Shore 935 User manual

OPERATION MANUAL

REVISION 1, DECEMBER 2020

Model 935

Moisture Tester

Model 935 Moisture Tester

SERIAL NUMBER

At Shore Measuring Systems, “we SERVICE what we sell”. To help us better

serve your operation and service needs, record the serial number of your tester

in the space provided below so this information is readily available when you

need to contact us.

Serial Number:

REGISTRATION CARD

When you receive your equipment, please complete and return the registration

card below. Shore Measuring Systems maintains a le of all Model 935 Moisture

Testers sold based on their serial numbers. With your help, your moisture tester

will be recognized by the buyer’s name and location.

Registration Card

Model 935 Moisture Tester

Serial Number: _____________________

Buyer’s Name: ______________________________________

Address: ________________________________________________

City: ________________________ State: ______________________

Zip Code: ______________________

Telephone Number: _________________

Date of Purchase: ___/___/___

Model 935 Moisture Tester

QUICK-START GUIDE

NOTE: These steps are a general guide to quickly begin testing when rst receiving

the tester. Some grains may require steps other than those presented, however the

touchscreen prompts will guide you through the moisture test regardless of the grain

being tested.

1. Unpack the tester and place the base of the tester on a at, level and stable

surface.

2. Place the Grain Cell in the tester so that the green dots and connectors at the

base of the cell and the tester are aligned.

3. Connect the power cable between the tester and a suitable power source,

and move the power switch to the ‘ON’ position.

NOTE: The power receptacle and the power switch are located at the back of the tester

housing.

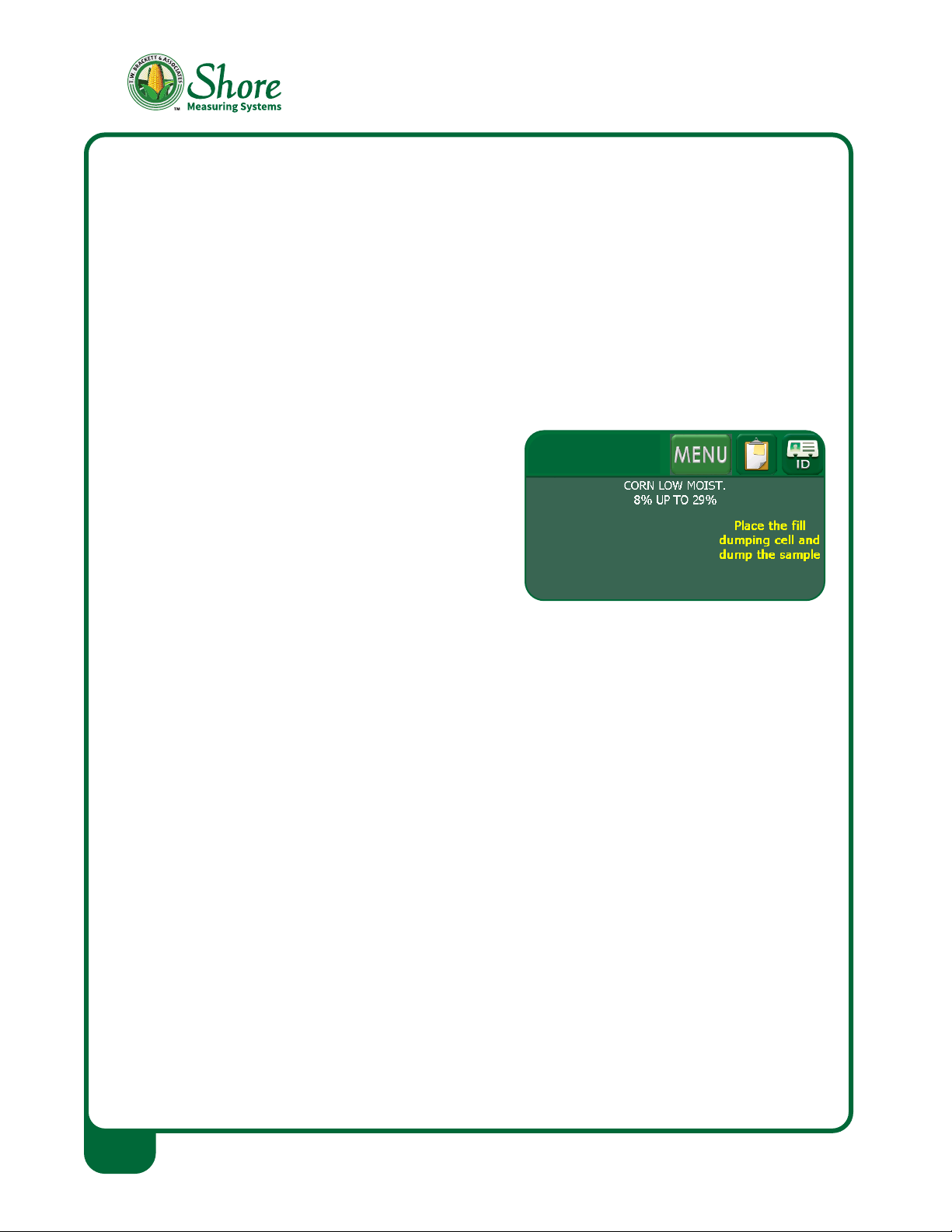

4. When prompted, place the Dump Cell

(clear plastic cylinder) in the top of the

Grain Cell so that the two cylinders form

a straight line.

