Shinko CHC-S1245-5 Use and care manual

YQE8-J0093E

Date: March 8, 2005

Revised:

Revision: First Edition

Confirmation Signature

(Shinko Electric Co., Ltd.)

Approved Inspected Drew

(Customer: )

Shinko Electric Co., Ltd.

Digital Photo Printer

CHC-S1245-5

Maintenance Parts

Replacement Procedures

YQE8-J0093E

Revision Record

Revised Date Correction

symbol

Descriptions ECN No.

3/8/2005 -First Edition

YQE8-J0093E

Contents

1.Scope.....................................................................................................................................................1

2.Applicable Models................................................................................................................................1

3.Related Documents..............................................................................................................................1

4.Tools Required.....................................................................................................................................2

5.Replacement Procedures.....................................................................................................................3

№ PartName PartNumber

1PCB HSSV7-CONT-F ASSY 164-11-09756 ・・・・・・・・・5

2PCB HSSV7-LCDSOSA-F ASSY 164-11-09757 ・・・・・・・・・6

3PCB HSSV7-JUNCTION-F ASSY 164-11-09758 ・・・・・・・・・7

4DC Power Supply 164-11-09625 ・・・・・・・・・8

5Thermal Head Assy 164-11-09770 ・・・・・・・・・9

6DCMotorAssy(RibbonWinding) 164-11-09627 ・・・・・・・・・11

7DCMotorAssy(ThermalHeadUp/Down) 164-11-09628 ・・・・・・・・・12

8DCMotorAssy(PinchRollerUp/Down) 164-11-09629 ・・・・・・・・・13

9DCMotorAssy(PaperFeedPinchUp/Down) 164-11-09630 ・・・・・・・・・14

10 Paper Cutter Unit 164-11-09760 ・・・・・・・・・15

11 Electromagnetic Clutch 164-11-09418 ・・・・・・・・・16

12 Ribbon Brake 2 Assy 164-11-09634 ・・・・・・・・・17

13 DC Fan (Thermal Head Cooling) 164-11-09765 ・・・・・・・・・18

14 Platen Assy 164-11-09766 ・・・・・・・・・19

15 Feed Roller Assy 164-11-09767 ・・・・・・・・・21

16 Ejection Roller Assy 164-11-09768 ・・・・・・・・・23

17 Pinch Roller Assy 164-11-09769 ・・・・・・・・・24

18 Timing Belt (Feed Roller Drive) 060-91-1803-101 ・・・・・・・・・26

19 Timing Belt (Feed Roller Drive) 060-91-1782-126 ・・・・・・・・・27

20 Timing Belt (Roll Paper Drive) 060-91-1810-256 ・・・・・・・・・28

21 Feed Roller Guide Assy 164-11-09761 ・・・・・・・・・29

22 Head Sensor Assy 164-11-09415 ・・・・・・・・・31

23 Pinch Roller Sensor Assy 164-11-09762 ・・・・・・・・・32

24 PCB HSSV7-SEN2-F ASSY 164-11-09764 ・・・・・・・・・35

25 Cleaning Roller Assy (Paper Feed Side) 164-11-09771 ・・・・・・・・・36

26 Cleaning Roller Assy (Paper Ejection Side) 164-11-09772 ・・・・・・・・・37

27 Ribbon Sensor Assy 164-11-09763 ・・・・・・・・・38

28 PCB HSSV7-USBCON-F ASSY 164-11-09759 ・・・・・・・・・39

29 DC Motor Assy (Ejection Pinch Up/Down) 164-11-09823 ・・・・・・・・・40

YQE8-J0093E1

1.Scope

This document describes the parts replacement procedures that are intended to ease the

task of parts replacement.

