Shinko JC-33A User manual

Instruction manual

JCS, R, D-33A (C5)

To prevent accidents arising from the misuse of this controller, please ensure the operator using it

receives this manual.

Warning

Turn the power supply to the instrument OFF before wiring or checking.

Working or touching the terminal with the power switched ON may result in

Electric Shock which may cause severe injury or death.

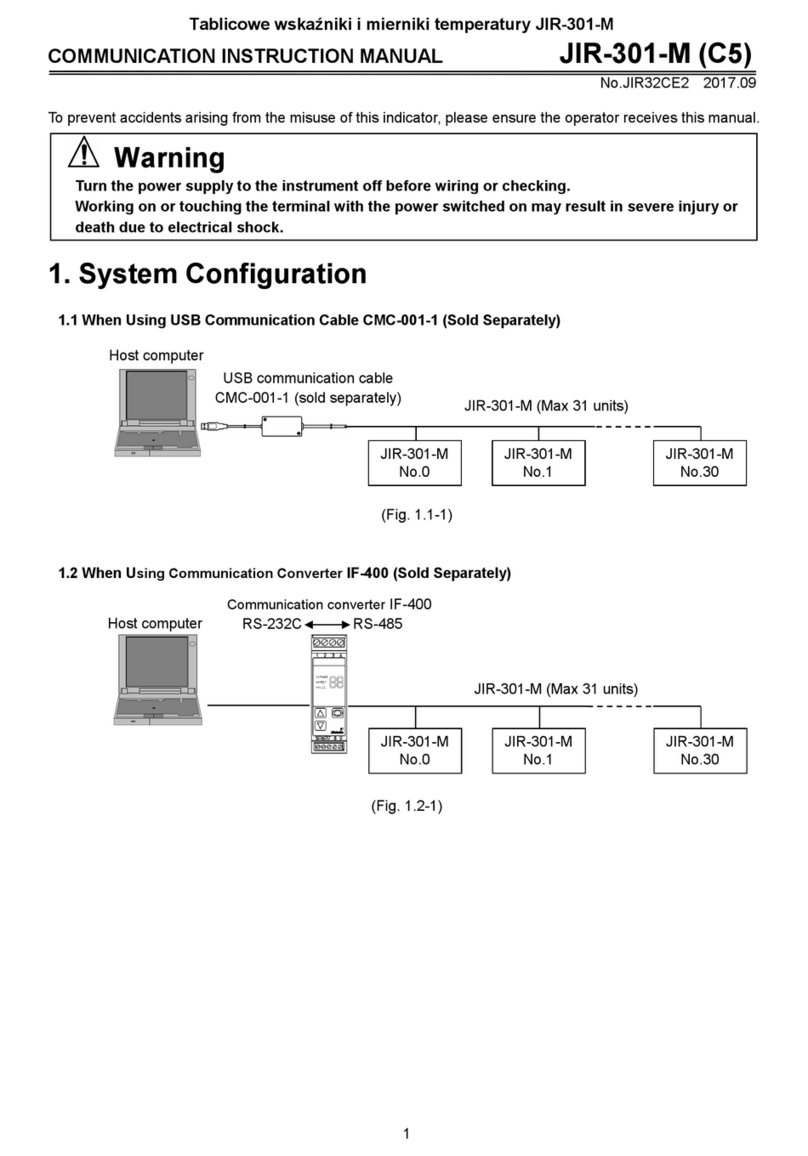

1. System configuration

RS-485 Multi-drop connection communication (Option: C5)

(Fig.1-1)

(Fig.1-2)

Wiring connection

When communication converter IF-300-C5 (RS-232C) is used

•Connector: D-sub connector 25-pin

Connection: RS-232C RS-485 (Data transfer rate: 2400, 4800, 9600, 19200bps)

(Fig.2-1)

RS-485

Host

computer

No.0

JC -33A

No.1 No.2 No.30

JC -33A JC -33A JC -33A

RS-485

RS-232C

Host

computer

232C

Communication

IF-300 485

No.0

converter

No.1 No.30

JC -33A JC -33A JC -33A

TXD

RXD

SG

FG

RTS

CTS

DSR

DTR

CD

2

3

7

1

4

5

6

20

8

Host computer

Shield wire

D-sub connecter 25-pin

COM

(6)

