9

Maintenance

Make certain

that the unit is

disconnected from the power source before

attempting to service or remove any com-

ponents!

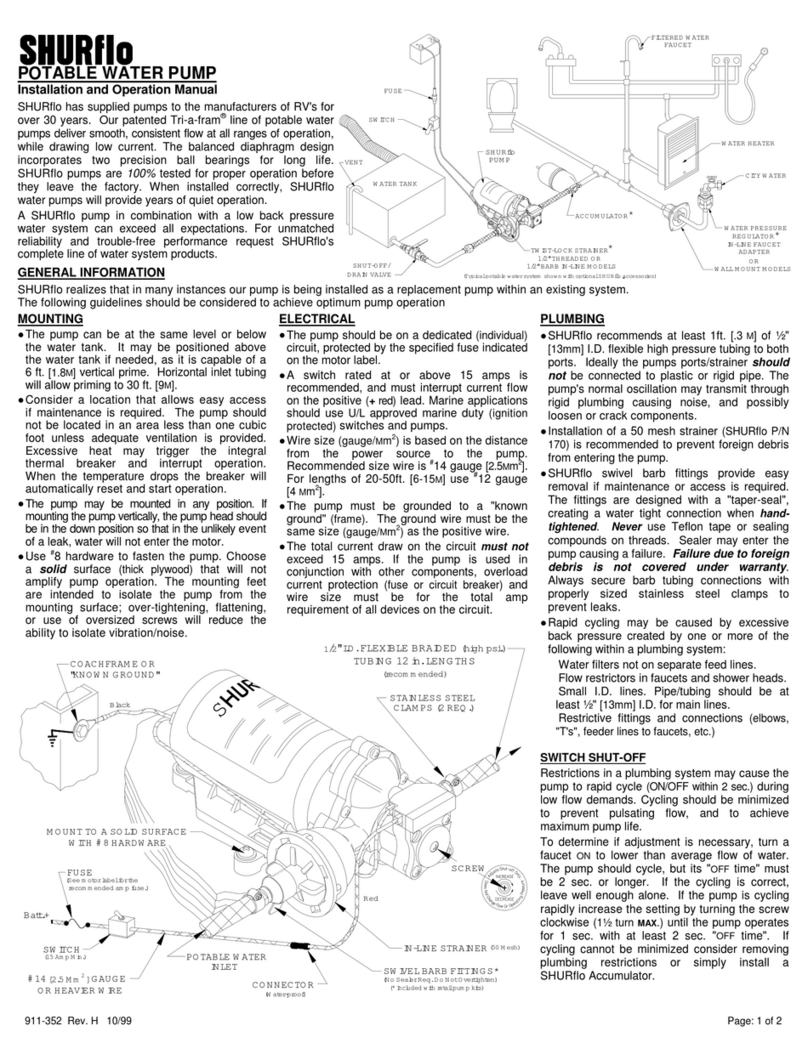

REMOVAL OF OLD SEAL ASSEMBLY

Should the mechanical seal (Ref. No. 5)

require repair, proceed as follows and

refer to Figures No. 2 thru 7.

IMPORTANT: Always replace both the

seal seat and seal as an assembly to

ensure proper mating of components!

1. Remove bolts (Ref. No. 12) connect-

ing the casing housing (Ref. No. 9)

to the body (Ref. No. 4).

2. Remove the casing housing (Ref.

No. 9).

Care should be taken

not to pinch or

”shave” the o-ring

gasket (Ref. No. 8) between the body and

the casing housing.

3. Remove the impeller (Ref. No. 7).

NOTE: Pump shaft must be held in

place to remove impeller.

IMPORTANT: Care should be taken to

ensure that the same number and

thickness of shim washers (Ref. No. 6)

are replaced behind the impeller as was

removed. The shim washers are located

directly behind the impeller and become

loose as the impeller is removed.

4. The seal (part of Ref. No. 5) can

now be pulled from the shaft

(see Figure 4).

