Shinko WIL-101-ORP User manual

Plug-in Type

Digital Indicating ORP Meter

WIL-101-ORP

Instruction Manual

2

Preface

Thank you for purchasing our WIL-101-ORP, Plug-in Type Digital Indicating ORP Meter.

This manual contains instructions for the mounting, functions, operations and notes when operating the

WIL-101-ORP. To ensure safe and correct use, thoroughly read and understand this manual before using

this instrument.

To prevent accidents arising from the misuse of this instrument, please ensure the operator receives this

manual.

Characters Used in This Manual

Indication

Number, / -1 0 1 2 3 4 5 6 7 8 9

Indication

Alphabet A B C D E F G H I J K L M

Indication

Alphabet N O P Q R S T U V W X Y Z

Caution

• This instrument should be used in accordance with the specifications described in the manual.

If it is not used according to the specifications, it may malfunction or cause a fire.

• Be sure to follow all of the warnings, cautions and notices. If they are not observed, serious injury or

malfunction may occur.

• The contents of this instruction manual are subject to change without notice.

• Care has been taken to assure that the contents of this instruction manual are correct, but if there are any

doubts, mistakes or questions, please inform our sales department.

• This instrument is designed to be installed on a DIN rail within a control panel. If it is not, measures must be

taken to ensure that the operator cannot touch power terminals or other high voltage sections.

• Any unauthorized transfer or copying of this document, in part or in whole, is prohibited.

• Shinko Technos Co., Ltd. is not liable for any damage or secondary damage(s) incurred as a result of

using this product, including any indirect damage.

Safety Precautions (Be sure to read these precautions before using our products.)

The safety precautions are classified into 2 categories: “Warning” and “Caution”.

Depending on the circumstances, procedures indicated by Caution may result in serious

consequences, so be sure to follow the directions for usage.

Warning

Caution

Procedures which may lead to dangerous conditions and cause death or

serious injury, if not carried out properly.

Procedures which may lead to dangerous conditions and cause superficial to

medium injury or physical damage or may degrade or damage the product, if

not carried out properly.

3

Warning

• To prevent an electrical shock or fire, only Shinko or other qualified service personnel may handle the

inner assembly.

• To prevent an electrical shock, fire or damage to the instrument, parts replacement may only be

undertaken by Shinko or other qualified service personnel.

SAFETY PRECAUTIONS

• To ensure safe and correct use, thoroughly read and understand this manual before using this

instrument.

• This instrument is intended to be used for industrial machinery, machine tools and measuring

equipment. Verify correct usage after purpose-of-use consultation with our agency or main office.

(Never use this instrument for medical purposes with which human lives are involved.)

• External protection devices such as protective equipment against excessive temperature rise, etc.

must be installed, as malfunction of this product could result in serious damage to the system or

injury to personnel. Also proper periodic maintenance is required.

•

This instrument must be used under the conditions and environment described in this manual.

Shinko Technos Co., Ltd. does not accept liability for any injury, loss of life or damage occurring due

to the instrument being used under conditions not otherwise stated in this manual.

Caution with respect to Export Trade Control Ordinance

To avoid this instrument from being used as a component in, or as being utilized in the manufacture of

weapons of mass destruction (i.e. military applications, military equipment, etc.), please investigate

the end users and the final use of this instrument. In the case of resale, ensure that this instrument is

not illegally exported.

PRECAUTIONS

1. Installation Precautions

Caution

This instrument is intended to be used under the following environmental conditions (IEC61010-1):

• Overvoltage category , Pollution degree 2

Ensure the mounting location corresponds to the following conditions:

• A minimum of dust, and an absence of corrosive gases

• No flammable, explosive gases

• No mechanical vibrations or shocks

• No exposure to direct sunlight, an ambient temperature of 0 to 50 (32 to 122 ) that does not

change rapidly, and no icing

• An ambient non-condensing humidity of 35 to 85 %RH

• No large capacity electromagnetic switches or cables through which large current is flowing.

• No water, oil or chemicals or where the vapors of these substances can come into direct contact

with the unit

• If the WIL-101-ORP is installed within a control panel, the ambient temperature of the unit – not the

ambient temperature of the control panel – must be kept to under 50 . Otherwise the life of

electronic parts (especially electrolytic capacitors) of the unit will be shortened.

Note: Do not install this instrument on or near flammable material even though the case of this

instrument is made of flame-resistant resin.

4

2. Wiring Precautions

Caution

• Do not leave wire remnants in the instrument, as they could cause a fire or a malfunction.

• Use a solderless terminal with an insulation sleeve in which the M3 screw fits when wiring the

WIL-101-ORP.

• Tighten the terminal screw using the specified torque. If excessive force is applied to the screw

when tightening, the terminal screw may be damaged.

• This instrument does not have a built-in power switch, circuit breaker and fuse.

It is necessary to install a power switch, circuit breaker and fuse near the instrument.

(Recommended fuse: Time-lag fuse, rated voltage 250 V AC, rated current 2 A)

• For a 24 V AC/DC power source, do not confuse polarity when using direct current (DC).

• Do not apply a commercial power source to the sensor which is connected to the input terminal nor

allow the power source to come into contact with the sensor.

• Use the ORP Combined Electrode Sensor in accordance with the sensor input specifications of the

WIL-101-ORP.

• Keep the input wires and power line separate.

Note about the ORP Combined Electrode Sensor Cable

The ORP Combined Electrode Sensor cable is a highly-insulated (electrical) cable. Please handle it

with utmost care as follows.

• Do not allow terminals and socket of the ORP Combined Electrode Sensor cable to come in contact

with moisture or oil of any kind. Likewise, ensure fingers are clean, otherwise the insulation will

deteriorate, resulting in unstable indication.

Be sure to keep the cable dry and clean at all times.

If the cable is stained, clean it with alcohol, and dry it completely.

• For calibration or electrode checking/replacement, the ORP Combined Electrode Sensor cable

should be wired with sufficient length.

• Keep the ORP Combined Electrode Sensor cable and junction cable away from electrical devices,

such as motors or their power lines from which inductive interference emanates.

Connection

The ORP Combined Electrode Sensor cable has the following terminals.

Symbol Terminal

M Metal electrode terminal

R Reference electrode terminal

3. Operation and Maintenance Precautions

Caution

• Do not touch live terminals. This may cause an electrical shock or problems in operation.

