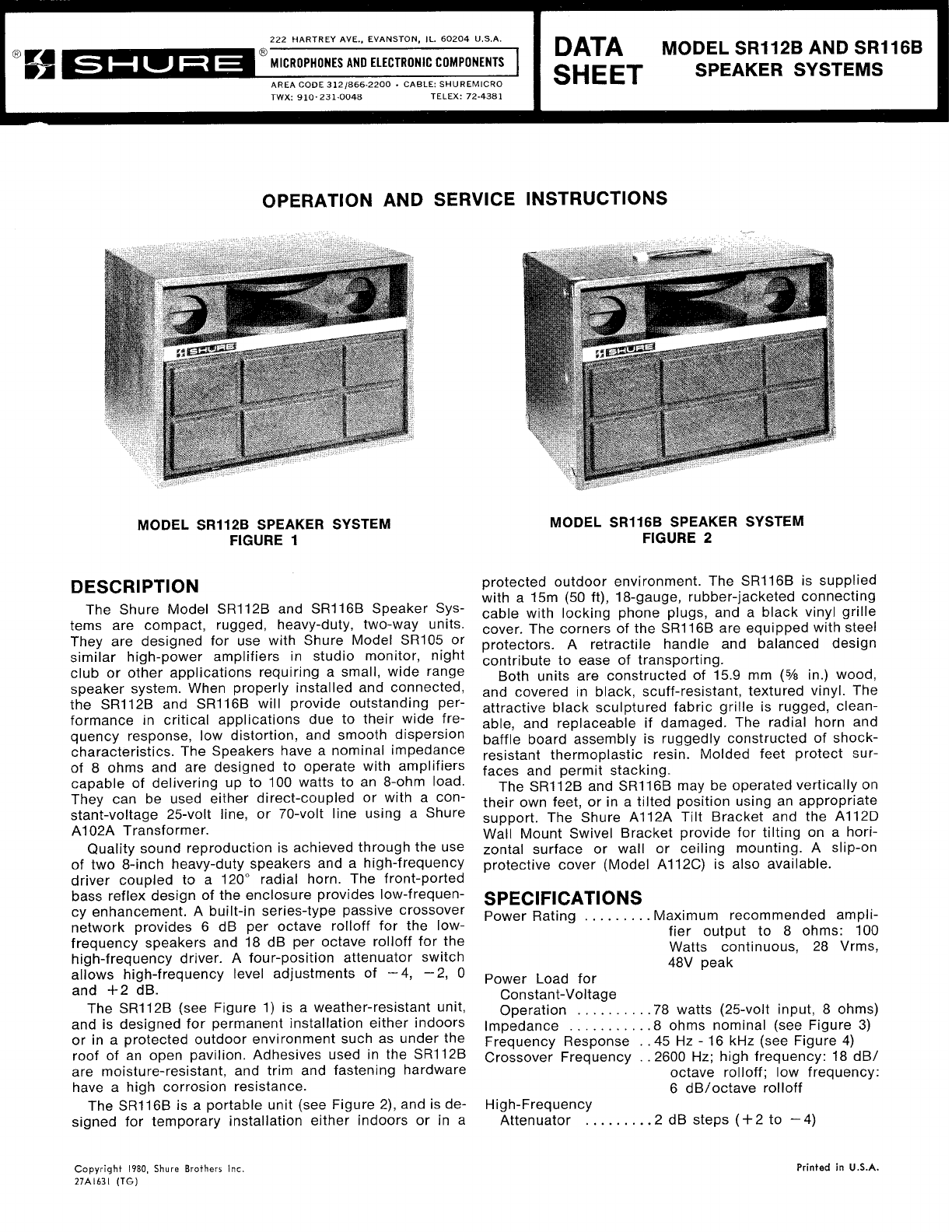

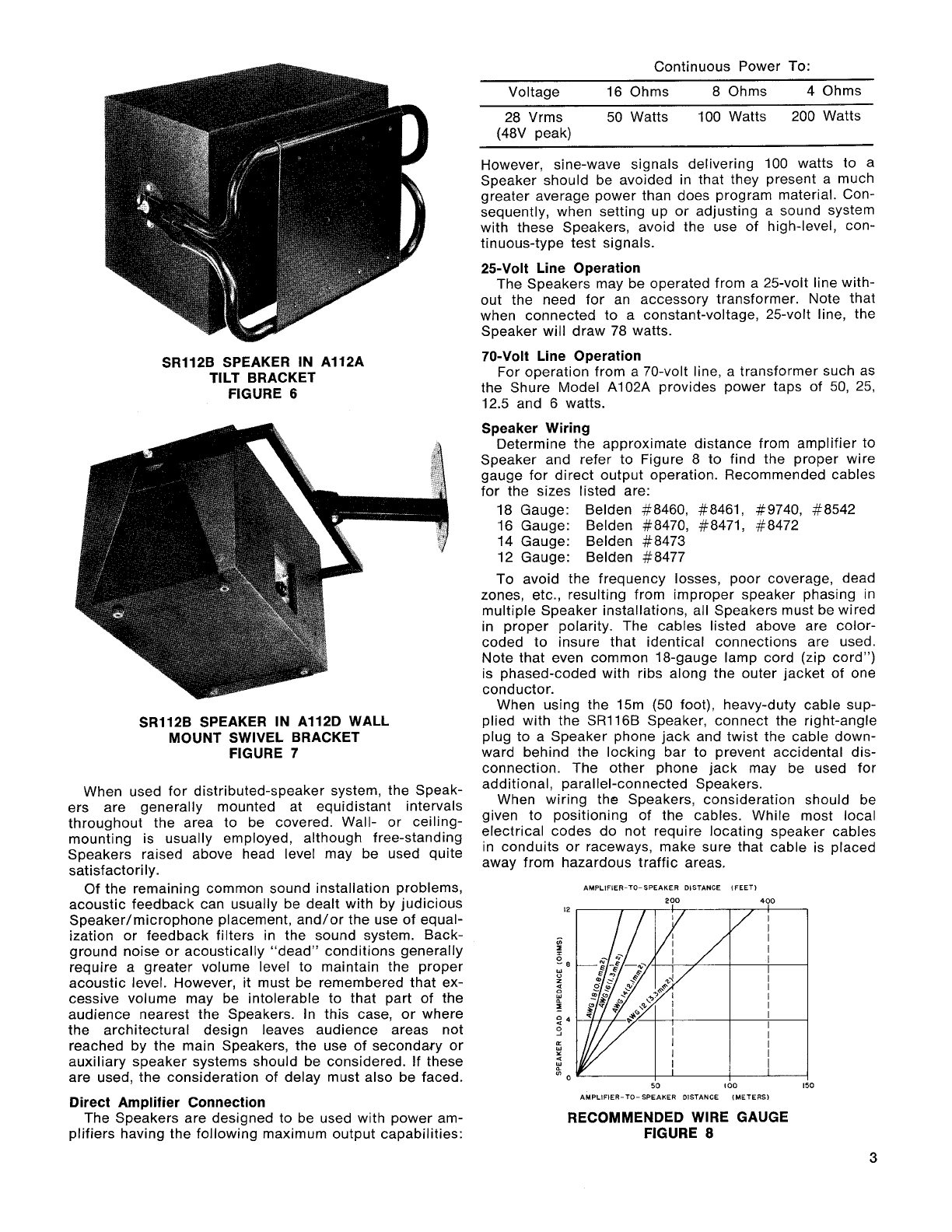

Installation

The SRll2B and SR116B may beoperated free-standing,

either on their own feet or on a Shure A112A Tilt Bracket,

or suspended on a wall or ceiling using an A112A or an

A112D Wall Mount Swivel Bracket. In positioning the

Speakers for optimum sound coverage, care must be

taken to locate the Speakers away from areas where

they may interfere with the movement of performers,

audience, curtains or stage sets.

If the Speaker is to be used at low power on a con-

stant-voltage, 70-volt system, a Shure Model A102A

70-Volt Transformer must be connected between the am-

plifier and Speaker. The transformer should be located as

close to the Speaker as possible; therefore the optimum

mounting location just above the connector panel should

be used. Mounting of the transformer adds approximately

82 mm (3Y4 in.) to the total depth of the Speaker.

