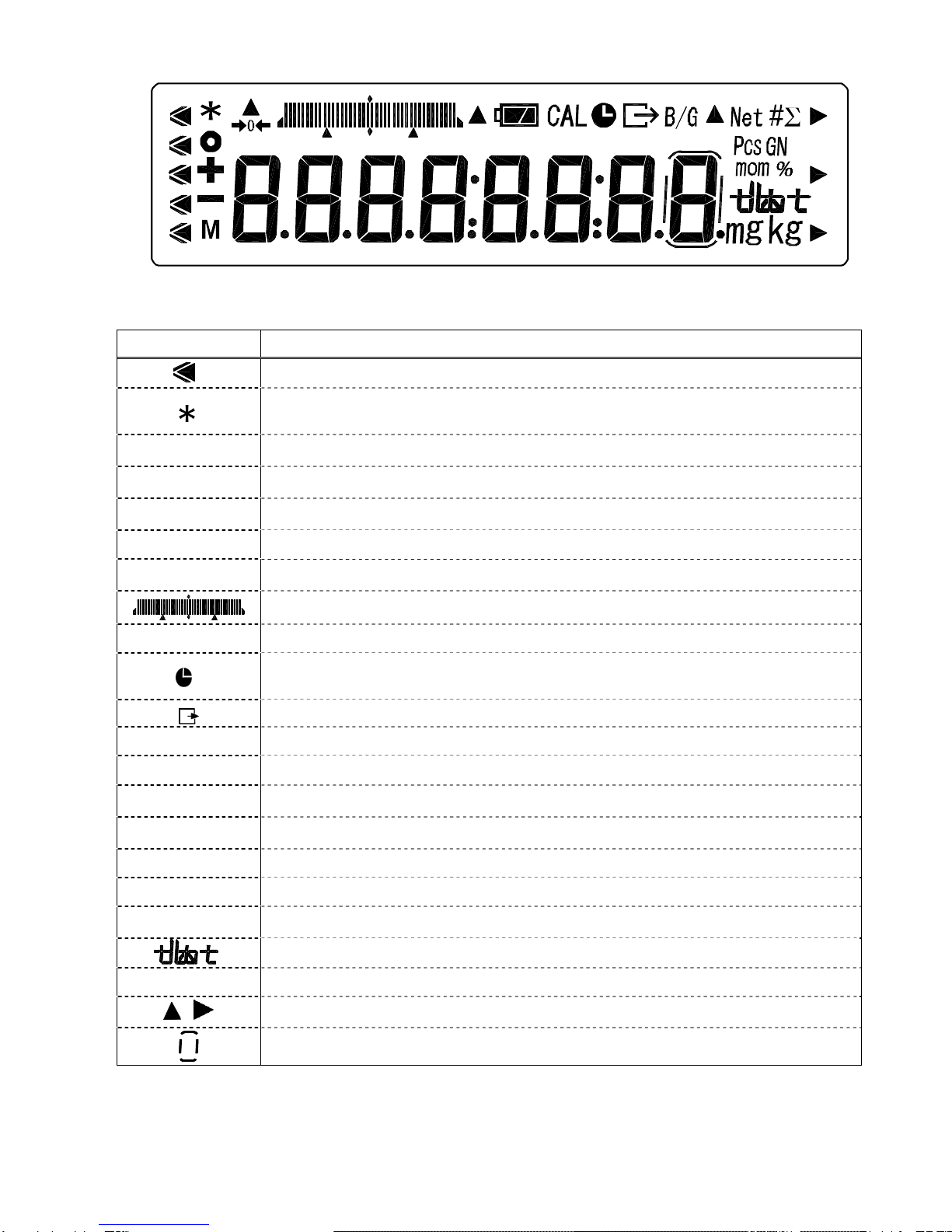

2.3 Displayed Signs

2.3.1 Displayed signs

Display Description

Displays the judgment results when the (five-point) limit function is enabled.

Displayed when the balance is in standby mode.

