SHURflo

RV

FRESH

WATER

PUMP

Installation

andOperationManual

Shurflo's

patented

RVFreshWater

Pumps

fordrinking

water

were

developed

to

deliver

smooth,

consistent

flow

atall

ranges

of

operation,

while

drawing

lowcurrent.The

balanced

diaphragm

design

incorporates

precision

ball

bearings

for

long

life.

Each

motor

is

equipped

with

an

integral

thermalbreaker

andall

units

areCEapproved.RV

fresh

water

pumps

are

enclosed

to

prevent

incidental

moisture

from

entering;

however,

they

arenot

intended

for

envi-

ronments

where

splashed

water

is

present.

When

installed

correctly,

RVFreshWater

Pumps

provide

years

of

quiet

operation.

General

Information

Sluirflo

water

pumps

meet

the essential health and

safety

requirements and are in conformity

with

the EU EMC directive 89/S36/FEC as specified in EN 55014 (1993).

Shurflo realizes

that

in

many

instances our

pump

is being installed as a replacement

pump

within an existing

system.

The following guidelines should be considered to

achieve optimum

pump

operation.

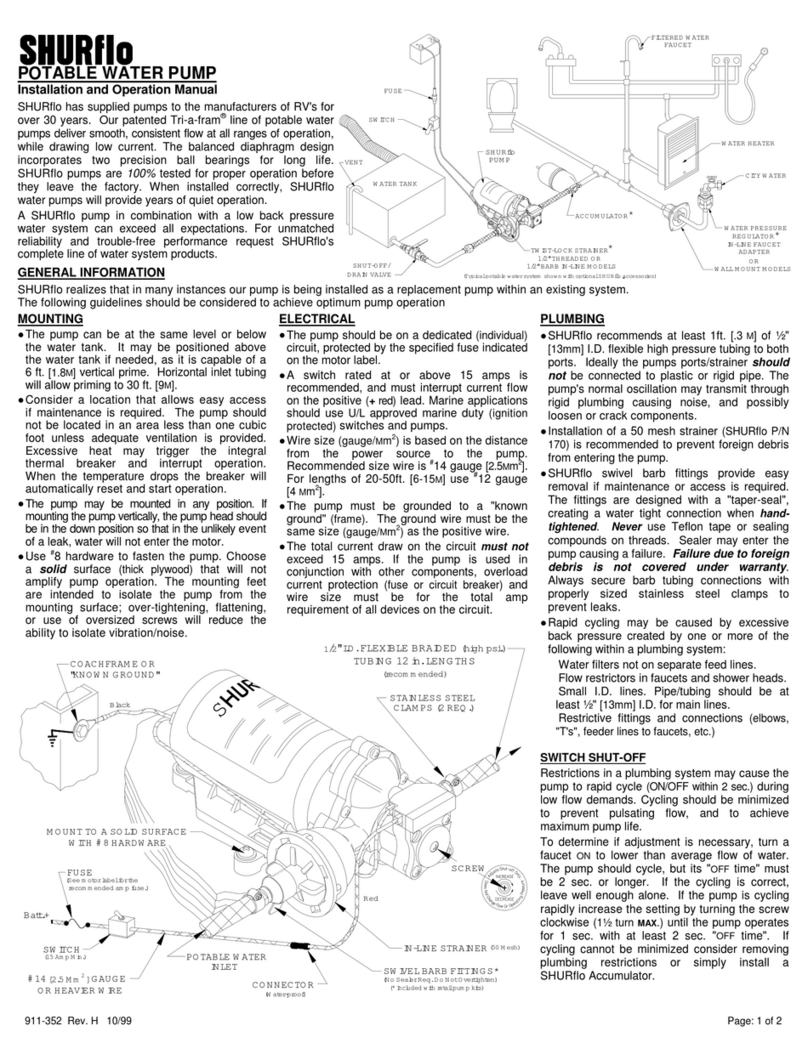

Mounting

The

pumpcanbeatthesame

level

orbelowthewatertank.Itmaybepositioned

abovethewatertankifneeded,asitiscapableora 6 ft(1.8m)

vertical

prime.

Horizontal

inlettubing

will

allow

priming

to30ft.(9m).

Consider

a dry

location

that

allowseasyaccessifmaintenanceisrequired.The

pumpshouldnotbelocatedinanareaoflessthanonecubicfoot(0.03m)unless

adequate

ventilationisprovided.Excessive

heat

maytriggertheintegralthermal

breakerandinterruptoperation.

When

thetemperaturedrops,thebreaker

will

auto-

matically

reset

and

start

theoperation.Thepumpmaybemountedinanyposition

If

mountingthepump

vertically,

thepumpheadshouldbeinthedownpositionso

that

inthe

unlikely

eventofa leak,water

will

notenterthemotor.

Use

No.8stainlesssteelhardwaretofastenthepump.Choosea

solid

surface(thic

plywood)

that

will

not

amplify

pumpoperation.Themounting

feel

areintendedto

isolate

thepump

from

themountingsurface;overtightening,flattening,oruseof

oversized

screws

will

reducethe

ability

toisolatevibration/noise.

