Shott WP7000 User manual

Nome file:

File name:

7528002EN - ISTRUZIONI WP7.8000 - EN.docx Rev. 1 24/05/2016

1-18

WP

7

000

WP

8

000

C

USTOMER MANUAL

(EN) I

NSTALLATION MANUAL

(EN)

Nome file:

File name:

7528002EN - ISTRUZIONI WP7.8000 - EN.docx Rev. 1 24/05/2016

2-18

I N D E X

Nome file:

File name:

7528002EN - ISTRUZIONI WP7.8000 - EN.docx Rev. 1 24/05/2016

3-18

1

Content organisation and consultation methods.................................................................................... 4

1.1

Symbols. ........................................................................................................................................ 4

1.2

Notes on graphics. ......................................................................................................................... 4

1.3

Glossary......................................................................................................................................... 4

2

General warnings and user information................................................................................................. 4

2.1

Warranty......................................................................................................................................... 4

General aspects...................................................................................................................... 4

Special conditions................................................................................................................... 5

Restrictions............................................................................................................................. 5

2.2

Returns........................................................................................................................................... 5

2.3

General and safety warnings.......................................................................................................... 5

General warnings.................................................................................................................... 5

Safety warnings. ..................................................................................................................... 6

2.4

Contacts and useful addresses...................................................................................................... 6

3

Product presentation............................................................................................................................. 7

3.1

Product scope................................................................................................................................ 7

3.2

Composition. ................................................................................................................................. 7

4

Technical specifications and features.................................................................................................... 7

5

Installation............................................................................................................................................. 8

5.1

Necessary tools.............................................................................................................................. 8

5.2

Storage features and conditions..................................................................................................... 8

5.3

Transport........................................................................................................................................ 8

5.4

Handling......................................................................................................................................... 8

5.5

Positioning...................................................................................................................................... 8

5.6

Connections and start-up............................................................................................................. 10

Hose connection................................................................................................................... 11

Priming.................................................................................................................................. 11

5.7

Reinstallation and reuse............................................................................................................... 12

5.8

Demolition and disposal............................................................................................................... 12

Electric/electronic waste disposal. ........................................................................................ 12

6

Operations and use............................................................................................................................. 12

6.1

Operating description................................................................................................................... 12

6.2

Application range. ........................................................................................................................ 12

6.3

Use............................................................................................................................................... 12

6.4

Operating limits and environmental limits..................................................................................... 13

6.5

Safety devices and signalling....................................................................................................... 13

6.6

Hazards and risks. ....................................................................................................................... 13

7

User instructions.................................................................................................................................. 13

7.1

Description of the control/command devices................................................................................ 13

Power plug with residual current device (RCD, when included)............................................ 13

Checking residual current device operations. ....................................................................... 13

8

Routine, scheduled and extraordinary maintenance. .......................................................................... 14

8.1

Routine maintenance................................................................................................................... 14

8.2

Extraordinary maintenance. ......................................................................................................... 14

9

Troubleshooting................................................................................................................................... 14

10

Retail and spare parts and relevant documentation......................................................................... 16

E N

Nome file:

File name:

7528002EN - ISTRUZIONI WP7.8000 - EN.docx Rev. 1 24/05/2016

4-18

1.1 Symbols.

Indicates hazardous situations and warnings. Carefully read the parts of the user manual marked with

this symbol.

Indicates that work must not be performed on live electrical devices. This work may only begin after all

suitable safety measures required by current international and/or national regulations are taken.

1.2 Notes on graphics.

Used the following printing types:

•

glossary of terms: italic;

•

the words "product", "customer manual" and "installation manual" highlighted.

1.3 Glossary.

1. Customer manual: document intended for the end user that

illustrates how to use the product.

2. Power cord: flexible cord, for power supply, attached to the

device.

3. Pump: electromechanical device used to move air.

4. Inlet: product input (IN).

5. Outlet: the product’s exit (OUT).

6. Flowrate: the amount of fluid (water) that crosses a section

in a unit of time.

7. Head: this is the maximum distance that a pump can lift water for.

8. Flooded: if the pump is positioned at a level below the water level to be sucked.

9. Bearing: this is a mechanical device used to reduce attrition between two rotating objects.

10.Rotor: it indicates all the rotating components of the pump.

11.Impeller: The front part of the rotor, made up of a plastic disc with small blades. With its rotation, it

transmits to the water the necessary mechanical energy to move water from the inlet to the outlet area.