2.Applicable Model

CHC-S1245-5 Series

3.Related Documents

- Maintenance Manual YQE8-J0092E

- Operation Manual YTE8-J0124E

YQE8-J0093E2

4.Tools Required

4.1 Parts Required

№Name Parts No. Q’ty Supplier Note

1Head Cleaning Kit 060-91-7146 1

2Isopropyl Alcohol Some Available locally

3Cloth Some Available locally

4Grease (Moricote PG-671) Some Available locally

5Wire Tire 060-64-8011 20

4.2 Tools

Name Model Q’ty

Phillips Screwdriver #0 (Micro-driver) 1

Phillips Screwdriver #1 1

Phillips Screwdriver (small) #2 (Length less than 100mm) 1

Phillips Screwdriver #2 1

Phillips Screwdriver #2 (Length more than 300mm) 1

Phillips Screwdriver #2 (ratchet type) 1

Flat-blade screwdriver (small) 2.5×100 1

Flat-blade screwdriver (small) 4.5×50 1

Nipper 1

Pliers 1

Scissors 1

Digital Voltmeter or Tester For the shape, see below. 2

Clip for Digital Voltmeter

4.3 Measuring Instrument Required

Name Note

Digital Voltmeter 0.1V unit of measurement

YQE8-J0093E3

5.Replacement Procedures

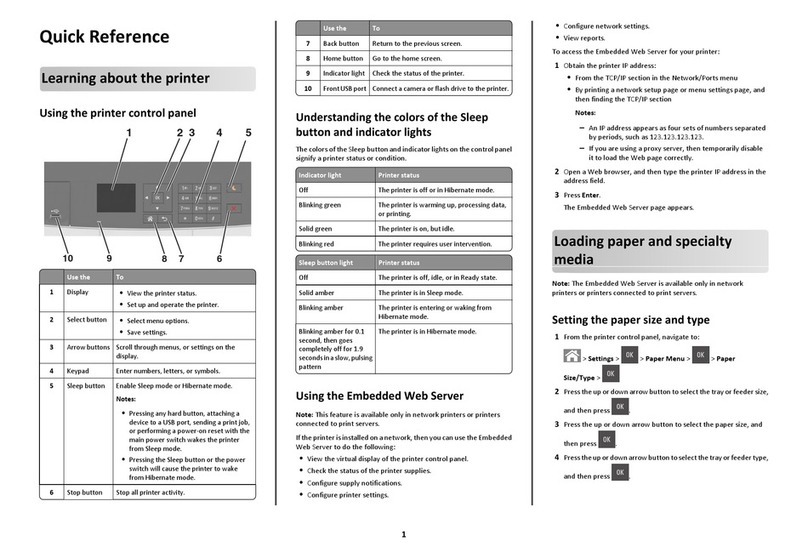

5.1 Removing Covers

To replace with the part, remove covers according to the following procedure.