Indicates that the addition function is enabled for accepting an additional load.

○Indication of stable balance (If this light is off, the balance is unstable.)

+Sign for sample addition when parts counting is performed

-Minus

M Display of set values from memory (If it is flashing, the value is being saved.)

→0←Zero-point

Bar graph (Refer to Hints on page 43).

CAL Displayed when calibration and Advice CAL are enabled.

Lights up when date/time is being set or displayed.

Blinks during interval output.

Displayed when data is output in compliance with ISO/GLP/GMP.

B/G Gross weight

Net Tare sign

#Unit converting

ΣDisplays a sum total.

Pcs Parts counting

mom Momme

%Percentage weighing

Displays the selected unit.

mg Milligram, gram

, Displayed according to the function.

Lights up only when the auxiliary scale interval is being displayed.

10

3 Installation of the Balance

1. Attach the pan base and pan.

Attach the pan base and pan to the main unit as shown in the figure.

2. Level the Balance.

Turn the adjuster so that the air bubble in the level gauge is within the circle.

3. Connect the AC adapter.

Connect the AC adapter to the balance.

After the balance has been moved, open the windshield door to allow it to

adapt to the ambient temperature for stable measurement.

In addition, allow five minutes after turning on the power for the balance to

warm up.

Pan base

(Turn the knob located in

the center to attach it.)

Pan

Adjuster

AC adapter connector

Position of the air

bubble in the level

11

4 Basic Operation

4.1 Power On/Off

Press the On/Off key to turn the power on and off.

The * sign is displayed when the balance is powered by the AC

adapter and is in standby mode.

When an object is lying on the pan, the blinking [ on 0 ] is displayed. In such cases,

remove all the objects on the pan.

If a unit other than “g” (gram), “mg” (miligram) or “ct” (carat) is selected as Unit A,

the unit automatically changes to “g”.

4.2 Weighing

Place a sample on the balance and close the windshield door.

A circle will be displayed after the measurement has stabilized.

Read the measurement while the circle is displayed.

The circle will not be displayed or will flicker if the balance is

subject to disturbance such as vibration. Take appropriate

measures to stabilize the balance.

The bar graph indicates the current load in relation to the

balance’s weighing capacity. As the load approaches the

weighing capacity, the bar extends towards the right.

When the weight of an object exceeds the balance’s weighing

capacity, [o-Err] is displayed.

If the pan is removed and the zero-point falls below the original

zero-point, [u-Err] is displayed.

4.3 Zero Adjustment

Press the Zero/Tare key.

Wait until the display becomes stable (the M sign

flashes), and set the display to “0”.

While the zero point is accurately maintained, the

[→0←] sign is displayed.

4.4 Tare (pan)

Place the tare (pan) on the balance and press the

Zero/Tare key.

When the display becomes stable, “0” is displayed.

(Continued on next page.)

On/Off

Stable

Unstable

Zero Weighing

capacity

Bar graph

12

This operation is called “tare” and “Net” is displayed

while the weight of the pan is being set.

After the weight of the pan has been set, if a sample is placed in the container the balance will

display the weight (net weight).

* When a tare range is set, the weighing capacity is reduced accordingly.

Weighing capacity = original weighing capacity – pan weight

Even after the weight of the pan has been set and the display is set to “0,” the value indicated

by the bar graph includes the pan weight.

4.5 Set a Gross Weight

Press the Function key while the weight of the pan is

being set.

The gross weight, which is the sum of the pan weight

and the weight of the sample put in it, is displayed.

The B/G sign is displayed while the gross weight is

being displayed.

Pressing the Function key will toggle the display

between net weight and gross weight. (Unit B (net

weight) is also displayed if it has been selected.)

Caution:

1. A gross weight can only be displayed when the balance functions as a weighing machine.

2. When a gross weight is displayed, you cannot set a tare range. You can only adjust the

zero-point.