12.Mechanical seal: a mechanical device is liable to isolating the two environments, among which there is

a shaft with a circular motion.

13.Dry operation: means the product’s operation without water.

14.Thermal protector: the device that cuts of power to the product if the product overheats.

15.Protection device: device whose operations prevent hazardous situations in abnormal operating

conditions.

16.Contact switch disconnection: disconnection of both power conductors with a single contact opening

action.

17.Residual Current Device: (RCD) also called fuse, it is an electro-technical device able to cut off the

circuit in the event of fault.

18.Hydraulic parts: components used to create the system where the product is used (pipes, valves,

couplings, hose connections, etc.).

19.Pool: artificial tank filled with water general intended for swimming or other aquatic activities.

20.Filter: a device where the water flowing in order to retain and/or eliminate the solid particles suspended.

21.Power plug: mechanical connector that can be inserted in a complementary electrical socket (power

outlet).

22.Maximum working pressure: maximum pressure the product is able to sustain during operations.

23.Tool: screwdriver, coin or any other object that can be used to move a screw or similar fastening

device.

24.Necessary clearance: minimum product installation area.

2.1 Warranty.

General aspects.

i. In accordance with these provisions, the dealer guarantees that the product covered by this warranty

(“the product”) does not have any compliancy defect upon delivery.

ii. The product is guaranteed for two (2) years from the date of delivery to the purchaser.

Fig. 1

IN

OUT

E N

Nome file:

File name:

7528002EN - ISTRUZIONI WP7.8000 - EN.docx Rev. 1 24/05/2016

5-18

iii. If a product compliance defect is found and the purchaser informs the dealer during the warranty

period, the dealer must repair or replace the product at his own expense and where he deems most

suitable, unless impossible or incommensurate.

iv. Should the product be irreparable or irreplaceable, the purchaser may request a proportionate price

discount or, if the compliance defect is sufficiently significant, the termination of the sales contract.

v. Parts replaced or repaired under this warranty do not extend the original product warranty period but

are covered by their own guarantee.

vi. Proof of product purchase is required for warranty validity.

vii. After six months from product delivery to the purchaser and compliance defects are found, the

purchaser must prove the origin and existence of the defect.

viii. This warranty certificate does not restrict or jeopardise consumer rights provided by mandatory

national regulations.

Special conditions.

i. This warranty covers the products referred to in this user manual.

ii. This warranty certificate only applies within the European Union.

iii. For warranty validity, the purchaser must strictly follow the manufacturer's instructions included in

the documents that accompany the product, when applicable according to the product range and model.

iv. Should a replacement, maintenance or cleaning schedule be specified for some product parts or

components, the warranty is only considered valid if these schedules are correctly observed.

Restrictions.

i. This warranty only applies to sales to consumers where "consumers" are the people who purchase

the product for personal, and not professional, use.

ii. The warranty does not cover normal product wear. As for replaceable or consumable parts,

components and materials such as rotors, bearings, light bulbs, o-rings, gaskets, sponges, cartridges, etc.,

that provided in the documentation that accompanies the product shall be observed.

iii. The warranty is null and void in the event the product:

a. is subject to incorrect treatment;

b. was repaired, maintained or tampered with by unauthorised personnel or

c. was repaired with non-original parts. Should the product compliance defect be consequent to

incorrect installation or start-up procedures, this warranty only applies when this installation or start-

up procedure is included in the product sales contract and performed by the dealer or his authorised

personnel.

2.2 Returns.

In the event of defects, faults and malfunctions, the product must be returned to the deal with the

completed claim report, where applicable.

2.3 General and safety warnings.

General warnings.

SHOTT International srl continuously strives to improve its products. We trust the user will understand

the technical modifications SHOTT International srl reserves the right.

SHOTT International srl is not liable for any damages due to improper product use.

Carefully read and keep the user manual.

In order to increase energy savings, only use the product when necessary.

Upon product receipt and/or purchase, check packaging integrity. The product must be accompanied by

the user manual. The user manual must be complete.

In the event of malfunctions, consult the user manual and, if necessary, contact specialised technicians.

Failure to observe the instructions in this user manual immediately null and voids the warranty.

Respect current regulations regarding accident prevention.

Due to the complex nature of the cases treated, the installation, user and maintenance instructions

contained in this customer manual do not seek to examine all possible and imaginable cases of service

and maintenance. Should your require additional instruction or have specific problems, please do not

hesitate to contact the distributor or the product manufacturer directly.

