Page1of26

©Copyright 2018 WESCO Industrial Products, LLC. Specifications subject to change. Not responsible for errors or omissions.

TABLE OF CONTENTS

1 General Information ........................................................................................................................... 2

1.1 Description.............................................................................................................................. 2

1.2 Specifications.......................................................................................................................... 2

2 Safety Information................................................................................................................................ 2

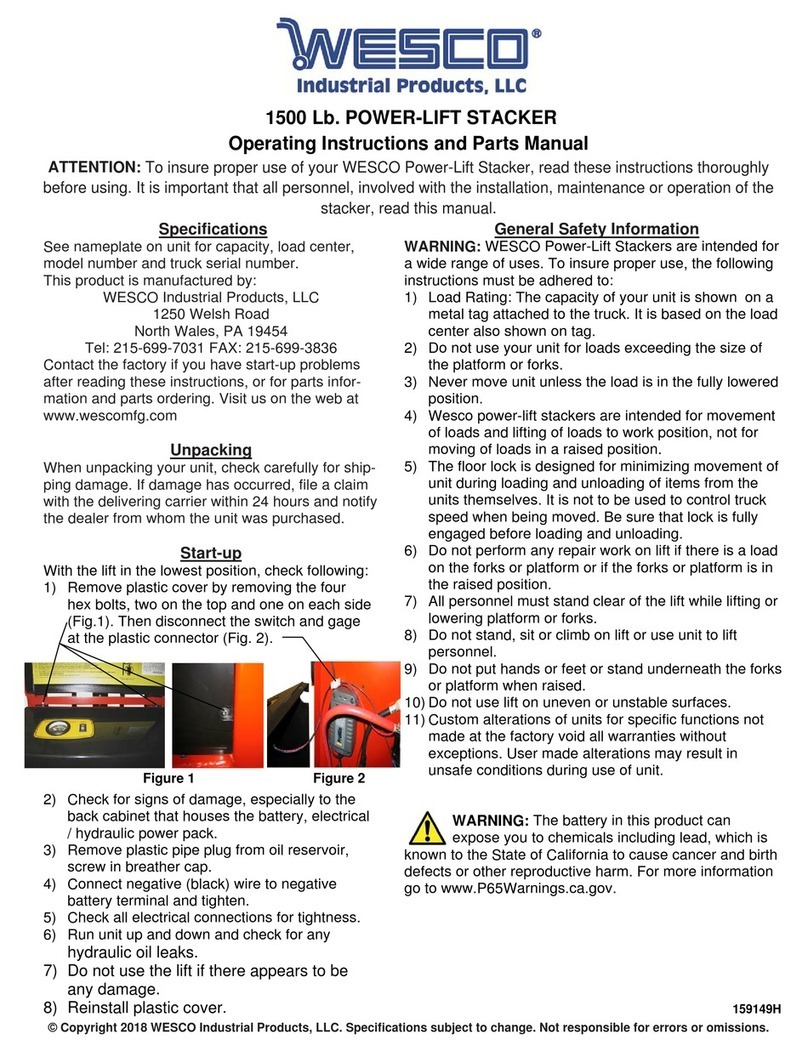

3 Assembly.....……….............................................................................................................................. 2

4 Hydraulic Valve Adjustment................................................................................................................. 2

5 Operation..............................................................................................................................................4

6 Battery Charging & Replacement.........................................................................................................5

7 Maintenance.........................................................................................................................................7

8 Trouble Shooting.................................................................................................................................. 8

9 Hydraulic & Circuit Diagrams............................................................................................................... 9

9.1 Hydraulic Flow Diagram (Models Manufactured Before 2010)................................................ 9

9.2 Circuit Diagram (Models Manufactured Before 2010)..............................................................9

9.3 Hydraulic Flow Diagram (Models Manufactured Between 2010 & 2015).................................10

9.4 Circuit Diagram (Models Manufactured Between 2010 & 2015).............................................. 10

9.5 Hydraulic Flow Diagram (Models Manufactured After 2015)................................................... 11

9.5 Circuit Diagram (Models Manufactured After 2015).................................................................11

10 Part Information (Models Manufactured Before 2010)......................................................................... 12

10.1 Handle Part Diagram................................................................................................................12

10.2 Handle Part List........................................................................................................................12

10.3 Frame Part Diagram.................................................................................................................13

10.4 Frame Part List.........................................................................................................................13

10.5 Pump Part Diagram..................................................................................................................14

10.6 Pump Part List..........................................................................................................................14

10.7 Steer Wheel Assembly Part Diagram.......................................................................................15

10.8 Steer Wheel Assembly Part List...............................................................................................16

10 Part Information (Models Manufactured Between 2010 & 2015)......................................................... 17

10.1 Frame & Handle Part Diagram.................................................................................................17

10.2 Frame & Handle Part List.........................................................................................................18

10.3 Pump Part Diagram..................................................................................................................19

10.4 Pump Part List..........................................................................................................................20

11 Part Information (Models Manufactured After 2015)............................................................................ 21

11.1 Handle Part Diagram................................................................................................................21

11.2 Handle Part List........................................................................................................................21

11.3 Frame Part Diagram.................................................................................................................22

11.4 Frame Part List.........................................................................................................................22

11.5 Pump Part Diagram..................................................................................................................23

11.6 Pump Part List..........................................................................................................................24

11.7 External Charger Part Diagram................................................................................................25

11.8 External Charger Part List........................................................................................................26

WESCOINDUSTRIALPRODUCTS,LLC

InstructionManual

ElectricNon‐TelescopingHighLiftTruck

PartNumber: 272460&272461

Note: Operator MUST read and understand these operating instructions before using

this High Lift Truck.