SHP Laboklav 55 User manual

Laboklav

edition 01/2020

Dampfsterilisatoren

Steam sterilizers

Type 55

-

195 Liter

User manual

SHP Steriltechnik AG

Schloss Detzel 1

D- 39345 Detzel Schloss / Satuelle

Tel: +49 (0) 39058 97 62- 0

Fax: +49 (0) 39058 97 62- 22

Internet: www.shp-steriltechnik.de

"Steam sterilizer Laboklav 55 - 195"

User manual

3

Please read these user instructions before starting the use of the steam sterilizer! It is necessary to

keep this user manual over the complete life cycle of the sterilizer nearby the unit.

Indications included in this manual and labeled warning, important and attention are very

important and to draw attention to them. They are marked with the following graphical

symbols.

Warning

Failing to observe these warnings can cause injury and even

death. This symbol also means that an operator must

acquaint with a suitable passage in the manual.

Important

This s

ymbol denotes important indications for example to

prevent sterilizer or load damage.

Attention

Observing the texts marked with this symbol facilitates

operation of the sterilizer.

General Warnings:

Access to sterilizer operations manual shou

ld be restricted

only to persons authorized to operate a sterilizer

During an installation of a sterilizer, after maintenance

performed by technical staff and during power outlet

exchange, the verification of null electric potential of the

elements be

ing touched by users should absolutely be

performed by authorized staff.

4User Manual "Steam sterilizer Laboklav 55 - 195

"

General safety instructions:

Observe the following safety instructions for the operation of the autoclave!

Determination

•Only use the autoclave for the purpose defined in the operating instructions.

Power cord and power plug

•Never damage or change the power cord or power plug.

•Never operate the autoclave if the power cord or plug is damaged.

•Never unplug the power cord from the wall outlet. Always touch the power plug directly.

Installation

•Follow the instructions in this manual to install and operate the unit. We recommend that the

first commissioning be carried out by authorised specialist personnel of SHP Steriltechnik AG.

•Do not operate the autoclave in potentially explosive atmospheres.

•Only have the electrical connection set up by a specialist.

Program termination

•Note, that hot water steam can leave the chamber when the door is opened immediately after

a program has been stopped manually.

•Depending on the time of program termination, the load may be not sterile. Observe the

instructions on the display of the autoclave. You may need to sterilize the item again.

•Never open the door with force.

Removal of sterile goods

•Use gloves to remove the trays or bottom plate and wait until the everything has cooled down.

Never touch the sterile goods with unprotected hands. The parts can be hot.

•Check the packaging of the items to be sterilized for removal from the autoclave.

Maintenance

•Have the service carried out by authorized persons only.

Malfunctions

•If you get repeated error messages when operating the autoclave, put the autoclave out of

service and, if necessary, inform your specialist or authorized service.

•Have the autoclave repaired only by authorized persons.

"Steam sterilizer Laboklav 55 - 195"

User manual

5

Content

Page

1. General application, construction and use of steam sterilizer line Laboklav 55-195 .......................................... 6

2. Steam sterilizer Laboklav xxx - technical data ....................................................................................................8

3. Programs available in steam sterilizer line Laboklav 55 - 195 ..........................................................................14

3.1. standard programs .................................................................................................................................14

3.2. Programs with fast cooling .....................................................................................................................16

3.3. Programs with vacuum (versions V, MV, MSV and MSLV) ................................................................... 17

3.4. Description of program steps .................................................................................................................18

3.5. Programs for testing ...............................................................................................................................19

3.6. Overview for predefined programs.........................................................................................................19

4. Operating the steam sterilizer Laboklav 55 – 195.............................................................................................21

4.1. List of delivered parts .............................................................................................................................21

4.2. Installation .............................................................................................................................................. 22

4.2.1. Power Supply..................................................................................................................................22

4.2.2. Water supply...................................................................................................................................22

4.3. General information for operation ..........................................................................................................23

4.3.1. Control panel and key functions .....................................................................................................23

4.3.2. Optional Touchscreen ....................................................................................................................24

4.4. First commissioning................................................................................................................................25

4.4.1. Setting up the device ......................................................................................................................25

4.4.2. Switching on ...................................................................................................................................25

4.4.3. Open the door/ lid ...........................................................................................................................26

4.4.4. Loading the device..........................................................................................................................26

4.4.5. Close the door/ lid...........................................................................................................................27

4.4.6. Choose a program .......................................................................................................................... 27

4.4.7. Program start ..................................................................................................................................29

4.4.8. STOP Button...................................................................................................................................29

4.4.9. Changing program parameters.......................................................................................................30

4.4.10. End of program .............................................................................................................................32

5. Sterilization cycle progress................................................................................................................................33

6. Error handling ....................................................................................................................................................40

7. Operating the sterilizer - general information ....................................................................................................41

7.1. Preheating the chamber......................................................................................................................... 41

7.2. Preparation of sterilization goods...........................................................................................................41

7.3. Removal of condensate..........................................................................................................................42

8. Documentation of sterilization cycles ................................................................................................................43

9. Decommissioning ..............................................................................................................................................43

10. Maintenance ....................................................................................................................................................44

10.1. Regular cleaning, maintenance and service activities .........................................................................45

10.2. Cleaning ...............................................................................................................................................46

10.3. Check of safety valve(s).......................................................................................................................47

10.4. Changing the venting air filter ..............................................................................................................48

10.5. Changing the lid seal............................................................................................................................48

10.6. Changing paper and ribbon cassette of the printer..............................................................................49

10.7. List of Consumables.............................................................................................................................51

11. Description of Safety devices .........................................................................................................................52

12. Additional information ......................................................................................................................................53

12.1. Definition of feed water quality .............................................................................................................53

12.2. Disposal................................................................................................................................................ 53

13. Service and maintenance................................................................................................................................ 54

6User Manual "Steam sterilizer Laboklav 55 - 195

"

1. General application, construction and use of steam sterilizer line Laboklav 55-195

The steam sterilizer line Laboklav 55 - 195 is equipped with a chamber by 55 Liter to 195 Liter

chamber volume. It is constructed for the steam sterilization of instruments, materials for non medical

use and liquids. All versions contain a thermo lock acc. to IEC 61010-2-40. Different versions

depending on the use of the sterilizers are available.

