Siamp VERSO BCM 800 Quick guide

GB

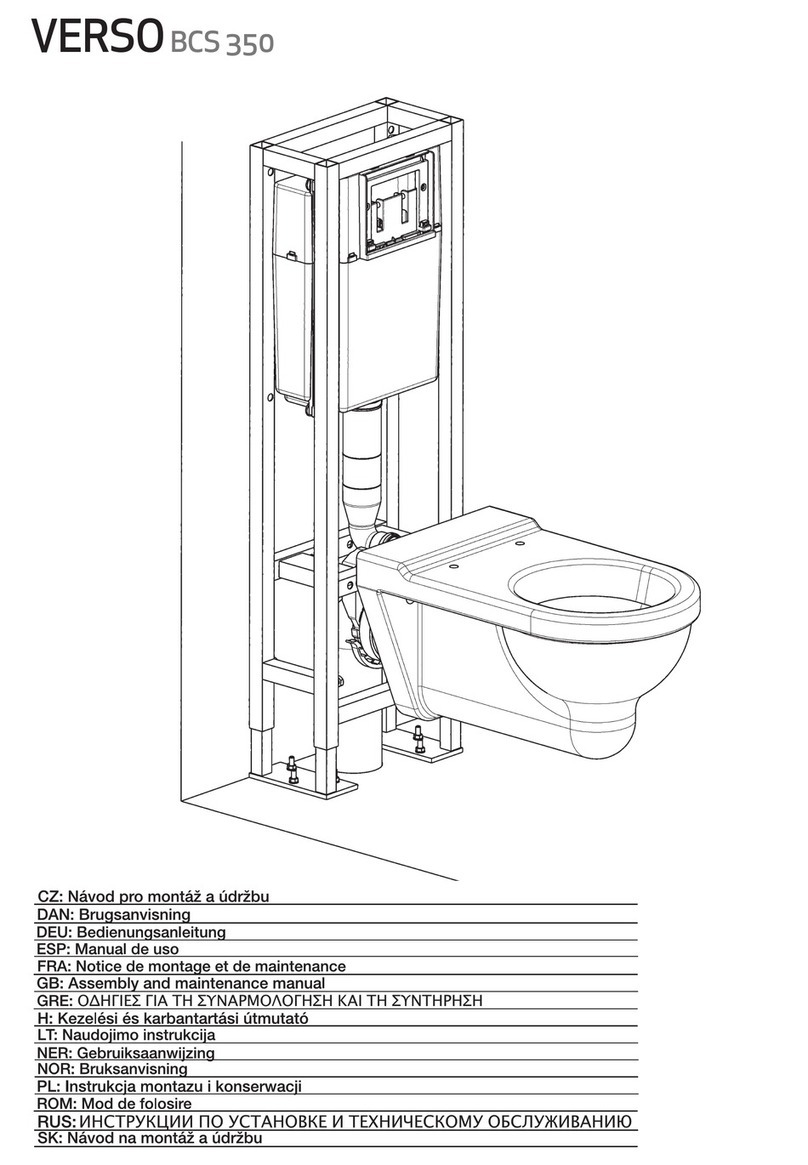

VERSO

ASSEMBLY AND MAINTENANCE MANUAL

2

a

c

d

e

h

i

j k

m

n

o

p

q

r

l

f

g

b

3

2

• Set of wrenches from 8 to 19 mm

• Hack saw

• Electric drill + bit dia 10 mm

• Spirit level

• Pencil + ruler

• Tape measure

• Hammer

• Screw driver

•‑ Keep the product package during

installation: there is a cutting template

on the back

•‑ Keep these instructions safety for any

maintenance operations.

Float valve

Shut‑off valve

Mechanism

PSE template

Supply bend

Supply bend cap

Toilet pipe cap

Supply sleeve

Bowl attaching kit

Flexible sheaths (x 2)

Pipe attaching collar

Toilet bowl attaching rods (x 2)

Setscrew (x 2)

Adjustable foot (x 2)

Screw plug (x 8)

Plug (x 8)

Toilet bowl stud attaching tab (x 2)

Attaching bracket

a

b

c

d

e

f

g

h

i

j

k

l

m

n

o

p

q

r

White double volume plate Ref. 31 1802‑10

Chrome double volume plate Ref. 31 1852‑10

Bent drain kit Ref. 92 4000‑07

Straight drain kit Ref. 92 4010‑07

Bent pipe

Frame

Straight pipe

Drain

sleeve

Manchon

d’évacuation

Screws (x 4)