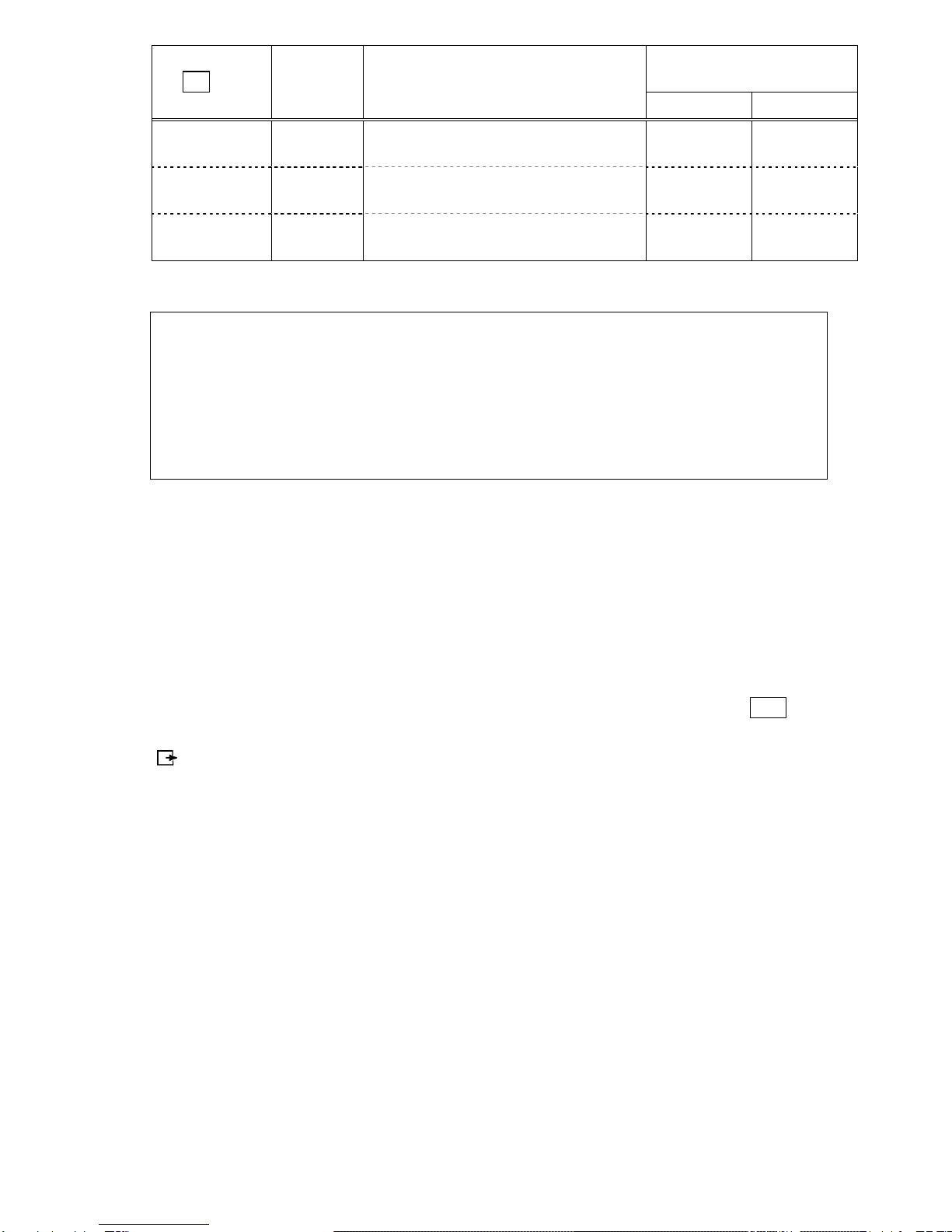

4.6 Single-touch Response Setting

This function allows you to switch the response of the balance with a single touch of the Set

button.

The balance will be subject to different levels of vibration depending on where it is placed.

Adjusting the balance’s response according to the magnitude of vibration reduces the variation

in its display and the time required for the display to stabilize.