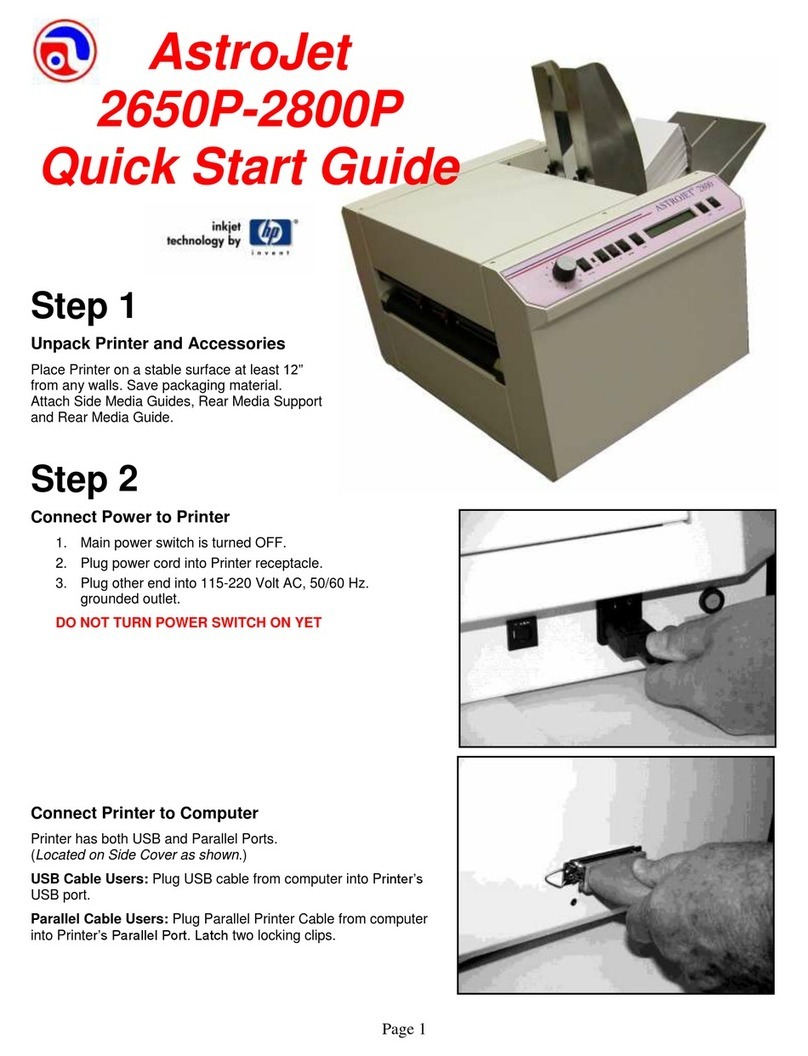

[Step 1] Remove 6 screws (M3x6) which hold Side Covers L and L2, then remove Side Covers L

and L2.

[Step 2] Remove 5 screws (M3x6) which hold Side Covers R and R2, then remove Side Covers R

and R2.

Screw

Screw

Side Cover L

Side Cover L2

Screw

Side Cover R2

Side Cover R

Caution

Be sure to turn off the power switch and remove the power plug from the outlet to

avoid any electric shock.

YQE8-J0093E4

[Step 3] Remove 4 screws (M3x6) which hold the Front Cover and 1 screw (M3x6) which holds

the ground wire, then remove the Front Cover.

[Step 4] Remove 4 screws (M3x6) (2 for right and left each), which hold the Upper Cover, then

remove the Upper Cover.

Front Cover Screw

Screw

Screw Screw

Upper Cover

Screw Ground Wire

YQE8-J0093E5

Maintenance Parts Replacement Procedures 1/1

Parts Name PCB HSSV7-CONT-F ASSY Part No. 164-11-09756

Tools Phillips Screwdriver (#2)

[Step 1] Remove Side Covers L and R and Front Cover.

[Step 2] Remove 3 connectors at the left side of PCB HSSV7-CONT-F Assy.

[Step 3] Remove 2 screws (M3x6) at the front and 1 screw on the back (M3x6), which hold the PCB

Holder.

[Step 4] Pull the PCB Holder slightly to the front, remove 8 connectors at PCB HSSV7-CONT-F

Assy, remove 4 screws, then remove PCB HSSV7-CONT-F Assy from the PCB Holder.

[Step 5] Replace the new PCB HSSV7-CONT-F Assy and assemble in reverse order.

Inspection - Verify that the connectors are properly connected.

- Perform the test print and verify that all the operations are normal.

Connector

Screw Screw

Screw

CN18 CN8 CN12

CN7, CN6, CN10, CN9, CN14, CN4, and CN13 from the left

CN3

YQE8-J0093E6

Maintenance Parts Replacement Procedures 1/1

Parts Name PCB HSSV7-LCDSOSA-F ASSY Part No. 164-11-09757

Tools Phillips Screwdriver (#2)

[Step 1] Remove Side Covers L and R and Front Cover.

