MV-A00000920 MOHAWK V-A SERIES: VERTICAL RISE DRIVE-ON MANUAL 35,000 - 64,000 LB MODEL

INDEX....................ENGLISH

IMPORTANT SAFETY INSTRUCTIONS............................................1-1

1. GENERAL INFORMATION...........................................1-1

1.1. MARKING DATA.............................................................................1-1

1.2. ASSISTANCE..................................................................................1-1

1.3. INTELLECTUAL AND INDUSTRIAL PROPERTY..........................1-1

1.4. DESCRIPTION OF PERSONNEL ..................................................1-1

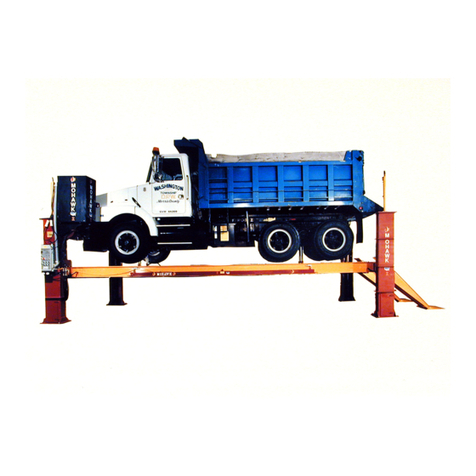

2. DESCRIPTION OF THE MACHINE................................2-1

2.1. EXPECTED USE.............................................................................2-1

2.2. TECHNICAL DATA .........................................................................2-1

2.3. NOMENCLATURE ..........................................................................2-1

2.4. OVERALL DIMENSIONS................................................................2-3

2.5. LOADING CONDITIONS.................................................................2-4

2.6. JACKING BEAM..............................................................................2-5

3. SAFETY.......................................................................3-1

3.1. GENERAL SAFETY REGULATIONS.............................................3-1

3.2. PRECAUTION.................................................................................3-2

3.3. OWNER/EMPLOYER RESPONSIBILITIES ...................................3-3

3.4. IMPROPER USE.............................................................................3-4

3.5. SAFETY DEVICE FEATURES........................................................3-5

3.6. RESIDUAL RISKS...........................................................................3-6

3.7. STICKERS AND PLATES...............................................................3-7

4. INSTALLATION.............................................................4-1

4.1. TRANSPORT AND HANDLING......................................................4-1

4.2. INSTALLATION...............................................................................4-3

4.2.1. Installation sequence...................................................4-3

4.3. PLACE OF INSTALLATION............................................................4-4

4.4. CONNECTING THE LIFT................................................................4-5

4.5. CONNECTING THE LIFT’S COMMANDS......................................4-5

4.5.1. Hydraulic connections..................................................4-5

4.5.2. Pneumatic connection................................................. 4-7

4.5.3. Electric connection...................................................... 4-8

4.6. FILLING OF THE CIRCUIT MASTER-SLAVE..............................4-11

4.7. LIFT POSITION.............................................................................4-12

4.8. EXTENSIONS INSTALLATION (IF PRESENT)............................4-13

4.9. CHECK..........................................................................................4-14

4.10. ANCHORAGE CAPSULE INSTALLATION...................................4-15

4.11. CHECKS BEFORE USE...............................................................4-16

4.12. FINAL TESTING............................................................................4-17

4.13. LIFT OPERATIONAL TEST..........................................................4-17

4.13.1. Lift Operation..............................................................4-17

4.13.2. Caution.......................................................................4-17

4.13.3. To Load a Typical Vehicle..........................................4-17

4.13.4. To Raise the Lift.........................................................4-17

4.13.5. To Lower the Lift.........................................................4-17

5. USE............................................................................... 5-1

5.1. OPERATION COMMANDS.............................................................5-1

6. MAINTENANCE ........................................................... 6-1

6.1. ORDINARY/EXTRAORDINARY MAINTENANCE..........................6-1

6.2. TABLE ADJUSTMENT PROCEDURES .........................................6-3

6.2.1. Maximum pressure valve calibration............................ 6-3

6.2.2. Photocell ..................................................................... 6-4

6.2.3. Parachute valve........................................................... 6-5

6.2.4. Platforms levelling....................................................... 6-6

6.2.5. Unblocking safety locks............................................... 6-7

6.2.6. Air bleeding from the volumetric circuit........................ 6-7

6.3. EMERGENCY MANUAL LOWERING ............................................6-8

6.4. ABNORMAL OPERATION..............................................................6-9

6.5. . LIFT LOCKOUT/TAGOUT PROCEDURE ..................................6-10

7. ACCESSORIES.......................................................................... 7-1