YA(-)

YB(+)

COM

RX

TX

COM

IF-300-C5

Built-in terminator 120

RS-232C RS-485

(2)

(1)

(11)

(4)

(5)

YA(-)

YB(+)

YA(-)

YB(+)

JCS-33A

COM

Shield wire

(13)

(14)

(15)

(13)

(14)

(15)

•Connector: D-sub connector 9-pin

Connection: RS-232C RS-485 (Data transfer rate: 2400, 4800, 9600, 19200bps)

(Fig.2-2)

Shield wire

Connect only one side of the shield wire to the FG or GND terminal so as not to allow current to

flow into the shield section.

If both sides of the shield section are connected to the FG or GND terminal, closed circuit will be

made between the shield wire and the ground.

As a result of this, current will run in the shield wire and the current may cause noise.

Never fail to ground FG or GND terminal.

Terminator

Do not connect terminator onto the communication line, because each of the JCS-33A, JCR-33A

and JCD-33A has a built-in terminator.

IF-300-C5 (sold separately) is available as a communication converter.

3. Setting the instruments

• It is necessary to set the instrument number individually to the instruments when plural

units are connected in serial communication (Option: C5).

Select the data transfer rate of the JC series in accordance with that of the host computer.

• Refer to the JCS-33A, JCR-33A and JCD-33A instruction manual as for instrument number setting

and transfer rate selection.

RXD

TXD

DCD

DTR

DSR

RTS

CTS

2

3

5

1

4

6

7

8

Host computer

D-sub connecter 9-pin

(6)

(7)

(8)

(14)

(15)

(16)

YA(-)

YB(+)

COM

RX

TX

COM

IF-300-C5

Built-in terminator 120

GND

RI 9

Shield wire

JCS-33A

RS-232C RS-485

Shield wire

(13)

YB(+)

YA(-)

COM

(14)

(15)

(13)

YB(+)

YA(-)

COM

(14)

(15)

4. Communication procedure

Communication starts with command transmission of the host computer (hereafter Master) and ends

with the response of the JCS-33A, JCR-33A and JCD-33A (hereafter Slave).

• Response with data

When the Master sends reading command, the Slave returns

the corresponding setting value or current action status as a

response.

• Acknowledgement

When the Master sends setting command, the Slave returns the

acknowledgement as a response after the processing is

terminated.

• Negative acknowledgement

When the Master sends non-existent command or value out of

the setting range, the Slave returns the negative acknowledgement.

• No response

When global address is set or either of framing error and checksum

is detected, the Slave will not respond to the Master.

(Fig.4-1)

Communication timing of the RS-485 (Option: C5)

Slave side;

When a slave starts transmission to RS-485 communication line, the JC series is arranged so as

to provide 1 character transmission period or more of idle status (mark status) before sending the

response to ensure the synchronization on the receiving side.

The JC series is arranged so as to disconnect the transmitter from the communication line

within the period of 1 character transmission after sending the response.

Master side (Notice of making a program);

Set the program so that the host computer can provide 1 character transmission period or more

of idle status (mark status) before sending the command to ensure the synchronization on the

receiving side when the host computer starts the transmission to RS-485 communication line.

Set the program so that the host computer can disconnect the transmitter from the communication

line within the period of 1 character transmission after sending the command in preparation for

reception of the response from the JC series.

To avoid the collision of transmissions between the host computer and the JC series,

send the next command after checking that the host computer received the response.

When the host computer communicates with the JC series through the line converter

(IF-300-C5), it is not required to manage the transmission timing described above,

because the converter takes the timing interpreting the protocol automatically.

5. Shinko protocol

5.1 Command configuration

All commands are written in ASCII. The data (setting value, decimal number) is converted to

Hexadecimal. ASCII is used for the command.

Negative numbers are represented by the 2's complement.

(1) Setting command

(Fig. 5.1-1)

Command

Data

Command

Acknowledgement

Command

Negative

acknowledgement

Command

No response

Master Slave

11 14 1241

Address

Command

type (50H)

Data

item

Checksum

Delimitter

(03H)

Header

(02H)

Sub

address

(20H)

Data

Number of

characters

(2) Reading command

(Fig. 5.1-2)

(3) Response with data

(Fig. 5.1-3)

(4) Acknowledgement

(Fig. 5.1-4)

(5) Negative acknowledgement

(Fig.5.1-5)

Header : Control code that represents the beginning of the command or response.