Checking Sound Coverage

When the Speakers, amplifier and other equipment

have been installed and connected, apply a fairly con-

stant level signal to the system (preferably program

material) and walk around the audience area. Listen for

a smooth, even output from the Speakers, with minimal

differences in volume and tone, and no distortion or

"dead spots." A dead spot-for audio purposes, an

audience area where no sound is heard, or where the

sound level is appreciably lower-may mean that the

Speakers are not covering that area, or that the speaker

wires are connected out-of-phase. Proper phasing may be

readily determined by checking the connections on each

Speaker, but inadequate coverage generally requires re-

positioning the Speakers. The dead area should be care-

fully examined to determine that the problem can be

corrected without resorting to auxiliary speakers.

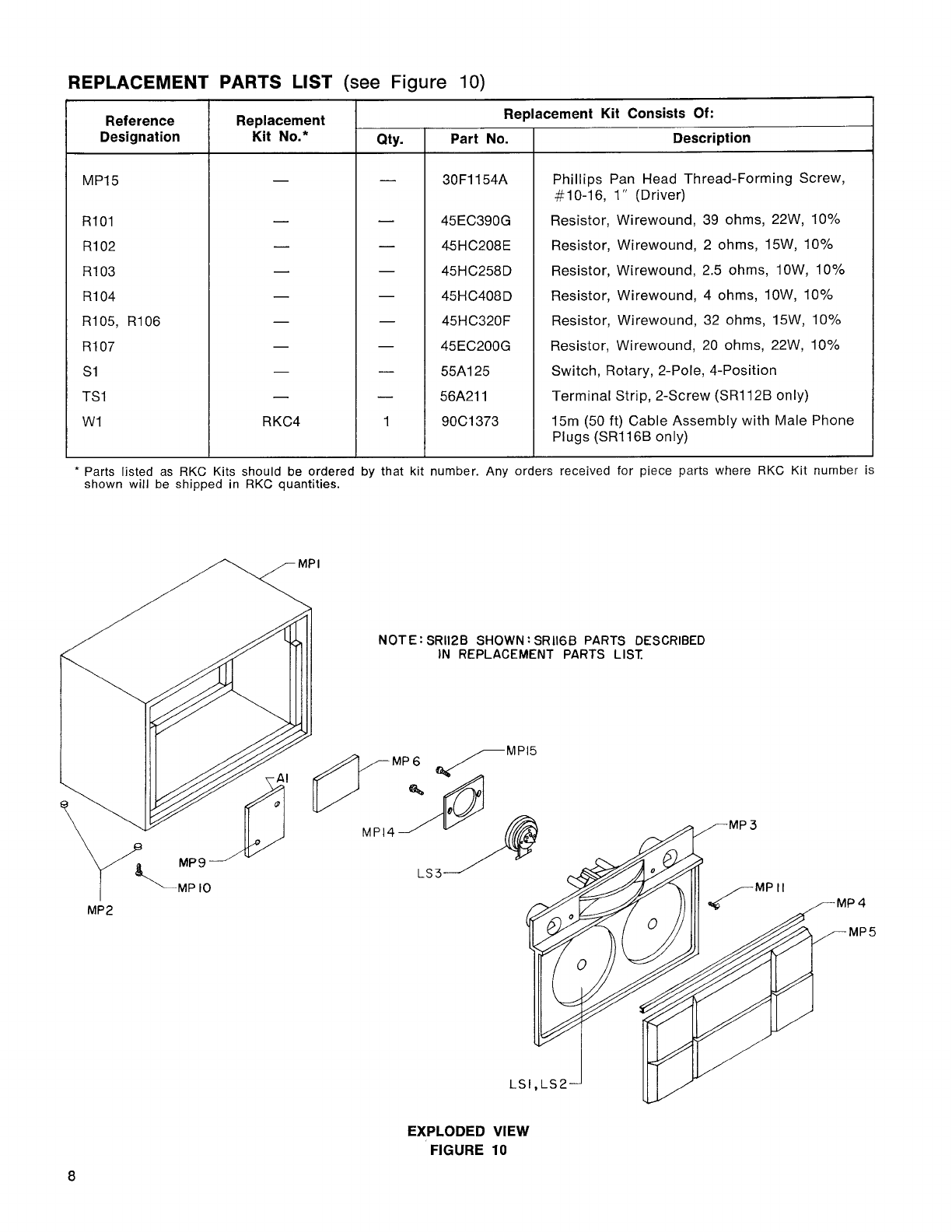

SERVICE INSTRUCTIONS

Speaker Servicing

1. Disconnect speaker cables from phone jacks or

terminal strip.