NOTE: The Dump Cell should t easily into the

Grain Cell.

5. Press the green start button ( ) and

allow the self-test to begin.

6. When prompted, remove the Dump Cell.

7. Press the green continue button and

allow the self-test to continue.

8. Begin a moisture test with the displayed

chart or press MENU to select a

different chart, perform Foreign Material

or Damaged Kernel tests or modify the

tester settings:

• To begin a moisture test with the

displayed chart, proceed with Step 9.

Model 935 Moisture Tester

• To select a different chart, press

CHARTS SELECTION. Refer to Page

11.

• To perform Foreign Material or

Damaged Kernel tests, press

SPECIAL FUNCTIONS. Refer to

Page 12.

• To modify the tester settings, press

SETTINGS. Refer to Page 13.

• To return to the previous screen, press MOISTURE.

9. Ensure that the buttery valve is in the locked-closed position by turning the

Dump Cell upside down, pressing and releasing the metal button on the side

of the cell and returning the cell to the upright position.

10. Place the Dump Cell in the center of a container that is suitable for catching

grain overow.

11. Overll the Dump Cell on the side with the ‘FILL THIS SIDE’ label and use the

leveling stick to level the grain in the Dump Cell.

12. Place the Dump Cell securely in the Grain Cell, and press the metal button on

the side of the Dump Cell to deposit the sample into the Grain Cell.

13. Remove the Dump Cell from the Grain Cell when prompted.

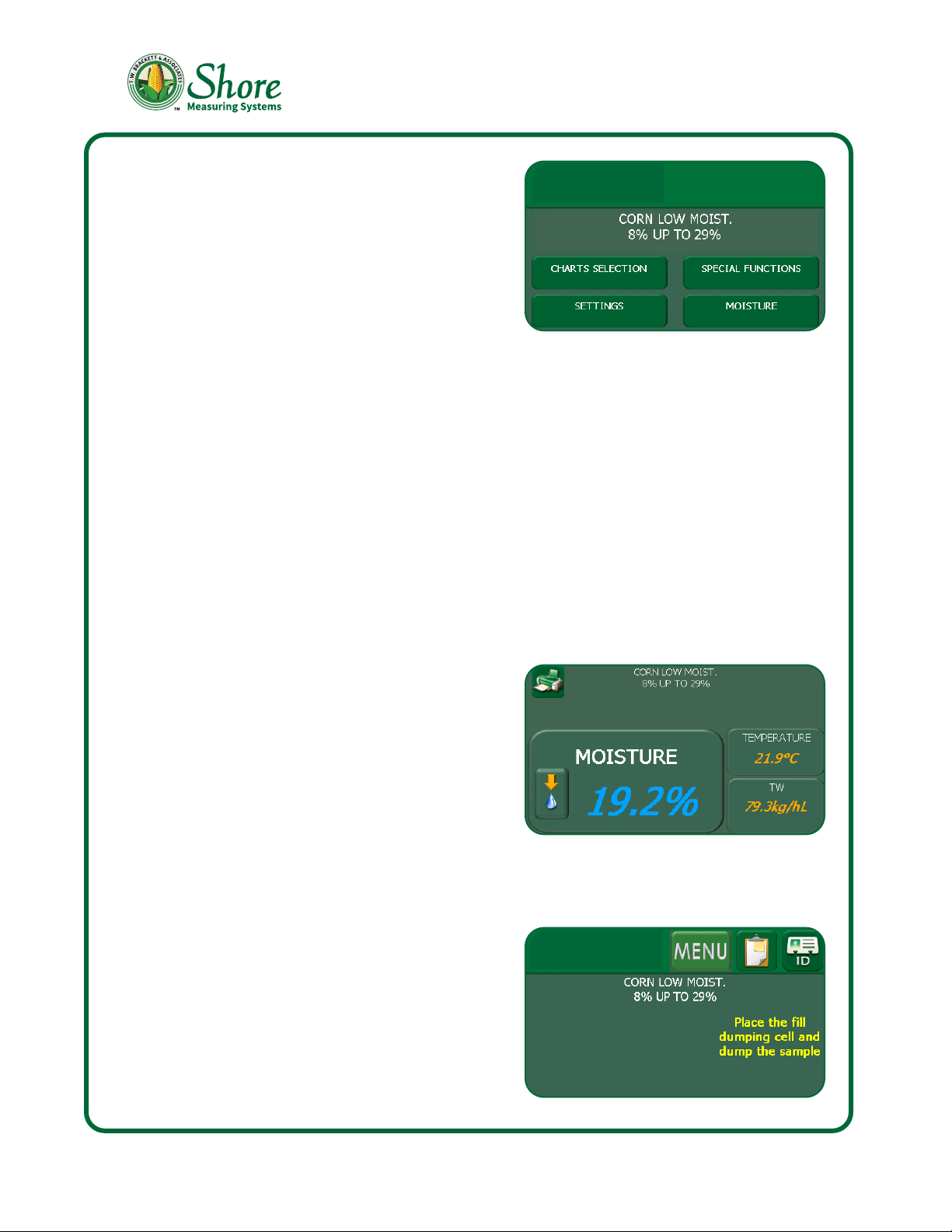

14. Allow the test to run, and wait for the

moisture, temperature, and test weight

readings to display on the screen.