Plate

4

➊ Wall fixing

I ‑ Frame depth = 180 to 245 mm

II ‑ Thickness of front cladding =

between 20 and 100 mm

III ‑ Thickness of top cladding =

between 25 and 60 mm

IV ‑ Height = Adjustable from 800

to 1000 mm

V ‑ Height of toilet bow

= 400 mm (finished floor level)

VI ‑ Maximum thickness of finished flooring

= 185 mm

I II

IV III

VI V

✓OK 0K

230mm

400mm

4

5

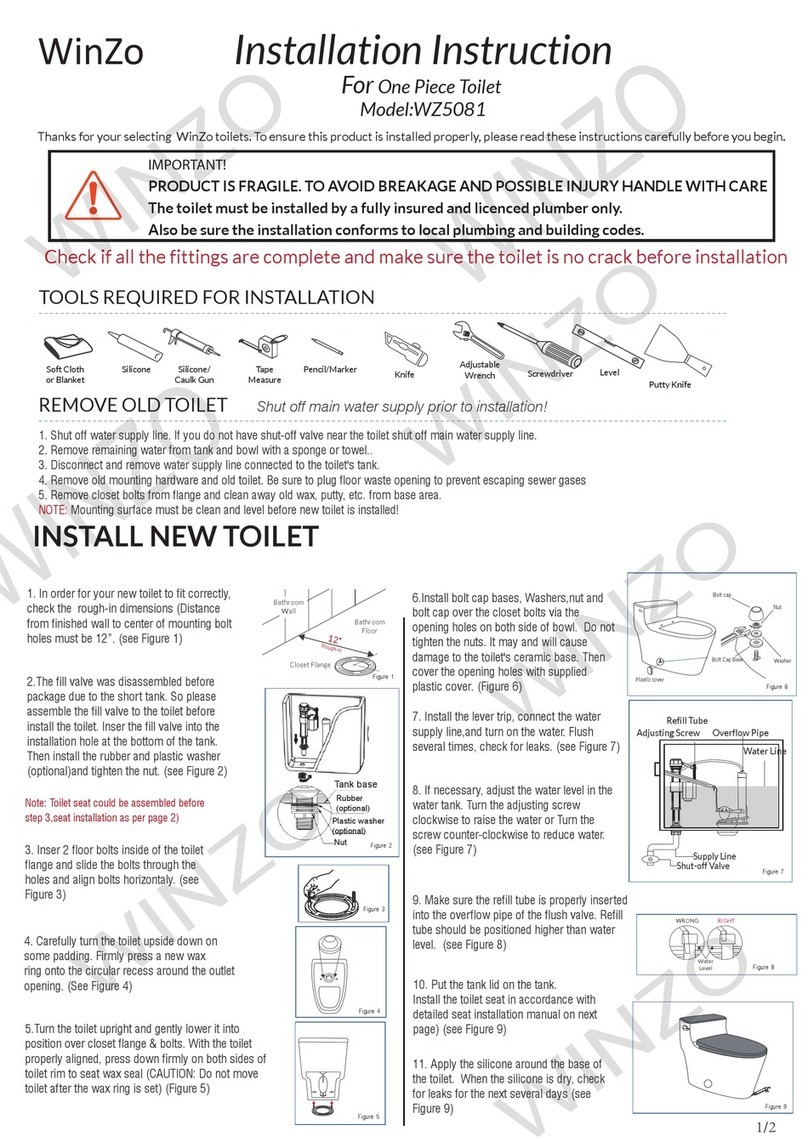

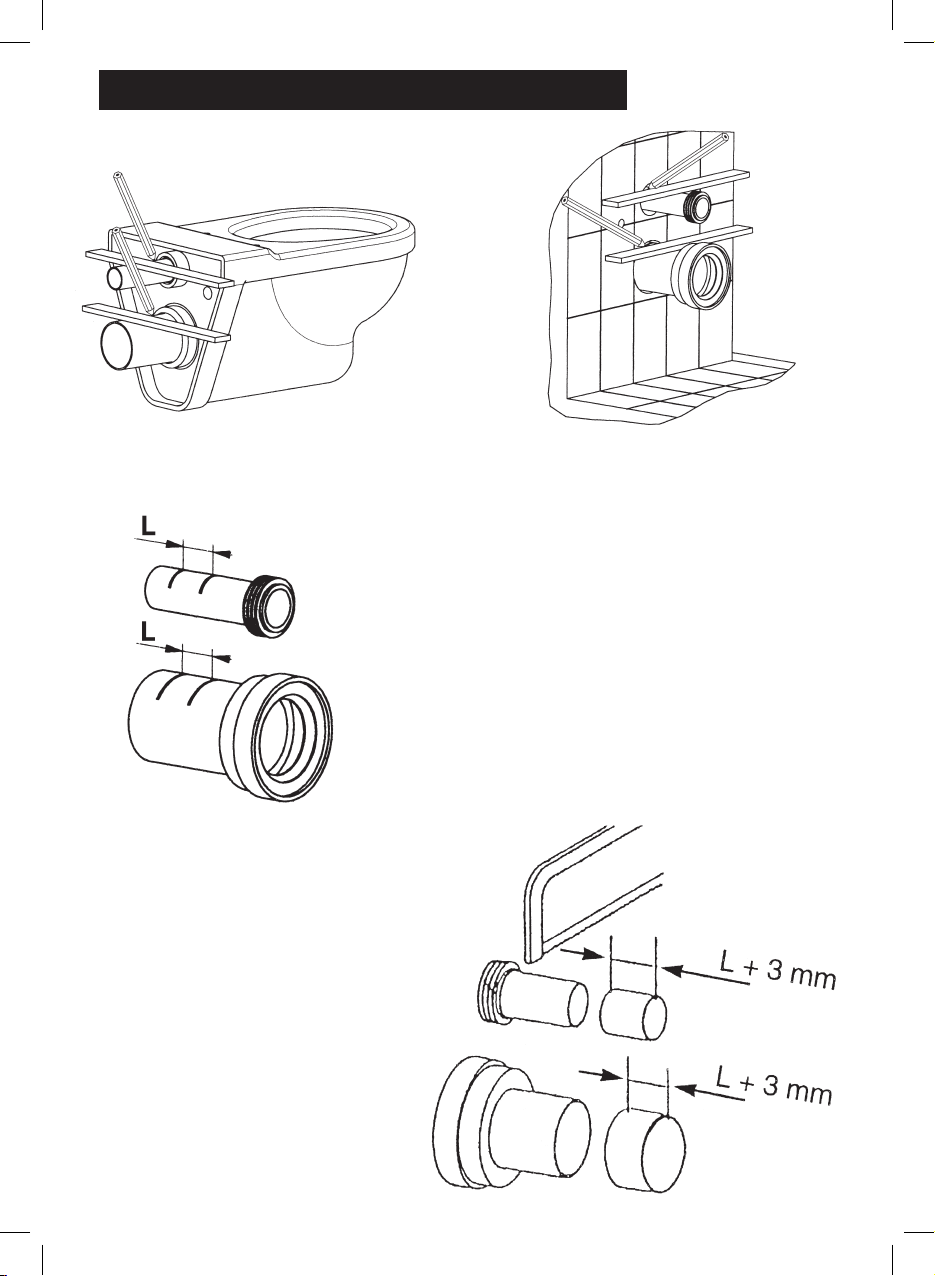

➊ Measure the center distance of the toilet

bowl (A)

➋ Insert the rods (I) into the holes of the frame,

corresponding to the center distance

➌ Position the frame in place

➍ Secure the attaching tabs (q) to the rods (l),

position the assembly against the wall and

lock with the nuts.

➎ Position the wall mounting bracket (r) against

the wall and attach it with the nuts, first

checking that the frame is vertically level

➏ Use a hacksaw to cut the threaded rods of the

bracket protruding from the frame

➊ Position the frame in its final location

➋ Undo the 2 setscrews (m)

➌ Adjust the height of the feet so that the top of the toilet

bowl is at a height of 400 mm from the finished floor level.

➍ Check that the frame is level (vertically and horizontally) and

tighten the setscrews

If the frame is being attached to an unfinished floor surface,

the maximum thickness of the finished floor surface shall

not be more than 185 mm.