• Turn the power supply to the instrument OFF when retightening the terminal or cleaning.

Working on or touching the terminal with the power switched ON may result in severe injury or death

due to electrical shock.

• Use a soft, dry cloth when cleaning the instrument.

(Alcohol based substances may tarnish or deface the unit.)

• As the display section is vulnerable, do not strike or scratch it with a hard object or put pressure on it.

5

Contents

1. Model Page

1.1 Model ---------------------------------------------------------------------------------- 7

1.2 How to Read the Model Label --------------------------------------------------- 7

2. Names and Functions of Sections ---------------------------------------------- 8

3. Mounting to the Control Panel

3.1 Site Selection ---------------------------------------------------------------------- 9

3.2 External Dimensions (Scale: mm) --------------------------------------------- 9

3.3 Mounting ---------------------------------------------------------------------------- 9

4. Removal -------------------------------------------------------------------------------- 11

5. Wiring ----------------------------------------------------------------------------------- 12

5.1 Lead Wire Solderless Terminal ------------------------------------------------ 13

5.2 Terminal Arrangement ------------------------------------------------------------ 13

5.3 Wire the Communication Line -------------------------------------------------- 14

6. Outline of Key Operation and Setting Groups

6.1 Outline of Key Operation -------------------------------------------------------- 16

6.2 Setting Groups --------------------------------------------------------------------- 16

7. Key Operation Flowchart --------------------------------------------------------- 18

8. Setup

8.1 Turn the Power Supply to the WIL-101-ORP ON ------------------------- 20

8.2 ORP Input Function Group ----------------------------------------------------- 20

8.3 Output Function Group ---------------------------------------------------------- 21

8.4 Special Function Group --------------------------------------------------------- 26

9. Calibration

9.1 Adjustment Mode ----------------------------------------------------------------- 33

9.2 Span Sensitivity Correction Mode -------------------------------------------- 34

9.3 Transmission Output Adjustment Mode ------------------------------------- 35

10. Measurement

10.1 Starting Measurement --------------------------------------------------------- 36

10.2 A Output --------------------------------------------------------------------- 36

10.3 ORP Input Error Alarm -------------------------------------------------------- 36

10.4 Cleansing Output --------------------------------------------------------------- 37

10.5 Manual Cleansing Mode ------------------------------------------------------ 38

10.6 Transmission Output ----------------------------------------------------------- 38

11. Communication

11.1 System Configuration Example ---------------------------------------------- 39

11.2 Setting Method of the ORP Meter ------------------------------------------- 39

11.3 Communication Procedure --------------------------------------------------- 40

11.4 Shinko Protocol

11.4.1 Transmission Mode ------------------------------------------------------ 41

11.4.2 Command Configuration ------------------------------------------------ 41

11.4.3 Checksum Calculation -------------------------------------------------- 42

11.5 Modbus Protocol

11.5.1 Transmission Mode ------------------------------------------------------ 43

11.5.2 Data Communication Interval ----------------------------------------- 43

11.5.3 Message Configuration ------------------------------------------------- 43

11.5.4 Message Example ------------------------------------------------------- 45

6

11.6 Communication Command Table

11.6.1 Notes about Setting/Reading Command --------------------------- 47

11.6.2 Setting/Reading Command -------------------------------------------- 47

11.6.3 Read Only Command --------------------------------------------------- 51

11.7 ORP Calibration and Transmission Output Adjustment

via Communication Command --------------------------------------------- 52

11.7.1 Adjustment Mode --------------------------------------------------------- 52

11.7.2 Span Sensitivity Correction Mode ----------------------------------- 52

11.7.3 Transmission Output Adjustment ------------------------------------ 53

11.8 Notes on Programming Monitoring Software

11.8.1 How to Speed up the Scan Time ------------------------------------- 54

11.8.2 How to Read the Set Value Changes

Made by Front Keypad Operation ------------------------------------ 54

11.8.3 Note when Sending All Set Values Simultaneously ------------- 54

12. Specifications

12.1 Standard Specifications ------------------------------------------------------- 55

12.2 Optional Specifications -------------------------------------------------------- 58

13. Troubleshooting

13.1 Indication -------------------------------------------------------------------------- 60

13.2 Key Operation -------------------------------------------------------------------- 60

13.3 Communication ------------------------------------------------------------------ 61

14 Character Tables ------------------------------------------------------------------- 62

7

1. Model

1.1 Model

W I L - 1 0 1 -ORP ,

Input Points 1 1 point

Input ORP ORP Combined Electrode Sensor

100 to 240 V AC (standard)

Supply Voltage 1 24 V AC/DC (*1)

EVT A output (A11, A12, A21, A22)

Option TA Transmission output (*2)

(*1) Supply voltage 100 to 240 V AC is standard.

When ordering 24 V AC/DC, enter “1” after the input code.

(*2) If the TA option is ordered, the EVT option (A1 output only) will be automatically added.

1.2 How to Read the Model Label

The model label is attached to the left side of the case.

(Fig. 1.2-1)

