ProMinent®

Page 6

1 About this pump

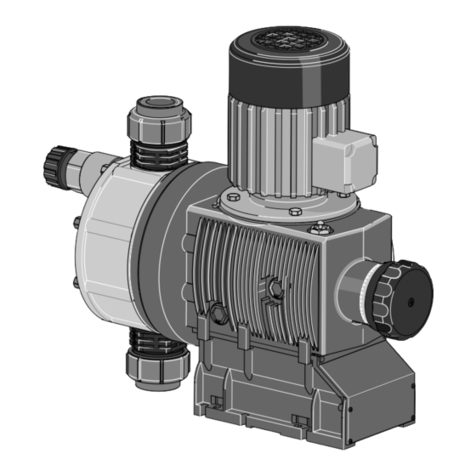

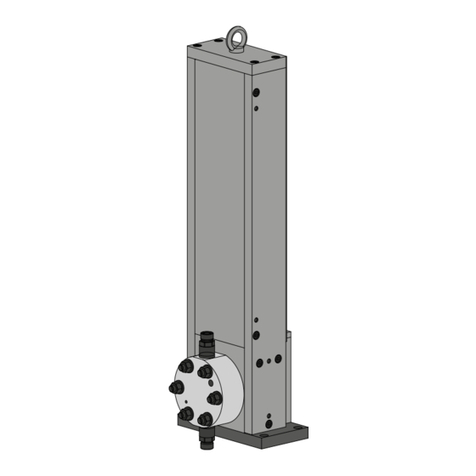

The ProMinent®Makro/5 metering pump is fitted as standard with a dual-wound 3 kW three

phase motor. The stroke length can be adjusted between 0. . . 50 mm (HM:0. . . 20 mm). The

bead-blasted graphite housing can be combined with up to 25 liquid end sizes and 5 gear ratios

(integrated into the spur wheel back-geared motor). The liquid ends are available in different

material combinations which are chosen to comply with the chemical media being metered. The

reproducible metering accuracy is better than ±0. 5 % in the stroke length range from 10 %-

100 % (HM:±1 %) under defined conditions and subject to correct installation.

The ProMinent®Makro/5 add-on metering pump can be combined with the Makro/5 main power

end to produce a duplex/multiplex pump. A main power end can be combined with up to four

add-on power ends. One power end can be used as both a single and a double head version.

The double head versions are fitted with a second liquid end which operates in counter cycle

(Boxer principle.).

2 Safety

Correct use

of equipment Use • The pump may be used for metering liquid media only!

• All other applications and modifications are prohibited!

• The pumps with piston liquid end are not suitable for metering life-threatening liquids.

• The pump is not suitable for metering gaseous media or solids.

• The pump may be used only within the stated pressure range.

• Please observe general limitations with regard to viscosity limits, chemical resistance and

density and the stated ambient conditions.

• It is essential that you read this operating instruction manual together with the “General

Operating Instructions for ProMinent®Metering Pumps and Hydraulic Accessories”

concerning assembly, installation and maintenance!

• The pump is to be operated by appropriately trained personnel only.

Safety instructions WARNING

• The pump starts to operate as soon as it is connected to the mains.

Ensure that hazardous media cannot leak out.

• The pump has no on/off switch.

In the event of an electrical fault, unplug the mains cable or switch off the

system at the emergency off-switch.

• Unplug the cable from the mains before working on the pump!

• Always depressurise the liquid end before working on the pump!

• Before working on the pump, empty the liquid end and rinse out if it has been

used with hazardous or unknown chemicals.

• Always wear suitable protective equipment when working on a liquid end

which has been used with hazardous or unknown chemicals.

• Pumps must be accessible at all times for operation and maintenance.

Access should never be impeded or blocked.

• Pumps which have been used with radioactiv media can not be sent.

• Before commissioning the pump, connect the overpressure sensor and the

diaphragm rupture sensor.

CAUTION

• It is prohibited to assemble and install ProMinent®metering pumps with parts

which have not been approved or recommended by ProMinent. Damage to

persons and property may ensue.

• When metering aggressive media, check the resistance of the pump materials

(See ProMinent®resistance list in the Product Catalogue or on our Homepage)

• Danger of burns from hot power end in the event of enfault.

• Observe all national directives which apply to installation!

About this pump / Safety

ProMinentGroup.ir