In the basic version (Laboklav xxx B) sterilization of the above mentioned sterilization items is

possible, the cycles are configured as general use cycles. Unpackaged instruments and materials as

well as liquids can be sterilized as long as they are approved for the applied temperature range. Do

not sterilize hollow bodies (e.g. tubes) and porous materials (e.g. textiles). For such materials, these

cycles cannot be validated in the basic version and the sterilization result is therefore undefined.

(Version with vacuum option is necessary here)

The version with fast liquid cooling option (Laboklav xxx M) is equipped to make the cooling

process of liquids faster than self cooling process can be. The use of the active cooling process is

constructed for the use of not tightly closed flasks! Reduce of process time of cooling process is about

40 % compared with basic version! In consequence of the active cooling process happens a loss of

liquids by 3 – 12 % depending of the pressure reduce speed (programmable by service).

Attention! This is always associated with an increased loss

of liquid in the sterilization material.

Further versions are equipped to reduce the loss of liquids and to allow the sterilization of tightly

closed flasks (Laboklav xxx MS und MSL).

The vacuum version includes a water ring vacuum pump. This makes the steam sterilization process

safe for wrapped, porous and hollow materials. Additionally this version includes the possibility of

drying of the materials.

The standard programs for the sterilization of liquids (as available in the basic unit) are also available

here.

The water ring pump

in units with vacuum option should run

minimum once per week. This

prolongers the life cycle of the

vacuum pump and protects against malfunctions.

The different options are possible to combine in one unit (Laboklav xxx MV, MSV, MSLV).

For the use of the sterilizer in safety laboratories a special steam exhaust filtration is available to

protect the environment against elusion of non sterilized microorganism.

The manufacturer is not liable or responsible for defects or

indefinitely results if the sterilizer is not under intended use.

The steam sterilizer line Laboklav 55 – 195 allows a fully automatic process cycle. That includes

deaeration, heating, sterilization, pressure remove and cooling or drying function (optional if included

in the actual version). All steps for an automatic process are controlled by a microprocessor control

board. The actual status is shown on a graphic display and includes all important information for the

user to operate the device. The supported temperature range of the sterilization process is 103°C to

136°C. The typical temperatures of 121°C and 134°C are programmed for different sterilizing

situations and different materials. All program positions can be reprogrammed by special trained

engineers / service stuff.

"Steam sterilizer Laboklav 55 - 195"

User manual

7

The steam sterilizer line Laboklav 55 – 195 includes the following additional advantages:

-Automatic preheating to reach defined condition in the start situation in each program separately

to define. This function is especially developed for fractionated prevacuum process to reduce the

condensate in the chamber and on the sterilization goods.

-Fully automatic deaeration of the sterilization goods by fractionated prevacuum (in vacuum option

only) or pressure purge process for solids and gravity process for liquid goods.

-Use of the principle of hot stone for the steam production reduces the use of water and decreases

the heating time of the device. That makes the process much more economic than the typical

steam generation process in a classic steam generator.

-Cooling process using the feed water stored in an included feed water tank (in all units with

included fast cooling option). That reduces the need of expensive demineralized water and saves

heating energy in the feed water. Additionally it is degassing the feed water for the next cycle so it

increases the quality of the complete sterilization process.

-Protection of the drain on house installation side by using normal tape water mixing to the steam

outlet. That process works temperature controlled by a PT 100 in the outlet installation. The

temperature is programmable for opening and closing the mixing valve.

-Automatic cleaning function for the steam generator in running in each cycle. It protects the unit

against heater damage forced by bad water quality.

-Microprocessor controlled process for fully automatic use.

Total view of the steam sterilizer Laboklav xxx

Figure 1: Total view of Laboklav xxx

The Laboklav should be operated while the normal laboratory working hours. If the device is not in

use it should be switched off by the main power plug (5). Over night and on the weekends the central

power plug (1) should be switched off. If that central power plug is missing, please use the main

breaker below the housing (4) on the right side of the unit.

Emergency Switch off

In case of a fatal switch off the device by turning the central

main power switch (1) or disconnect the sterilizer from power

supply by using the power plug (2).

4

5

1

2

8User Manual "Steam sterilizer Laboklav 55 - 195

"

2. Steam sterilizer Laboklav xxx - technical data

Laboklav 55

Overall dimension (free standing unit) (W x H x D)…. 740 x 765 x 600 mm

Footprint (Bench top unit) (W x D)............................... 740 x 670 mm

Weight (netto).............................................................. ca. 125 kg

Volume Feed Water tank............................................. ca. 16 l

Maximum Load:

-Instruments ..................... 20 kg

-Textiles ........................... 10 kg

-Liquids...........…………….. 15 Liter Total volume

Sterilizer chamber:

Total volume ................................................................ ca. 62 l

Chamber dimension (φx D).......................................... φ410 x 460 (+50-round.) mm

Usable Volume....... ..................................................… ca. 60 l

Maximum allowable pressure (PS)............................... 2.8 bar

Maximum allowable temperature (TS).......................... 138°C

Working pressure safety valve....................................... 2.8 bar

Material of chamber and double jacket..................….... 1.4404 (SS 316 L)

Surface roughness ……………………........................… ≤0,8 µm

Pressure Device Directive 2014/68/EU......................... CE0036, Kat. II, Modul B+C2

Power supply:

Voltage ......................................................................... 3N 400V~ (±5%), 50 Hz, 16A

Power cord……...………................................................. CEE-plug 16 A

Working power ............................................................... 4,5 kW

Averaged power consumption per cycle......................... 5 kWh

Protection class ......................…………………………... I

Protection…......................…………………...…………... IP24

Electromagnetic compatibility ..........……..……………… DIN EN 61326

Water supply:

Destilled or demineralized Water

(acc. to annex C EN 13060)

Averaged feed water consumption per cycle................... ca. 3,5 l - 8 l

(depending on initial state, program and load)

Storing conditions:

Temperature................................................................... 5 ÷40°C

Humidity ........................................................................ max. 85%

Heat emission to the environment................................. ca. 12% of rated capacity

Programs:

10 predefined programs in user level 1:

The program definition depends on the available options included in the model. The programs

can be individually changed.

10 further programs in user level 2 (program P11 - P20) code protected, Predefinition is like P1.