Press the PRINT button to print the

results, if necessary.

15. Lift the Grain Cell out of the tester and

pour out the sample.

16. Test another sample or print prior results:

• To test another sample, place the Grain Cell back onto the tester as

described in Step 2, and repeat Steps 9 through 15.

• To print any or all of the last twenty

test results, place the Grain Cell back

onto the tester as described in Step 2

and press the HISTORY button. Refer

to “Test History” on Page 16.

(Page Intentionally Left Blank)

Model 935 Moisture Tester

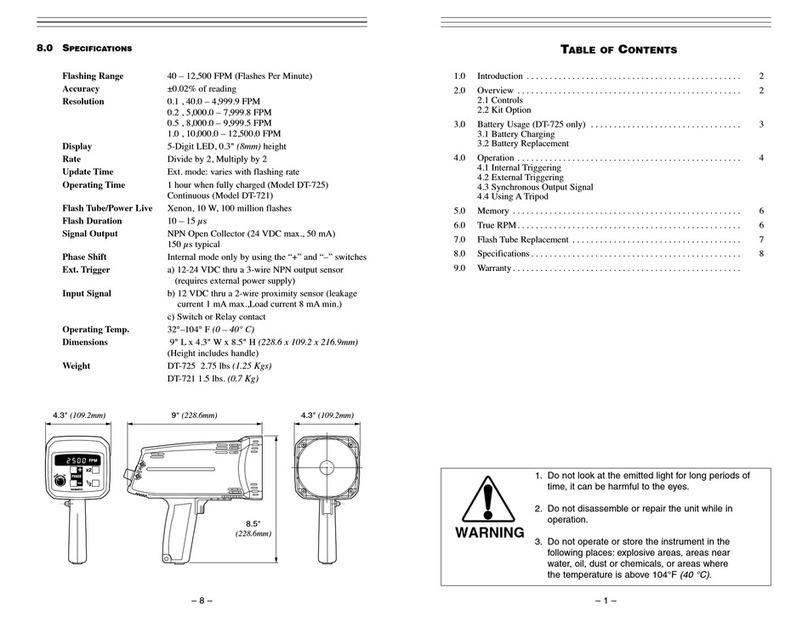

TABLE OF CONTENTS

GENERAL INFORMATION

Product Overview....................................................................................1

Product Features ....................................................................................1

Commodities ...........................................................................................2

Main Components...................................................................................4

Dump Cell ....................................................................................................4

Scale ............................................................................................................4

Grain Cell .....................................................................................................4

Tester Housing .............................................................................................4

Touchscreen Display....................................................................................4

Power...........................................................................................................4

Touchscreen Legend...............................................................................5

Testing Guidelines...................................................................................6

Notes............................................................................................................6

Unpacking ...............................................................................................7

OPERATION

Startup ....................................................................................................9

Main Menu ............................................................................................10

Charts Selection....................................................................................11

Special Functions..................................................................................12

Settings .................................................................................................13

Time ...........................................................................................................13

Averaging...................................................................................................13

Test Weight UOM.......................................................................................13

Language ...................................................................................................14

Temperature Scale.....................................................................................14

Charts Installation ......................................................................................14

Test Weight Measurement ....................................................................15

Error Message ......................................................................................15

Test History ...........................................................................................16

Tester ID................................................................................................16

Resetting Procedures ...........................................................................17

Model 935 Moisture Tester

CARE AND MAINTENANCE

Care ......................................................................................................19

Maintenance .........................................................................................19

Software Update ...................................................................................19

Serial Communication...........................................................................20

WARRANTY AND TERMS OF USE

Warranty................................................................................................21

Terms of Use.........................................................................................21

Warranty Use .............................................................................................22

1

Model 935 Moisture Tester

GENERAL INFORMATION

Product Overview

The Model 935 Moisture Tester is a bench-top instrument used to determine the

moisture content that is retained in grains and other agricultural products.

• Moisture in the grain sample is determined by evaluating changes in the

dielectric properties of the sample caused by the presence of moisture. Using

calibration charts, these changes are automatically interpreted as a percentage

of moisture.

• A touchscreen panel provides simple navigational and process icons. Results

are quick and accurate, tests are simple to perform and can be customized to

t the product sampled and the user’s needs.

Product Features

• The measurement principle is based on the dielectric properties of the grain.

• The range of moisture and temperature for each selected chart is displayed.

• An advanced system of weight and temperature readout is used, eliminating

the need for an external thermometer and scale.

• A preset mass is not required.

• Weight and temperature measurements are automatic and are performed prior

to the display of the moisture percentage.

• For grains of the same type, multiple tests can be performed without changing

settings.

• Operation is easy and results are displayed clearly on a touchscreen display.

• The last twenty results are saved and all results can be printed.

• Universal voltage capability is provided (100 to 240 VAC).

• Calibration charts are available for a wide range of grain types.

• Meets requirements set forth by Handbook 44 (HB44) of the National Institute

of Standards and Technology (NIST).

• Single measurements can be taken, or an average of three readings can be

calculated for greater precision.