E N

Nome file:

File name:

7528002EN - ISTRUZIONI WP7.8000 - EN.docx Rev. 1 24/05/2016

6-18

Safety warnings.

This product can be used by children aged from 8 years and

above and person with reduced physical, sensory or mental

capabilities or lack of experience and knowledge if they have

been given supervision or instruction concerning use of the

product in a safe way and understand the hazards involved.

Children shall not play with the product. Cleaning and user

maintenance shall not be made by children without supervision.

The product must never be operated in the swimming pool

when people are present.

Do not submerge the product in water.

Be sure to disconnect the power plug from the power outlet

before operating on the product.

Attention to the moving parts.

Attention to the inlet/outlet points because they can trap

parts of the body and/or hair and cause serious personal

injuries and even death.

It is compulsory to check that the inlet ends are not blocked.

Pumps, filters, and other equipment/components of a pool

filtration system can operate under pressure. If not correctly

installed they can cause serious personal injuries and even

death.

Packaging materials are not children’s toys. Films can be

hazardous and cause suffocation.

Do not use the pool if the product (filter/pump) cannot be

used.

If the power cord is damaged, it must be replaced by the

manufacturer or its technical service centre or by personnel with

similar qualifications, to prevent any risks (specialised

technicians).

2.4 Contacts and useful addresses.

Information at:

•

Shott International srl +39 049 9401150.

•

www.shott.it.

Fig. 2

Fig. 3

Fig. 4

Fig. 5

H20

Pa

E N

Nome file:

File name:

7528002EN - ISTRUZIONI WP7.8000 - EN.docx Rev. 1 24/05/2016

7-18

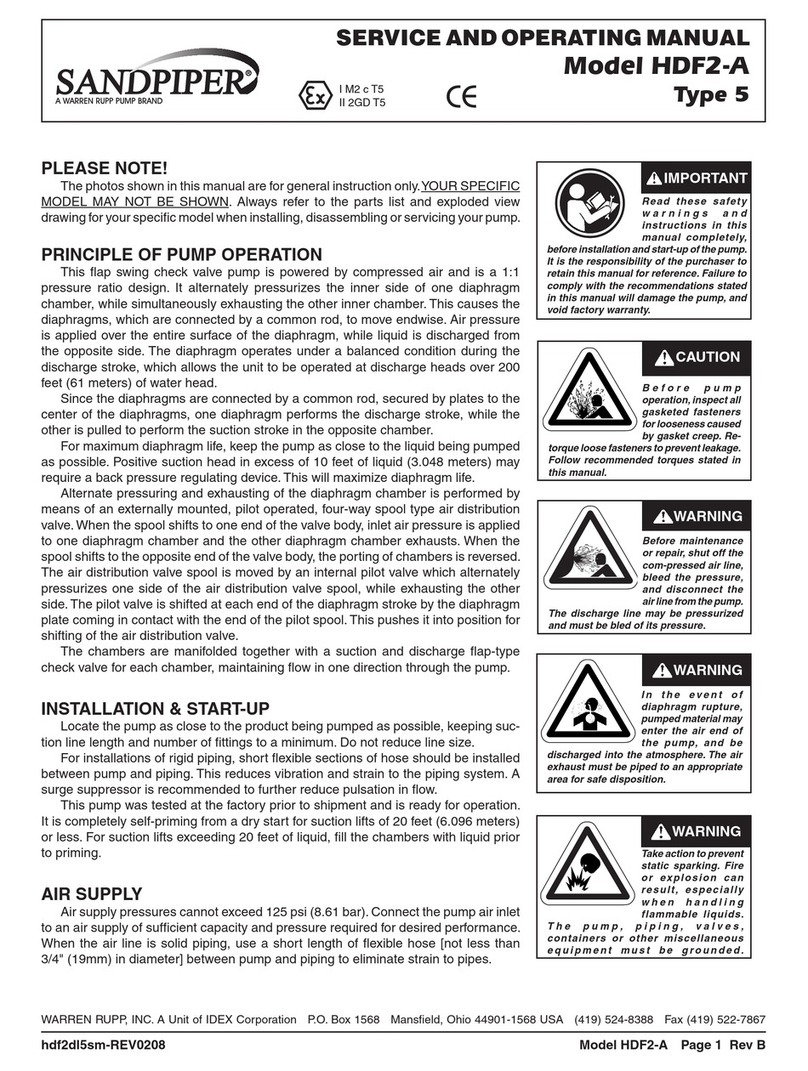

3.1 Product scope.

The product you purchased is a

centrifugal pool pump designed to pump

fresh and salt water.