[Step 2] Remove two white collars which cover buttons of PCB HSSV7-LCDSOSA-F Assy.

[Step 3] Remove the connector (CN21) at PCB HSSV7-LCDSOSA-F Assy, remove 2 screws (M3x6)

which hold the PCB, then remove PCB HSSV7-LCDSOSA-F Assy from the printer.

[Step 4] Replace the new PCB HSSV7-SOSALCD-F Assy and assemble in reverse order.

Be sure to peel the protective vinyl away from the LCD surface.

Inspection - Verify that the connectors are properly connected.

- Perform the test print and verify that all the operations are normal.

Connector (CN21)

Collar

Screw

YQE8-J0093E7

Maintenance Parts Replacement Procedures 1/1

Parts Name PCB HSSV7-JUNCTION-F ASSY Part No. 164-11-09758

Tools Phillips Screwdriver (#2)

[Step 1] Remove Left Side Cover.

[Step 2] Remove 12 connectors at PCB HSSV7-JUNCTION-F Assy.

[Step 3] Remove 2 screws (M3x6) which hole PCB HSSV7-JUNCTION-F Assy and remove PCB

HSSV7-JUNCTION-F Assy from the printer.

[Step 4] Replace the new PCB HSS-JUNCTION Assy and assemble in reverse order.

Inspection - Verify that the connectors are properly connected.

- Perform the test print and verify that all the operations are normal.

Screw

Connector CN50 (other connectors are

CN39, CN40, CN52, CN41, CN42,

CN43, CN48, CN45, CN46, CN53, and

CN49 clockwise from CN50.)

YQE8-J0093E8

Maintenance Parts Replacement Procedures 1/1

Parts Name DC Power Supply Part No. 164-11-09625

Tools Phillips Screwdriver (#2, longer than 300mm), Digital Voltmeter

[Step 1] Remove Left Side Cover and Right Side Cover.

[Step 2] Remove 3 connectors (1 connector on the right, 2 connectors on the left) at DC Power

Supply and remove 2 left screws (M4x8) and 1 right screw (M4x8) which hold the DC

Power Supply.

[Step 3] Remove the Power Supply Holder.

[Step 4] Slide the DC Power Supply and take it out to the left side of the printer.

[Step 5] Replace the new DC Power Supply and assemble in reverse order.

[Step 6] Refer to Maintenance Manual (YQE8-J0092E) to perform voltage setting (+5V,THV).

Inspection - Verify that the connectors are properly connected.

- Perform the test print and verify that all the operations are normal.

Connector

(TB3,TB2) Connector

(

TB1

)

ScrewScrew

Screw

Power Supply Holder

YQE8-J0093E9

Maintenance Parts Replacement Procedures 1/2

Parts Name Thermal Head Assy Part No. 164-11-09770

Tools Phillips Screwdriver (#2)

[Step 1] Remove 2 screws (M3x6) which hold the head gear cover, remove 2 screws (M3x6) which

hold the head open lever, and remove the head gear cover and head open lever.

[Step 2] Loosen 2 screws (1 for right and left each) (M3x6) which hold the head mount lever at both

dies of Thermal Head.

[Step 3] Remove 2 connectors at the Thermal Head Assy, and remove 1 screw (M4x8) which holds

the Thermal Head Assy.

Head Open Lever

Connector (CN22, CN23)

Screw Screw

Caution: Do not loosen wrong screws.

Head Gear Cover

Screw

Screw

Screw

YQE8-J0093E10

Maintenance Parts Replacement Procedures 2/2

Parts Name Thermal Head Assy Part No. 164-11-09770

Tools Phillips Screwdriver (#2)

[Step 4] Press the head mount lever at both sides of Thermal Head Assy to the direction indicated

by an arrow, and move the Thermal Head Assy upward. This moves the head lever and

releases the spring pressure that pushes the Thermal Head Assy downward. The spring

for thermal head will be unlocked from the head press lever.

