LWCC-M-10

MicroLWCC (WPI #LWCC-M-10) is a new fiber optic, low volume flow cell for UV/

VIS/NIR absorbance analysis.

Based on WPI’s established

liquid core waveguide tech-

nology, the analyte solution

functions as the core of a fluid

filled light waveguide. Wetted

parts in the sample cell light

path are PEEK, fused silica and

Teflon. Optical fibers are used

to transport light to and from

the sample cell. The cell can be

used in biochemistry for DNA,

RNA and protein quantification,

colorimetric nutrient and trace

metal analysis, drug discovery

and dissolution testing, process

control and HPLC analysis.

ASSEMBLY

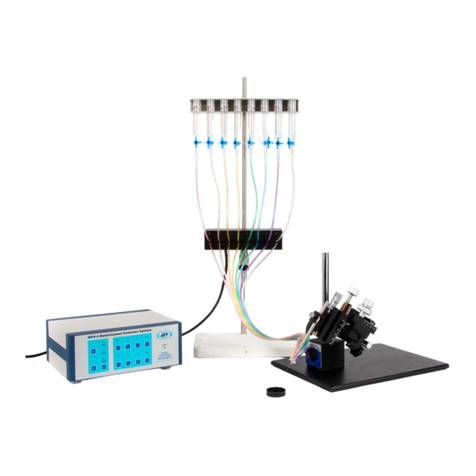

Light source and detector can be connected to the LWCC-M-10 via two SMA-termi-

nated fiber optic cables with a core diameter of 600µm. The fiber optic connections

are interchangeable in that either connector can be used to connect to the light

source or to the spectrometer.

As with the fiber optic connectors, the liquid ports are also interchangeable. It makes

no difference which port is set-up as inflow and which port serves as the outflow.

However, if an in-line filter is to be installed, it should be connected on the input side

of the liquid flow path. Use standard HPLC type 10-32 coned PEEK 1/16th tubing fit-

tings (WPI #800827) to make connections to the pump and waste receptacle.

OPERATING INSTRUCTIONS

The following procedures can be used to verify the transmission, noise and refractive

index of your LWCC-M.

Transmission Verification

1. Connect one 600mm diameter fiber optic assembly to a light source and one

600mm diameter fiber optic assembly to the detector.

2. Use an SMA bulkhead adapter (WPI #13395) to butt-couple the fibers. This is the

reference for the measurement of transmission.

3. Remove the SMA bulkhead adapter and insert the LWCC-M.

4. Record the percent transmission. Values for the 254nm, 280nm and 550nm

should exceed 40%.

Noise Determination

Noise is determined using the ASTME685-93 standard as reapproved in 2000. Use

methanol as the solvent at a flow rate of 1.0mL/min. Using the WPI test setup, noise

values are below 35uAU. See www.astm.org/Standards/E685.htm to obtain a copy of

the standards document.

Refractive Index

The refractive index between methanol and cyclohexane is measured using a flow

rate of 3.0mL/min. Because of the immiscibility of the solvents, ethanol is used be-

tween the solvents to prevent unwanted interaction between methanol and clyclohex-

ane. An RI value between zero and seven is acceptable at the 280nm wavelength.

MAINTENANCE

Cleaning

With normal use, the LWCC-M-10 will rarely need cleaning. If measurement results

diminish, clean your LWCC-M-10. Use the cleaning kit for liquid waveguides (WPI

#501609).

1. Connect the exit tubing (for example, silicon or equivalent) from the fluid output

of the LWCC-M-10 to a waste container.

2. Rinse the cell thoroughly using Ultra Pure water. Obtain a new reference intensity

and take a baseline absorbance reading.

3. Inject 1cc “Cleaning Solution 1” into the LWCC-M-10 fluid input port.

4. Inject 1cc “Methanol Solution 2” into the fluid input port of the LWCC-M-10.

5. Inject 1cc “HCl Solution 3” into the fluid input port of the LWCC-M-10.

6. Flush out the cleaning solutions with distilled, Ultra Pure, reverse osmosis or

equivalent quality water and take an absorbance reading.

7. Repeat these cleaning cycles until a stable absorbance signal can be obtained.

8. If the UV readings are still low after cleaning, swab the fiber optic surfaces of the

sample cell with a fiber optic Q-tip dipped in isopropyl alcohol.

Storage

To store the instrument, clean the LWCC-M-10, and then seal the fluid input and

output ports using either the caps provided or an alternative.

SPECIFICATIONS

LWCC-M-10

Optical pathlength 10mm

Internal volume 2.4mL

Wavelength Range 200–1000nm

Fiber Connection (SMA) 600µm

Transmission at 254nm* > 40%

Liquid Connection 10-32 coned port for 1/16th tubing

Maximum Pressure 1000 PSI

Refractive Index at 280nm** < 7 mAU

Wetted materials PEEK, Fused Silica, Teflon

* Reference: Two 600µm fibers, butt-coupled

** Measured using ASTM E 685 - 93

WPI U.S. Patents: 5,444,807; 5,570,447; 5,604,587; 6,603,556; 6,385,380.

Light Input

600µm SMA Light Output

600µm SMA

Fluid Input

800827 Connector

Fluid Output

800827 Connector

1.00"

1.38”

Fig. 1–LWCC-M-10 showing connections.