ASCII is used.

Setting command, Reading command : (02H) fixed

Response with data, Acknowledgement : (06H) fixed

Negative acknowledgement : (15H) fixed

Address : Numbers with which a master discerns slaves.

Instrument number 0 to 94 (20H to 7EH) and Global address 95 (7FH)

The numbers are used by giving 20H of bias, because 00H to 1FH are

used for control code.

95 (7FH) is called Global address, which is used when the same command

is sent to all the slaves connected. However, the response is not returned.

Sub address : (20H) fixed

Command type : Code to discern Setting command (50H) and Reading command (20H)

Data item : Data classification for the command object

Composed of hexadecimal 4 digits (Refer to the Communication command table.)

Data : The contents of Data (setting value) differ depending on the setting command

Composed of hexadecimal 4 digits (Refer to the Communication command table.)

Checksum : 2-character data to detect communication errors

Delimiter : Control code to indicate the end of command (03H) fixed

Error code : Indicates error type Composed of hexadecimal 1 digit

1 (31H)-----Non-existent command

2 (32H)-----Not used

3 (33H)-----Out of the setting value range

4 (34H)-----Status unable to set (e.g. AT is performing)

5 (35H)-----In setting mode by key operation

5.2 Checksum calculation

Checksum is used for detecting received command or data errors.

Make a program for the host computer side as well to calculate the checksum of the response

data from the slaves so that the communication errors can be checked.

The checksum range is from the address (instrument number) up to the character before the

checksum. Adding up all the character codes in the range, obtain 2’s complement to the total value,

and then describe it in hexadecimal number.

The lower 2-digit of the total value shown by the hexadecimal number is described by ASCII, that

is checksum.

●Checksum calculation example for setting the Main setting value: 600 (0258H)

11 14 121

Address

Command

type(20H)

Data

item

Checksum

Delimitter

(03H)

Header

(02H)

Sub

address

(20H) Number of

characters

11 14 1241

Address

Command

type(20H)

Data

item

Checksum

Delimitter

(03H)

Header

(06H)

Sub

address

(20H)

Data Number of

characters

11 12

Address

Checksum

Delimitter

(03H)

Header

(06H)

Number of

characters

11 2 11

Address

Checksum

Delimiter

(03H)

Header

(15H)

Error

code Number of

characters

with the Address (instrument number): 0 (20H) is shown as follows.

• 1’s complement: Make each bit of binary 0 and 1 reverse.

• 2’s complement: Add 1 to 1’s complement.

5.3 Command contents

Notice of setting and reading command

• Possible to set the setting value by setting command of the communication function

even if

the setting value is locked

• Even if the option is not applied, it is possible to set it by the setting command, however,

the contents of the command is ineffective.

• The setting value can be extended around 1,000,000 times before the memory expires.

If the number of setting times exceeds the limit, it cannot memorize data. So frequent

transmission via communication is not recommended.

• When connecting plural JC series, instrument numbers (address) must not be duplicated.

• When sending a command by Global address [95 (7FH)], the same command is sent to all the

slaves connected. However, the response is not returned to the Master.

• The instrument number and data transfer rate of the JC series cannot be set by communication.

Setting command

• The settable range is the same as the one in the case of key operation.

Refer to the communication command table of this manual as for communication command.

•All commands are written in ASCII.

• The data (setting value) is converted from decimal to a hexadecimal number, and ASCII is used.

Negative numbers are represented by 2's complement. When the data (setting value) has

a decimal point, use the whole number as response omitting decimal point.

Reading command

• All commands are written in ASCII.

• The data (setting value) is converted from decimal to hexadecimal number, and ASCII is used.

Negative number is represented by 2's complement. When the data (setting value) has

a decimal point, it returns the whole number with the decimal point omitted.

6. Modbus protocol

6.1 Transmission mode

There are 2 transmission modes (ASCII mode and RTU mode) in Modbus protocol.