3.2 Composition.

1. Hosetail

2. O-ring

3. Draining tap

4. Frame

5. Cover

6. Lock nut

7. Prefilter

8. Impeller

9. Rubber

10. Flange

11. Fan

12. Carter

13. Power cord

14. Capacitor

15. Cover

The hydraulic parts used for the building of the system which shall include the product modify the

performance (head and flowrate) of the product.

WP

7

000

WP

80

00

Power

[kW]/[hp] 0.450/0.603

0.500/0.623

Standard voltage 220-240[V]~50[Hz]

Protection grade at water input

IPX5

Inlet

[mm] Ø 32 – Ø 38

Outlet

[mm] Ø 32 – Ø 38

Max flowrate

[m

3

/h]/[gpm] 9.3/2044 12.0/2640

Max head

[m]/[ft] 11.50/37.6 12.00/36.6

Max water temperature 35 [°C]

95 [°F]

Minimum water temperature 4 [°C]

39 [°F]

Tab. 1

Fig. 6

1

2

22

3

2

4

5

6

7

8

9

10

11

12

13

14

15

E N

Nome file:

File name:

7528002EN - ISTRUZIONI WP7.8000 - EN.docx Rev. 1 24/05/2016

8-18

Fig. 7

5.1 Necessary tools.

Fig. 8

5.2 Storage features and conditions.

Store the product in a dry place and keep away from the elements.

Storage temperature: -10 [°C] (+14 [°F]) to +60 [°C] (+140 [°F]).

5.3 Transport.

Handle the product with care to avoid damages.

The product is delivered suitably protected against transport damages. However, handle with care to

avoid damages.

5.4 Handling.

Handle the product with care to avoid damages.

5.5 Positioning.

The product must be positioned under head.

Fig. 9

0

2

4

6

8

10

12

14

16

0 2 4 6 8 10 12 14 16

H [m]

Q [m3/h]

n=2850 [min-1]

WP7000

WP8000

T

Phillips

H20

IN

E N

Nome file:

File name:

7528002EN - ISTRUZIONI WP7.8000 - EN.docx Rev. 1 24/05/2016

9-18

The product must be placed in an area not subject to flooding.

Fig. 10

The product cannot be used on the water surface.

The product must always be located at least 3.5 [m] from the edge of the swimming pool from which

water is drawn.

Fig. 11

Considering the following aspects is recommended:

•

Dimensions and position of hydraulic components.

•

Necessary clearance.

Fig. 12

•

Power cord position.

•

Location of the power supply (electrical socket, at least 3,5 [m] from the edge of the pool).

Fig. 13

•

Support and its location.

If the product is used with a filter, the latter must be downstream from the product.

H20

3.5m

138in

20 cm

(8 in)

13 cm

(5 in)

13 cm

(5 in)

10 cm

(4 in)

13 cm

(14 in)

3.5m

138in

E N

Nome file:

File name:

7528002EN - ISTRUZIONI WP7.8000 - EN.docx Rev. 1 24/05/2016

10-18

Fig. 14

If the product is placed outside it is advisable to put a simple cover to protect it from rain.

Make sure the product is positioned in a place where noise generated during normal operations does not

create disturbances.

The product must run in a horizontal position. Make sure its position is not altered once it is correctly

placed.

Fig. 15

The product must be fixed on a firm base, with screws of 6 [mm] diameter, through the prepared holes in

the foot.

Fig. 16

The product must be positioned in a shady and aerated place.

5.6 Connections and start-up.

The electrical system must meet current international and/or national regulations.

The product must be connected to an power outlet equipped with a residual current device with

sensitivity over 30 [mA]. Before starting the product make sure this device is installed in your electrical

system. Contact a technician if necessary.

Make sure the product complies with your electrical system.

The power outlet must be at a suitable distance from the water but easily accessible in order to be able

to easily turn off the product in the event of fault (electrical socket, at least 3,5 [m] from the edge of the

pool). Cutting the power cord and/or replacing the power plug is strictly prohibited.

The power cord must be positioned to avoid possible damages such as bends and/or cuts.