Pressing the Set key once displays the current settings ([norMAL] etc.).

Pressing the Set key again toggles the display between [norMAL→SLoW→FASt].

After the balance settings have been completed, the display automatically returns to the

weighing mode.

This function corresponds to the settings [5. rE. *] and [6. Env. *] of Function 1, and the

settings in Function 1 are also changed at the same time.

(Continued on next page.)

(Unit B)

13

Corresponding settings in

Function 1

Set key Meanings Description

6. EnV. 5. rE.

FASt FAST

The balance responds quickly but it

is easily affected by vibration 0 1

norMAL NORMAL The balance’s response is

somewhere between fast and slow 0 3

SLoW SLOW

The balance responds slowly but is

not easily affected by vibration 1 3

(Refer to “Section 5: Function 1” on page 15 for further information on Function 1.)

In [6. EnV. *], [0] indicates a fast response. Use this setting when the balance is

subject to a low level of vibration.

[1] indicates a slow response. Use this setting when the balance

is subject to a high level of vibration.

In [5. rE. *], [1] indicates the fastest response. Use this setting when the

balance is subject to a low level of vibration. As the number

approaches [5], the balance’s response becomes slower but it is

also less affected by vibration.

* To adjust the response more finely, use Function 1.

Caution

This function is unavailable when the gravimeter or addition function is enabled.

4.7 Data Output

Measured data and GLP data can be output to a personal computer, printer, or similar device

via the built-in RS-232C interface. In the factory default setting, pressing the Print key once

will output the current measured value when the measurement becomes stable.

[] is displayed while the data is being output.

Refer to “Section 5.5: Interface” on page 20 for further information on the output settings.

4.8 Hanging Measurement

The balance is equipped with a hanging hook to suspend a hanging pan for weighing.

Perform hanging measurements when weighing electromagnetic, electrostatic, or

high-temperature samples that cannot be accurately weighed on the normal pan.

Remove the pan and gently tilt the balance backward.

Take care that the door does not fall off.

(Continued on next page.)

14

Caution

1. Tools (hanging pan etc.) suspended from the hook are regarded as a tare (pan). Weights

equal to the weighing capacity cannot be measured.

Measurable weight = Weighing capacity – Total weight of tools suspended

2. Be sure to close the cover of the hanging hook when not in use to prevent dust from

entering the balance.

Hook for hanging

measurements

Loosen the screw and turn the

cover 90°. Then tighten the

screw to secure the cover.