[ASCII mode]

Hexadecimal (0 to 9,A to F), which is divided to MSD (4-bit) and LSB (4-bit) out of 8-bit binary

data in command is transmitted as ASCII characters.

STX ETX

P00010258

02H 20H 20H 50H 30H 30H 30H 31H 30H 32H 35H 38H 03H

[Characters above are represented by ASCII]

Checksum

Checksum calculation range

[e.g.]

E

45H 30H

0

20H

20H

50H

30H

30H

30H

31H

30H

32H

35H

38H

0010 0000

0010 0000

0101 0000

0011 0000

0011 0000

0011 0000

0011 0001

0011 0000

0011 0010

0011 0101

0011 1000

+

10 0010 0000

[Hexadecimal] [Binary]

1101 1111

1

+

1110 0000

E0

45H 30H

[1's complement]

[2's complement]

[Hexadecimal]

[ASCII]

Checksum

Data structure Start bit : 1 bit

Data bit : 7-bit

Paritybit : Even/ None/ Odd (Selectable)

Stopbit : 1 bit/ 2-bit (Selectable)

Error detection : LRC (Longitudinal redundancy check)

Data interval : 1 second or less

[RTU mode]

8-bit binary data in command is sent as it is.

Data structure Start bit : 1 bit

Data bit : 8-bit

Parity bit : Even/ None/ Odd (Selectable)

Stop bit : 1 bit/2-bit (Selectable)

Error detection: CRC-16 (Cyclic redundancy check)

Data interval : 3.5 characters transmission time or less

6.2 Message configuration

ASCII mode message is configured to start by [: (colon)(3AH)] and end by [CR (carriage return)

(0DH) + LF (Line feed)(0AH)]. (Fig. 6.2-1)

(Fig. 6.2-1)

RTU mode is configured to start after idle time processing more than 3.5 character transmission

time and end after idle time processing more than 3.5 character transmission time (Fig. 6.2-2)

(Fig. 6.2-2)

6.3 Slave address

Slave address is set within the range 0 to 95 by the individual instrument number of slave side.

The master identifies slaves by the slave address of the requested message.

The slaves inform the master which slave is responding to the master adding their own slave

address to the response message.

(Slave address 0, broadcast address can identify all the slaves. However slaves do not respond.)

6.4 Function code

The function code is the command code what action to take. (Table 6.4-1)

(Table 6.4-1)

Function code Contents

03 (03H) Reading setting value and information of slaves

06 (06H) Setting to slaves

Function code is used as a pointer whether it is a normal response (acknowledgement) or an error

(negative acknowledgement) when the Slave returns responsive message to the Master.

When acknowledgement is returned, original function code is returned with its response.

When negative acknowledgement is returned, MSD of the original function code with 1 is returned.

(For example, when the Master sends request message setting 10H to function code by mistake,

Slave returns 90H setting 1 to the MSD, because it is illegal function.)

For negative acknowledgement, abnormal code (Table 6.4-2) below is set to the data of response

message and returned to the Maser in order to inform it that what kind of error has occurred.

(Table 6.4-2)

Abnormal code Contents

1 (01H) Illegal Function (Non-existent function)

2 (02H) Illegal data address (Non-existent data address)

3 (03H) Illegal data value (Value out of the setting range)

17 (11H) Shinko error code 4 (Unsettable status)

18 (12H) Shinko error code 5 (During setting by key operation mode, etc)

6.5 Data

Data differs depending on the function code.

A request message from master side is composed of data item, number of data and setting data.

A response message is composed of number of bytes, data and abnormal code in negative

acknowledgement from slave side. Effective range of data is -32768 to 32767 (8000H to 7FFFH).

Slave

address

Function

code Data Error check

LRC

Delimiter

(CR)

Header

(:)

Delimiter

(LF)

3.5 idle

characters

Slave

address

Function

code Data Error check

LRC

3.5 idle

characters

6.6 Error check

Error check differs depending on the type of transmission mode.

[ASCII mode]

After calculating LRC (Longitudinal redundancy check) from slave address to data section,

calculated 8-bit data is converted to ASCII 2 characters and they are added to the end of data.

How LRC is calculated,

(1) Create a message in RTU mode.