2

Model 935 Moisture Tester

Commodities

The Model 935 Moisture Tester is designed to perform moisture tests for the

following commodities:

Alfalfa, Meal

Barley, Rolled 2% up to 20.1%

Barley, Six-Rowed

Barley, Two-Rowed

Beans, Baby Lima

Beans, Black

Beans, Black Eye

Beans, Canary

Beans, Cranb & Thor Lima

Beans, Cranberry High Moisture

Beans, Dark Red Kidney

Beans, Garbanzo

Beans, Great Northern

Beans, Kidney High Moisture

Beans, Large Lima

Beans, Lentils

Beans, Light Red Kidney

Beans, Mung

Beans, Pea (Navy)

Beans, Pink

Beans, Pinto

Beans, Red Ball

Beans, Small Red

Beans, Small White

Beans, Yellow Eye

Buckwheat

Cabbage Col Seed, Chart CC-5

Canola

Canola Meal

Canola Meal, Over 20%

Coffee, Green Beans

Coffee, Parchment

Corn, Broken with Foreign Material

Corn, Cob Ground

Corn, Gluten

Corn, Goya Big

Corn, High Moisture

Corn, Low Moisture

Corn, Meal

Corn, Rolled Flake

Crambe, Seed

Cranberry, High Moisture

Cucumber Seeds, Pointset-Ashley

Cucumber, Beta Alfa CBA-1

Cucumber, C-F1-74

Distillers Dried, Grain

Dried Brewers, Grain

Fescue, Chart KY31

Flaxseed

Flaxseed, Western

Lespedza Seeds, Chart LS-1

Mash & Pellets, M-P Tentative

Millet

Mustard, Brown

Mustard, Oriental

Mustard, Yellow

Oats

Oats, Low Density

Peanut, Meal

Peanuts, Runner

Peanuts, Runner High Moisture

Peanuts, Spanish

Peanuts, Spanish High Moisture

Peanuts, Virginia

3

Model 935 Moisture Tester

Peas, Austrian Winter

Peas, Wrinkled Dry

Pellets Dairy, Poultry Stock

Pellets, Milk Flo Mash

Pellets, Milk Flo Whole

Pellets, Paper Kitty Litter

Pepper, Seed

Pepper, Seed Green Jalapeno-

Cayenne

Pine Nuts

Popcorn, White

Popcorn, Yellow

Pumpkin Seed, Hulled Seeds

Radish Seeds, Chart RS-1

Red Altaswede, Clover 201262

Rice, Brown Long Grain

Rice, Brown Long Grain Parboiled

Rice, Brown Medium Grain

Rice, Brown Short Grain

Rice, Milled 2nd Head Parboiled

Rice, Milled Brewers & Screens

Rice, Milled Brewers Parboiled

Rice, Milled CAL2 CAL Second Head

Rice, Milled Long Grain

Rice, Milled Long Grain Parboiled

Rice, Milled Medium Grain

Rice, Milled Medium Grain Coated

Rice, Milled Medium Grain Parboiled

Rice, Milled Short Grain

Rice, Rough Calrose High Moisture

Rice, Rough Long Grain

Rice, Rough Long Grain Parboiled

Rice, Rough Long High Moisture

Rice, Rough Medium Grain

Rice, Rough Medium High Moisture

Rice, Rough Medium Low Moisture

Rice, Rough Short High Moisture

Rice, Rough Short Low Moisture

Rye

Sesame Seeds, SS-1

Sorghum, High Moisture

Sorghum, Low Test Weight

Sorghum, Milo

Soybean, Meal

Soybeans

Soybeans, Ground Hull Mill Feed

Soybeans, Immature

Soybeans, Over 20%

Squash, SQ-1-73

Sunower Seed

Sunower Seed, 7% Up To 25%

Sunower Seed, Confectionery

Sunower Seed, High Moisture

Sunower Seed, Hulled

Sunower Seed, Low Moisture

Timothy Seed, TM-1 Tentative

Tomato, Filon TF-1-73

Triticale

Wheat, Durum

Wheat, Hard Red Spring

Wheat, Hard Red Winter

Wheat, Hard White

Wheat, Middlings W MD 01

Wheat, Soft Red Winter

Wheat, Soft Red Winter High Moisture

Wheat, Soft White

Wheat, Soft White High Moisture

4

Model 935 Moisture Tester

Main Components

Dump Cell

The grain sample is placed in the Dump Cell. The Dump Cell is a clear, plastic

cylinder that is equipped with a manually-operated buttery valve. This design

ensures that the sample is always uniformly deposited into the Grain Cell.

Scale

The correct amount of grain that is required for each grain type is measured

by the scale when the grain sample is placed in the Dump Cell. This advanced

weighing system is used to obtain the most accurate moisture measurements.

NOTE: The built-in scale is active at all times.

Grain Cell

Moisture content is measured in the Grain Cell. The Grain Cell is a metal cylinder

that is equipped with a temperature sensor. When the grain is deposited into the

Grain Cell, the temperature sensor is automatically activated.

To provide maximum precision, the Grain Cell is designed to evenly disperse the

sample. The patented cell-post system compensates for differences in volume,

weight and those caused by uneven grain release.

Tester Housing

The tester housing is designed to withstand the rigors of eld use. The electronic

circuits are isolated from the interior of the cabinet.

The power switch, communication ports, power receptacle and printer output are

located at the rear of the housing.

Touchscreen Display

The LCD touchscreen display is located at the front of the housing and has a

screen resolution of 480x272 pixels. All user functions and measurement results

are available on the touchscreen display.