2 test programs (Bowie & Dick-Test, P11, vacuum test, P12) - in vacuum versions only

Computer interface:

- serial interface RS 485

Printer (optional)

"Steam sterilizer Laboklav 55 - 195"

User manual

9

Laboklav 80

Overall dimension (free standing unit) (W x H x D)…. 740 x 915 x 600 mm

Footprint (Bench top unit) (W x D)............................... 740 x 820 mm

Weight (netto).............................................................. ca. 165 kg

Volume Feed Water tank............................................. ca. 30 l

Maximum Load:

-Instruments ..................... 30 kg

-Textiles ........................... 10 kg

-Liquids...........…………….. 21 Liter Total volume

Sterilizer chamber:

Total volume ................................................................ ca. 82 l

Chamber dimension (φx D).......................................... φ410 x 610 (+50-round.) mm

Usable Volume....... ..................................................… ca. 80 l

Maximum allowable pressure (PS)............................... 2.8 bar

Maximum allowable temperature (TS).......................... 138°C

Working pressure safety valve....................................... 2.8 bar

Material of chamber and double jacket..................….... 1.4404 (SS 316 L)

Surface roughness ……………………........................… ≤0,8 µm

Pressure Device Directive 2014/68/EU......................... CE0036, Kat. II, Modul B+C2

Power supply:

Voltage ......................................................................... 3N 400V~ (±5%), 50 Hz, 16A

Power cord………...……................................................. CEE-plug 16 A

Working power ............................................................... 4,5 kW

Averaged power consumption per cycle......................... 5 kWh

Protection class ......................…………………………... I

Protection…......................…………………...…………... IP24

Electromagnetic compatibility ..........……..……………… DIN EN 61326

Water supply:

Destilled or demineralized Water

(acc. to annex C EN 13060)

Averaged feed water consumption per cycle................... ca. 3,5 l - 10 l

(depending on initial state, program and load)

Storing conditions:

Temperature................................................................... 5 ÷40°C

Humidity ........................................................................ max. 85%

Heat emission to the environment................................. ca. 12% of rated capacity

Programs:

10 predefined programs in user level 1:

The program definition depends on the available options included in the model. The programs

can be individually changed.

10 further programs in user level 2 (program P11 - P20) code protected, Predefinition is like P1.

2 test programs (Bowie & Dick-Test, P11, vacuum test, P12) - in vacuum versions only

Computer interface:

- serial interface RS 485

Printer (optional)

10 User Manual "Steam sterilizer Laboklav 55 - 195

"

Laboklav 100

Overall dimension (free standing unit) (W x H x D)…. 740 x 1065 x 600 mm

Footprint (Bench top unit) (W x D)............................... 740 x 970 mm

Weight (netto).............................................................. ca. 195 kg

Volume Feed Water tank............................................. ca. 30 l

Maximum Load:

-Instruments ..................... 40 kg

-Textiles ........................... 25 kg

-Liquids...........…………….. 30 Liter Total volume

Sterilizer chamber:

Total volume ................................................................ ca. 102 l

Chamber dimension (φx D).......................................... φ410 x 760 (+50-round.) mm

Usable Volume....... ..................................................… ca. 100 l

Maximum allowable pressure (PS)............................... 2.8 bar

Maximum allowable temperature (TS).......................... 138°C

Working pressure safety valve....................................... 2.8 bar

Material of chamber and double jacket..................….... 1.4404 (SS 316 L)

Surface roughness ……………………........................… ≤0,8 µm

Pressure Device Directive 2014/68/EU......................... CE0036, Kat. II, Modul B+C2

Power supply:

Voltage ......................................................................... 3N 400V~ (±5%), 50 Hz, 16A

Power cord…………...…................................................. CEE-plug 16 A

Working power ............................................................... 6,5 kW

Averaged power consumption per cycle......................... 6,5 kWh

Protection class ......................…………………………... I

Protection…......................…………………...…………... IP24

Electromagnetic compatibility ..........……..……………… DIN EN 61326

Water supply:

Destilled or demineralized Water

(acc. to annex C EN 13060)

Averaged feed water consumption per cycle................... ca. 4,5 l - 12 l

(depending on initial state, program and load)

Storing conditions:

Temperature................................................................... 5 ÷40°C

Humidity ........................................................................ max. 85%

Heat emission to the environment................................. ca. 12% of rated capacity

Programs:

10 predefined programs in user level 1:

The program definition depends on the available options included in the model. The programs

can be individually changed.

10 further programs in user level 2 (program P11 - P20) code protected, Predefinition is like P1.

2 test programs (Bowie & Dick-Test, P11, vacuum test, P12) - in vacuum versions only

Computer interface:

- serial interface RS 485

Printer (optional)

"Steam sterilizer Laboklav 55 - 195"

User manual

11

Laboklav 135

Overall dimension (free standing unit) (W x H x D)…. 840 x 965 x 700 mm

Footprint (Bench top unit) (W x D)............................... 840 x 870 mm

Weight (netto).............................................................. ca. 205 kg

Volume Feed Water tank............................................. ca. 40 l

Maximum Load:

-Instruments ..................... 40 kg

-Textiles ........................... 25 kg

-Liquids...........…………….. 30 Liter Total volume

Sterilizer chamber:

Total volume ................................................................ ca. 135 l

Chamber dimension (φx D).......................................... φ500 x 660 (+50-round.) mm

Usable Volume....... ..................................................… ca. 130 l

Maximum allowable pressure (PS)............................... 2.8 bar

Maximum allowable temperature (TS).......................... 138°C

Working pressure safety valve....................................... 2.8 bar

Material of chamber and double jacket..................….... 1.4404 (SS 316 L)

Surface roughness ……………………........................… ≤0,8 µm

Pressure Device Directive 2014/68/EU......................... CE0036, Kat. II, Modul B+C2

Power supply:

Voltage ......................................................................... 3N 400V~ (±5%), 50 Hz, 16A

Power cord……………................................................... CEE-plug 16 A

Working power ............................................................... 10 kW

Averaged power consumption per cycle......................... 15 kWh

Protection class ......................…………………………... I

Protection…......................…………………...…………... IP24

Electromagnetic compatibility ..........……..……………… DIN EN 61326

Water supply:

Destilled or demineralized Water

(acc. to annex C EN 13060)

Averaged feed water consumption per cycle................... ca. 5,5 l - 15 l

(depending on initial state, program and load)

Storing conditions:

Temperature................................................................... 5 ÷40°C

Humidity ........................................................................ max. 85%

Heat emission to the environment................................. ca. 12% of rated capacity

Programs:

10 predefined programs in user level 1:

The program definition depends on the available options included in the model. The programs

can be individually changed.