15

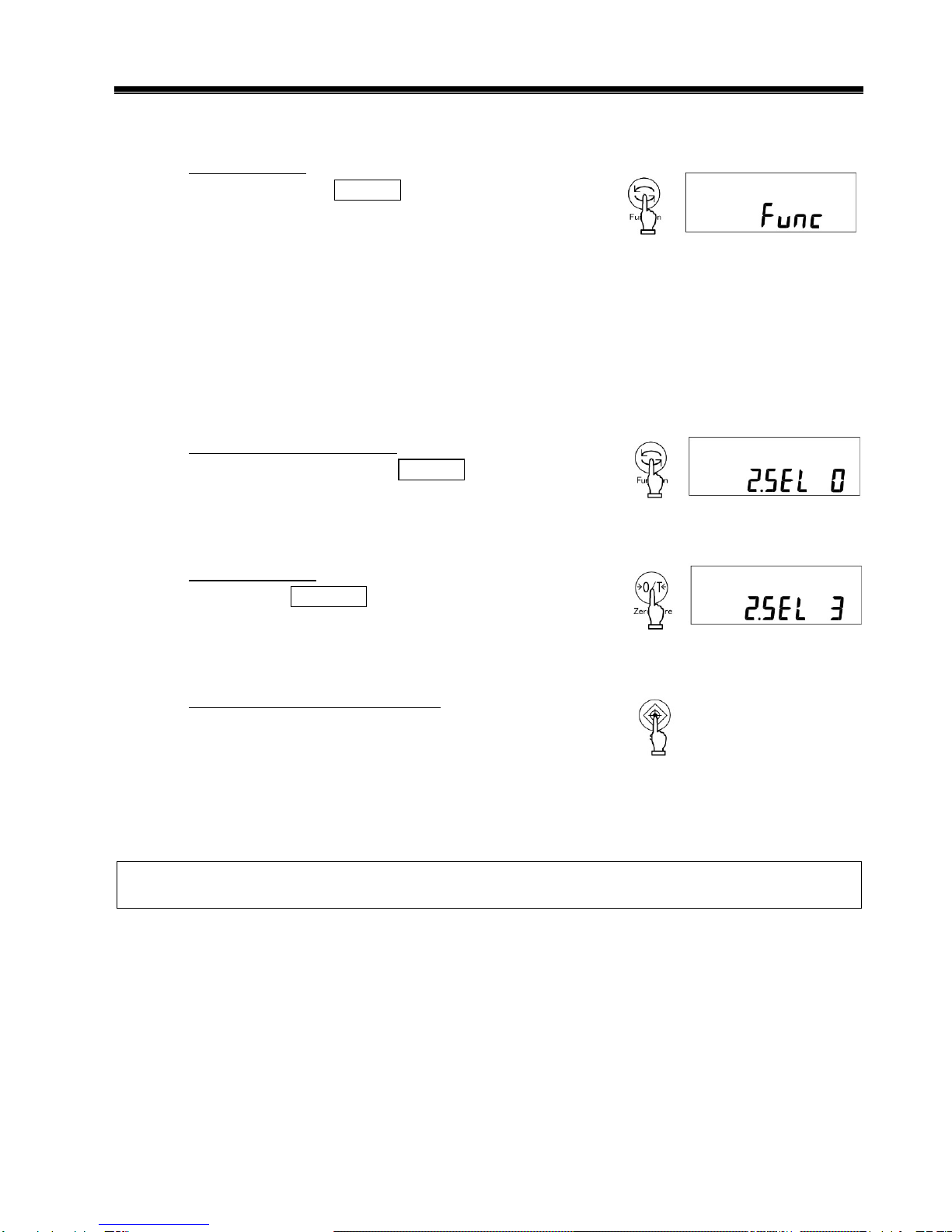

5 Function 1

5.1 Setting and Check

1. Call Function 1.

Press and hold the Function key for a few seconds.

When the display is changed to [Func] , release the

key.

The display switches to the Function 1 setting

screen and the first setting item [1. SEt 1] is

displayed.

(Refer to “Section 5.2: Description of Function 1” on

page 16).

2. Select the next setting item.

Every time you press the Function key, you are

moved one item forward.

3. Change settings.

Pressing the Zero/Tare key toggles the right-hand

value. Choose the appropriate setting.

4. Complete the setting of functions.

Press the Set key, or press the Function key

several times until the balance enters

measurement mode.

The setting of functions is completed, and the

balance goes back into measurement mode.

The setting values of Function 1 are stored after the power is turned off. Therefore, you do not

need to reenter the settings the next time the balance is used unless you wish to change them.