[Step 5] Remove the Thermal Head Assy.

[Step 6] Replace it with the new Thermal Head Assy and assemble it in reverse order of

disassembly. To tighten the screw which holds the Thermal Head Assy in Step 3, push

the head lever to the direction indicated by the arrow.

[Step 7] Refer to Maintenance Specifications (YQE8-J0092E) to set the head voltage (THV) and

print density and reset the maintenance print counter.

Inspection - Verify that the connectors are properly connected.

- Perform the test print and verify that all the operations are normal.

Caution: Keep holding the Thermal Head Assy during this operation

because dropping it is likely to damage it.

Head Mount Lever Head Mount Lever

Head Lever Head Lever

YQE8-J0093E11

Maintenance Parts Replacement Procedures 1/1

Parts Name DC Motor Assy (Ribbon Winding) Part No. 164-11-09627

Tools Phillips Screwdriver (#2)

[Step 1] Remove Left Side Cover.

[Step 2] Remove connector of DC Motor Assy (Ribbon Winding).

[Step 3] Remove 2 screws (M3x6) which holds the DC Motor Assy (Ribbon Winding) and remove

the DC Motor Assy (Ribbon Winding) from the printer.

[Step 4] Replace the new DC Motor Assy (Ribbon Winding) and assemble in reverse order.

Inspection - Verify that the connectors are properly connected.

- Perform the test print and verify that all the operations are normal.

DC Motor Assy (Ribbon Winding)

Connector (CN61: Brown/Gray)

Screw

YQE8-J0093E12

Maintenance Parts Replacement Procedures 1/1

Parts Name DC Motor Assy (Thermal Head Up/Down) Part No. 164-11-09628

Tools Phillips Screwdriver (#2), Nipper

[Step 1] Remove the Upper Cover.

[Step 2] Remove 2 screws (M3x6) which hold the head gear cover and 2 screws (M3x6) which hold

the head open lever, and remove the head gear cover and head open lever.

[Step 3] Cut down 2 locks which holds the connector of DC Motor Assy (Thermal Head Up/Down)

Remove 1 connector.

[Step 4] Remove 2 screws (M3x6) which holds DC Motor Assy (Thermal Head Up/Down) and

remove the DC Motor Assy from the printer.

[Step 5] Replace the new DC Motor Assy (Thermal Head Up/Down) and assemble in reverse order.

Inspection - Verify that the connectors are properly connected.

- Perform the test print and verify that all the operations are normal.

Head Open LeverScrew ScrewHead Gear Cover

Wire Tire

Connector (CN68 Cable Color: Brown/Black))

Screw

DC Motor Ass

y

(Head U

p

/Down)

YQE8-J0093E13

Maintenance Parts Replacement Procedures 1/1

Parts Name DC Motor Assy (Pinch Roller Up/Down) Part No. 164-11-09629

Tools Phillips Screwdriver (#2),Nipper

[Step 1] Remove Left Side Cover.

[Step 2] Cut down 2 locks which holds cables, and remove the connector (CN62 cable color:

Brown/black) of DC Motor Assy (Pinch Roller Up/Down).

[Step 3] Remove 2 screws (M3x6) which holds DC Motor Assy (Pinch Roller Up/Down) and remove

the DC Motor Assy from the printer.

[Step 4] Replace the new DC Motor Assy (Pinch Roller Up/Down) and assemble in reverse order.

Inspection - Verify that the connectors are properly connected.

- Perform the test print and verify that all the operations are normal.

DC Motor Assy (Pinch Roller Up/Down)

Screw

YQE8-J0093E14

Maintenance Parts Replacement Procedures 1/1

Parts Name DC Motor Assy(Paper Feed Pinch Up/Down) Part No. 164-11-09630

Tools Phillips Screwdriver (#2)

[Step 1] Remove Right Side Covers R and R2.