10 further programs in user level 2 (program P11 - P20) code protected, Predefinition is like P1.

2 test programs (Bowie & Dick-Test, P11, vacuum test, P12) - in vacuum versions only

Computer interface:

- serial interface RS 485

Printer (optional)

12 User Manual "Steam sterilizer Laboklav 55 - 195

"

Laboklav 160

Overall dimension (free standing unit) (W x H x D)…. 840 x 1065 x 700 mm

Footprint (Bench top unit) (W x D)............................... 840 x 975 mm

Weight (netto).............................................................. ca. 220 kg

Volume Feed Water tank............................................. ca. 40 l

Maximum Load:

-Instruments ..................... 40 kg

-Textiles ........................... 25 kg

-Liquids...........…………….. 45 Liter Total volume

Sterilizer chamber:

Total volume ................................................................ ca. 165 l

Chamber dimension (φx D).......................................... φ500 x 760 (+50-round.) mm

Usable Volume....... ..................................................… ca. 163 l

Maximum allowable pressure (PS)............................... 2.8 bar

Maximum allowable temperature (TS).......................... 138°C

Working pressure safety valve....................................... 2.8 bar

Material of chamber and double jacket..................….... 1.4404 (SS 316 L)

Surface roughness ……………………........................… ≤0,8 µm

Pressure Device Directive 2014/68/EU......................... CE0036, Kat. II, Modul B+C2

Power supply:

Voltage ......................................................................... 3N 400V~ (±5%), 50 Hz, 16A

Power cord……..………................................................. CEE-plug 16 A

Working power ............................................................... 10 kW

Averaged power consumption per cycle......................... 17 kWh

Protection class ......................…………………………... I

Protection…......................…………………...…………... IP24

Electromagnetic compatibility ..........……..……………… DIN EN 61326

Water supply:

Destilled or demineralized Water

(acc. to annex C EN 13060)

Averaged feed water consumption per cycle................... ca. 5,5 l - 17 l

(depending on initial state, program and load)

Storing conditions:

Temperature................................................................... 5 ÷40°C

Humidity ........................................................................ max. 85%

Heat emission to the environment................................. ca. 12% of rated capacity

Programs:

10 predefined programs in user level 1:

The program definition depends on the available options included in the model. The programs

can be individually changed.

10 further programs in user level 2 (program P11 - P20) code protected, Predefinition is like P1.

2 test programs (Bowie & Dick-Test, P11, vacuum test, P12) - in vacuum versions only

Computer interface:

- serial interface RS 485

Printer (optional)

"Steam sterilizer Laboklav 55 - 195"

User manual

13

Laboklav 195

Overall dimension (free standing unit) (W x H x D)…. 840 x 1215 x 700 mm

Footprint (Bench top unit) (W x D)............................... 840 x 1085 mm

Weight (netto).............................................................. ca. 255 kg

Volume Feed Water tank............................................. ca. 40 l

Maximum Load:

-Instruments ..................... 40 kg

-Textiles ........................... 25 kg

-Liquids...........…………….. 45 Liter Total volume

Sterilizer chamber:

Total volume ................................................................ ca. 195 l

Chamber dimension (φx D).......................................... φ500 x 990 (+50-round.) mm

Usable Volume....... ..................................................… ca. 182 l

Maximum allowable pressure (PS)............................... 2.8 bar

Maximum allowable temperature (TS).......................... 138°C

Working pressure safety valve....................................... 2.8 bar

Material of chamber and double jacket..................….... 1.4404 (SS 316 L)

Surface roughness ……………………........................… ≤0,8 µm

Pressure Device Directive 2014/68/EU......................... CE0036, Kat. II, Modul B+C2

Power supply:

Voltage ......................................................................... 3N 400V~ (±5%), 50 Hz, 16A

Power cord……..………................................................. CEE-plug 16 A

Working power ............................................................... 10 kW

Averaged power consumption per cycle......................... 18 kWh

Protection class ......................…………………………... I

Protection…......................…………………...…………... IP24

Electromagnetic compatibility ..........……..……………… DIN EN 61326

Water supply:

Destilled or demineralized Water

(acc. to annex C EN 13060)

Averaged feed water consumption per cycle................... ca. 8,5 l - 18 l

(depending on initial state, program and load)

Storing conditions:

Temperature................................................................... 5 ÷40°C

Humidity ........................................................................ max. 85%

Heat emission to the environment................................. ca. 12% of rated capacity

Programs:

10 predefined programs in user level 1:

The program definition depends on the available options included in the model. The programs

can be individually changed.

10 further programs in user level 2 (program P11 - P20) code protected, Predefinition is like P1.

2 test programs (Bowie & Dick-Test, P11, vacuum test, P12) - in vacuum versions only

Computer interface:

- serial interface RS 485

Printer (optional)

14 User Manual "Steam sterilizer Laboklav 55 - 195

"