A

➊

A = 180 mm

A = 230 mm

➍

➎

➏

m

6

➊ Mark the drilling points (6 for wall and 2 for floor)

➋ Remove the frame and drill to a depth of 70 mm at the least, using

an 10 mm diameter drill bit

➌ Position the screw plugs in the holes

➍ Move the frame back in place and connect the drain pipe

➊ Attach the collar (k)

➋ Position the drain outlet pipe

➌ Tighten the collar (k)

Before gluing the drain outlet pipe to the main drain

pipe, ensure that the frame is correctly positioned.

If the drainpipe is not opposite the outlet pipe, the

connection can be made using PVC bends and

couplings.

Bend outlet

Straight outlet

➋➌

x 6

x 2

➊

k

7

6

➊ Mark the drilling points (6 for wall and 2 for floor)

➋ Remove the frame and drill to a depth of 70 mm at the least, using

an 10 mm diameter drill bit

➌ Position the screw plugs in the holes

➍ Move the frame back in place and connect the drain pipe

➊ Attach the frame definitively

x 2

➊ Insert the water supply tube in the cistern

➋ Connect your pipe to the shut‑off valve

(b) either using the dual cone supplied or

directly with the nuts provided on the water

inlet (in this case, ensure tightness using

a fibre washer)

➌ Connect the shut‑off valve (b) to the float

valve (a) (ensure tightness by a fibre

washer).

b

a

8

➊

➍

➊ Insert the supply sleeve (h) and the drain

sleeve on the toilet bowl

➋ Position the toilet bowl on the frame

➌ Turn on the water using the shut‑off valve (b)

and wait until the toilet bowl fills

➍ Manually operate the mechanism (c) using

the flush‑pull control

➎ Check the tightness of the supply and drain

connections

➏ Close the shut‑off valve and drain the

cistern

➐ Remove the toilet bowl

c

Silicone

Grease

➋

➐

9

8

➊ Fasten the PSE template (d) on the access trap

using two grey screws which can be found in the

control panel box

➋ Fit the caps (f) and (g) on the supply bend (e) and

on the drain pipe as well as the flexible sheaths

(i) over the attaching rods of the toilet bowl (l)

The thickness of the cladding must be between 20 and 100 mm (for

the front) and 25 and 60 mm (for the top) and must be firmly attached

to the building structure.

Cladding can be of various materials (brick, plaster blocks, plaster board,

water repellent wood panels etc).

Cut the various holes (control panels and drain and supply of toilet bowl

and toilet bowl attaching holes). There is a cutting template included on

the back of the package.

d

f

g

10

➊ Using a rule placed as shown in the above drawing,

draw a mark on the toilet bowl side, on the two

sleeves.

➋ Remove the sleeves from the toilet bowl and fit them

to the frame. Using a rule placed as shown in the

drawing above, make a mark on the wall side, on

the two sleeves

➌ For each of the sleeves, measure the dimension

(L) between the two marks.

➍ Transfer this dimension (L) by

increasing by 3 mm at the end

(frame side) the size obtained on

each sleeve. For instance, if L = 50

mm, shorten the sleeve by 53 mm.

➎ Cut the sleeves using a hack saw.

11

10

➋ Remove the sleeves from the toilet bowl and fit them

to the frame. Using a rule placed as shown in the

drawing above, make a mark on the wall side, on

the two sleeves

➏ Deburr the cut pipes using a file

➐ Measure the thickness at the rear of the toilet

bowl (B)

➑ If necessary, cut the attaching rods (I) so that

the part protruding from the wall measures (B)

+ 20 mm

➒ Shorten the flexible sheaths (j) so that the part

protruding from the wall measures (B) ‑ 15 mm

l

j

B + 20 mm

➓ Fit the supply sleeve (h) and the drain

sleeve onto the toilet bowl.

Then position the toilet bowl on the

two attaching rods.

To facilitate the fitting of the drain

sleeve onto the bowl and the pipe,

use soapy water.