Model, Option

Input

Supply voltage, Power consumption

Serial number

Manufacturer

Factory ID

RoHS directive compliant

8

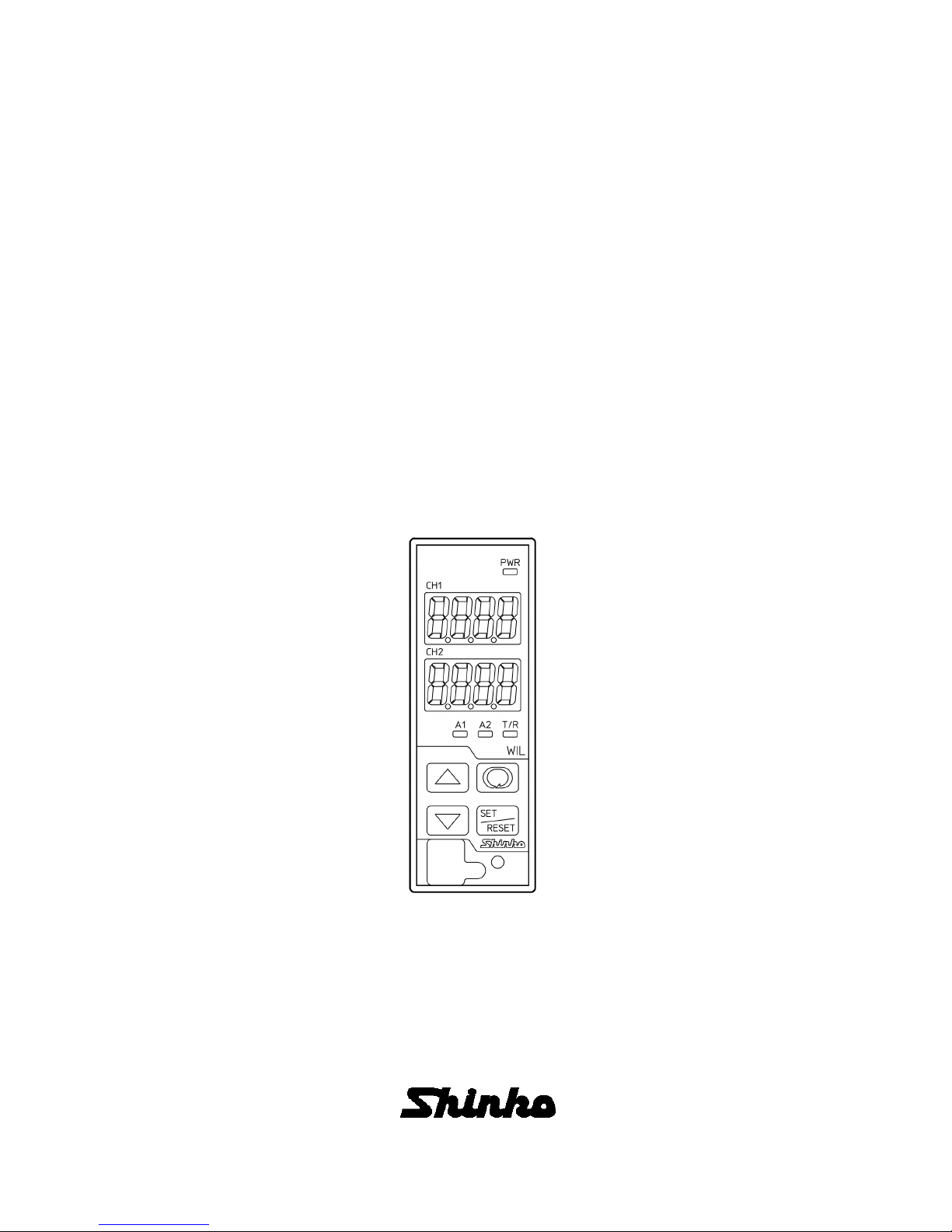

2. Names and Functions of Sections

(Fig. 2-1)

Displays

ORP Display: ORP value or characters in setting mode are indicated in red.

Setting Display: Values in setting mode are indicated in red.

Indications differ depending on the selections in [Setting Display indication (p.27)].

Unit labels

Unit label: Attach the user’s unit of ORP Display and Setting Display from the included unit

labels if necessary.

Action Indicators

Power Indicator: When power supply to the instrument is turned ON, the yellow LED is lit.

A1 Indicator: When A1 output (Contact output 1) is ON, the red LED is lit.

A2 Indicator: When A2 output (Contact output 2) is ON, the yellow LED is lit.

T/R Indicator: The yellow LED is lit during Serial communication TX output (transmitting).

Keys

UP key: Increases the numeric value.

DOWN key: Decreases the numeric value.

MODE key: Selects a setting group.

SET/RESET key: Switches the setting modes, and registers the set value.

Light Sensor: Automatically measures and controls brightness of the ORP Display,

Setting Display and Action indicators.

Notice

When setting the specifications and functions of this instrument, connect mains power cable to terminals

13 and 14 first, then set them referring from “6. Outline of Key Operation and Setting Groups” to “8.

Setup (pages 17 to 32)” before performing “3. Mounting to the Control Panel (p.9)” and “5. Wiring (p.12)”.

A2 Indicator

ORP Display

Setting Display

A1 Indicator

UP key

DOWN key

Power Indicator

T/R Indicator

MODE key

SET/RESET key

Light Sensor

Unit label

Unit label

9

3. Mounting to the Control Panel

3.1 Site Selection

Caution

Use within the following temperature and humidity ranges.

Temperature: 0 to 50 (32 to 122 ) (No icing), Humidity: 35 to 85 %RH (Non-condensing)

If the WIL-101-ORP is installed within a control panel, the ambient temperature of the unit – not the

ambient temperature of the control panel – must be kept to under 50 . Otherwise the life of

electronic parts (especially electrolytic capacitors) of the unit will be shortened.

This instrument is intended to be used under the following environmental conditions (IEC61010-1):

Overvoltage category , Pollution degree 2

Ensure the mounting location corresponds to the following conditions:

• A minimum of dust, and an absence of corrosive gases

• No flammable, explosive gases

• No mechanical vibrations or shocks

• No exposure to direct sunlight, an ambient temperature of 0 to 50 (32 to 122 ) that does not

change rapidly

• An ambient non-condensing humidity of 35 to 85 %RH

• No large capacity electromagnetic switches or cables through which large current is flowing

• No water, oil or chemicals or where the vapors of these substances can come into direct contact

with the unit

3.2 External Dimensions (Scale: mm)

(Fig. 3.2-1)

3.3 Mounting

(1) Hook the upper part of the socket on the DIN rail, and mount it (A clicking sound is heard).

(Fig. 3.3-1)

Hook the upper part of the

socket on the DIN rail.

Socket (sold separately)

DIN rail

85

3

30 108

79 (29)

3.3

10

Caution

Before inserting the WIL-101-ORP into the socket, wire the unit while referring to Section “5. Wiring”

(p.12).

(2) Check that the Lock Release has been lowered.

(Fig. 3.3-2)

(3) Insert the WIL-101-ORP into the socket.

(Fig. 3.3-3)

(4) Fix the WIL-101-ORP and the socket by pushing the Lock Release up.

(Fig. 3.3-4)

When inserting, be careful about

the position of pins and slots.

Lock Release

Lock Release

Check that the WIL-101-ORP and the socket

are locked by pushing the Lock Release up.

11

4. Removal

(1) Turn the power supply to the unit OFF.

(2) Pull the Lock Release down, and release the WIL-101-ORP from the socket.

(Fig. 4-1)

(3) Separate the WIL-101-ORP from the socket.

(Fig. 4-2)

(4) Remove the socket from the DIN rail by pulling the socket Lock Release

(at the bottom of the socket) down.

