WARNING: “Risk of electrical shock.” The pump is supplied with a grounding connector and grounding-type

attachment plug. To reduce the risk of electrical shock, be certain that it is connected only to a

properly grounded, grounding-type receptacle. To prevent electrical shock, disconnect power

before initiating any work. In the case of pump failure, the motor housing and/or the pumped fluid

may carry high voltage to components normally considered safe.

WARNING: Never pressurize the accumulator tank higher than its maximum operating pressure of 117 psi [8

bar] limit. Never expose the tank to higher than 120ºF [49ºC] ambient temperature environment.

CAUTION: DO NOT adjust the pump pressure switch setting. Switch setting will not significantly alter flow

rate or pressure. Improper adjustment may cause severe overload or premature failure, not covered

under warranty.

CAUTION: DO NOT operate the pump at pressures, which cause the motor to exceed the amperes rating

indicated on the nameplate. The pump is equipped with thermal breakers to interrupt operation

due to excessive heat. Once the temperature of the motor is within proper limits it will

automatically reset, and the pump will start operation without warning. The motor is equipped

with an integral non-serviceable fuse. Pumps which have an “open” fuse are not covered under

the limited warranty.

ACCUMULATOR STORAGE/FLOW-RATES

SHURflo Water Boost Systems are for applications when low, fluctuating, or no water pressure exists. The

pump and accumulator maintain consistent water pressure to a source (for a given duration) as long as incoming

water is sufficient. Depending upon the Water Boost System model, support of up to 4 non-carbonated valves in

moderate volume accounts is achievable. The Water Boost Systems may be used to supply water to a carbonator

for back-up, during short periods of insufficient water pressure. The pump pressurizes the accumulator to 90

psi. [6 bar]. Consult the flowchart for projected length of flow and/or back-up. The pump is NSF, UL and C-UL

listed.

INSTALLATION

WARNING: DO NOT pre-charge the accumulator with CO2. In the event of failure carbonated water will react

with brass components in system equipment. Use clean, dry air or nitrogen.

CAUTION: a qualified electrician, in accordance with all local electrical codes should perform all electrical

outlet (receptacle) wiring connections. Circuit protection is dependent on the individual application

requirements. Failure to provide proper circuit protection may result in a motor failure, which is not covered

under warranty.