3. Programs available in steam sterilizer line Laboklav 55 - 195

3.1. standard programs

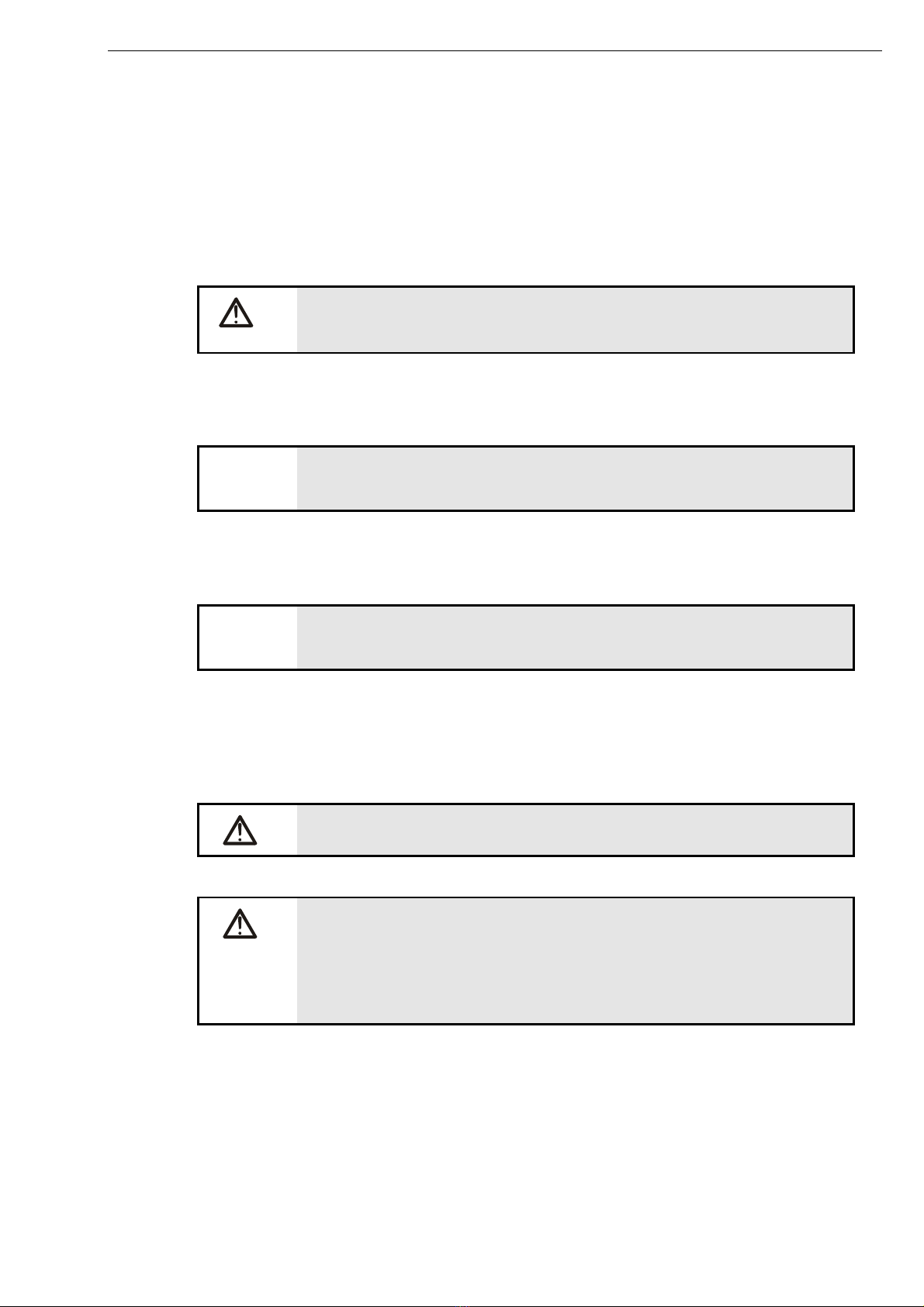

Program Instruments ST available in version Laboklav xxx B, M, MS und MSL

Müll

0

50

100

150

200

250

Zeit

Druck (kPa)

0

20

40

60

80

100

120

140

Temp (°C)

Athmosphärischer Druck [kPa]

120 kPa

190 kPa

automat. Vorheizen

Entlüften mit

Druckwechselverfahren

Aufheizen

Sterilisieren

Dampfablaß

Ausgleich

Programmende

Program Destruction ST in version Laboklav xxx B, M, MS, MSL

Müll ST

170 kPa

170 kPa

Instruments

ST

Instrumente

0

50

100

150

200

250

Zeit

Druck (kPa)

0

20

40

60

80

100

120

140

Temp (°C)

Athmosphärischer Druck [kPa]

190 kPa

120 kPa

automat. Vorheizen

Entlüften mit

Druckwechselverfahren

Dampfablaß

Sterilisieren

Ausgleich

Programmende

Aufheizen

Destruction ST

Instruments ST

170 kPa

"Steam sterilizer Laboklav 55 - 195"

User manual

15

Flüssigkeit

0

50

100

150

200

250

Zeit

Druck (kPa)

0

20

40

60

80

100

120

140

Temp (°C)

Athmosphärischer Druck [kPa]