Power

Power Specications:

• 100 to 240 VAC

• 50/60 Hz, 1.5 A

5

Model 935 Moisture Tester

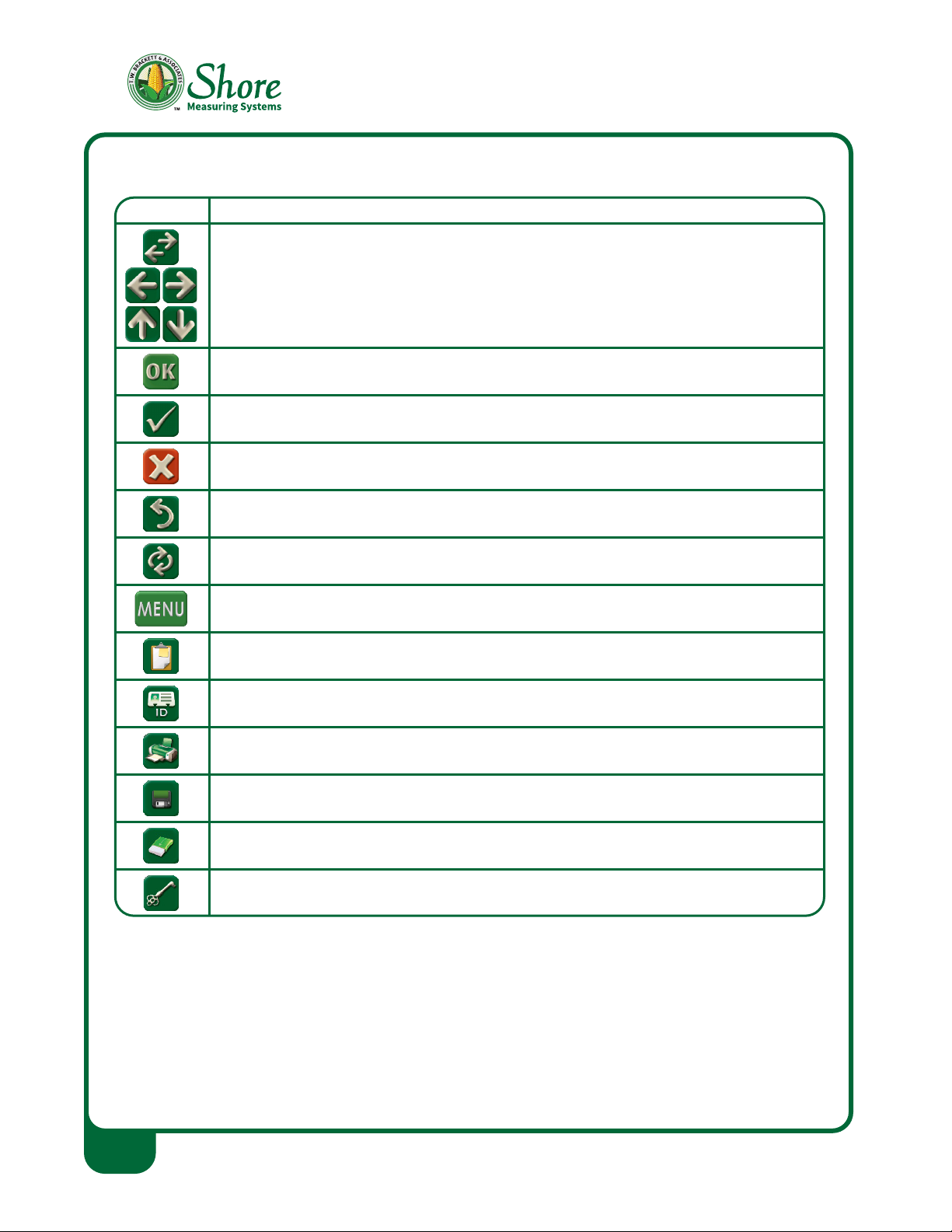

Touchscreen Legend

Icon Description

Scroll

Conrm selection / entry

Start / Select

Cancel / Deselect

Return to previous screen

Continue

Access the Main Menu

Access the History screen

Access the Identication (ID) screen

Print

Save

Save to USB drive

Restricted access

6

Model 935 Moisture Tester

Testing Guidelines

The Model 935 Moisture Tester was designed to provide moisture readings

quickly and accurately for various types of grain. For the tester to perform as

designed, familiarize yourself with the following general guidelines:

• The sample should be as clean as possible (free of foreign material).

• The grain should be removed from various sections of a batch and mixed prior

to performing a moisture test. This is necessary because the moisture retained

in a large amount of grain can vary considerably.

For even more accurate results, Shore recommends the use of a grain divider

to mix the collected sub-samples. If you do not have this equipment, a similar

process should be used to ensure that a correct sample is available and an

accurate percentage is calculated.

• A large amount of grain should be used for the measurement of the sample.

This is necessary to obtain an accurate average with a minimum of variations.

This tester has a 3.5 in (8.9 cm) cell with a capacity of 10.5 oz (300 g), depending

on the density, and the sample size is determined automatically without the

need for an external scale.

• The temperature standards set forth by the NIST should be adhered to. These

standards were set to ensure consistency across moisture measurements.

• Ambient temperature: 50 °F to 86 °F (10 °C to 30 °C).

• Ideal temperature of the grain sample: 40 °F to 104 °F (4.4 °C to 40 °C).