B

Silicone

Grease

12

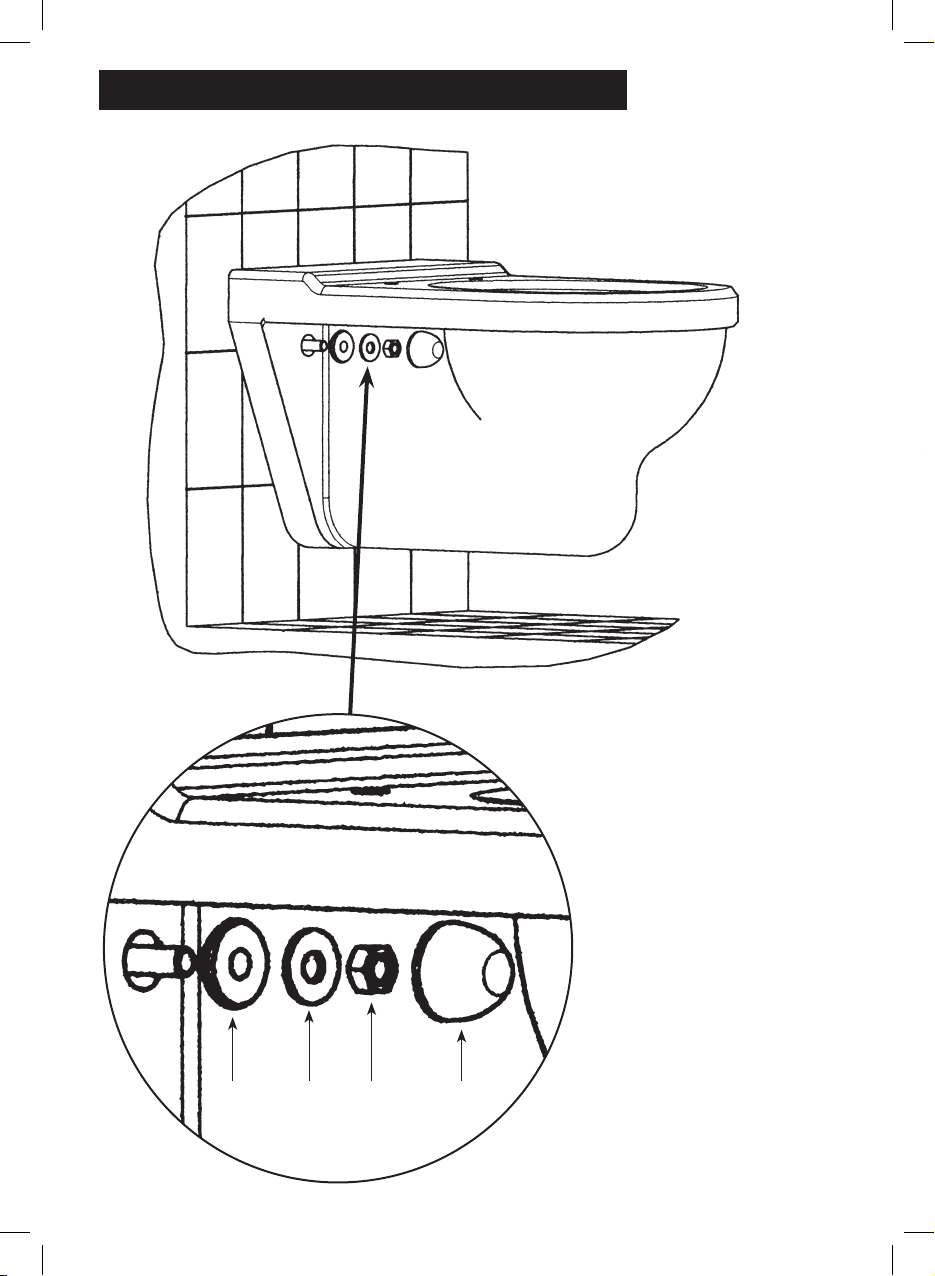

➊ When the toilet bowl is correctly

positioned, attach it using the kit (i)

complying with the part stacking order:

i = centering washer

ii = metal washer

iii = nut

iv = cover

ii iii iv

13

12

➊ When the toilet bowl is correctly

positioned, attach it using the kit (i)

complying with the part stacking order:

i = centering washer

ii = metal washer

iii = nut

iv = cover

15 mm

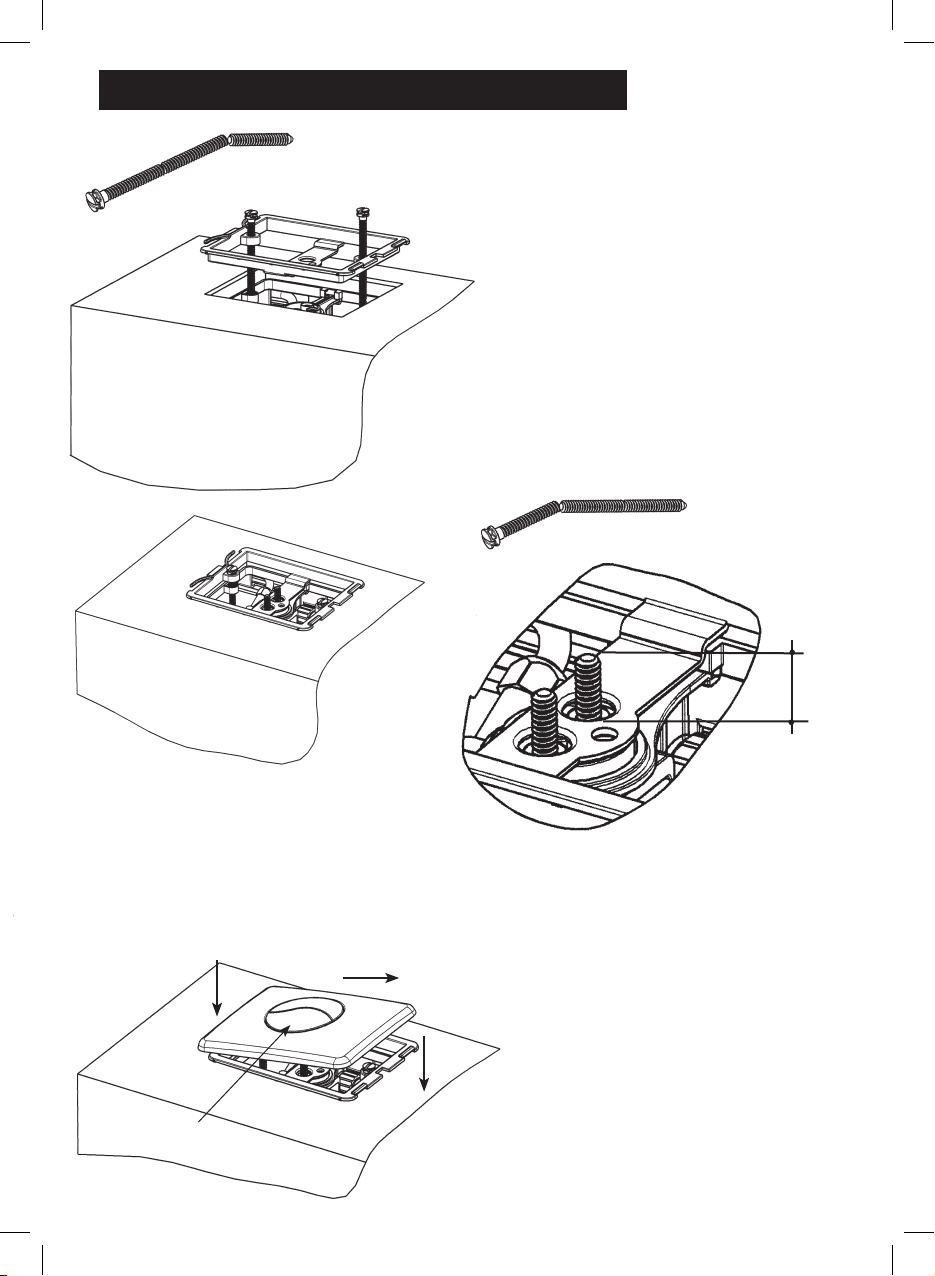

➊ Fasten the frame with two grey screws

If the cladding is not very thick, shorten the

screws by simply breaking them at the notch

intended for this purpose.

➍ Put the control panel in place.

A ‑ Position the panel (small button at the front) on

the frame spring (left side)

B ‑ Pull over to the right

C ‑ Place panel on cladding and release

➋ Break off the heads of the remaining screws

at the highest point (throw away the head part)

➌ Screw the two remaining parts into the

mechanism so that the tops are 15 mm

higher than the stirrup

A

B

C

Small button

14

During the use of your VERSO BCM 800 flushing cistern, you may be required to maintain

the equipment.

I - MAINTENANCE OF THE VALVE (filter cleaning, replacement of membrane)

➊ Remove the panel

A ‑ Push towards the right

B ‑ Lift up panel on the right‑hand side

C ‑ Remove panel

➋ Unscrew and remove frame

➌ Unscrew one of the plate screws

➍ Remove the plate and the spacer

➎ Close the shutoff valve (b) and separate it from the

float valve (a).