(2) Add the start data (slave address) to the end of data. --X

(3) Complement X (bit reverse). --X

(4) Add 1 (X=X+1)

(5) Add X as an LRC to the end of the message.

(6) Convert the whole data to ASCII characters.

[RTU mode]

After calculating CRC-16 (cyclic redundancy checksum) from slave address to data section,

calculated 16-bit data is added to the end of data in the order of LSB and MSD

How CRC is calculated,

In the CRC system, the information to be transmitted is divided by a generating polynomial,

the resulting remainder being added to the data. The generation polynomial is as follows.

(X16 + X 15 + X 2 + 1)

(1) Initialize the CRC-16 data (assumed as X) (FFFFH)

(2) Exclusive logical sum (EX-OR) between data 1 and X X

(3) Shift X 1 bit to the right X

(4) When a carry is generated, take A001H and EX-OR. If not, go to 5. X

(5) Repeat (3) and (4) until shifting 8 times.

(6) EX-OR between the next data and X X

(7) Same as (3) to (5).

(8) Repeat up to the last data.

(9) Create a message in the sequence from lower to upper orders of the calculated 16-bit data (X).

6.7 Message example

[ASCII mode]

(1) Reading of the instrument number (address) 1 and SV

• A request message from the master side

(Fig. 6.7-1)

• A response message from slave side in normal status (When SV=100 )

(Fig. 6.7-2)

• A response message from slave side in abnormal status (When data item is mistaken)

(Fig. 6.7-3)

1 is set to the MSD of function code for response message in abnormal status. (83H)

An abnormal code (02H: Illegal data address) is returned as a content of error.

(2) Setting (Address 1, SV=100 )

• A request message from master side

Slave

address

Function

code Data item Error check

LRC DelimiterHeader

(01H) (03H) (0001H) (0001H)

Number of

data

(FAH) (CR・LF)(:)

12 2 4 4 2 2

Number of

characters

Slave

address

Function

code

Number of

response bytes

Error check

LRC DelimiterHeader

(01H) (03H) (02H) (0064H)

Data

(96H) (CR・LF)(:)

12224 22

Number of

characters

Slave

address

Function

code

Abnormal

code

Error check

LRC DelimiterHeader

(01H) (83H) (02H) (7AH) (CR・LF)(:)

12 2 2 4 2

Number of

characters

Slave

address

Function

code Data item Error check

LRC DelimiterHeader

(01H) (06H) (0001H) (0064H)

Data

(94H) (CR・LF)(:)

12 2 4 4 2 2

Number of

characters

(Fig. 6.7-4)

• A response message from slave side in normal status

(Fig. 6.7-5)

• A response message from slave side in abnormal status

(When a value out of the setting range is set.)

(Fig. 6.7-6)

1 is set to the MSD of function code for response message in abnormal status. (86H)

An abnormal code (03H: A value out of the setting range) is returned as a content of error.

[RTU mode]

(3) Reading (Address1, SV)

• Request message from the master side

(Fig. 6.7-7)

• Response message of slave side in normal status (When SV=100 )

(Fig. 6.7-8)

• Response message of slave in abnormal status (When data item is mistaken)

(Fig. 6.7-9)

1 is set to the MSD of function code for response message in abnormal status. (83H)

An abnormal code (02H: Illegal data address ) is returned as a content of error.

(4) Setting (Address 1, SV=100 )

• Request message from master side

(Fig. 6.7-10)

• Response message of slave in normal status

(Fig. 6.7-11)

• Response message in abnormal status (When a value out of the setting range is set)

(Fig. 6.7-12)

1 is set to the MSD of function code for response message in abnormal status. (86H)

An abnormal code (03H: A value out of the setting range) is returned as an content of error.