automat. Vorheizen

Entlüften mit

Sterilisieren

Abkühlen

Ausgleich

Programmende

Belüften

Gravitationsverfahren

Aufheizen

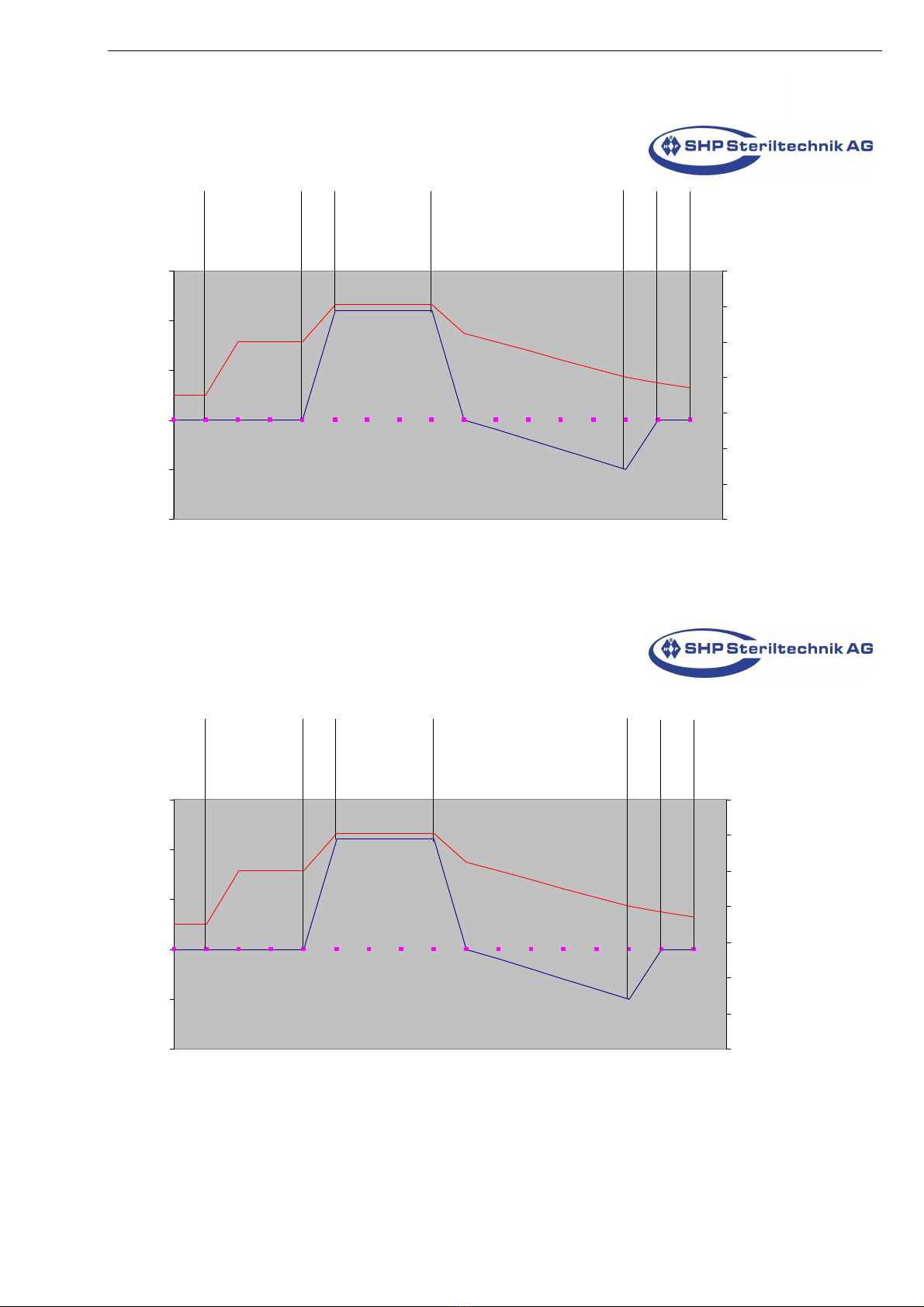

Program Liquids ST in version Laboklav xxx B und V

Flüssigmüll

0

50

100

150

200

250

Zeit

Druck (kPa)

0

20

40

60

80

100

120

140

Temp (°C)

Athmosphärischer Druck [kPa]

automatisches Vorheizen

Entlüften mit

Sterilisieren

Abkühlen

Ausgleich

Programmende

Belüften

Gravitationsverfahren

Aufheizen

Program Destruction LI in all versions Laboklav xxx, in versions with cooling active fast cooling RM is

activated (decreases the cooling time)

Flüssigkeit ST

Liquids ST

Destruction LI

16

User Manual "Steam sterilizer Laboklav 55 - 195

"

3.2. Programs with fast cooling

Flüssigkeit

0

50

100

150

200

250

Zeit

Druck (kPa)

0

20

40

60

80

100

120

140

Temp (°C)

Athmosphärischer Druck [kPa]

Ausgleich

Gravitationsverfahren

automat. Vorheizen

Entlüften mit

Aufheizen

Abkühlen aktiv/passiv

Sterilisieren

Abkühlen aktiv

Belüften

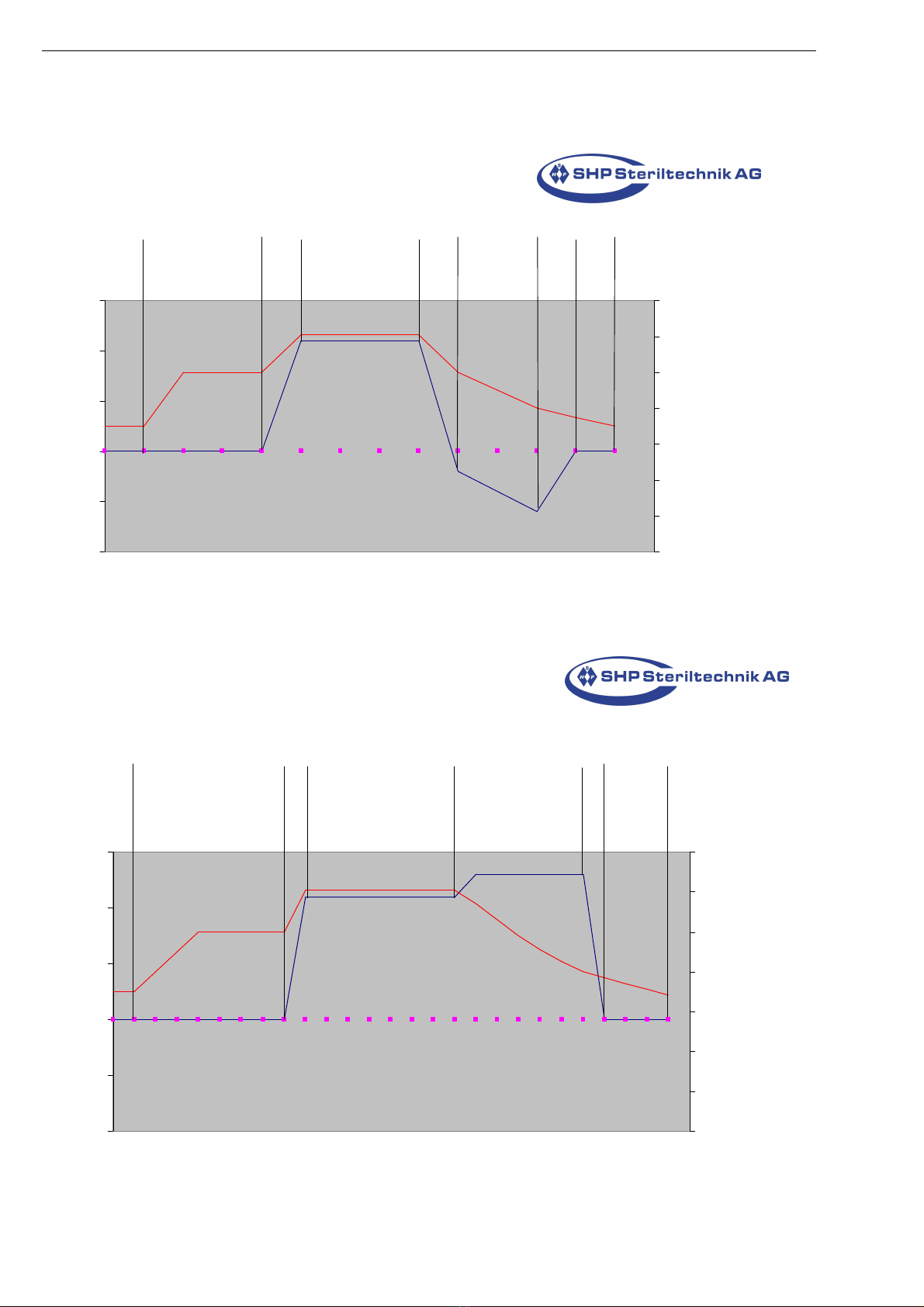

Program Liquids RM in version Laboklav xxx M, MS,MSL, MV, MSV und MSLV

Flüssigkeit RO

0

50

100

150

200

250

Zeit

Druck (kPa)