5. Remove the retaining ring (Ref. No. 1)

and press the shaft assembly (Ref.

No. 2) out of the body. Take care not

to damage the impeller threads.

6. Use a wooden dowel to push out the

seal seat (part of Ref. No. 5) from the

body (Ref. No. 4). (See Figure 5.)

INSTALLATION OF NEW SEAL ASSEMBLY

The precision

carbon/ceramic faces

on the mechanical seal are easily damaged.

Handle your repair seal carefully. Do not

touch the carbon/ceramic seal faces.

IMPORTANT: Be sure that shaft

shoulder does not damage carbon face.

1. Thoroughly clean all surfaces of the

seal seat cavity in body (Ref. No. 4).

2. Using a clean cloth, wipe the shaft

and shaft sleeve and make certain

that they are perfectly clean.

NOTE: Inspect the shaft for scratches

or spiral grooves. If they exist, replace

shaft assembly (Ref. No. 2).

3. Wet the rubber portion of the new

seal seat (part of Ref. No. 5) with a

light coating of soapy water. While

wearing clean gloves or using a

clean light rag, press seal seat

squarely into body recess (Ref. No.

4). Use the cardboard washer (usu-

ally supplied with new seal) to place

over the polished ceramic surface

and use a piece of pipe or dowel

rod to press in firmly but gently (See

figure 6). Avoid scratching the

ceramic face, usually white.

4. Dispose of cardboard washer.Check

again to see that ceramic surface is

free of dirt and all other foreign

particles and that it has not been

scratched or damaged.

5. Install the pump shaft assembly

(Ref. No. 2). Replace the retaining

ring (Ref. No. 1). Be careful not to

damage the seal seat when sliding

over the pump shaft.

6. Wet the inside rubber portion of

the new seal (part of Ref. No. 5)

with a light coating of soapy water.

Slide seal onto the pump shaft

with the precision sealing surface

(carbon) facing the seal seat

ceramic face (see Figure 7). This

completes seal installation.

NOTE: Ashort “run-in” period may be

necessary to provide completely

leakproof seal operation.

7. Screw impeller (Ref. No. 7) onto

shaft. To hold the shaft from

turning, clamp with a web wrench

to prevent marring the shaft. A

drop of removable thread lock

should be applied to the impeller

threads. Impeller should be torqued

to 15 to 18 ft-lbs. (180 to 210 in-

lbs.).