Continuous

Press

Key released

16

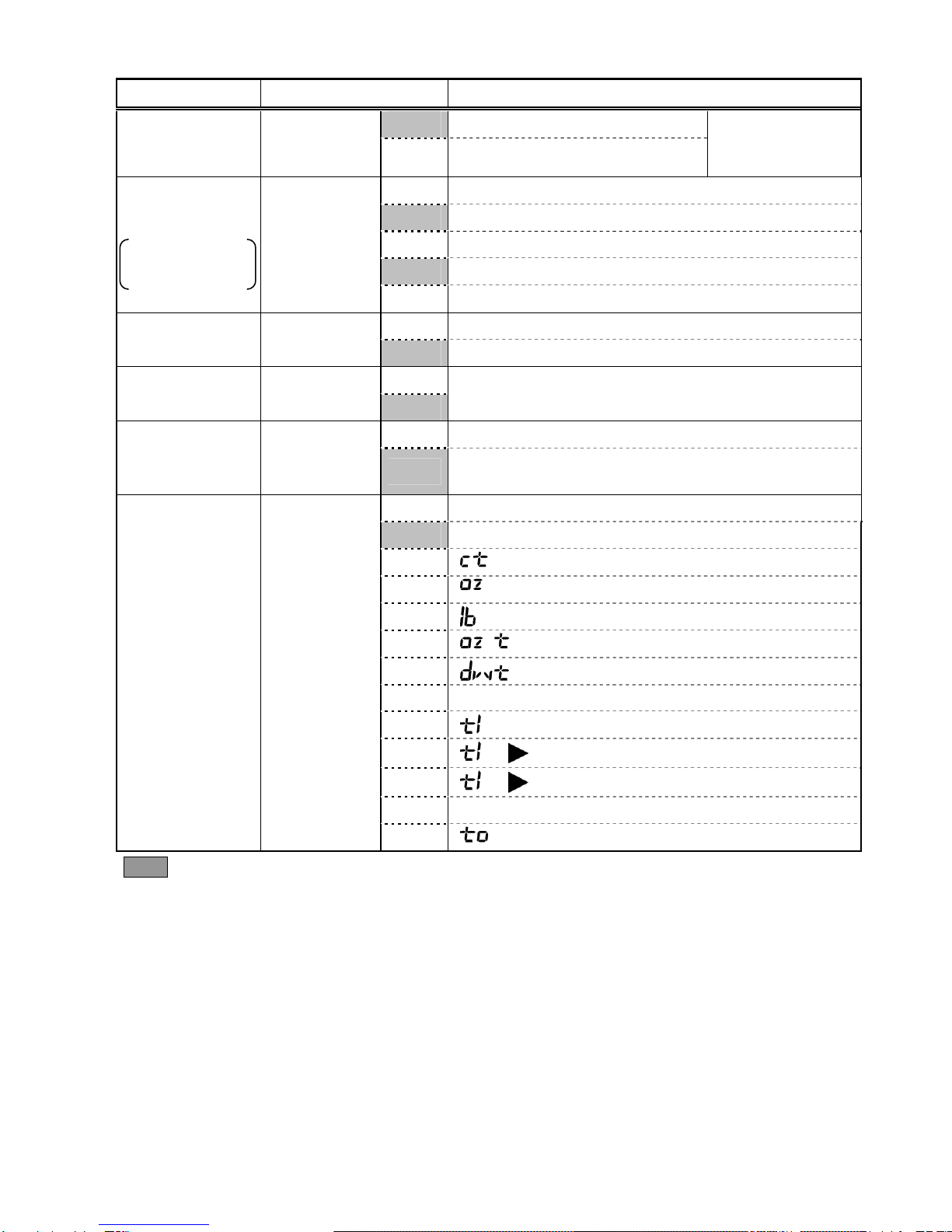

5.2 Description of Function 1

Contents of Function 1 (1/3)

Item Set Value Description

1 Weighing machine (only supports weight measuring)

2 Parts counting (parts counting and weight measuring)

3 Percentage weighing (weight percent measuring and

weight measuring)

4 Unit converting (coefficient multiplying and weight

measuring)

5 Gravimeter (Measuring specific

gravity of a solid)

Weighing Mode 1. SEt

6 Gravimeter(Measuring specific

gravity of a liquid)

→Proceed to

“Section 5.3:

Specific Gravity

Setting.”

0 Disable additional functions

1 Addition function ⇒[26. Ad.M]

2 Limit function

Additional

Functions 2. SEL

3 Addition and limit functions

Refer to “Section

5.4, Limit/Addition

Functions.”

0 Disable

Auto-Zero

(Zero Tracking) 3. A.0 1 Enable

2

3

Stability

Judgment 4. S.d.

4

Wide (Mild)

Narrow (Strict)

0 Measurement by consecutive weighings

1

2

3

4

Response Speed 5. rE.