[Step 2] Remove 2 screws (M3x6) which hold the AC wire guide and 2 screws (M3x6) which hold

the AC inlet, and remove the AC wire guide and AC inlet from the printer.

[Step 3] Remove 1 screw (M3x6) which holds the motor holding plate and remove the DC Motor

Assy (Paper Feed Pinch Up/Down) from the printer.

[Step 4] Remove connectors at DC Motor Assy (Paper Feed Pinch Up/Down)

[Step 5] Replace the new DC Motor Assy (Paper Feed Pinch Up/Down) and assemble in reverse

order.

Inspection - Verify that the connectors are properly connected.

- Perform the test print and verify that all the operations are normal.

A

C Inlet

Screw

A

C Wire Guide

DC Motor Assy (Paper Feed Pinch Up/Down)

Screw

Motor Holding Plate

Connector (CN69 Cable Color: Red/Black)

YQE8-J0093E15

Maintenance Parts Replacement Procedures 1/1

Parts Name Paper Cutter Unit Part No. 164-11-09760

Tools Phillips Screwdriver (#2),Nipper

[Step 1] Remove Side Covers L and R and Front Cover.

[Step 2] Remove 2 screws (M3x6) which hold the paper cutter unit and pull out the paper cutter

unit from the printer to the front.

[Step 3] Cut 1 wire tire that holds the cables.

Remove the connectors on the paper cutter unit.

(3 connectors in right, left, and center sides and 1 connector on DC Motor)

[Step 4] Replace the new paper cutter unit and assemble it in reverse order of disassembly.

[Step 5] Refer to Maintenance Specifications (YQE8-J0092E) to reset the cut counter.

Inspection - Verify that the connectors are properly connected.

- Perform the test print and verify that all the operations are normal.

Paper Cutter Unit

Screw

Connector: Right (CN92 Cable Color: Black/Gray/Black), Left (CN93

Cable Color: Brown/Gray/Brown), Center (CN91 Cable

Color: Blue/Gray/Blue)

DC Motor (CN10 Cable Color: Black/Brown)

Wire Tire

YQE8-J0093E16

Maintenance Parts Replacement Procedures 1/1

Parts Name Electromagnetic Clutch (Paper Feed) Part No. 164-11-09418

Tools Phillips Screwdriver (#2), Flat-blade Screwdriver (2.5 x 100)

[Step 1] Remove Side Covers L and L2.

[Step 2] Remove connector which is connected to Electromagnetic Clutch (Paper Feed).

[Step 3] Use the flat-blade screwdriver to widen the hook of Electromagnetic clutch (Paper Feed)

and pull off the Electromagnetic clutch from the printer.

[Step 4] Replace the new Electromagnetic Clutch and assemble in reverse order.

Assemble by putting the anti-rotation part of Electromagnetic Clutch to the guide.

Inspection - Verify that the connectors are properly connected.

- Perform the test print and verify that all the operations are normal.

Electromagnetic Clutch

Connector (CN65 Cable Color: Blue/Blue)

Hook

anti-rotation part

YQE8-J0093E17

Maintenance Parts Replacement Procedures 1/1

Parts Name Ribbon Brake 2 Assy Part No. 164-11-09634

Tools Phillips Screwdriver (#2), Nipper

[Step 1] Remove Left Side Cover.

[Step 2] Remove the connector which is connected to Ribbon Brake 2 Assy.

Cut 1 wire tire that holds the cables.

[Step 3] Remove 2 screws (M3x6) which holds Ribbon Brake 2 Assy and remove Ribbon Brake 2

Assy from the printer.

[Step 4] Replace the new Ribbon Brake Assy and assemble in reverse order.

Inspection - Verify that the connectors are properly connected.

- Perform the test print and verify that all the operations are normal.

Screw

Ribbon Brake 2 Assy

Connector (CN66 Cable Color:

Blue/Blue) Wire Tire

Table of contents

Other Shinko Printer manuals