2. Using an ohmmeter, measure the resistance be-

tween the plus

(+)

and minus

(-)

terminal screws

or tip and sleeve of phone jack. The dc resistance

should be

5.5

to

7

ohms.

3. To gain access to the individual speakers, remove

the grille by pulling the two cloth tabs at the bot-

tom of the grille. Remove the screws securing the

horn/baffle board assembly. Remove the horn/

baffle board assembly, taking care not to stress

the wiring.

4.

Using an ohmmeter, measure the resistance of each

speaker voice coil. A clicking sound will be made

by a "good" speaker when an ohmmeter is con-

nected or disconnected. Note that the resistance of

each 8-inch speaker cannot be measured without

disconnecting one lead connecting the two speak-

ers. Each 8-inch speaker should measure between

11 and 13 ohms. With its leads disconnected, the

high-frequency driver should measure between 6.7

and 7.7 ohms.

5.

If the above tests do not locate the problem unit,

apply a small ac voltage from an oscillator and am-

plifier to each speaker individually (approximately

4V,

50 Hz to 5 kHz for 8-inch speakers; approxi-

mately 2V, 3 kHz to

15

kHz for high-frequency

speakers).

WARNING

Sound pressure levels generated by this test may

be damaging to your hearing. Aim speakers away

from listeners and toward sound-absorbent material

(curtains, blanket, etc.). Carefully adjust test signal

amplitude to avoid unnecessarily high sound pres-

sure levels for prolonged periods.

As the test signal frequency is varied, any erratic

buzzes or rattles indicate possible failure.

6. Reconnect, replace and tighten the 8-inch speak-

ers. Reconnect the high-frequency driver and re-

place the horn/baffle board and grille. Tighten all

hardware to avoid rattles.

High-Frequency Driver Replacement

To replace the high-frequency driver, follow these steps:

1. Remove grille assembly and horn/baffle board as

described in Speaker Servicing.

2. Remove leads from driver terminals. Note color

coding of speaker wires.

3. For earlier production units, remove three 6-32 x

1

Ye

in. screws securing high-frequency driver to

horn/baffle board. For later production units, re-

move two 10-16 x 1 in. screws holding driver

mounting plate to horn/baffle board. Remove driver

mounting plate and driver from horn/baffle board.

4.

Replace driver diaphragm and voice coil assembly

as described in High-Frequency Diaphragm and

Coil Replacement instruction sheet.

5.

For earlier production units, carefully place repaired

or new high-frequency driver in position over horn/

baffle/board, taking care to line up holes in driver

over holes in horn/baffle board. Be sure that driver

terminals are positioned downward (toward low-

frequency speakers). Replace three 6-32 x 1% in.

screws, and tighten high-frequency driver assembly.

6. For later production units, carefully place repaired

or new high-frequency driver in position over horn/

baffle board with driver terminals downward (toward

low-frequency speakers). Position driver mounting

plate over driver, lining up holes in mounting plate

over threaded holes in horn/baffle board. Replace

two 10-16

x

1 in. screws, and tighten securely.

7. Replace removed driver leads. Note polarity mark-

ing on driver.

8. ~ssemblehorn/baffle board and grille to enclo-

?

and fasten securely to avoid rattles.

Nameplate

Should it become necessary to replace or re-fasten the

front-panel nameplate, be sure to use a heavy-duty

weather-resistant adhesive. Goodyear PLIOBOND or

equivalent cement is recommended.

ACCESSORIES

The following optional accessories are available for use

with SR112B and SRl16B Speakers:

A112A Tilt Bracket permits 360" rotation of the Speaker

about a horizontal axis. Heavy-duty tubular steel with a

flat steel baseplate that provides stable floor or shelf for