NOTE: This tester can accept samples with a temperature up to 160 °F (71.1 °C).

• The difference in temperature between the grain sample and the tester should

not exceed 18 °F (10 °C) when performing a moisture test.

Notes

• Averaging:

• If averaging is set to ‘YES’, the test result will display only after the third

reading.

• If averaging is set to ‘OVER 20%’, the test result will display only after the

third reading if the moisture content of the initial sample is greater than 20%.

• If the tester detects a discrepancy between the ranges of temperature and

moisture of the selected product and of the product being analyzed, test results

will not be displayed.

• If the tester indicates that the sample volume exceeds 100% capacity, remove

grain manually until that level reaches 100%.

7

Model 935 Moisture Tester

• If you need to change any tester setting, press the MENU button and access

the applicable screen.

• If you need to save a measurement remotely, insert a USB ash drive into the

back of the tester housing prior to starting a moisture test. The results will be

saved in a text-document format, which will include the date and the time of

the test.

Unpacking

When unpacking your tester, conrm that the following components were provided:

• Model 935 Moisture Tester

• Power cord

• Dump cell

• Grain cell

• Leveling stick

• Operation manual

The Model 935 Moisture Tester was carefully inspected to be free of defects.

Inspect all components for damage that may have occurred during shipment.

If any components are damaged or were not provided, place the tester and its

components in the original box and contact Shore Measuring Systems:

Shore Measuring Systems

103 North Perry St.

Attica, IN 47918

Phone: (765) 769-3000

Toll-Free: (800) 837-0863

Email: [email protected]

www.moisturetesters.com

(Page Intentionally Left Blank)

9

Model 935 Moisture Tester

OPERATION

Startup

When the tester is turned on, the self-test/calibration will start automatically for

the next moisture test. This self-test requires minimal manual intervention, and

the tester will then be ready to perform a moisture test with the last selected chart

without further adjustment of settings.

• To complete the self-test, follow the touchscreen prompts.

• To initiate a self-test at any time, use the power switch to the turn the tester off

and back on.

• To perform a moisture test with the

last selected chart (which is displayed

on the touchscreen when the self-test

is complete), follow the touchscreen

prompts.

• To select a different chart, perform a

Foreign Material or Damaged Kernel test

or change the moisture settings, press the

MENU button. Refer to “Main Menu” on

Page 10.

• To review or print any or all of the last twenty tests, press the HISTORY button.

Refer to “Test History” on Page 16.

• To specify the License Plate and/or the Batch/Lot on the printout for the next

moisture test(s), press the IDENTIFICATION button. Refer to “Tester ID” on

Page 16.