Slave

address

Function

code Data item Error check

LRC DelimiterHeader

(01H) (06H) (0001H) (0064H)

Data

(94H) (CR・LF)(:)

12 2 4 4 2 2

Number of

characters

Slave

address

Function

code

Abnormal

code

Error check

LRC DelimiterHeader

(01H) (86H) (03H) (76H) (CR・LF)(:)

1222 42

Number of

characters

3.5 idle

characters

Slave

address

Function

code Data item Error check

CRC

3.5 idle

characters

(01H) (03H) (0001H)

Number of

data

(0001H) (D5CAH)

11 2 2 2

Number of

characters

3.5 idle

characters

Slave

address

Function

code

Number of

response bytes

Error check

CRC

3.5 idle

characters

(01H) (03H) (02H)

Data

(0064H) (B9AFH)

11 1 2 2

Number of

characters

3.5 idle

characters

Slave

address

Function

code

Abnormal

code

Error check

CRC

3.5 idle

characters

(01H) (83H) (02H) (COF1H)

1112

Number of

characters

3.5 idle

characters

Slave

address

Function

code Data item Error check

CRC

3.5 idle

characters

(01H) (06H) (0001H)

Data

(0064H) (D9E1H)

11 2 2 2

Number of

characters

3.5 idle

characters

Slave

address

Function

code Data item Error check

CRC

3.5 idle

characters

(01H) (06H) (0001H)

Data

(0064H) (D9E1H)

11 2 2 2

Number of

characters

3.5 idle

characters

Slave

address

Function

code

Abnormal

code

Error check

CRC

3.5 idle

characters

(01H) (86H) (03H) (0261H)

1112

Number of

characters

7. Communication command table

When the data (setting value) has a decimal point, remove the decimal point and represent it as a

whole number, then describe the whole number in hexadecimal number.

Shinko standard

command type

Modbus

function code Data item Data

20H/50H 06H/03H 0001H: SV1 Setting value

20H/50H 06H/03H 0002H: Not used

20H/50H 06H/03H 0003H: AT setting 0: Cancel 1: Perform

20H/50H 06H/03H 0004H: OUT1 proportional band setting Setting value

20H/50H 06H/03H 0005H: OUT2 proportional band setting Setting value

20H/50H 06H/03H 0006H: Integral time setting Setting value

20H/50H 06H/03H 0007H: Derivative time setting Setting value

20H/50H 06H/03H 0008H: OUT1 proportional cycle setting Setting value

20H/50H 06H/03H 0009H: OUT2 proportional cycle setting Setting value

20H/50H 06H/03H 000AH: Not used

20H/50H 06H/03H 000BH: A1 setting Setting value

20H/50H 06H/03H 000CH: A2 setting Setting value

20H/50H 06H/03H 000DH: Not used

20H/50H 06H/03H 000EH: Not used

20H/50H 06H/03H 000FH: HB (Heater burnout alarm setting) Setting value

20H/50H 06H/03H 0010H: LA(Loop break alarm time setting) Setting value

20H/50H 06H/03H 0011H: LA(Loop break alarm span setting) Setting value

20H/50H 06H/03H 0012H: Setting value lock selection (*1) 0: Unlock 2: Lock 2

1: Lock 1 3: Lock 3

20H/50H 06H/03H 0013H: SV high limit setting Setting value

20H/50H 06H/03H 0014H: SV low limit setting Setting value

20H/50H 06H/03H 0015H: Sensor correction value setting Setting value

20H/50H 06H/03H 0016H: Overlap/ Dead band setting Setting value

20H/50H 06H/03H 0017H: Not used

20H/50H 06H/03H 0018H: Scaling high limit setting Setting value

20H/50H 06H/03H 0019H: Scaling low limit setting Setting value

20H/50H 06H/03H 001AH: Decimal point place selection 0: XXXX (No decimal point)

1: XXX.X(1 digit after decimal

point)

2: XX.XX(2 digit after decimal

point)

3: X.XXX(3 digit after decimal

point))

20H/50H 06H/03H 001BH: PV filter time constant setting Setting value

20H/50H 06H/03H 001CH: OUT1 high limit setting Setting value

20H/50H 06H/03H 001DH: OUT1 low limit setting Setting value

20H/50H 06H/03H 001EH: OUT1 ON/OFF action hysteresis

setting

Setting value

20H/50H 06H/03H 001FH: OUT2 action mode selection

0: Air cooling

1: Oil cooling

2: Water cooling

20H/50H 06H/03H 0020H: OUT2 high limit setting Setting value

20H/50H 06H/03H 0021H: OUT2 low limit setting Setting value

20H/50H 06H/03H 0022H: OUT2 ON/OFF action hysteresis Setting value

20H/50H 06H/03H 0023H: A1 action type selection (*2)