(Fig. 4-3)

Lock Release

Check that the WIL-101-ORP and

the socket are unlocked by pulling

the Lock Release down.

Lock Release

12

5. Wiring

Warning

Turn the power supply to the instrument off before wiring or checking.

Working on or touching the terminal with the power switched on may result in severe injury

or death due to electrical shock.

Caution

• Do not leave wire remnants in the instrument, as they could cause a fire or a malfunction.

• Use a solderless terminal with an insulation sleeve in which the M3 screw fits when wiring the unit.

• Tighten the terminal screw using the specified torque. If excessive force is applied to the screw

when tightening, the terminal screw may be damaged.

• This instrument does not have a built-in power switch, circuit breaker or fuse.

It is necessary to install a power switch, circuit breaker or fuse near the instrument.

(Recommended fuse: Time-lag fuse, rated voltage 250 V AC, rated current 2 A)

• For a 24 V AC/DC power source, do not confuse polarity when using direct current (DC).

• Do not apply a commercial power source to the sensor which is connected to the input terminal

nor allow the power source to come into contact with the sensor.

• Use the ORP Combined Electrode Sensor in accordance with the sensor input specifications of this unit.

• Keep the input wires and power line separate.

Note about the ORP Combined Electrode Sensor Cable

The ORP Combined Electrode Sensor cable is a highly-insulated (electrical) cable. Please handle it

with utmost care as follows.

• Do not allow terminals and socket of the ORP Combined Electrode Sensor cable to come in contact

with moisture or oil of any kind. Likewise, ensure fingers are clean, otherwise the insulation will

deteriorate, resulting in unstable indication. Be sure to keep the cable dry and clean at all times.

If the cable is stained, clean it with alcohol, and dry it completely.

• For calibration or electrode checking/replacement, the ORP Combined Electrode Sensor cable should

be wired with sufficient length.

• Keep the ORP Combined Electrode Sensor cable and junction cable away from electrical devices,

such as motors or their power lines from which inductive interference emanates.

Connection

The ORP Combined Electrode Sensor cable has the following terminals.

Symbol Terminal

M Metal electrode terminal

R Reference electrode terminal

13

5.1 Lead Wire Solderless Terminal

Use a solderless terminal with an insulation sleeve in which an M3 screw fits as follows.

The tightening torque should be 0.63 N•m.

Solderless

Terminal Manufacturer Model

Y-type Nichifu Terminal Industries CO.,LTD. TMEV1.25Y-3S

(Fig. 5.1-1)

5.2 Terminal Arrangement

M, R: Electrode sensor terminals ( 1-2)

ORP Combined Electrode Sensor

A1: A1 output (Contact output 1) terminals

(9-10 )

(When the EVT option or TA option is

ordered)

A2: A2 output (Contact output 2) terminals

(11 -12 )

(When the EVT option is ordered)

TRANSMIT OUTPUT:

Transmission output terminals (

11

-12 )

(When the TA option is ordered)

POWER SUPPLY: Power terminals ( 13 -

14

)

24 V AC/DC (Enter 1 after the input

code.)

RS-485: Serial Communication modular jack

Modular Jack Pin (WIL-101-ORP side arrangement)

(Fig. 5.2-1)

3

.2

mm

or more

5.

9

mm

or less

4 mm or less

4

.8

mm

or more

14

WIL-101-ORP (Max 31 units)

CDD or CPP (sold-separately)

CMC-001-3 (sold-separately)

Bottom of WIL-101-ORP

Host computer

USB port

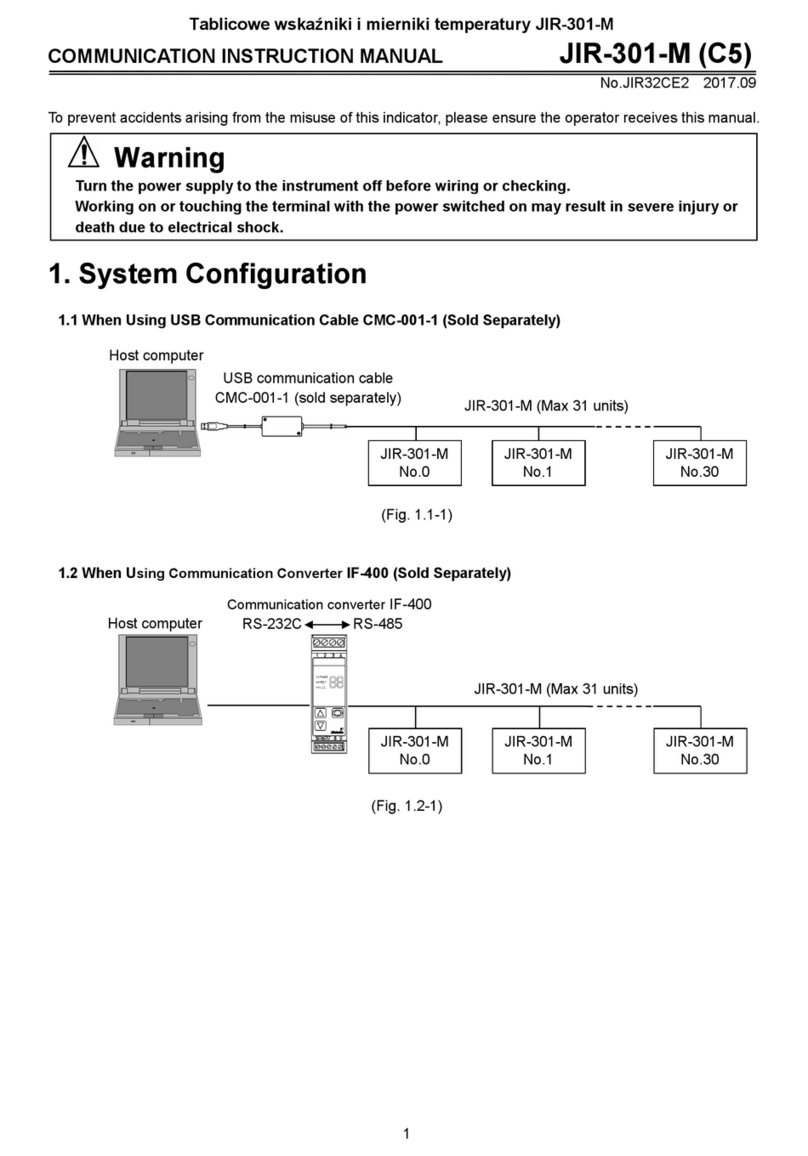

5.3 Wire the Communication Line

Connect to the modular jack at the bottom of the instrument, using CDD or CPP (sold separately).