10

Model 935 Moisture Tester

Main Menu

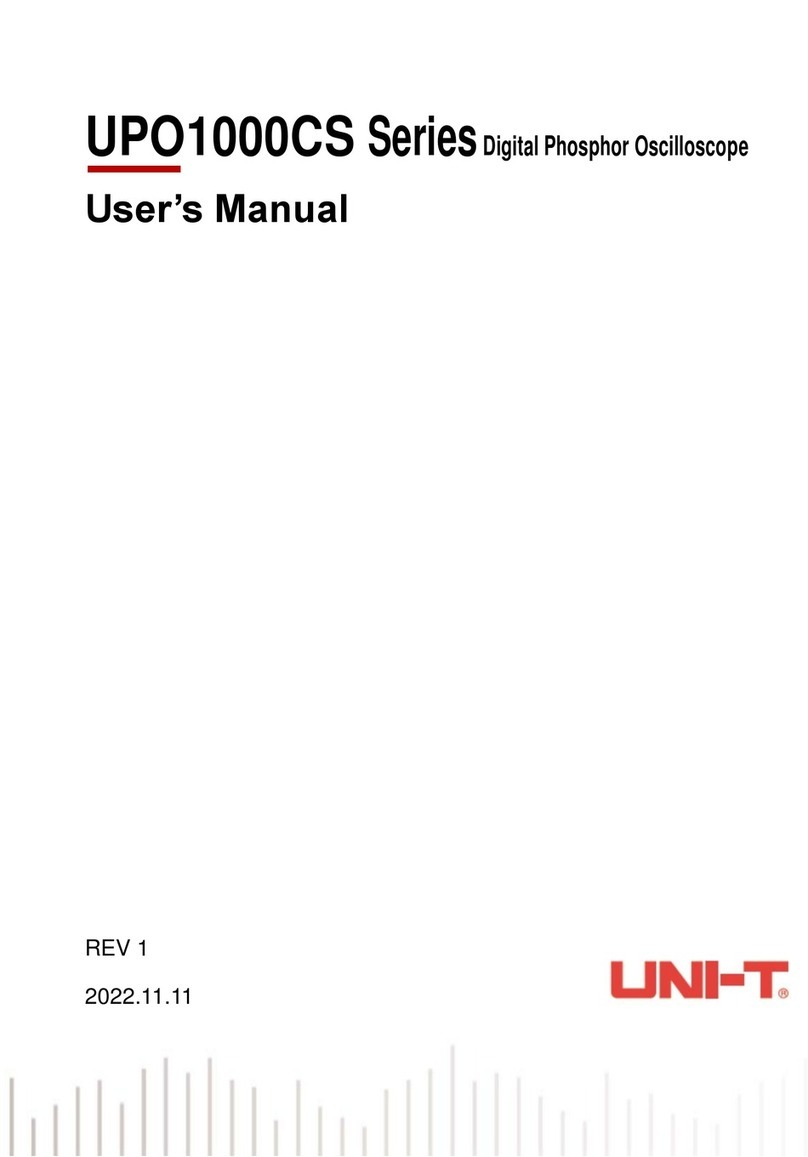

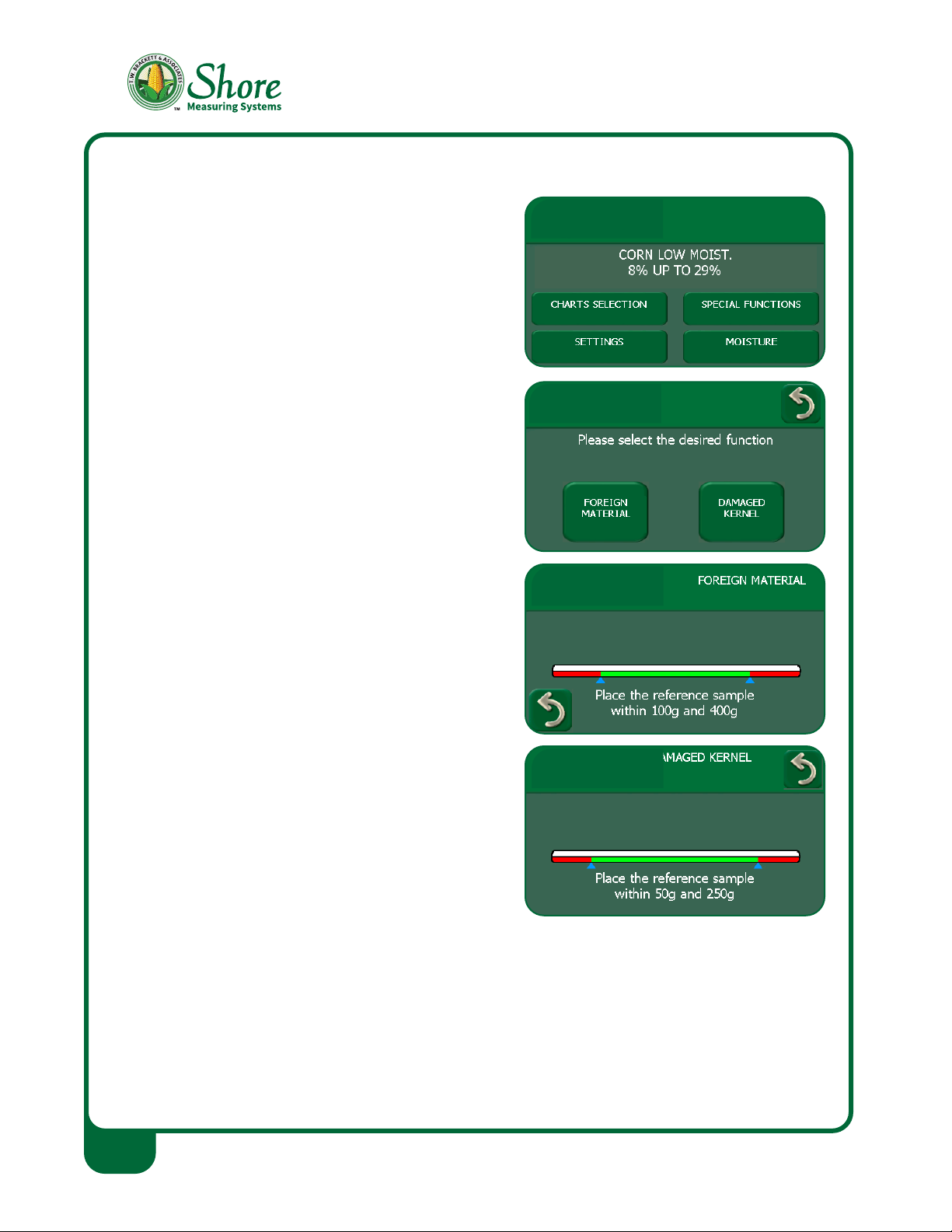

The main menu is accessible after the

self-test has completed, charts have been

selected, settings have been changed or a

moisture test or special test is performed.

Press MENU to access the main menu.

The main menu displays the grain type

(chart) selected for analysis and provides

access to main functions:

• Press CHARTS SELECTION to select the

applicable chart for the grain to be tested.

Refer to Page 11.

• Press SPECIAL FUNCTIONS to perform

Foreign Material or Damaged Kernel

tests. Refer to Page 12.

• Press SETTINGS to adjust tester settings such as time, language, units of

measurement (UOM) and averaging, and to install charts other than those pre-

installed by Shore. Refer to Page 13.

• Press MOISTURE to return to the previous screen and/or initiate the moisture

test.

11

Model 935 Moisture Tester

Charts Selection

The charts selection screen is accessible

from the main menu. Press CHARTS

SELECTION to access the charts selection

screen.

This screen allows selection of the installed

chart that is applicable to the grain to be

tested.

To select the applicable chart:

1. Press the button that is applicable to the

grain to be tested.

2. Use the scroll buttons at the bottom

of the screen to display the applicable

chart.