0

20

40

60

80

100

120

140

Temp (°C)

Athmosphärischer Druck [kPa]

Speisewasservorrat prüfen

Aufheizen

Sterilisieren

Stützdruck abbauen

Ausgleich

Programmende

unter Stützdruck

Entlüften mit

Gravitationsverfahren

Abkühlen aktiv

Program Liquids RO in version Laboklav xxx MS,MSL, MSV und MSLV

Flüssigkeit RM

automat. Vorheizen

Liquids RM

Liquids RO

"Steam sterilizer Laboklav 55 - 195"

User manual

17

Flüssigkeit RG

0

50

100

150

200

250

Zeit

Druck (kPa)

0

20

40

60

80

100

120

140

Temp (°C)

Athmosphärischer Druck [kPa]

Speisewasservorrat prüfen

Vorwärmen

Stützdruck aufbauen

Aufheizen

Sterilisieren unter

Abkühlen unter

Stützdruck abbauen

Ausgleich

Programmende

Stützdruck

Stützdruck

unter Stützdruck

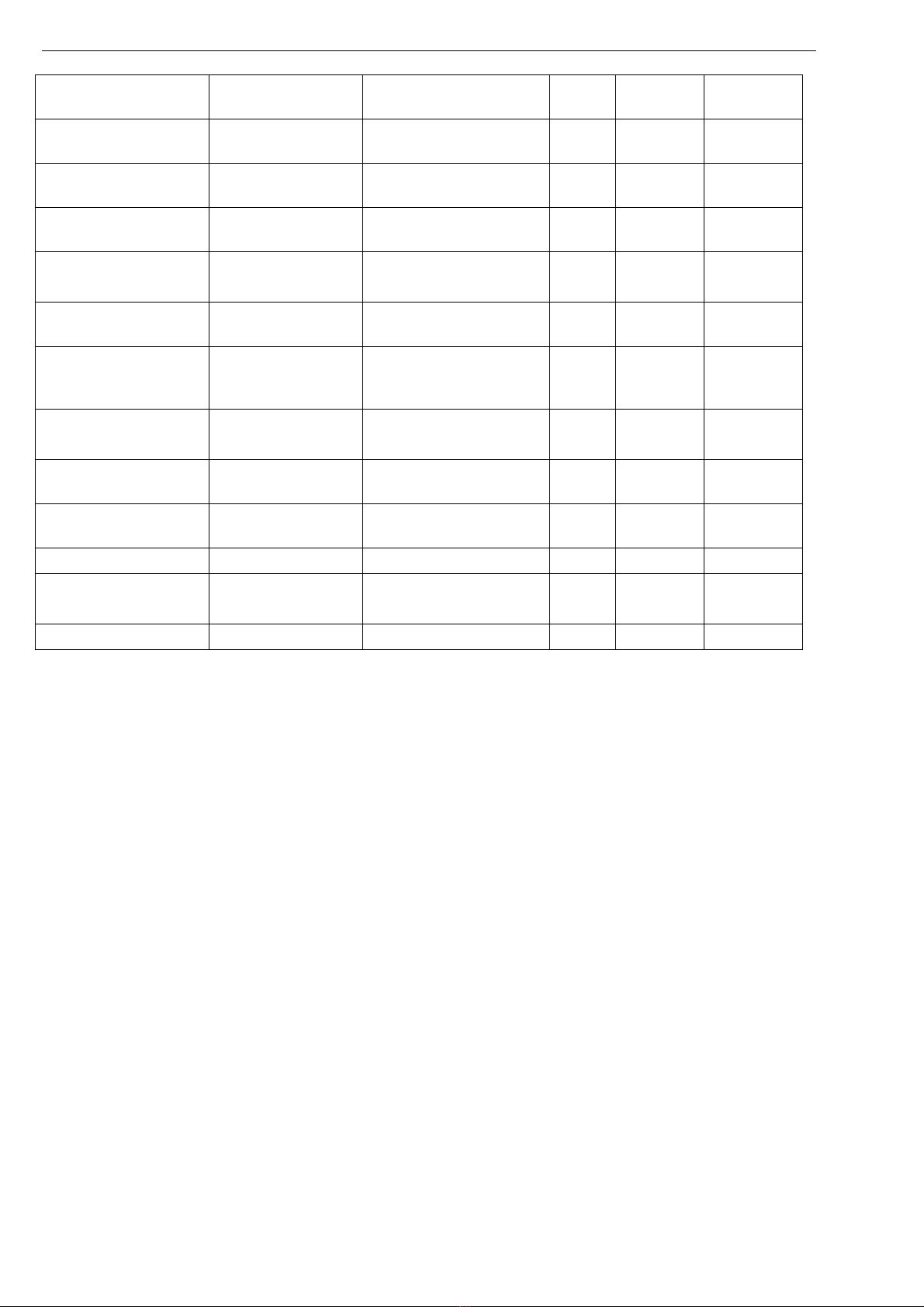

Program Liquids RG in version Laboklav xxx MSL und MSLV

3.3. Programs with vacuum (versions V, MV, MSV and MSLV)

Instrumente

mit Trocknungsvakuum

0

50

100

150

200

250

Zeit

Druck (kPa)

0

20

40

60

80

100

120

140

Temp (°C)

Athmosphärischer Druck [kPa]

170kPa

min 7 kPa

Vorheizen / Start

Entlüften mit

fraktioniertem

Vorvakuum

Dampfspülen

Aufheizen

Sterilisieren

Dampfablaß

Trocknungsvakuum

Belüften

Ausgleich

Program Instruments FV in version Laboklav xxx V, MV, MSV und MSLV

Instrumente FV (mit Trocknungsvakuum)

automat. Vorheizen

Liquids RG

Instruments FV

18

User Manual "Steam sterilizer Laboklav 55 - 195

"

3.4. Description of program steps

The sterilizing process

in steam sterilizer line Laboklav xxx (see drawings above) contains the

following program steps:

-

Preheating

The steam generator and if programmed the chamber is preheated until reaching a specified

temperature. It takes about 5 to 10 minutes. If the chamber temperature is high enough, it decreases

the preheating time or preheating is switched off.

-

Deaeration

In all liquids programs a gravity deaeration is preselected automatically.