Electrical

The

pumpshouldbeona dedicated

(individual)

circuit

protectedbythe

specified

fuseasindicatedonthemotor

label.

A

switch

ratedatorabove15ampsisrecommended,andmustinterruptcurrent

flow

onthepositive(+red)lead.

The

pumpmustbegroundedtoanearth(battery).Theearthwiremustbethesame

size

(gauge/mm2)asthepositive

wire.

Wire

size(gauge/mm*)isbasedonthedistance

from

thepowersourcetothepum|

The

minimum

recommendedsizewireisNo.14gauge(2.5mm1).Lengthsof20-

50ft.

(6-15m)useNo.12gauge(4mm).

The

totalcurrentdrawonthe

circuit

mustnotexceed15amps.Ifthepumpisusedii

conjunction

with

othercomponents,overloadcurrentprotection(fuseor

circuit

breal

er)andwiresizemustbeforthetotalamprequirementofalldevicesonthe

circuit.

Plumbing

Shurflo

recommendsatleast1 ft.(0.3m)of1/2"(13mm)I.D.

flexible

high

pressure

tubing

tobothports.Ideallythepump'sports/strainer

should

not beconnectedto

plastic

or

rigid

pipe.Thepump'snormal

oscillation

maytransmitthrough

rigid

plumbing

causingnoise,andpossiblyloosenorcrackcomponents.

Installation

ofa 50meshstrainerisrecommendedtopreventforeigndebris

from

enteringthepump.

The

Shurflo

In-Line

Strainer(1/Band2/B)hasa

twist-lock

feature

allowing

simple

cleaning

whenplumbed

with

flexible

tubing.

Shurflo

swivel

barbfittingsprovideeasyremovalifmaintenanceoraccessis

required.

Thefittingsaredesigned

with

a "taper-seal",creatingwatertightconnec-

tion

whenhand

tightened.

Always

securebarbtubingconnections

with

properly

sized

stainlesssteelclampstopreventleaks.Never use

Teflon

tape

orsealing

com-

poundsonthreads.Sealermayenterthepumpcausinga

failure.

Failure

due to foi

eign

debris is not covered

under

warranty.

Rapid

cycling

maybecausedbyexcessivebackpressurecreatedbyoneormoreo

the

following

within

a plumbingsystem:

•

Waterfiltersandpurifiersnoton

separate

feed

lines.

•

Flow

restrictorsin

taps

andshowerheads.

•

Small

I.D.

lines.

Pipe/tubingshouldbeatleast1/2"(13mm)I.D.formain

lines.

•

Restrictivefittingsandconnections(elbows,

"T's",

feederlinestolaps,etc.)

Switch

Shut-Off

Restrictions

ina plumbingsystemmaycausethepumptorapid

cycle

(ON/OFF

within

2 sec.)duringlow

flow

demands.

Cycling

shouldbe

minimized

toprevent

pulsating

flow,

andtoachievemaximumpump

life.

To

determineifadjustmentisnecessary,turntapontolowerthanaverage

flow

of

water.Thepumpshould

cycle,

butits"OFFtime"mustbe2 sec.orlonger.Ifthe

cycling

iscorrect,leave

well

enoughalone.Ifthepumpis

cycling

rapidly

increase

thesettingbyturningthescrew

clockwise

(11/2turn

MAX.)

until

thepumpoper-

ates

for1 sec.

with

atleast 2 sec."OFFtime"'.If

cycling

cannotbe

minimized

con-

sider

removingplumbingrestrictionsor

simply

install

a

Shurflo

Accumulator.

Sanitizing

Fresh

watersystemsrequireperiodicmaintenancetodelivera consistent

flow

of

fresh

water.Dependingontheuseandtheenvironmentthesystemissubjectto,san-

itizing

isrecommendedpriortostoringandbeforeusingthewatersystemaftera

period

ofstorage.Systems

with

newcomponents,orones

that

havebeensubjected

tocontamination,shouldalsobedisinfectedas

follows:

1.Useoneofthe

following

methodstodeterminetheamountofcommonhouse-

hold

bleachneededtosanitizethelank.

A)

Multiply

"gallons(UK)orlankcapacity"by0.156;theresultisouncesof

bleach

neededtosanitizethetank.

B)

Multiply

"litresoflankcapacity"by1;theresultisthe

millililres

ofbleach

neededtosanitizethetank.

2.Mixintosolutiontheproperamountofbleach

within

a containerofwater.

3.Pourthesolution(water/bleach)intothetankand

fill

thetank

with

freshwater.

4.

Openalllaps(HOT&

COLD)

allowing

thewatertorun

until

thedistinctodour

of

chlorineisdetected.•»

5.Thestandardsolutionmusthavefour(4)hoursofcontact

lime

todisinfect

com-

pletely.

Doubling

thesolutionconcentrationallowsforcontact

lime

of(1)hour.

6.

When

thecontacttimeiscompleted,drainthetank.

Refill

with

freshwaterand

purgetheplumbingofall

sanitizing

solution.

NOTE:

The

sanitizing

procedureoutlinedaboveisinconformance

with

the

approved

proceduresofthe

U.S.

Public

Health

Service.

:~'MD

ENGLISH