IN

IN

OUT

M6

M6

112mm

E N

Nome file:

File name:

7528002EN - ISTRUZIONI WP7.8000 - EN.docx Rev. 1 24/05/2016

11-18

Fig. 17

The cover must be tightly screwed-in before connecting the product to the power mains.

Fig. 18

Hose connection.

Proceed as follows:

1. Position the O-rings (Fig. , # A) on the rubber holder (Fig. , # B).

2. Screw the two rubber holders in (Fig. ) on the inlet and outlet side of the pump.

Fig. 19

3. Apply some turns of the supplied teflon around the rubber holders (Fig. 20, # C; hydraulic parts) to

ensure the pipe is sealed (hydraulic parts) onto the rubber holder.

4. Connect the inlet pipe (hydraulic part) to the IN rubber holder (Fig. 0, # D) and the outlet pipe to the

OUT rubber holder (Fig. 0, # E). Fix the pipes (hydraulic part) with clips (Fig. 0, # F).

Fig. 20

Check the hydraulic pipe is as short as possible to minimize the decrease in flowrate. Avoid any

deformation or occlusion in the hydraulic pipes because they might affect the product operation.

Support the inlet and outlet pipes (hydraulic parts) of the product in order to minimize the load on it.

Priming.

Make sure all hydraulic components and the pump prefilter are full of water, turn on the product connecting

the electrical plug to the electrical socket, the product will discharge residual air and start running at

working regime.

O

38 mm

O 38 mm

O 32 mm

A

B

B

C

E

D

F

F

E N

Nome file:

File name:

7528002EN - ISTRUZIONI WP7.8000 - EN.docx Rev. 1 24/05/2016

12-18

Fig. 21

Fig. 22

5.7 Reinstallation and reuse.

Clean the product and the moving parts accurately before stopping the product for a while, such as, for

instance, during the winter months.

Do not lubricate and/or use detergents and chemical cleaning products.

If there is the risk of freezing, the product must be carefully emptied from the liquids in its hydraulic

circuit. It is advisable to empty all the hydraulic parts.

5.8 Demolition and disposal.

Collecting recyclable material, both those used for packaging (cardboard, nylon,

etc.) and those replaced during maintenance is recommended. Suitable

collection of waste material for recycling, processing and environmentally

compatible disposal contributes in avoiding possible negative effects on the

environment and health and promotes the reuse and/or recycling of product

materials.

Illicit product disposal by the user may be punishable by current international

and/or national laws.

Electric/electronic waste disposal.

EU directive 2012/19/EU classifies this product as an electrical or

electronic tool. The barred bin symbol on the equipment or packaging indicates that the product

must be separated from other waste at the end of its working life. Therefore, the user must take

equipment to electronic and electro-technical waste collection centres at the end of its working life

or return it to the dealer when purchasing similar new equipment, on a one to one basis. Suitable

collection of decommissioned equipment for recycling, processing and environmentally compatible

disposal contributes in avoiding possible negative effects on the environment and health and

promote the reuse and/or recycling of device materials. Illicit product disposal by the user may be

punishable by current national laws.

Do not use glue, sealant or other chemical products on threads or other product parts.

To disconnect the product from the power mains, remove the power plug from the power outlet without

pulling on the power cord.

6.1 Operating description.

The product you purchase is designed to move water in swimming pool. The rotor turns and transfers

water from the inlet to the outlet.

6.2 Application range.

The product cannot be used to purify water for human consumption.

This powerful and reliable product can be used in swimming pool, together with a filter, for water treatment.

6.3 Use.

Cutting and/or altering the power cord is strictly prohibited.

The product cannot be used to purify water for human consumption.

The product cannot be used to purify liquids other than fresh water.

The product cannot be used for medical/therapeutic purposes,

Dry operations are prohibited.

Fig. 23

E N

Nome file:

File name:

7528002EN - ISTRUZIONI WP7.8000 - EN.docx Rev. 1 24/05/2016

13-18

6.4 Operating limits and environmental limits.

•

Maximum water temperature: +35 [°C].

•

Minimum water temperature: +4 [°C].

6.5 Safety devices and signalling.

The product is equipped with a thermal protector. Following any thermal

protector operation, check the causes that originated the product’s

malfunction. For this purpose, please consult the “Troubleshooting”

section.

The product shall go back to normal operating conditions after it has

cooled down (about 2÷3 hours) and/or the caused that triggered the

thermal protector have been eliminated.