5

Fast

Slow

0 Use when the balance is subject

to a low level of vibration

Vibration

Response

Setting

6. EnV.

1 Use when the balance is subject

to a high level of vibration

Linked to the

single-touch

response setting

function.

0 Stop input/output

2 Numeric 7-digit format

3 Extended 7-digit numeric format

Interface 7. I.F.

4 Special formats

→Refer to

“Section 5.5:

Interface.”

factory setting.

17

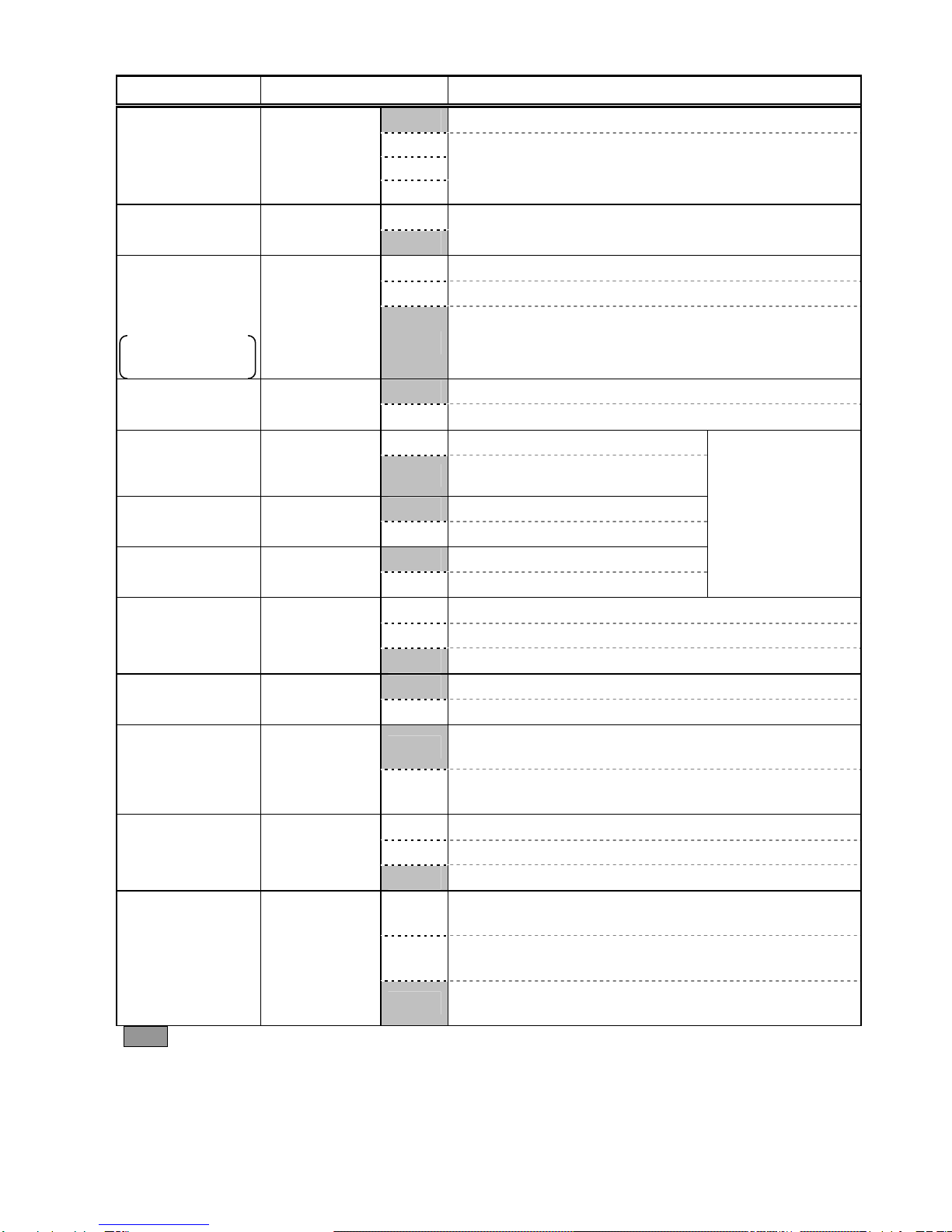

Contents of Function 1 (2/3)

Item Set Value Description

41 Special formats 1

Special Formats 7. I.F. 42 Special formats 2

Displayed when

[7. 1F 4] is

selected.