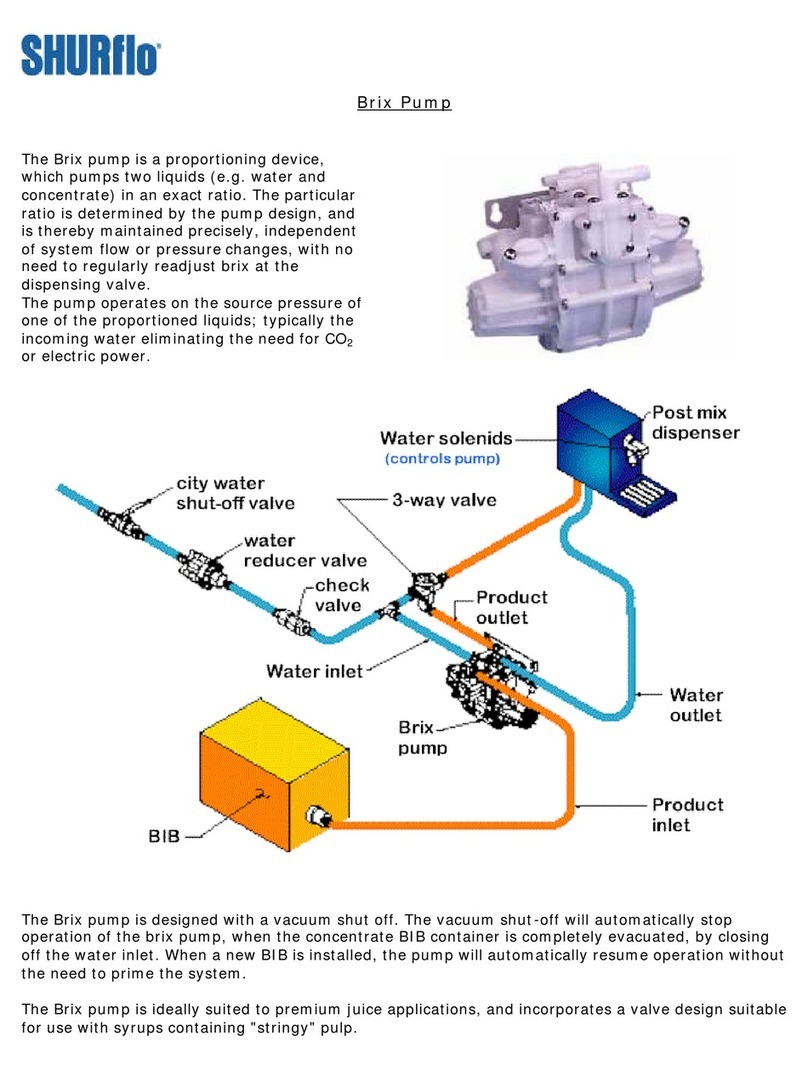

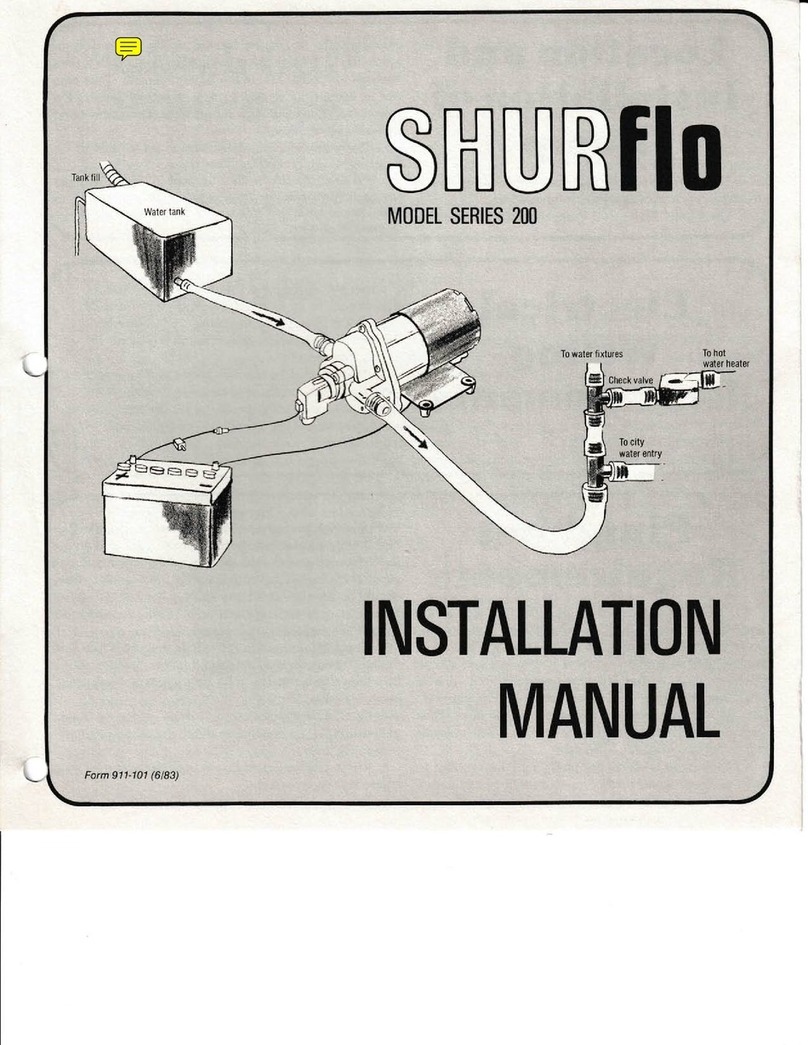

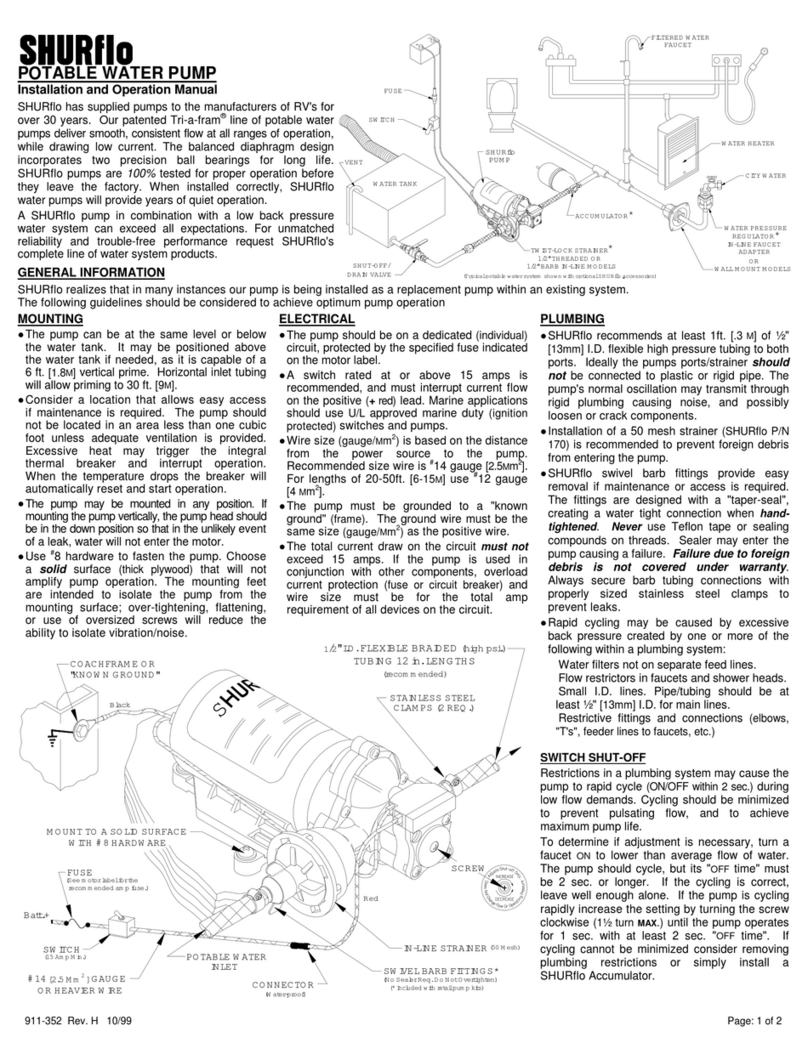

1. The water booster system is to be installed between the water source and non-carbonated valve(s) and/or

carbonator (see Installation figure in the following page). Turn off city water supply before installation.

Note 1: Depending upon your application, it is recommended that a SHURflo 50 psi water pressure reducer

valve be installed after the filter system before the line is teed just prior to the carbonator and the non-carb

valves.

2. Secure water booster to a solid surface. It may be mounted vertical or horizontal near the city water entry; 2

gal. water booster will fit under most drop-in dispenser cabinet. Be certain the pre-charge valve is accessible

for checking/filling the tank.

* Draw down volume varies with tank pre-charge, pump operating pressure and city water pressure. Specs

reflect tests at 50 psi [3.4 bar] pre-charge w/20 psi [1.3 bar] city water pressure.

WATER BOOST SYSTEM LIMITED WARRANTY

SHURflo Water Boost Systems are warranted to be free of defects in material and workmanship under normal

use, for a period of one (1) year from the date of manufacture, or one (1) year of use, with proof of purchase.

This limited warranty will not exceed two (2) years, in any event.

The limited warranty will not apply to Water Boost Systems that were improperly installed, misapplied, or

incompatible with fluids or components not manufactured by SHURflo. Water Boost System failure due to

foreign debris is not covered under the terms of this limited warranty. SHURflo will not warrant any Water

Boost System which is damaged or modified outside the SHURflo factory.

Returns are to be shipped postage prepaid to either service center; SHURflo Cypres, CA or Elkhart, IN.

SHURflo shall not be liable for freight damage incurred during shipping, package returns carefully.

For complete warranty details consult S/B #1049.