6.6 Hazards and risks.

Attention to the inlet/outlet points because they can trap parts of the

body and/or hair and cause serious personal injuries and even death.

Pumps, filters, and other equipment/components of a pool filtration

system can operate under pressure. If not correctly installed they can

cause serious personal injuries and even death.

The product is powered electrically, so maximum diligence in its

installation and maintenance is required, in order to avoid danger. Please

pay particular attention to:

•

the conditions of its power cord, which must not be damaged;

•

do not use the product without its pre-filter basket (Fig. ?, # ?),

otherwise the product may jam or be irreparably damaged;

•

when using any type of stop valve make sure the line is completely

open as the product must never run with valves closed.

7.1 Description of the control/command devices.

Power plug with residual current device (RCD, when included).

Before turning on the product, always press the RESET button. Check

power plug with residual current device operations by pressing the TEST

button (T).

Do not attempt to repair or open the power plug with residual current

device; in the event of fault, replace the entire power plug with residual

current device with the power cord.

The power plug with residual current device does not replace mandatory

electrical safety components: the electrical system must meet current

international and/or national regulations. If necessary, contact specialised

technicians.

The power plug with residual current device is an additional electrical safety component able to cut off a

circuit in the event of fault. In order for it to work, it must:

•

always be in the vertical position,

•

always be clean and free of dust or water,

•

be connected to a perfectly efficient ground line,

•

check residual current device operations before turning on the product.

Checking residual current device operations.

Plug the power plug with residual current device into the power outlet:

1. press the RESET button to allow the product to be turned on: the light

turns red.

2. press the TEST (T) button to test residual current device operations: the

light turns off and the residual current device cuts off electrical power,

therefore the product cannot be turned on unless the RESET button is

pressed again.

If the residual current device triggers (turns off the product) during product

use, unplug the power plug with residual current device from the power outlet

Fig. 24

Fig. 25

Fig. 26

Pa

Fig. 27

TEST (T)

RESET

E N

Nome file:

File name:

7528002EN - ISTRUZIONI WP7.8000 - EN.docx Rev. 1 24/05/2016

14-18

and do not use the product. Contact a specialised technician.

Before proceeding with any maintenance activity, remember to disconnect

the power plug from the power outlet, and not to put your hands in the water if

the product is turned on.

Do not lubricate and/or use detergents and/or chemical products to clean

the product.

All extraordinary maintenance (replacement of supply cord,etc.) must be

carried out by specialised technicians.

Replace any damaged and/or worn components as quickly as possible; use

only original spare parts. For this purpose, please consult the “Retail and

spare parts and relevant documentation”.

For regular control:

•

Check that the mechanical parts are tightly secured and check the

condition of the screws supporting the product.

•

Check that the power cord and isolating parts are in their correct position, are secure and in a good

state of repair.

•

Check the temperature of the product and the electric motor. In the event of a fault, stop the product

immediately and contact specialised technicians.

•

Check for product vibrations. In the event of a fault, stop the machine immediately and contact

specialised technicians.

8.1 Routine maintenance.

To be performed at least once a year, or more frequently if necessary.

Product components that, due to their normal use, suffer wear and/or tear must be regularly replaced to

ensure good product performance. The following table shows the perishables and/or consumables used in

the product and their estimated working life.

O rings and general seals

1 year

Mechanical seal 1 year

Bearing 1 year

8.2 Extraordinary maintenance.

Extraordinary product maintenance must be performed by a specialised technicians.

This consists in replacing worn or damaged parts (power cord, bearing, rotor, impeller, etc.).

P

ROBLEM

C

AUSE

1

ST

S

OLUTION

2

ND

S

OLUTION

1. The product does not

work. No or insufficient power

supply. Check the power supply.

Contact specialised

technicians.

2. The product does not

work.

The power plug is not

correctly inserted in the

power outlet.

Firmly insert the power

plug in the power outlet. Contact specialised

technicians.

3. The product does not

work. Hydraulic components

clogged or bent. Clean and adjust

hydraulic components. Contact specialised

technicians.

4. The product does not

work. The thermal protector

has been triggered. Wait until the product

(blower) cools. Contact specialised

technicians.

5. Power cord damaged.

Wear and/or negligence. Contact specialised

technicians. -

6. Plastic components

damaged. Wear. Replace. Contact specialised

technicians.