•Wiring Example Using a USB Communication cable CMC-001-3 (sold-separately)

(Fig. 5.3-1)

•Wiring Example Using a Communication Converter IF-400 (sold-separately)

(Fig. 5.3-2)

Bottom of IF-400, WIL-101-ORP

Host Computer

D-sub 9-pin Connector

Shield

Wire FG

WIL-101-ORP (Max 31 units)

IF-400 (Sold Separately)

CDD or CPP (sold separately)

15

Shield Wire

Be sure to ground only one end of the shield wire so that current cannot flow to the shield wire.

If both ends of the shield wire are grounded, the circuit will be closed, resulting in a ground loop.

This may cause noise. Be sure to ground the FG terminal.

Recommended cable: OTSC-VB 2PX0.5SQ (made by Onamba Co., Ltd.) or equivalent

(Use a twisted pair cable.)

Terminator (Terminal Resistor)

The terminator is mounted at the end of the wire when connecting a personal computer with

multiple peripheral devices. The terminator prevents signal reflection and disturbance.

Do not connect a terminator with the communication line because each WIL-101-ORP has

built-in pull-up and pull-down resistors instead of a terminator.

Communication converter IF-400 (sold separately) has a built-in terminal resistor.

16

6. Outline of Key Operation and Setting Groups

6.1 Outline of Key Operation

Setting items are divided into groups, and group selection has to be made with keypads.

Press the key in ORP Display Mode or Cleansing Output Mode. The unit enters Group Selection

Mode.

Select a group with the key, and press the key. The unit enters each setting item.

To set each setting item, use the or key, and register the set value with the key.

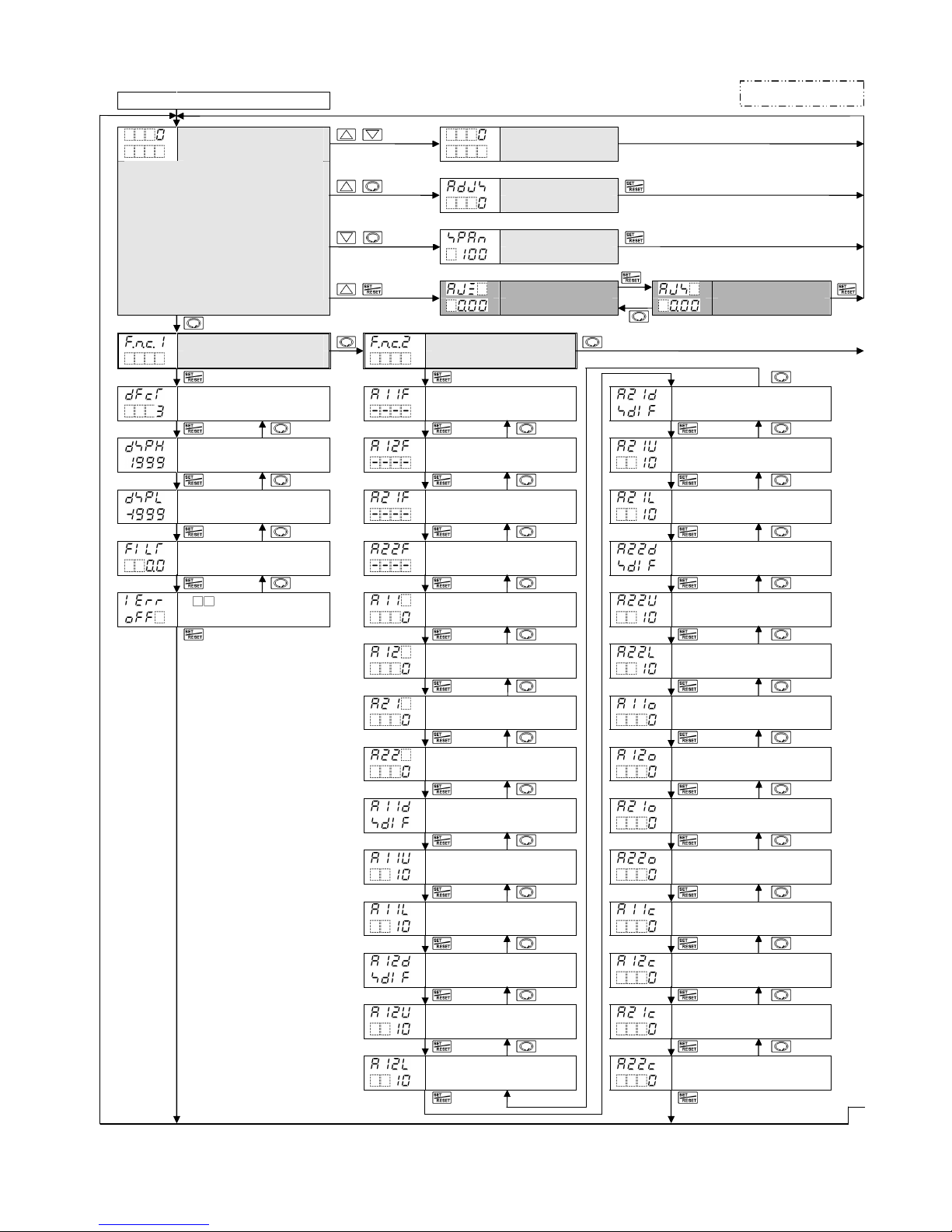

6.2 Setting Groups

Power ON

+ (3 sec) (*2) (*2)

ORP Display Mode or Manual Cleansing Mode

Cleansing Output Mode

(*1) + (3 sec) (*3)

Adjustment Mode

+ (3 sec) (*3)

Span Sens.Correc. Mode

+ (3 sec)

Transmission Output Transmission Output

Zero Adjust. Mode Span Adjust. Mode

Group Selection Mode See pages 20-32 for details of each setting item.