0024H: A2 action type selection (*2)

0: No alarm action

1: High limit alarm

2: Low limit alarm

3: High/Low limits alarm

4: High/Low limit range alarm

5: Process high alarm

6: Process low alarm

7: High limit alarm w/standby

8: Low limit alarm w/standby

9: High/Low limits alarm

w/standby

20H/50H 06H/03H 0025H: A1 action hysteresis setting Setting value

20H/50H 06H/03H 0026H: A2 action hysteresis setting Setting value

20H/50H 06H/03H 0027H: Not used

20H/50H 06H/03H 0028H: Not used

20H/50H 06H/03H 0029H: A1 action delayed timer setting Setting value

20H/50H 06H/03H 002AH: A2 action delayed timer setting Setting value

20H/50H 06H/03H 002BH: Not used

20H/50H 06H/03H 0036H: Not used

20H/50H 06H/03H 0037H: OUT/OFF selection 0: OUT

1: OFF

20H/50H 06H/03H 0038H: Auto/Manual control 0: Automatic control

1: Manual control

20H/50H 06H/03H 0039H: Manual manipulated variable Setting value

20H/50H 06H/03H 003AH: Not used

20H/50H 06H/03H 003FH: Not used

20H/50H 06H/03H 0040H:

A1 action Energized/Deenergized 0: Energized 1: Deenergized

20H/50H 06H/03H 0041H:

A2 action Energized/Deenergized 0: Energized 1: Deenergized

20H/50H 06H/03H 0042H: Not used

20H/50H 06H/03H 0043H: Not used

20H/50H 06H/03H 0044H: Input type selection 0: K [-200 to 1370 ]

1: K [-199.9 to 400.0 ]

2: J [-200 to 1000 ]

3: R [0 to 1760 ]

4: S [0 to 1760 ]

5: B [0 to 1820 ]

6: E [-200 to 800 ]

7: T [-199.9 to 400.0 ]

8: N [-200 to 1300 ]

9: PL- [0 to 1390 ]

10: C (W/Re5-26) [0 to 2315 ]

11: Pt100 [-199.9 to 850.0 ]

12: JPt100 [-199.9 to 500.0 ]

13: Pt100 [-200 to 850 ]

14: JPt100 [-200 to 500 ]

15: K [-320 to 2500 ]

16: K [-199.9 to 750.0 ]

17: J [-320 to 1800 ]

18: R [0 to 3200 ]

19: S [0 to 3200 ]

20: B [0 to 3300 ]

21: E [-320 to 1500 ]

22: T [-199.9 to 750.0 ]

23: N [-320 to 2300 ]

24: PL- [0 to 2500 ]

25: C (W/Re5-26)[0 to 4200 ]

26: Pt100 [-199.9 to 999.9 ]

27: JPt100 [-199.9 to 900.0 ]

28: Pt100 [-300 to 1500 ]

29: JPt100 [-300 to 900 ]

30: 4 to 20mA DC[-1999 to 9999]

31: 0 to 20mA DC[-1999 to 9999]

32: 0 to 1V DC [-1999 to 9999]

33: 0 to 5V DC [-1999 to 9999]

34: 1 to 5V DC [-1999 to 9999]

35: 0 to10V DC [-1999 to 9999]

20H/50H 06H/03H 0045H: Direct/Reverse action selection 0: Heating (Reverse action)

1: Cooling (Direct action)

20H/50H 06H/03H 0046H: Not used

20H/50H 06H/03H 0047H: AT bias setting Setting value

20H/50H 06H/03H 0048H: ARW (anti reset windup) setting Setting value

20H/50H 06H/03H 006FH: Key LOCK selection 0: Key enabled 1: LOCK

50H 03H 0070H:

Key operation change flag clearing 0: No action 1: All clearing

20H 06H 0080H: PV (input) value reading Present PV (input) value

20H 06H 0081H: OUT1 MV reading Setting value

20H 06H 0082H: OUT2 MV reading Setting value

20H 06H 0083H: Not used

20H 06H 0084H: Not used

20H 06H 0085H: OUT status reading 0000 0000 0000 0000

215 to 2

0

20digit: OUT1

0:OFF 1:ON

21digit: OUT2

22digit: A1output

0:OFF 1:ON

23digit: A2 output

0:OFF 1:ON

24digit: Not used (Always 0)

