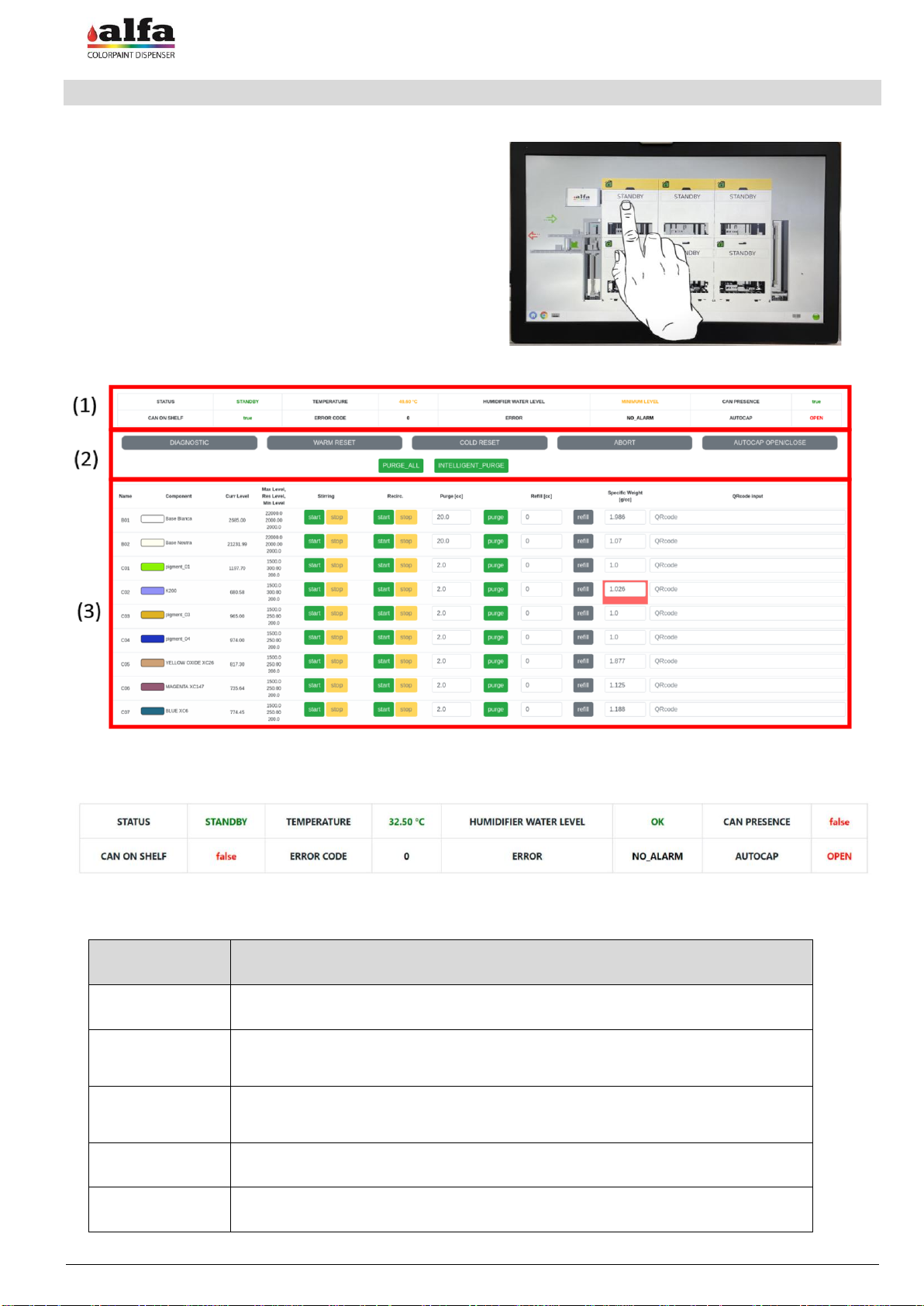

The bottom part (3) refers to the products circuits. Each line represents one circuit associated to a specific

product, while the columns contain parameters and controls of each circuit, as described in more details below.

The name of the circuit displayed as "CX" where X is a number from 01 to 16.

The name of the product contained in the circuit and its RGB.

The current level of the product contained in the circuit (expressed in cc).

MAX LEVEL

RES LEVEL

MIN LEVEL

The maximum level of product that can be contained in each circuit.

The product warning level (the circuit will continue to dispense).

The product minimum level (the circuit will stop to dispense.

Manual START and STOP stirring commands. When the stirring command is

given for a circuit, all the circuits of the same dispensing head are stirred because

the function is associated with the rotation of the turning table.

Manual START and STOP recirculation commands

Purge a single circuit with the amout set by default. The value can be manually

increased or decreased by modifying the value displayed in the box.

Refill a single circuit by the quanity expressed in cc. The command to rotate the

table will be executed to set ithe circuit to the refill position.

At each refill the operator can manually modify the specific weight of the product

and the circuit will dispense accordingly.

Scan the QRcode on the product’s package to complete all refill information

automatically (refill amount and specific weight).