ORP Input Function Moving average A output when

Group data amount input errors occur

Output Function A11 type A22 OFF delay time

Group

Special Function Set value lock Restore time after

Group cleansing

(*1) Measurement starts, indicating ORP in the ORP Display, and the item selected in [Setting Display indication (p.27)]

of Special function group in the Setting Display. If power is turned ON again, the last mode (ORP Display Mode or

Cleansing Output Mode) from when power was turned OFF will resume.

(*2) If (Cleansing output) is selected in any of [A11, A12, A21, A22 type (pp.21, 22)] in the Output Function

Group, the unit will enter Manual Cleansing Mode.

After cleansing action is complete, the unit automatically reverts to Cleansing Output Mode.

Abbreviation

s

:

Sens.: Sensitivity

Correc.: Correction

Adjust.: Adjustment

17

(*3) The unit cannot enter Adjustment Mode or Span Sensitivity Correction Mode in the following cases:

• When (Lock 1),( Lock 2) or (Lock 3) is selected in [Set value lock (p.26)] in the Special

Function Group

• When (Cleansing output) is selected in any of [A11, A12, A21, A22 type (pp.21, 22)] in the Output Function

Group, and cleansing action is performing using the ‘Cleansing time’ and ‘Restore time after cleansing’ settings.

: Available only when the TA option is ordered.

About Key Operation

• + (3 sec): Press and hold the key and key (in that order) together for 3 seconds.

The unit will proceed to Manual Cleansing Mode.

• + (3 sec): Press and hold the key and key (in that order) together for 3 seconds.

The unit will proceed to Adjustment Mode.

• + (3 sec): Press and hold the key and key (in that order) together for 3 seconds.

The unit will proceed to Span Sensitivity Correction Mode.

• + (3 sec): Press and hold the key and key (in that order) together for 3 seconds.

The unit will proceed to Transmission Output Zero Adjustment Mode.

• or : Press the or key. The unit will proceed to the next setting item,

illustrated by an arrow.

• or : Press the or key until the desired setting mode appears.

• To revert to ORP Display Mode or Cleansing Output Mode, press and hold the key for 3

seconds while in any mode.

18

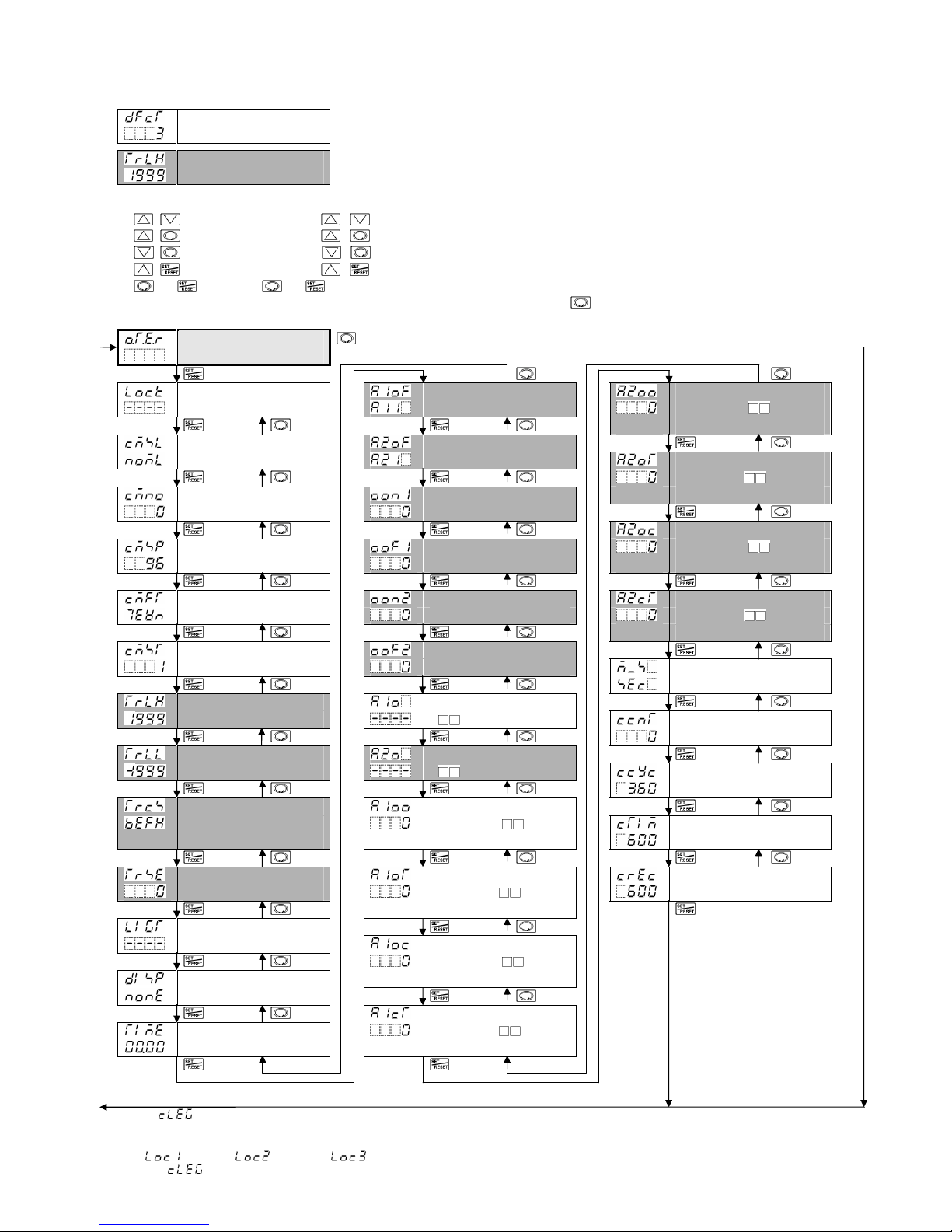

7. Key Operation Flowchart

Power ON

ORP Display Mode or + (3sec) (*1) Manual Cleansing (*1)

Cleansing Output Mode mode

+ (3sec) (*2) Adjustment

mode

+ (3sec) (*2) Span Sensitivity

Correction mode

+ (3 sec) Transmission output Transmission output

In ORP Display Mode or Cleansing Output

Mode, measurement starts, indicating ORP

in the ORP Display and an item selected

in [Setting Display indication (p.27)] of Special

function group in the Setting Display.

If power is turned ON again, the last mode

(ORP Display Mode or Cleansing Output

Mode) from when power was turned OFF

will resume.