➏ Turn the spacer supporting the valve and remove the

valve

➐ After operation repeatedly operations in the opposite

order, taking care to reopen the shut‑off valve (b) and

re‑locate the spacer

Spare parts:

Membrane: P/N 349513‑07

Complete valve: P/N 309503‑07

➊

➋

➌

b

a

➍

Membrane

C

A

B

15

14

During the use of your VERSO BCM 800 flushing cistern, you may be required to maintain

the equipment.

I - MAINTENANCE OF THE VALVE (filter cleaning, replacement of membrane)

II - MECHANISM MAINTENANCE (cleaning or replacement of the seal)

Proceed in the same way as for the maintenance of the valve up to point

➍ then:

➊ Grasp the mechanism by the base and remove it from the cistern

Spare parts:

Seal P/N 34 2332‑07

Complete mechanism: P/N 32‑4544‑07

➋ When maintenance is over, repeat all the steps in the opposite order.

To position the mechanism properly it is provided with a polariser on the base

Seal

You have just installed a cistern frame forming part of the VERSO range by

SIAMP and we would like to thank you for your confidence in our products.

As expert in technical equipment and accessories for the toilet, SIAMP has

taken every possible measure to apply all the necessary care to the design and

production of this product, offering a ten‑year guarantee except for rubber parts

and manpower.

For any complementary information, or indicated claim, please contact your dealer.

Or contact directly:

4, quai Antoine 1er - BP 219 - MC 98007 MONACO Cedex

Site Internet : http://www.siamp.com

Réf. 5627

Table of contents

Other Siamp Toilet manuals

Popular Toilet manuals by other brands

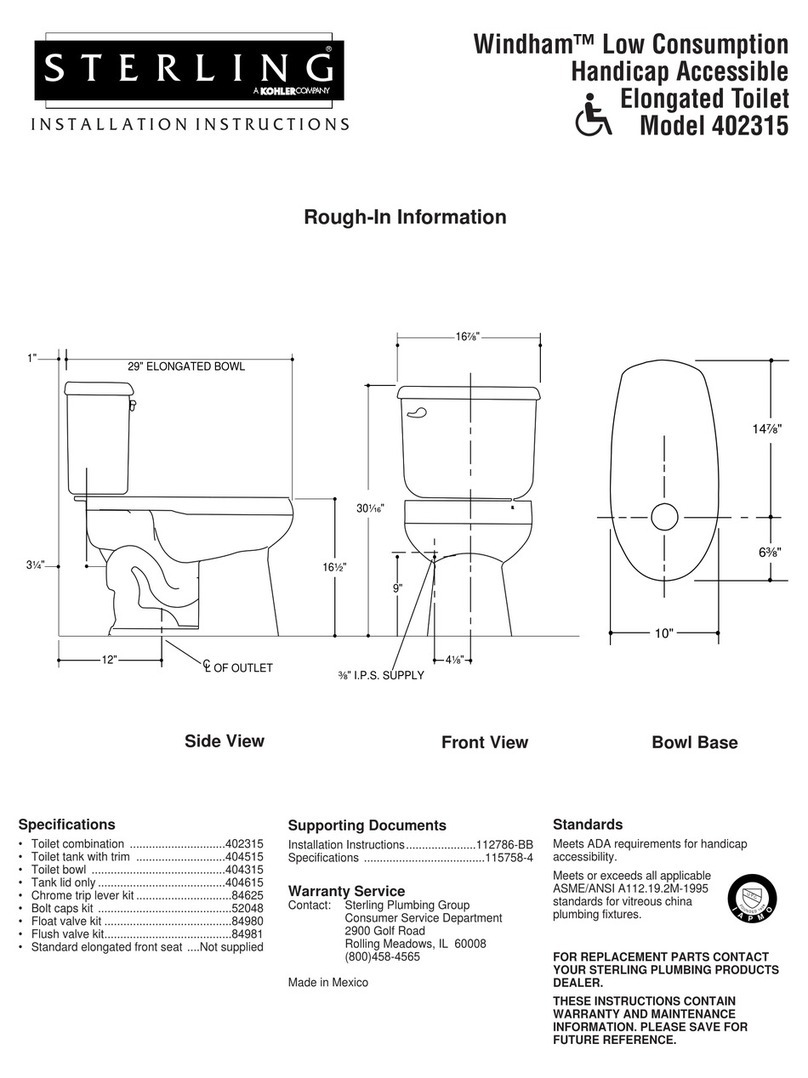

Kohler

Kohler Sterling Windham 402315 installation instructions

American Standard

American Standard Ultima VorMax 203AA.104 owner's manual

Sun-Mar

Sun-Mar CENTREX 1000 owner's manual

Uspa

Uspa UB-7035R Operating instructions manual

Kohler

Kohler HARKEN K-22695T-S installation instructions

Cinderella

Cinderella Comfort NA owner's manual

Swiss Madison

Swiss Madison SM-2T130 installation instructions

THE BOLD LOOK OF KOHLER

THE BOLD LOOK OF KOHLER K-4647 installation guide

Dometic

Dometic SeaLand MasterFlush MF 7200 Series Operation manual

Kohler

Kohler SAN SOUCI K-21865T-ITHC2 installation instructions

clivus multrum

clivus multrum CM8 installation manual

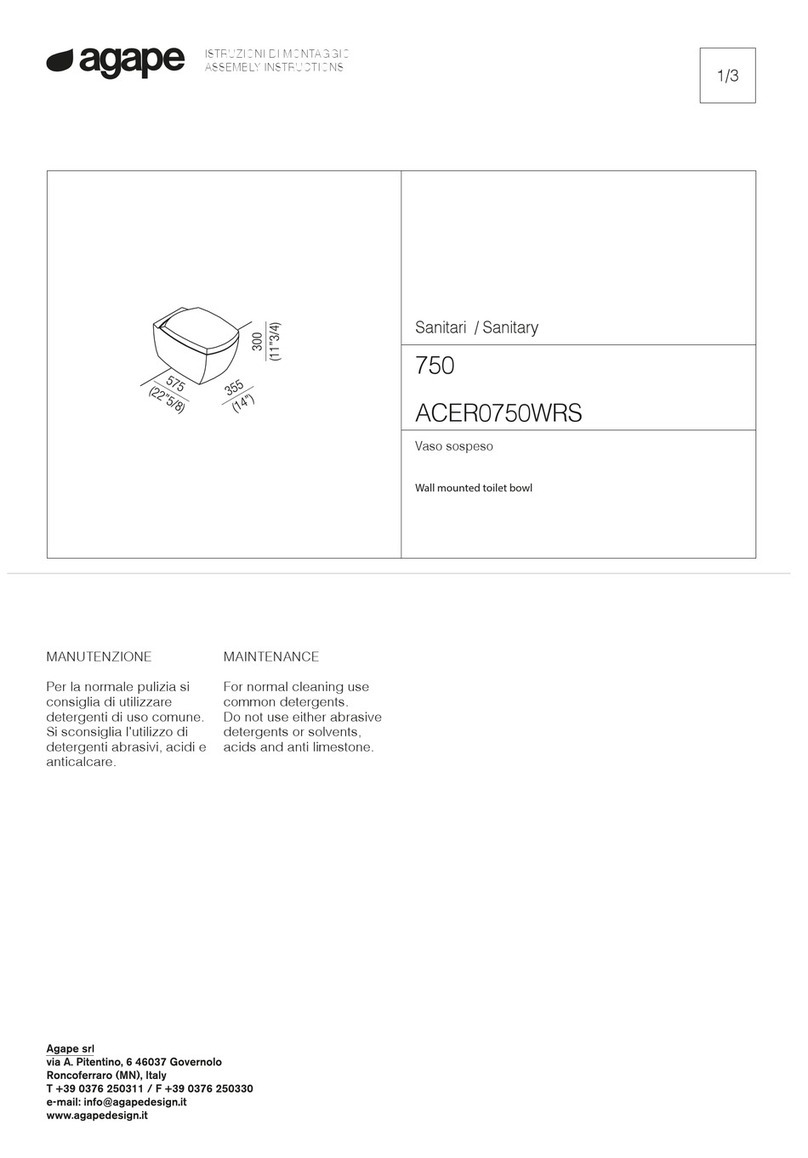

Porcelanosa

Porcelanosa Noken URBAN C 100160146 N369225479 manual