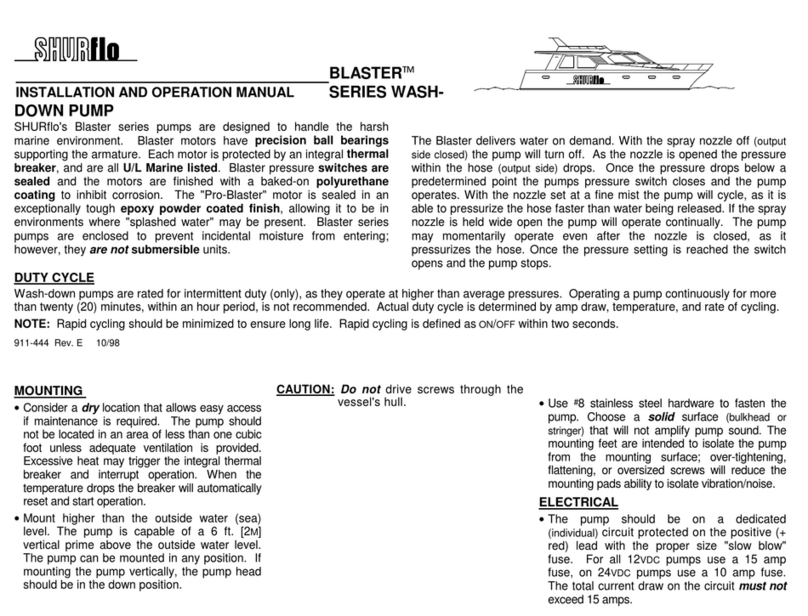

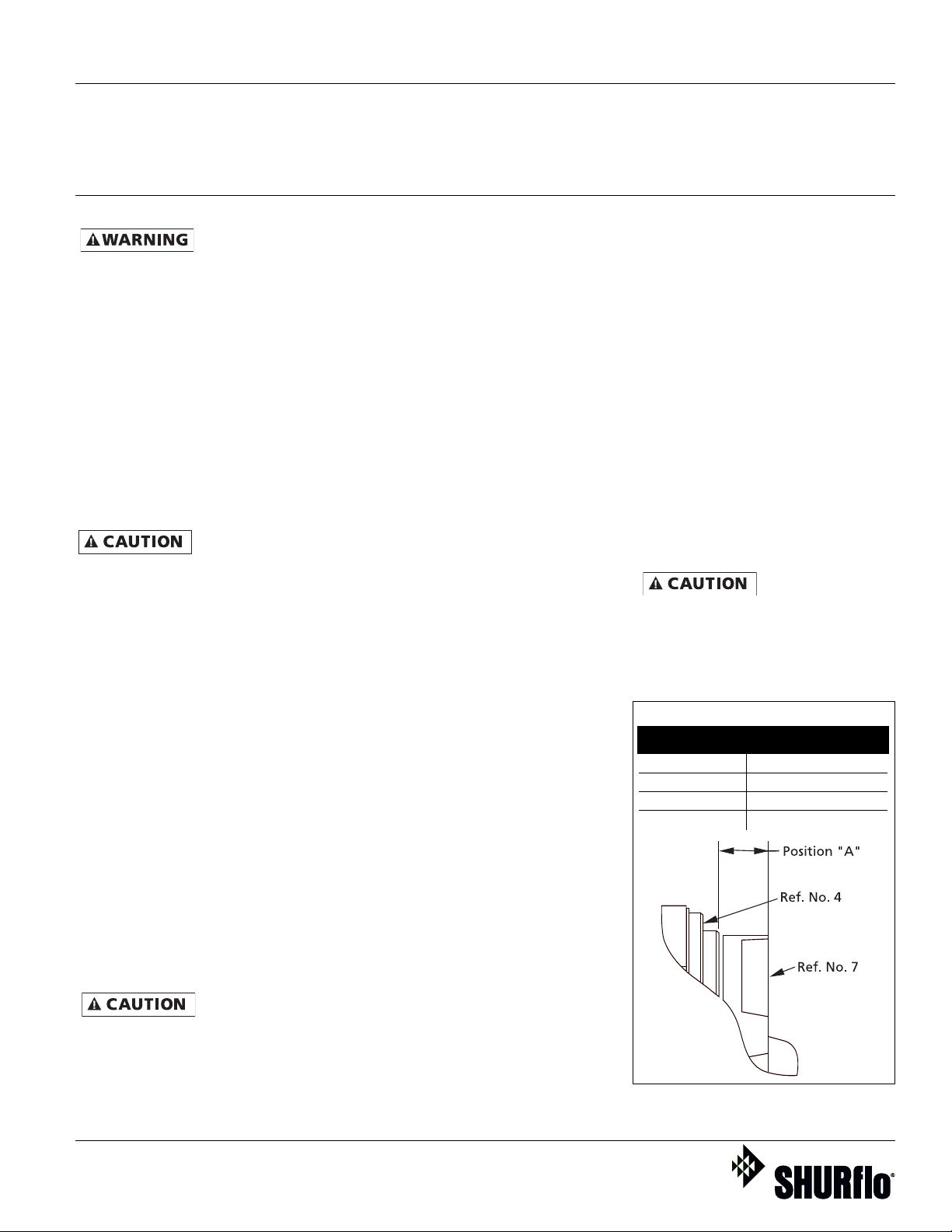

8. By replacing the original shims that

came with the pump, the impeller

height should be properly set. The

chart accompanying figure 3 gives

the correct body to impeller height

dimension for optimum pump

performance. After installing, check

if shaft turns freely by spinning

impeller. If rubbing or binding is

found, remove impeller and add a

shim (Ref. No. 6) to shaft, then

recheck. Repeat procedure until all

rubbing is eliminated.