Zero adjust. mode Span adjust. mode

ORP Input Function Output Function

Group Group

Moving average A11 type A21 hysteresis type

data amount

Input high limit A12 type A21 ON side

Input low limit A21 type A21 OFF side

ORP input A22 type A22 hysteresis type

filter time constant

A output when input A11 value A22 ON side

errors occur

A12 value A22 OFF side

A21 value A11 ON delay time

A22 value A12 ON delay time

A11 hysteresis type A21 ON delay time

A11 ON side A22 ON delay time

A11 OFF side A11 OFF delay time

A12 hysteresis type A12 OFF delay time

A12 ON side A21 OFF delay time

A12 OFF side A22 OFF delay time

①

②

Abbreviation:

Adjust.: Adjustment

19

●About Setting Items

Moving average • Upper left: ORP Display: Indicates the setting item characters.

data amount • Lower left: Setting Display: Indicates the factory default. • Right side: Indicates the setting item.

Transmission output Setting item in shaded section will be indicated only when the corresponding option is ordered.

high limit A2 related items cannot be used if TA option is ordered.

●About Key Operation

• + (3 sec): Press and hold , keys (in that order) for 3 sec. The unit enters Manual Cleansing Mode.

• + (3 sec): Press and hold , keys (in that order) for 3 sec. The unit enters Adjustment Mode.

• + (3 sec): Press and hold , keys (in that order) for 3 sec. The unit enters Span Sensitivity Correction Mode

• + (3 sec): Press and hold , keys (in that order) for 3 sec. The unit enters Transmission Output Zero Adjustment Mode.

• or : Press the or key. The unit enters the next setting item, illustrated by an arrow.

• To revert to ORP Display Mode or Cleansing Output Mode, press and hold the key for 3 sec while in any mode.

Special Function

Group

Set value lock A1 output allocation A2 ORP input error alarm

span when A output

ON

Communication A2 output allocation

protocol A2 ORP input error alarm

time when A output

Instrument number Output ON time ON

when A1 output ON

A2 ORP input error alarm

Communication Output OFF time span when A output

speed when A1 output ON OFF

Data bit/Parity Output ON time A2 ORP input error alarm

when A2 output ON time when A output

OFF

Stop bit Output OFF time

when A2 output ON ORP input error alarm

time unit

Transmission output A1 ORP input error alarm

high limit A type Number of cleansing

cycles

Transmission output A2 ORP input error alarm

low limit A type Cleansing interval

Transmission output status A1 ORP input error alarm

in Adjustment Mode, Span span when A output Cleansing time

Sensitivity Correction Mode ON

Set value HOLD A1 ORP input error alarm Restore time after

time when A output cleansing

ON

Auto-light function

A1 ORP input error alarm

span when A output

Setting Display OFF

indication

A1 ORP input error alarm

Indication time time when A output

OFF

(*1) When (Cleansing Output) is selected in any of [A11, A12, A21, A22 type (pp.21, 22)] in the Output Function Group, the unit will enter Manual

Cleansing Mode. After cleansing is complete, the unit automatically reverts to Cleansing Output Mode.

(*2) The unit cannot enter Adjustment Mode or Span Sensitivity Correction Mode in the following cases.

•If (Lock 1),(Lock 2) or (Lock 3) is selected in [Set value lock (p.26)] in the Special Setting Group

•When (Cleansing output) is selected in any of [A11, A12, A21, A22 type (pp.21, 22)] in the Output Function Group, and cleansing action

is performing using the ‘Cleansing time’ and ‘Restore time after cleansing’ settings.

①

②

20

8. Setup

Setup should be done before using this instrument, according to the user’s conditions:

Setting the ORP input function (input high limit, input low limit), Output function (A11, A12, A21, A22

types), Special function (Communication, Cleansing action, etc.).

Setup can be conducted in the ORP Input Function Group, Output Function Group and Special Function

Group.

If the user’s specification is the same as the factory default of the WIL-101-ORP, or if setup has already

been completed, it is not necessary to set up the instrument. Proceed to Section “9. Calibration (p.33)”.

8.1 Turn the Power Supply to the WIL-101-ORP ON.

For approx. 4 seconds after the power is switched ON, is indicated in the ORP Display.

During this time, all outputs are in OFF status, and LED indicators except the Power Indicator go off.

After that, measurement starts, indicating ORP in the ORP Display and an item selected in [Setting

Display indication (p.27)] in the Setting Display.

This status is called ORP Display Mode or Cleansing Output Mode.

8.2 ORP Input Function Group

To enter the ORP Input Function Group, follow the procedure below.

1Press the Key once in ORP Display Mode or Cleansing Output Mode.

2Press the Key once.

The unit proceeds to the ORP Input Function Group, and ’Moving average data amount’ appears.

Character Setting Item, Function, Setting Range Factory Default

Moving average data amount 3

• Sets the number of ORP inputs for calculating the moving average.

• Setting range: 1 to 20

Input high limit 1999 mV

• Sets the high limit value for ORP input indication.

• Setting range: Input low limit value to 1999 mV

Input low limit -1999 mV

• Sets the low limit value for ORP input indication.

• Setting range: -1999 mV to Input high limit value

ORP input filter time constant 0.0 sec.

• Sets ORP input filter time constant.

If the value is set too large, it affects A output due to the delay of response.

• Setting range: 0.0 to 60.0 seconds

A output when input errors occur Disabled

• If input errors, such as ORP Combined Electrode Sensor burnout or short-circuited

occur, A output Enabled/Disabled can be selected.

If “Enabled” is selected, A output and A output status will be maintained

when input errors occur.

If “Disabled” is selected, A output and A output status will be turned OFF

when input errors occur.

• If (Cleansing output) is selected in [A type], cleansing action takes

priority regardless of this selection.