25digit: Not used (Always 0)

26digit: HB(Heater burnout alarm output)

0:OFF 1:ON

(When sensor burnout,0: OFF)

27digit: LA(Loop break alarm output)

0:OFF 1:ON

28digit: Overscale

0:OFF 1:ON

29digit: Underscale

0:OFF 1:ON

210 digit: OUT/OFF selection

211 digit: AT/ AT reset is active

0:OFF 1:ON

212 digit: OFF key selection

0:OFF 1:MANU

213 digit: Not used (Always 0)

214 digit: Auto/Manual control

0:Auto 1:MANU

215 digit: Key operation change

0:No1:Yes

20H 06H 0086H: Not used

20H 06H 0087H: Not used

20H 06H 00A0H: Not used

20H 06H 00A1H: Instrument info reading 0000 0000 0000 0000

215 to 2

0

20digit: Not used (Always 0)

21digit: Cooling function

0:No1:Yes

22digit: A1 function

0:No1:Yes

23digit: A2 function

0:No1:Yes

24digit: Not used (Always 0)

25digit: Not used (Always 0)

26digit: Heater burnout alarm

0:No1:Yes

27digit: LA (Loop break alarm)

0:No1:Yes

28to 215 digit: Not used (Always 0)

(*1) When Lock 3 is designated, the setting data is not saved in memory.

This is why the setting value reverts to the previous value before Lock 3 when power is turned OFF.

(*2) When alarm action type is changed, the alarm setting values reverts to the one when this instrument

is shipped and alarm output status is initialized too.

* Notice

When data setting is changed by key operation at the front panel of the instrument, the data

that is related to the changed item is also changed automatically as shown the example 1 below.

However, when the data setting is changed by communication function, the related data does not

change as shown the example 2 below. (Only the changed data changes.)

(Example 1) Main setting value high limit: 1370

Main setting value : 1000

Both main setting value high limit and main setting value are changed to 800

(Example 2) Main setting value high limit: 1370

Main setting value : 1000

Main setting value high limit is 800 but main setting value keeps the same temperature (1000 )

8. Specifications

Communication : Half-duplex

Data transfer rate : 9600bps (2400, 4800, 9600, 19200bps) Selectable by key operation

Synchronous system : Start-stop synchronous

Code form : ASCII

Error correction : Command request repeat system

Error detection : Parity check, Checksum

Dataformat Startbit: 1

Databit: 7

Parity : Even

Stopbit: 1

9. Troubleshooting

If any malfunction occurs, refer to the following items after checking if the power is supplied to the host

computer and the JC series.

• Phenomenon: If it is unable to communicate,

Check the following

The connection or wiring of communication is securely done.

Burnout or imperfect contact on the communication cable and the connector.

Data transfer rate of the JC series coincides with that of the host computer.

Whether the data bit, parity and stop bit of the host computer accord with those of the JC series.

The instrument number of the JC series coincides with that of the command.

The instrument numbers are duplicated in multiple JC series.

When communicating by RS-485 (option: C5) without IF-300-C5 (communication converter),

make sure that the program is proper for the transmission timing.

• Phenomenon: Though it is able to communicate, 'NAK' is responded.

Check the following

The command code is surely existent or not.

Whether the setting command exceeds the setting range or not.

In the case of the situation being unable to set (such as AT of JC series performing)

Whether the operation mode is under the setting mode by the key operation

• If you have any inquiries, please consult our agency or the shop where you purchased the unit.

No. JC3CE2 March 2002

SHINKO TECHNOS CO.,LTD.

OVERSEAS DIVISION

:

:

:

:

Reg. Office

Mail Address

URL

E-mail

2-48, 1-Chome, Ina, Minoo, Osaka, Japan

P.O.Box 17, Minoo, Osaka, Japan

http://www.shinko-technos.co.jp

Tel :

Fax:

81-727-21-2781

81-727-24-1760

When the main setting value high limit is

changed to 800 by key operation at the

front panel of the instrument.

When the main setting value high limit is

changed to 800 by communication

function

Table of contents

Other Shinko Measuring Instrument manuals