0 Disable the Cal key.

☆A 1 Span adjustment using built-in weights

2 Span test using built-in weights

☆B 3 Span adjustment with external weight

Span Adjustment

Span Test

HT Series 0,3,and 4

can be selected only.

8. CA.

4 Span test with external weight

0 No display

Bar Graph 9. b.G. 1 Displays the bar graph

0

Auto Power Off A. A.P. 1 Not Available in HT(R)-CE

0 Disable

Auto Backlight

OFF Function b. A.b. 1 Enable (The backlight goes off if the balance is not

used for about three minutes.)

1 [mg]

2 [g]

4 [ ] [carat]

5 [ ] [ounce]

6 [ ] [pound]

7 [ ] [troy ounce]

8 [ ] [penny weight]

9 [GN] [grain]

A [ ] [tael](Hong Kong)

b [ ,Upper right] [tael](Singapore,Malaysia)

C [ ,Lower right] [tael](Taiwan)

d [mom] [momme]

Unit A C1. u.A

E [ ] [tola]

factory setting. ☆A is factory setting of HTR series. ☆B is factory setting of HT series.

18

Contents of Function 1 (3/3)

Item Set Value Description

0 None

1

|

Unit B C3. u.b

E

The settings of [1, 2, 4-E] are the same as those of

Unit A.

0 Disable.

Auxilliary

indication setting d. Ai. 1 Enable

☆B 0 Disable

1 Advice CAL

Advice CAL and

Full-automatic

Span Adjustment

HT series 0, 1 only

be selected.

E. Ad.C.

☆A 2 Full-automatic Span Adjustment (Displayed only with

the HTR series)

0 Disable

Compliance with

ISO/GLP/GMP F. GLP 1 Enable

0 Disable

Output of Span

Adjustment and

test results

F1. out 1 Enable

0 Disable

Data compliant

with GLP F2. od. 1 Enable

1 English

Printed

Language F3. P.F. 2 Japanese (Katakana)

Displayed when

[F. GLP1] is

selected.

1 Output in Year-Month-Day format.

2 Output in Month-Day-Year format.

Date Display G. dAtE

3 Output in Day-Month-Year format.

0 Disable

Time Stamp

Output H. t.o. 1 Outputs time together with measurement data.

0 The balance enters standby mode when the AC

adapter is plugged in.

Direct Start n. d.St.

1 The balance is turned on when the AC adapter is

plugged in.

0 Always OFF

1 ON

Backlight P. b.L.

2 ON

1 No output when an auxilliary scale interval is being

displayed

2 Output in the mormal format even when an auxilliary

scale interval is being displayed.

Auxilliary scale

interval output

format 3

r. Pr.F.

3 A slash “/“ output in the digit preceding the auxilliary

scale interval.

factory setting. ☆A is factory setting of HTR series. ☆B is factory setting of HT series.

This manual suits for next models

11

Table of contents

Other Shinko Denshi Scale manuals

Shinko Denshi

Shinko Denshi FS623 User manual

Shinko Denshi

Shinko Denshi LN 223CE User manual

Shinko Denshi

Shinko Denshi AZ Series User manual

Shinko Denshi

Shinko Denshi LN 423 User manual

Shinko Denshi

Shinko Denshi PF-R150 User manual

Shinko Denshi

Shinko Denshi FZ623Ex User manual

Shinko Denshi

Shinko Denshi LF124R User manual

Shinko Denshi

Shinko Denshi CT603 User manual