7. Low flowrate from

outlet The product is dirty Clean the product. Contact specialised

technicians.

8. Low flowrate from

outlet Hydraulic components

clogged or bent. Clean and adjust

hydraulic components. Contact specialised

technicians.

Fig. 28

E N

Nome file:

File name:

7528002EN - ISTRUZIONI WP7.8000 - EN.docx Rev. 1 24/05/2016

15-18

P

ROBLEM

C

AUSE

1

ST

S

OLUTION

2

ND

S

OLUTION

9. Low flowrate from

outlet The impeller’s blades are

worn out. Replace the impeller. Contact specialised

technicians.

10.Low flowrate from

outlet The pump has not been

primed correctly. Prime the pump. Contact specialised

technicians.

11.The product does not

work. The thermal protector

has been triggered.

Check that the water

temperature does not

exceed +35 [°C] and, if

necessary, add cold

water to the pool to lower

water temperature.

Contact specialised

technicians.

12.The product does not

work. The thermal protector

has been triggered.

Blocked drive shaft,

follow the instructions in

Blocked rotor.

Contact specialised

technicians.

13.Water leak. Gaskets or o-rings

incorrectly installed Check correct gasket

and o-ring installation. Contact specialised

technicians.

14.Water leak. Fast connections or

cover not tight. Tighten fast connections

and cover. Contact specialised

technicians.

15.Loss of water from

mechanical seal.

A mechanical seal is

used to isolate the pump

body and the motor

body. Some drops of

water may flow out once

in a while this is normal,

especially after periods

of non use.

If the leaks are

consistent Please

contact specialised

technicians..

-

16.Blocked rotor.

Foreign bodies block the

rotating elements of the

product (impeller or

cooling fan).

Remove any foreign

bodies. Contact specialised

technicians.

17.Blocked rotor. Blocked drive shaft, it

can happen after a long

period of inactivity.

Do the following:

1. unplug the

product from the

power outlet;

2. make the drive

shaft turn 9-10

times, using a

screwdriver as

shown in Fig. ;

3. insert the power

plug of the

product into the

power outlet.

Contact specialised

technicians.

Tab. 2

Fig. 29

E N

Nome file:

File name:

7528002EN - ISTRUZIONI WP7.8000 - EN.docx Rev. 1 24/05/2016

16-18

Replace any damaged and/or worn components as quickly as possible; use only original spare parts.

Fig. 30

#

WP7000

WP8000

1 XQ708I23

2a XQ710I23

2b XQ700I23

2c XQ709I23

3 XQ711I10 (Ø 32/38[mm])

4 XQ711I20 (Ø 38[mm])

5 XQ712I13

6 XQ713I23

7 XQ714I53 XQ714I63

8 XQ715I23

11 XQ718I23

12 XQ719I23

13 XQ720I10

14 XQ721I10

15 XQ722I13

16 XQ723I23

Tab. 3

Nome file:

File name:

7528002EN - ISTRUZIONI WP7.8000 - EN.docx Rev. 1 24/05/2016

17-18

Nome file:

File name:

7528002EN - ISTRUZIONI WP7.8000 - EN.docx Rev. 1 24/05/2016

18-18

S

HOTT

I

NTERNATIONAL

S.

R

.

L

.

V

IA DELLE

P

EZZE

,

35

35013

C

ITTADELLA

(PD)

-

I

TALY

T

EL

.

+39

049-9401150

F

AX

.

+39

049-9409140

E

-

MAIL

:

info@shott.it

WEB

:

www.shott.it

This manual suits for next models

1

Table of contents

Other Shott Water Pump manuals

Popular Water Pump manuals by other brands

Bestway

Bestway PowerTouch owner's manual

Wayne

Wayne VIP50 Operating instructions and parts manual

Grundfos

Grundfos ALPHA+ Series Installation and operating instructions

JABSCO

JABSCO 50870 Series manual

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 83B2-B Installation, operation, and maintenance manual with parts list

Sandpiper

Sandpiper HDF2-A Service and operating manual

ProMinent

ProMinent Makro/ 5 HK operating instructions

Orion

Orion 21650 user manual

Rioned

Rioned FLEXMATIC+ user manual

MASTERLUBE

MASTERLUBE Minimaster PMM2CD troubleshooting guide

Laing

Laing Ultracirc S1 Series Installation and operating instructions

Armstrong

Armstrong 4200H Installation and operating instructions