In versions B, M, MS and MSL - (no vacuum available) the deaeration for Instruments and Destruction

is preselected as a pressure purge cycle. It works with 3 or 5 pressure purges between

170 and 120 kPa absolute pressure (number of pressure purges depends on start temperature).

In versions V, MV, MSV and MSLV the deaeration for Instruments and Destruction programs works

with fractionated pre-vacuum.

-

Heating

While preheating the chamber is filled with steam up to the preset pressure and temperature. In

preheating phase a deaeration clock is working in most of the programs.

-

Sterilizing

While sterilization phase the unit is keeping the set temperature over the sterilization time. In case

over lower temperature that set temperature, the timer for the sterilization time is stopping.

-

Pressure removal

The steam is removing from chamber until reaching programmed pressure in chamber.

-

Cooling

This is programmed for liquids only. Depending on the integrated fast cooling options different cooling

versions are possible: passive or active, in active cooling slow, fast or forced is possible.

-

Drying

(for versions V, MV, MSV and MSLV only)

Program is drying with vacuum with a programmed drying time. Alternate an intermitting venting and

vacuum cycle is possible. The venting function is automatically using the venting air filter.

-

Venting

The program is using for the venting function the integrated venting air filter automatically. The

function works until reaching the programmed air pressure.

-

Equalizing

For additional safety the device is waiting a few seconds after reaching the program finish to make

sure that no measurement mistake has set the program to finish. Equalizing time depends on

program and sterilization goods and can be different.

-

End of Program

After the end of a program, the control waits for the operator to acknowledge the program! This state

is indicated by a flashing display and a short acoustic signal. The acknowledgment is done by

pressing the stop button (11). The lid is unlocked automatically and then opened gradually.

"Steam sterilizer Laboklav 55 - 195"

User manual

19

3.5. Programs for testing

The Bowie&Dick-Test is proofing the process for steam penetration of the sterilization good (mainly

for textiles or paper wrap). This test is implemented in vacuum option only. The test is normally for

medical use only! The test body for this test should be an usable test package only.

The vacuum test is implemented in vacuum option only. It can be used for testing the leakage rate of

the unit. For the normal use it is not necessary to run this test (implemented for service/maintenance).

The test should run if the chamber is cold! The chamber temperature should be not higher than 40°C

(otherwise it is impossible to start the test).

If the test result is “Incorrect” the unit should get a service /

maintenance! In that case you should not use the device until

qualified service stuff has checked the device!

3.6. Overview for predefined programs

All sterilization cycles are running automatically. The duration of a single cycle depends on the load,

kind of deaeration, number of vacuum fractions in fractionated pre-vacuum and the start conditions

(warm or cold), drying time, kind of cooling etc. Even so the type of sterilization goods and kind of

loading the good inside the chamber have an enormous effect on the cycle time. In case of a

validation you can define the goods and loads. When ever the same good / load with same program

and same parameters is started, the time depends mainly from start temperature. Basically, the

higher the mass of the load and the colder the items to be sterilized and the sterilization chamber, the

longer the time per cycle.

The table gives an overview for the different preselected programs:

(later changes are possible)

Prog. Material Deaeration Steril.

time

Steril.

temp.

drying/coo

ling

P1 (B/M/MS/MSL)

Instr. ST

Instruments Pressure purge:

3-5x 170 kPa / 120 kPa

15 min 134°C No drying

P1 (V/MV/MSV/MSLV)

Instr. FV

Instruments Vacuum + steam:

30/40/50kPa / 140kPa

15 min 134°C 5 min

P2 (B/M/MS/MSL)

Instr. ST

Instruments Pressure purge:

3-5x 170 kPa / 120 kPa

15 min 134°C No drying

P2 (V/MV/MSV/MSLV)

Instr. FV

plastics (e.g.

pipettes)

Vacuum + steam:

30/40/50kPa / 140kPa

25 min 134°C 40 min

P3 (B/M/MS/MSL)

Instr. ST

Plastics and gum

ware

Pressure purge:

3-5x 170 kPa / 120 kPa

20 min 121°C No drying

P3 (V/MV/MSV/MSLV)

Instr. FV

Plastics and gum

ware

Vacuum + steam:

30/40/50kPa / 140kPa

20 min 121°C 15 min

P4 (B/M/MS/MSL)

Destruction ST

Waste / Trash

(solid mat. only!)

Pressure purge:

3-5x 170 kPa / 120 kPa

15 min 134°C No drying

P4 (V/MV/MSV/MSLV)

Destruction FV

Waste / Trash

(solid mat. only!)

Vacuum + steam:

30/40/50kPa / 140kPa

15 min 134°C No drying

P5 (B/M/MS/MSL)

Destruction ST

Waste / Trash

(solid mat. only!)

Pressure purge:

3-5x 170 kPa / 120 kPa

15 min 134°C No drying

P5 (V/M

V/MSV/MSLV)

Destruction FV

Waste / Trash

(solid mat. only!)

Vacuum + steam:

30/40/50kPa / 140kPa

15 min 134°C 2 min

20

User Manual "Steam sterilizer Laboklav 55 - 195

"

P6 (all) Destruction LI Unwrapped waste

/Trash with liquids

Gravitation 15 min 134°C slow/fast

RM

P7 (

all)

Liquids ST

Liquids Gravitation 20 min 121°C Slow

P8 (B/V)

Liquids ST

Liquids Gravitation 20 min 121°C Slow

P8 (all without B u.V)

Liquids RM

Liquids Gravitation 20 min 121°C Fast

P9 (B/V)

Liquids

ST

Liquids Gravitation 20 min 121°C Slow

P9 (M/MV)

Liquids RM

Liquids Gravitation 20 min 121°C Fast

P9

(MS/

MSV/MSL/MSLV)

Liquids RO

Liquids Gravitation 20 min 121°C Forced

P10 (B/V)

Liquids

ST

Liquids Gravitation 20 min 121°C Slow

P10

(M/MV/MS/MSV)

Liquids RM

Liquids Gravitation 20 min 121°C Fast

P10 (MSL/M

SLV)

Liquids RG

Liquids Gravitation 20 min 121°C Forced

Special

P11 – P20 Same like P1 Same like P1 like P1 like P1 like P1

P21 Bowie&Dick-Test Vacuum + steam

20/30/40kPa / 140kPa

3:30

min

134°C

P22 Vacuum test

Other manuals for Laboklav 55

1

This manual suits for next models

5

Table of contents

Other SHP Laboratory Equipment manuals