9. Place o-ring (Ref. No. 8) on pump

body. Attach housing (Ref. No. 9)

using bolts (Ref. No. 12) being care-

ful not to pinch or “shave” o-ring.

As the housing is being tightened,

periodically spin impeller to check

for interference with housing.

Seal assembly will produce minor

drag when spinning drive shaft, but rub-

bing anywhere else must be eliminated!

Otherwise, damage to pump and/or motor

may occur.

SHURflo Operating Instructions, Performance,

Specifications and Parts Manual

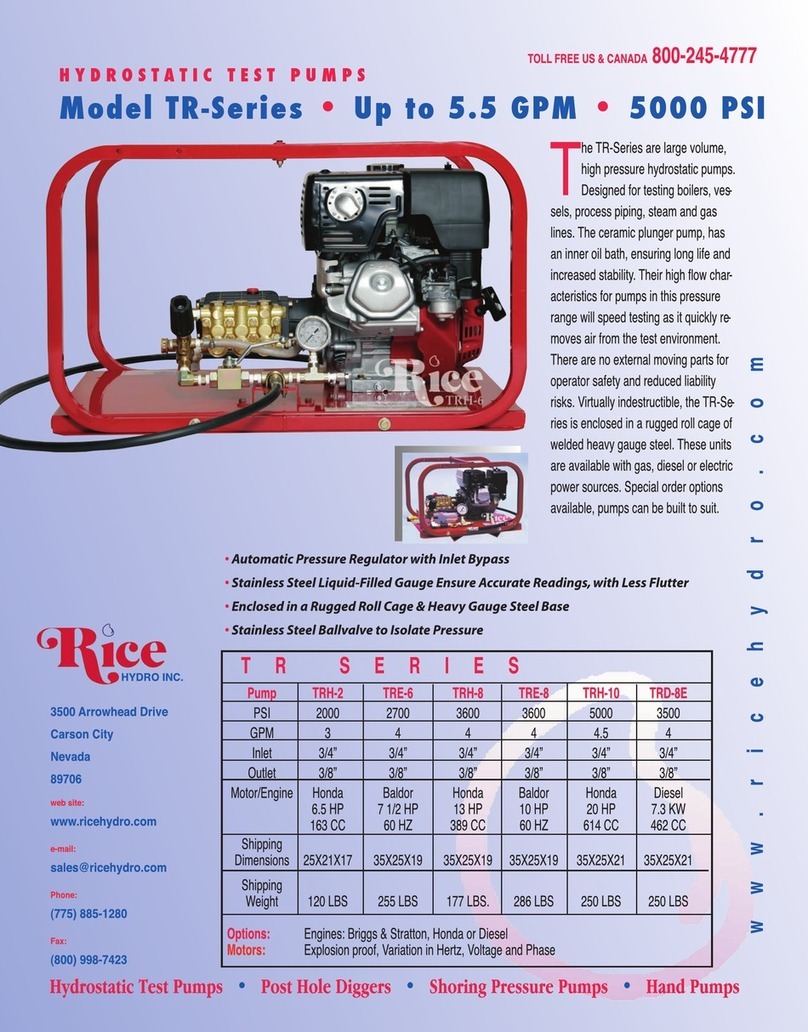

Impeller # Position “A”

1 0.634"-0.674"

3 0.742"-0.782"

5 0.874"-0.914"

7 0.840"-0.870"

Figure 3

IMPELLER CLEARANCE DIMENSIONS

316 Stainless Steel, Bronze and Cast Iron Models

Form L-4075 (12/09)