3. Press OK.

12

Model 935 Moisture Tester

Special Functions

The special functions screen is accessible

from the main menu. Press SPECIAL

FUNCTIONS to access the special functions

screen.

This screen allows Foreign Material and

Damaged Kernel tests to be performed.

To perform a Foreign Material or Damaged

Kernel test, press the appropriate button

and follow the touchscreen prompts.

13

Model 935 Moisture Tester

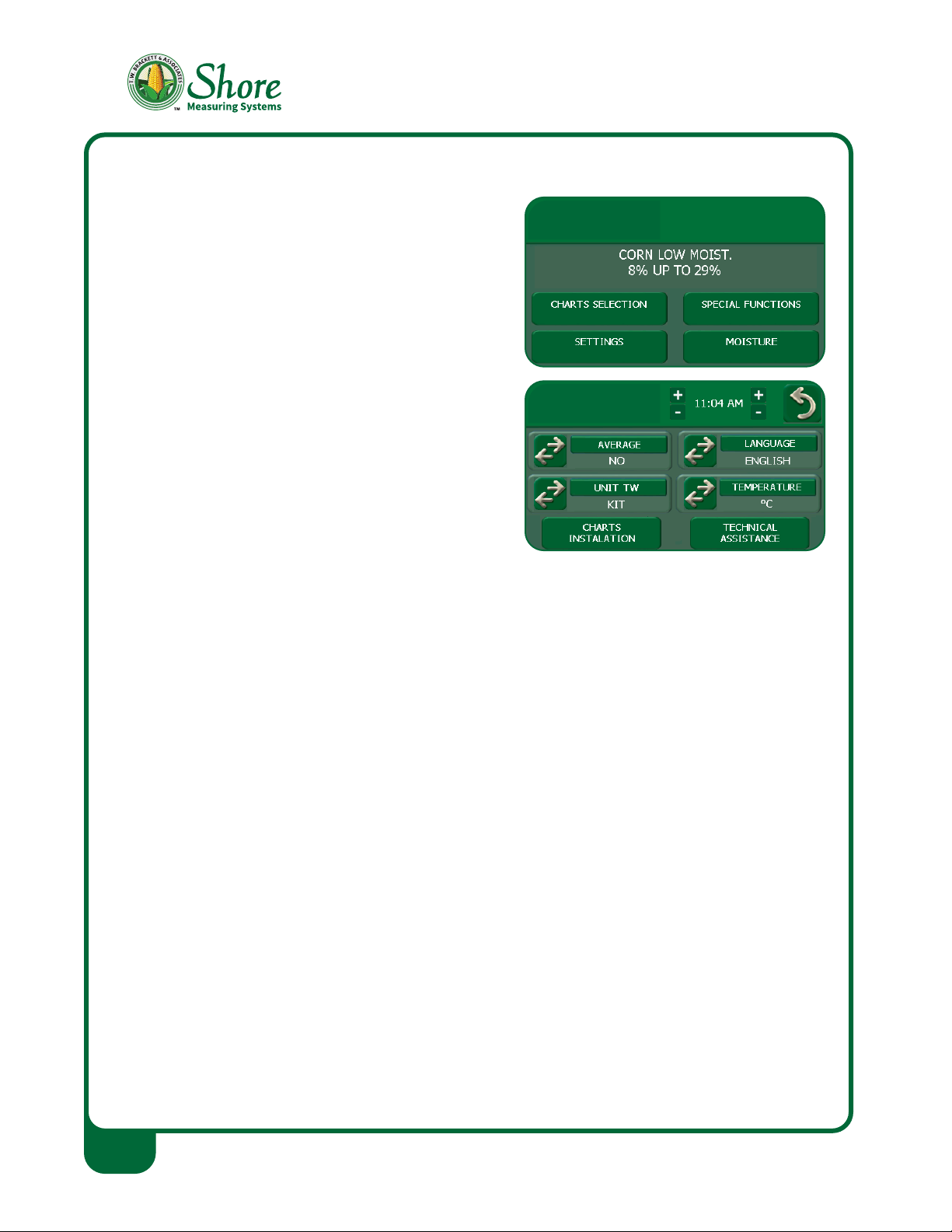

Settings

The settings screen is accessible from the

main menu. Press SETTINGS to access the

settings screen.

This screen allows adjustment of the time,

tester language, UOM and averaging, and

installation of charts other than those pre-

installed by Shore.

NOTE: The Technical Assistance screen is used

by Shore to set up the tester prior to use.

Time

• To adjust the hour, use the plus and minus buttons to the left of the time display.

• To adjust the minute, use the plus and minus buttons to the right of the time

display.

• Press the return button to save the time setting.

Averaging

Use the scroll button to the left of the AVERAGE display to select the desired type

of averaging, and then press the return button to save the setting:

• NO: Results are based on a single test of the sample.

• YES: Results are based on an average of three tests of the sample.

• OVER 20%: Test results that are over 20% moisture will be based on an

average of three tests.

Test Weight UOM

Use the scroll button to the left of the UNIT TW display to select the desired test

weight UOM/setting, and then press the return button to save the setting:

• lb/bu: Pound per bushel

• lb/A bu: Pound per bushel ‘Avery’

• lb/W bu: Pound per bushel ‘Winchester’

• KIT: Measurement of the test weight will occur after the moisture test. Refer to

“Test Weight Measurement” on Page 15 to perform this test.

Table of contents