• : Enabled

: Disabled

Table of contents

Other Shinko Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Bender

Bender Isometer IR420-D4 manual

Renkforce

Renkforce A460 operating instructions

Agilent Technologies

Agilent Technologies 2100 Bioanalyzer System Installation and safety guide

Burster

Burster TRANS CAL 7270 user manual

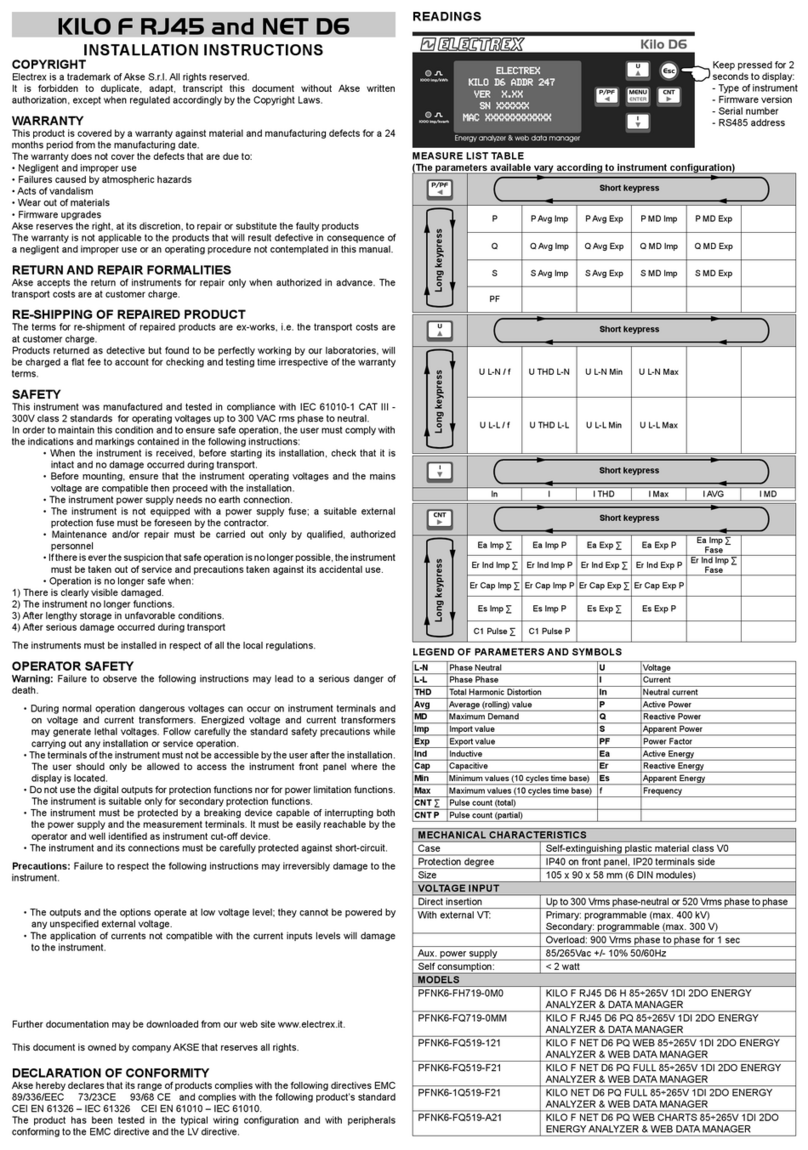

Electrex

Electrex KILO F RJ45 installation instructions

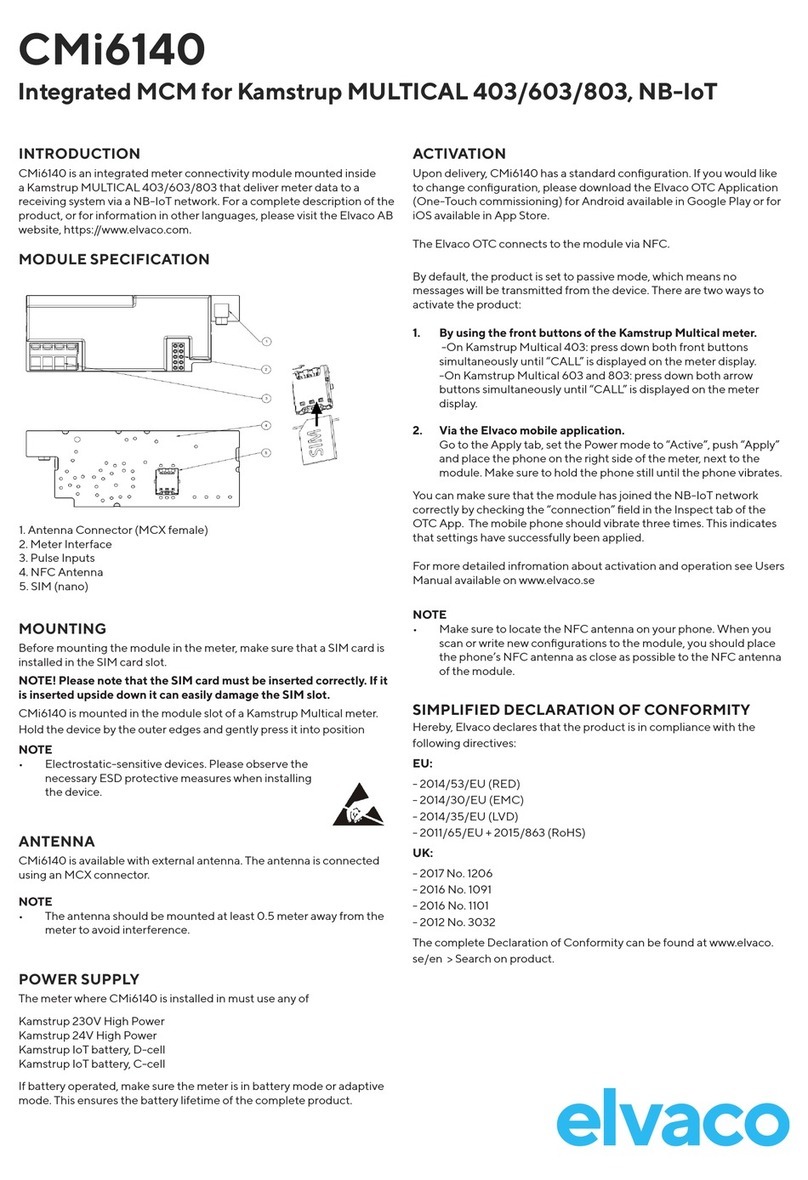

Elvaco

Elvaco CMi6140 quick start guide

SIMARINE

SIMARINE SDI01 user manual

Mark-10

Mark-10 2 Series quick start guide

AR

AR DC7490 Operating and service manual

TSI Incorporated

TSI Incorporated IAQ-CALC 7515 Operation and service manual

Tektronix

Tektronix TLA7S08 instruction manual

Endress+Hauser

Endress+Hauser Analytikjena SELECT Head 8/250 ml operating manual